Documente Academic

Documente Profesional

Documente Cultură

2012-11-17 DPR No 14

Încărcat de

Gema SuryaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

2012-11-17 DPR No 14

Încărcat de

Gema SuryaDrepturi de autor:

Formate disponibile

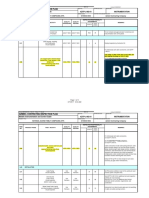

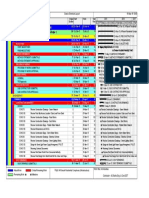

Facility : Day : 14

Location : Date :

Weather : Cloud Time : 20.00

Wind Speed : 6-14 knots

Wave : Low

Today Prev Today Total

1 Maleo Producer 14 5,662 220 5,882 249 256

1 AWB King Fisher 246 45,249 3,343 48,592 41 43

2 CB. SAMUDRA 0 2,251 - 2,251 3 3

3 TB. ANUGRAH.L.1 0 2,458 - 2,458 63 67

4 TB. KJ 03 11 1,916 132 2,048 5 5

5 TB. CELINE 11 2,327 132 2,459 217 227

6 Puma 99 2 599 24 623

7 TB. SWISCO.S.H 0 1,236 - 1,236

8 CB.Pan Marine 12 8 192 96 288 0 0

9 TB. ANUGRAH.L.5 11 312 132 444 0 0

0 0

Near Miss 0

Hazard Observation Card 4

Emergency Drill 0

PTW 10

Engineering & Development Project Department

Maleo Compression Modification Project

FIELD DAILY ACTIVITY REPORT

MALEO

MALEO Saturday, 17 November 2012

EHS Induction 7

Tool Box Meeting 2

EHS Inspection 0

POB (PROJECT TEAM) EHS

No

PERSONNEL

EHS Output Previous Today

EHS Input Previous Today Total

Accommodation

Total

MAN HOURS

First Aid 0

MTI 0 0 0

TOTAL 303 62,203 4,079 66,282 0 0

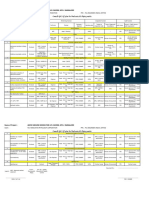

15-Nov-12 16-Nov-12 15-Nov-12 Remarks

Tug Boat Anugrah Lautan 5 188,863.0 17,868.0 ###### 3.1 3.5 3.1

AWB Kingfisher 145,629.0 125,953.0 710.0

CB.Pan Marine 12 (Replace Samudra1) 3,616.0 4.5 - No Report

FTB Puma 99 + Tug Boat KJ3 14,267.0 14,067.0 17.0

AHT Celine 56,471.0 51,152.0 27.0

TOTAL 408,846.0 209,040.0 761.6

Notes: -

A.

B.

Piping

SUMMARY ROB (REMAINING ON BOARD)

Vessel

Fuel (Ltr) Fresh Water (Mt)

Last Day Consumed 16-Nov-12

Last Day

Consumed

MTI 0

LTI 0

200.0 14.0

5,319.0 24.0

19,676.0 712.0

3,616.0

Continue to complete install Air Intake at the top Turbine enclosure

VARIOUS ACTIVITY

199,806.0 750.0

TODAY HIGHLIGHTS & RISK ACTIVITIES

COMPRESSOR ACTIVITY-INDOTURBINE :

Continue Install Lube Oil Separator

Instrument

Continue Install Fan Vent,Duct ,Vent,Elbow, Silencer

Piping

Structure

No

A

1 Continue

2 Continue

3

Completed

Continue

5

Electrical

Preparation For Pulling cable

Instrument

20" RG-2016-3C1R- 1 of 6 ( Spools 1-3 )

VARIOUS

Re position AWB to Platform

Continue Dimensional and actual Check Line Pipe and support Location and Modification Spools before Installation for RG line

TODAY ACTIVITIES

Description Remarks

Install Support and Pipe Spool :

Continue Install Support Ladder 300 at Turbine MCC

20" RG-2001-3C1R

Continue to Complete Install Stopper and Stubing Guide for Extension Paltform and Platform Above existing Piperack

Pulling Cable for Battery Bank (23-KA-311-EP-01 ) at Turbine MCC Room

Pulling Cable for Battery Charger (23-KA-311-BC-01) AT Turbine MCC Room

Continue Install Support Ladder 300 at Turbine MCC

Continue Install Tray at Acomodation

Continue Install Cable Ladder at Upper Deck area Cooloing Water Pump Continue Install Scaffolding & Welding Habitat for Pipe Support

Continue Install cablle ladder at Upper Main Deck Booster Compressor Lube Oil Cooler Completed Cutting existing grating for location New After Cooler

Continue Intallation Pipe spool 20" RG Line

Continue Modification and install spools for 10" RG-RG 2025-3C1R

Continue install spools for 12" RG-3107 Pulling Cable for Lube Oil Motor Starter at Turbine MCC Room

Continue Dimensional and actual Check Line Pipe and support Location before Installation Pulling Cable for VFD (23-KA-311-VFD-03) AT Turbine MCC Room

5

6

Completed

Completed

7

Completed

Completed

B

1 Continue

2 Continue

C MARINE

1 See Detail Report (one day delay-cut off time 00 PM)

2 See Detail Report (one day delay-cut off time 00 PM)

3 See Detail Report (one day delay-cut off time 00 PM)

4 See Detail Report (one day delay-cut off time 00 PM)

5 AHT Celine See Detail Report (one day delay-cut off time 00 PM)

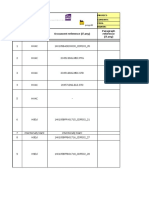

23-TCP-311-5-From BALANCE OF PLANT 23-JB-311To PCS MARSHALLING CABINET (D)Pair 12P

23-TCP-311-4-From BALANCE OF PLANT 23-JB-311To PCS MARSHALLING CABINET (A)Pair 8P

23-TCP-311-3A-From BALANCE OF PLANT BOX TCP-311To SIS MARSHALLING CABINET (D) Pair 8P

23-TCP-311-3B-From BALANCE OF PLANT BOX TCP-311To SIS MARSHALLING CABINET (D) Pair 12P

AWB Kingfisher

FTB Puma 99 + Tug Boat KJ3

COMPRESSOR ACTIVITY-INDOTURBINE :

Continue Installation Electrical & Instrument Support JB and Cable Tray

Continue Install Silincer,Screen Inlet,Filter Inlet at top Turbine enclosure

Tug Boat Anugrah Lautan 5

CB. Pan Marine 12

Continue Install Support Ladder 300 at Turbine MCC

Instrument Pulling for PCS System

Instrument Pulling for ESD System

4

No

A

1

2

3

B

Piping

2

3

4

5

6

Structure

2

3

Instrument :

1

2

TOMORROW PLAN

COMPRESSOR ACTIVITY-INDOTURBINE

Continue Install Auxillary Intake and continue Install Support skid roof

Install Manhold Stack Exhoust

Install Duct Vent,Silincer Vent,Fan Vent

Continue Install Pipe Spool 10 " RG 2025

Description

Remarks

Continue Install support tray at bellow main deck

Continue Install support at main deck and Perforated Tray at Main Deck

Install Stopper and Stubing Guide for Extension Platform and After Cooler

Continue to Complete PCR Support

VARIOUS ACTIVITY

Continue instaII scaffolding for pipe support and Welding Habitat

Continue Install Pipe Spool 20 RG-2001

Continue Modification 16 " RG 3806 Line from Raw Gas Filter to Glicol incl. Raw Gas Cooler

Continue Install and Welding Support PS 059-01, PS 066-03

2

3

Electrical:

1

2

3

4

5

No

Total Qty Progress Progress % Finish Date

A Pre - Pre Shutdown (Without AWB) (02 Oct 2012 - 29 Oct 2012)

Transfer Material Scaffolding 1 Lot 60%

Install Scaffolding for E/I 1 Lot 85%

Cold Cutter for MCT & MCT Installation 19 19 100% 14-Nov-12

Demolition Compressor Train 2 Acces Platform D198-D-DW-4030D - ELV.(+) 20.645- (Demolish Ledder , Structure, firewall):

Demolish Fire Wall 1 1 100% 30-Oct-12

Install stopper Booster compressor 4 4 100% 29-Oct-12

Strengthened support beam 3 3 100% 2-Nov-12

Demolish Ledder 1 1 100% 2-Nov-12

Install Well #3 Cover 1 1 100% 25-Oct-12

Install base plate (Compressor Support) - Welding Habitat required 3 3 100% 27-Oct-12

Pulling Cable

Continue Install support at main deck and Perforated Tray at Main Deck

Continue Install Ladder at Turbine MCC Room

Description

Continue Install Ladder 300 at Bellow Main Deck

Continue Install Support Ladder 300 at Main Deck

Pulling Cable

Continue Install Tray at Accomodation

DETAIL ACTIVITIES

Install base plate (Compressor Support) - Welding Habitat required 3 3 100% 27-Oct-12

B Pre - Pre Shutdown With AWB Kingfisher & Gangway (Pre Shutdown Phase I ) (30 Oct 2012 - 21 Nov 2012) Total Qty Progress Progress % Finish Date

100% 2-Nov-12

100% 2-Nov-02

100% 4-Nov-02

3 3 100% 4-Nov-02

1 1 100% 4-Nov-02

1 1 100% 4-Nov-02

1 1 100% 4-Nov-02

1 1 100% 10-Nov

1 1 100% 5-Nov-12

1

100% 15-Nov-12

12 10

1 1 100% 10-Nov-12

On Position 1 25%

1 1 100% 13-Nov-12

1 1 100% 12-Nov-12

1 1 100% 12-Nov-12

1 1 100% 12-Nov-12

1 1 100% 13-Nov-12

2 2 100% 10-Nov-12

Trial Final position AWB Kingfisher againt Maleo

Handling over from operation after # 1 unit Compressor Off

Install AVM for Compressor Unit

Welding Completed

Welding Habitat at Comprssor area

Install Pipe Support 9701-P-008 Gas Inlet System :

PS-0053-001 /083

PS-0059-001/098

LIFTING NO.1-Compressor equipment ( 23-ka-311) +/- 30 mt

Demolish Painting Storage ,Clear area for PCR & Compressor

LIFTING NO.2 Installation of PCR support (Structure only) +/- 4 MT

Installation Gang way/ access

Install Welding Habitat for Gangway Support

Re Install FireWall

PS-0064-001/126 Welding Completed

PS-0063-008/223

PS-0059-002/099

PS-0063-001/120

PS-0063-002/121

PS-0063-004/123

AWB Kingfisher Anchor Job Complete

Welding Completed

Welding Completed

Welding Completed

Welding Completed

Welding Completed

2 2 100% 10-Nov-12

1 1 100% 12-Nov-12

1 1 100% 10-Nov-12

1 70%

22 15

1

1

1 1 100% 16-Nov-12

1 1 100% 16-Nov-12

20" RG-2001-3C1R-2 of 5 ( Spools 2-1 ) 1 1 100% 14-Nov-12

1 1 100% 14-Nov-12

1

1

1

1 1 100% 14-Nov-12

1 1 100% 12-Nov-12

1 1 100% 12-Nov-12

1 1 100% 12-Nov-12

1 1 100% 17-Nov-12

1 1 100% 11-Nov-12

Welding On Progress

20" RG-2001-3C1R-1 of 5 ( Spools 1-3 )

20" RG-2001-3C1R-1 of 5 ( Spools 1-4 )

20" RG-2001-3C1R-1 of 5 ( Spools 1-5 )

20" RG-2016-3C1R- 5 of 6 ( Spools 5-1 )

20" RG-2001-3C1R-5 of 5 ( Spools 5-2 )

PS-0064-001/126 Welding Completed

PS-0065-001/129 Welding Completed

PS-0064-002/127 Welding Completed

20" RG-2016-3C1R- 1 of 6 ( Spools 1-4 )

20" RG-2016-3C1R- 1 of 6 ( Spools 1-3 )

20" RG-2001-3C1R-2 of 5 ( Spools 2-2 )

20" RG-2001-3C1R-2 of 5 ( Spools 2-3 )

20" RG-2001-3C1R-2 of 5 ( Spools 2-4 )

20" RG-2001-3C1R-2 of 5 ( Spools 2-5 )

PS-0066-003/133

Install Pipe Spools 9701-P-008 Gas Inlet System :

20" RG-2001-3C1R-1 of 5 ( Spools 1-2 )

20" RG-2019-3C1R- 1 of 1 ( Spools 1)

20" RG-2016-3C1R- 5 of 6 ( Spools 5-2 )

4

Pre - Pre Shutdown With AWB Kingfisher & Gangway (Pre Shutdown Phase I ) (30 Oct 2012 - 21 Nov 2012) Total Qty Progress Progress % Finish Date

1 1 100% 11-Nov-12

1 1 100% 13-Nov-12

1 1 100% 13-Nov-12

1

1 1 100% 14-Nov-12

1

1 1 100% 15-Nov-12

1 1 100% 16-Nov-12

1

Ball Valve for Line 20" RG-2001 1 1 100% 16-Nov-12

Check Valve for Line 20" RG-2001 1 1 100% 16-Nov-12

1 1 100%

4 3 75%

Elect. :

100% 16-Nov-12

100% 16-Nov-12

100% 16-Nov-12

100% 16-Nov-12

100% 16-Nov-12

10" RG-2025-3C1R- 1 of 2 (Spools 1-2 )

Allocation material accessories Turbine Compressor to turbine MCC room

24 DC Panel Balance of Plant (BOP) - Box-13

Battery Charger - Box-3

23-SDV-301 for Line 20" RG-2001

25 FCV 001

25 FT 003 for Line 20" RG-2019

Install Guide Device / Cone for all new Structural Module

Support ( Reinforce Beam Structure) under compressor

Continue work for Mechanical & EI at MCC System 9701-P-009-COMPRESSOR SYSTEM :

Battery Rack - Box-3

VFD - Box-2

Lube Oil Motor Starters - Box -14

20" RG-2019-3C1R- 1 of 1 ( Spools 4)

20" RG-2019-3C1R- 1 of 1 ( Spools 5)

10" RG-2025-3C1R- 1 of 2 (Spools 1-1 )

20" RG-2019-3C1R- 1 of 1 ( Spools 2)

20" RG-2019-3C1R- 1 of 1 ( Spools 3)

10" RG-2025-3C1R- 1 of 2 (Spools 1-3 )

100% 16-Nov-12

Install MCT MG # 3A 1 1 100% 13-Nov-12

Install Support for Cable Tray at Main Deck and Bellow Main Deck -LQ 70%

Measure Length cable and from to Main deck area and bellow main deck) 70%

Inst.:

Install MCT MG # 7-1,7-3, 7-4 and MCT# 4-2 4 4 100% 13-Nov-12

Install Scafflding(Machinery Space / Bellow Maindeck) 90%

Measure Length cable and from to Main deck area and bellow main deck) 90%

Allocatation Instrument Junction Box at main deck area 90%

12 5 17%

30%

40%

54 15 27.8%

SL No. 20 5 25.0%

11 23-JBA-310-From 23-JBA-310To PCS MARSHALLING CABINET (A)Pair 12P 1

13 23-TIT-307-From 23-TIT-307To 23-JBA-312Pair 1P 1 1 100.0% 16-Nov-12

14 23-PT-307A-From 23-PT-307ATo 23-JBA-312Pair 1P 1 1 100.0% 16-Nov-12

15 23-PT-307B-From 23-PT-307BTo 23-JBA-312Pair 1P 1 1 100.0% 16-Nov-12

21 23-JBA-312-From 23-JBA-312To PCS MARSHALLING CABINET (A)Pair 12P 1

Install Cable Tray at LQ

Lube Oil Motor Starters - Box -14

Continue cutting plate electrical bellow Turbine Compressor at Main Deck

Continue cutting plate Instrument bellow Turine Compressor at Main Deck

Install JB

Instrument Pulling for PCS System

Instrument

Cable Tray

Puling Cable :

Cable Ladder

21 23-JBA-312-From 23-JBA-312To PCS MARSHALLING CABINET (A)Pair 12P 1

28 49-JBA-430-From 49-JBA-430To PCS MARSHALLING CABINET (A)Pair 12P 1

33 49-JBA-301-2-From 49-JBA-301 (Seal Gas Pkg)To 49-CP-430 (PCR)Pair 8P 1

34 49-CP-430-From 49-CP-301To 50-JBD-001Pair 8P 1

37 63-JBA-002-From 63-JBA-002To PCS MARSHALLING CABINET (A)Pair 8P 1

38 23-TCP-311-1-From TURBINE BOX 23-TCP-311ATo PCS MARSHALLING CABINET (D)Pair 8P 1

39 49-JBD-430-2-From 49-JBD-430To PCS MARSHALLING CABINET (D)Pair 12P 1

42 45-JBD-311-2-From 45-JBD-311To PCS MARSHALLING CABINET (D)Pair 8P 1

43 23-TCP-311-5-From BALANCE OF PLANT 23-JB-311To PCS MARSHALLING CABINET (D)Pair 12P 1 1 100.0% 17-Nov-12

44 23-TCP-311-4-From BALANCE OF PLANT 23-JB-311To PCS MARSHALLING CABINET (A)Pair 8P 1 1 100.0% 17-Nov-12

45 82-EN-102-1-From 82-EN-102To PCS MARSHALLING CABINET (D)Pair 12P 1

46 82-EN-110-1-From 50-JBD-001To PCS MARSHALLING CABINET (D)Pair 12P 1

47 82-EN-111-1-From 50-JBD-001To PCS MARSHALLING CABINET (D)Pair 12P 1

48 82-EN-103-2-From 82-EN-103To PCS MARSHALLING CABINET (D)Pair 8P 1

49 84-EN-101-From 84-EN-101To PCS MARSHALLING CABINET (D)Pair 8P 1

50 64-CZ-691-From 64-CZ-691To PCS MARSHALLING CABINET (D)Pair 8P 1

SL No. 34 10 29.4%

6 45-JBD-311-1-From 45-JBD-311To SIS MARSHALLING CABINET (D) Pair 12P 1

11 23-TCP-311-2-From CO2 CYLINDER CABINETTo TURBINE BOX TCP-311A Pair 12P 1

19 23-JBA-311-From 23-JBA-311To BALANCE OF PLANT BOX 23-JB-311 Pair 12P 1 1 100.0% 16-Nov-12

24 23-XV-303-From 23-XV-303To 23-JBD-311 Pair 1P 1 1 100.0% 16-Nov-12

26 23-XV-305-From 23-XV-305To 23-JBD-311 Pair 1P 1 1 100.0% 16-Nov-12

Instrument Pulling for ESD System

26 23-XV-305-From 23-XV-305To 23-JBD-311 Pair 1P 1 1 100.0% 16-Nov-12

27 23-JBD-311-1-From 23-JBD-311To BALANCE OF PLANT BOX 23-JB-311 Pair 12P 1 1 100.0% 16-Nov-12

32 23-ZSC/O-303-From 23-ZSC/O-303To 23-JBD-311 Pair 2P 1 1 100.0% 16-Nov-12

34 23-JBD-311-2-From 23-JBD-311To BALANCE OF PLANT BOX 23-JB-311 Pair 12P 1 1 100.0% 16-Nov-12

35 23-ZSC/O-305-From 23-ZSC/O-305To 23-JBD-311 Pair 2P 1 1 100.0% 16-Nov-12

36 23-JBD-311-3-From 23-JBD-311To BALANCE OF PLANT BOX 23-JB-311 Pair 12P 1 1 100.0% 16-Nov-12

41 49-JBA-310-From 49-JBA-310To SIS MARSHALLING CABINET (A) Pair 12P 1

48 49-JBD-430-1-From 49-JBD-430To SIS MARSHALLING CABINET (D) Pair 12P 1

58 23-TCP-311-12-From TURBINE BOX TCP-311ATo BACK UP L/O PUMP STARTER Pair 5C 1

59 23-TCP-311-6-From TURBINE BOX TCP-311ATo 23-KA-311-BC-01 Pair 5C 1

60 23-TCP-311-8-From TURBINE BOX TCP-311ATo MCC 82-EN-102 Pair 12P 1

63 23-TCP-311-10-From TURBINE BOX TCP-311ATo E-MCC 84-EN-101 Pair 8P 1

64 23-TCP-311-9-From TURBINE BOX TCP-311ATo SIS MARSHALLING CABINET (D) Pair 8P 1

67 23-TCP-311-3A-From BALANCE OF PLANT BOX TCP-311To SIS MARSHALLING CABINET (D) Pair 8P 1 1 100.0% 17-Nov-12

68 23-TCP-311-3B-From BALANCE OF PLANT BOX TCP-311To SIS MARSHALLING CABINET (D) Pair 12P 1 1 100.0% 17-Nov-12

69 XY-0120-From BALANCE OF PLANT BOX TCP-311To LP COMPRESSOR 23-TCP-311B Pair COAXIAL 1

70 XY-0121-From BALANCE OF PLANT BOX TCP-311To LP COMPRESSOR 23-TCP-311B Pair COAXIAL 1

71 XY-0150-From LP COMPRESSOR 23-TCP-311BTo ENGINE VIBRATION Pair COAXIAL 1

72 XY-0151-From LP COMPRESSOR 23-TCP-311BTo ENGINE VIBRATION Pair COAXIAL 1

73 XY-0060-From ENGINE VIBRATIONTo TURBINE BOX TCP-311A Pair COAXIAL 1

74 XY-0061-From ENGINE VIBRATIONTo TURBINE BOX TCP-311A Pair COAXIAL 1

4

Pre - Pre Shutdown With AWB Kingfisher & Gangway (Pre Shutdown Phase I ) (30 Oct 2012 - 21 Nov 2012) Total Qty Progress Progress % Finish Date

75 82-EN-111-2-From 50-JBD-001 (BY.ELECT.)To SIS MARSHALLING CABINET (D) Pair 12P 1

76 82-EN-110-2-From 50-JBD-001 (BY ELECT.)To SIS MARSHALLING CABINET (D) Pair 8P 1

77 82-EN-101-From 82-EN-101To SIS MARSHALLING CABINET (D) Pair 8P 1

78 84-EG-001-From 84-EG-001To SIS MARSHALLING CABINET (D) Pair 2P 1

79 82-EN-103-1-From 82-EN-103To SIS MARSHALLING CABINET (D) Pair 2P 1

80 23-HS-300-From 23-HS-300 (DCS CONSOLE)To SIS MARSHALLING CABINET (D) Pair 2P 1

94 23-FJB-101-1-From 23-FJB-101To SIS MARSHALLING CABINET (A) Pair 12TR 1

97 23-FJB-101-2-From 23-FJB-101To SIS MARSHALLING CABINET (D) Pair 8P 1

113 82-FGP-100-From 82-FGP-100 (BY VENDOR)To SIS MARSHALLING CABINET (D) Pair 8P 1

TURBINE MCC (82-EN-102) : 2 0

1 T82-EN-215-PFrom TURBINE MCC, (MODULE 5.5)To VFDCor/Pair 3/C+ECross Seqtion 70 (2/0 AWG) 1

2 T82-EN-216-H1From TURBINE MCC, (MODULE 5.5)To VFD (HEATER)Cor/Pair 3/C+ECross Seqtion 2.5 (14 AWG) 1

LV DISTRIBUTION BOARD (82-EN-110) 13 0

36 T82-EN-221-P1From PROCESS MCC, (MODULE 8.4)To LV DISTRIBUTION BOARDCor/Pair 1/CCross Seqtion 300 1

37 T82-EN-221-P2From PROCESS MCC, (MODULE 8.4)To LV DISTRIBUTION BOARDCor/Pair 1/CCross Seqtion 300 1

38 T82-EN-221-P3From PROCESS MCC, (MODULE 8.4)To LV DISTRIBUTION BOARDCor/Pair 1/CCross Seqtion 300 1

39 T82-EN-221-P4From PROCESS MCC, (MODULE 8.4)To LV DISTRIBUTION BOARDCor/Pair 1/CCross Seqtion 300 1

40 T82-EN-221-P5From PROCESS MCC, (MODULE 8.4)To LV DISTRIBUTION BOARDCor/Pair 1/CCross Seqtion 300 1

41 T82-EN-221-P6From PROCESS MCC, (MODULE 8.4)To LV DISTRIBUTION BOARDCor/Pair 1/CCross Seqtion 300 1

42 T82-EN-221-P7From PROCESS MCC, (MODULE 8.4)To LV DISTRIBUTION BOARDCor/Pair 1/CCross Seqtion 300 1

Electrical

43 T82-EN-221-P8From PROCESS MCC, (MODULE 8.4)To LV DISTRIBUTION BOARDCor/Pair 1/CCross Seqtion 300 1

44 T82-EN-221-P9From PROCESS MCC, (MODULE 8.4)To LV DISTRIBUTION BOARDCor/Pair 1/CCross Seqtion 300 1

45 T82-EN-221-P10From PROCESS MCC, (MODULE 8.4)To LV DISTRIBUTION BOARDCor/Pair 1/CCross Seqtion 300 1

46 T82-EN-221-P11From PROCESS MCC, (MODULE 8.4)To LV DISTRIBUTION BOARDCor/Pair 1/CCross Seqtion 300 1

47 T82-EN-221-P12From PROCESS MCC, (MODULE 8.4)To LV DISTRIBUTION BOARDCor/Pair 1/CCross Seqtion 300 1

48 T82-EN-221-P13From PROCESS MCC, (MODULE 8.4)To LV DISTRIBUTION BOARD (GROUNDING)Cor/Pair 1/CCross Seqtion 150 1

C Total Shutdown For Heavy Lifting- Use Crane Barge GIANT POE 6 (Total Shutdown Phase I ) (22 Nov 2012 - 26 Nov 2012)

LIFTING NO.3- After Cooler 23-Ha-312 (9701-G-001-2 AFTER COOLER SKID +/- 47.5

LIFTING NO.4 -Booster compressor suction scrubber 23-vg-310 (9701-G-001-4 SUCTION SCRUBBER)+/- 9.8 MT

LIFTING NO.5 Extension Platform +/-16.3 MT- (9701-G-001-1 EXTENDED PLATFORM)

LIFTING NO.6 Above Extention Platform (Light but in high elevation)

LIFTING NO.7-PCR Building (electrical room ) +/- 30 mt

D Pre - Pre Shutdown With AWB Kingfisher & Gangway (Pre Shutdown Phase II ) (27 Nov 2012 - 04 Dec 2012)

E Total Shutdown With AWB Kingfisher & Gangway (Total Shutdown Phase II ) (05 Dec 2012 - 27 Dec 2012)

1

2

3

4

LIFTING NO.8 Silencer Support + Silencernya (Light but in high elevation)

AREA OF CONCERN

One Unit Maleo Crane Breakdown 12 November 2012 +/-10 Am, this is will be impact to the Installation and Construction activity and Progress achievement

All open flame works should be covered by welding habitat

Modification 20" RG Line from Raw Gas Filter to Glicol incl. Raw Gas Cooler

Modification 3" OL line

Tie In Identification

4

5

6

1

Trinaryanto Benyamin S Nur Endro Buwono

Project Control Construction Coordinator Project Leader

Prepared by Reviewed by Approved by

19 Ton Pedestal Crane at Maleo broken at 10.00, predicted the gear box was failure. Maybe take more time to solve this problem.

Modification 3" OL line

Shortage number of Welding Habitat Technician, minimum should be 8 technician for 5 set welding habitat (currently only have 4 technician on board)

Modification 16" RG line at Raw Gas Filter and existing Seal Gas

ISSUE / HIGHLIGHT

4

PROGRESS PHOTO MALEO PRE SHUTDOWN - 17 NOVEMBER 2012

NEW LINE 20"RG-2019-3C1R, 20" RG-2016

COMPLETED CUTTING EXISTING GRATING FOR NEW AFTER COOLER

NEW LINE 20"RG-2019-3C1R-AND SDV 301,CHECK VALVE

CONTINUE TO COMPLETE PCR SUPPORT

NEW LINE RG 20" & 12" TO NEW SUCTION SCRUBBER

INSTALL CABLE TRAY , JUNCTION BOX AT NEW COMPRESSOR AREA

PULLING CABLE AT TURBINE MCC ROOM

NEW COMPRESSOR INSTALLATION IN PROGRESS

NEW COMPRESSOR INSTALLATION IN PROGRESS

Sea Sky Visibility

Wind Air Temp. Barometer

Swell Ht

Real Full Capacity ROB Value

CONSUM

ED

RECEIVED

200000 ltr 17868 995

93187 ltr 21200 3500

1987 ltr 792 -

- 87 -

ROB Unit FROM / TO

m3

m3

m3

m3

Thruster 1

Bow

12 12 3 3

Time

PTW : Enh. TBT:

TBT: JSA :

Cumulated hours

Running hours since last servicing

Hours

Load in %

24:00 STILL STAND BAY AT BARGE PUMA 99

20:00 STILL STAND BY AT BARGE PUMA 99

16:00 STILL STAND BY AT BARGE PUMA 99

Activities Activities Time

Activities

Engine

Genset 1 Genset 2 Genset 3 Genset 4 Genset 5 Port/ME Stbd/ME

EM. GEN.

Spare Garbage bag

Loaded Garbage bag

HAZARDOUS WASTE

BLACK WATER

GARBAGE (Biodegradable)

GARBAGE (non- Biodegradable)

DIRTY OIL

CARGO ON BOARD

ITEM TRANSFERED RECEIVED REMARKS

GO

OILY WATER

LO

HO

FO

FW

ROB

ITEM TRANSFERRED REMARKS

VESSEL DAILY REPORT

VESSEL ANUGERAH LAUTAN 5

Weather & Sea

Conditions:

DATE/TIME 16/11/2012 TIME 24:00 LT

LOCATION MALEO RIG AREA

DRAFT (F/A)

07:00 PREPARE TO BARGE PUMA 99

04:00 STILL STAND BY AT BOUY MALEO

07:30 ALONG SIDE AT BARGE PUMA 99

08:00 STILL STAND BY AT PUMA 99

12:00 STILL STAND BY AT BARGE PUMA 99

14:15 SIFTING PUSSH HALUAN PUMA 99

14:45 SIFTING FINISH

Drill(s) Topic:

Number of Participants: Company Name:

Topic(s) trained:

Number of participants: Company name: PT. ANUGERAH WIJAYA BERSAUDARA

Stop Card(s): Total this month: Stop card(s) topic(s):

Total This month: Subject(s): Total HOC/ HAZARD Today:

Trainings

SAFETY

Drills

Meeting

Other meeting: Topic(s):

Number of participants: Company Name: PT. ANUGERAH WIJAYA BERSAUDARA

PTW Topics:

TBT Topics:

Reminder: As soon as a drill is performed on board, please send the report attached to the daily e-mail.

Meeting(s), training(s) or stop card(s) can be sent all together once a week by e-mail or in an enveloppe.

Hazard Report

Page 1 de 2

RANK

Offsigners

Offsigners

Offsigners

Offsigners

Offsigners

Offsigners

Offsigners

Onsigning Date NAMES Offsigning Date RANK

Next Offsigners

Next Offsigners

Next Offsigners

Next Offsigners

Next Offsigners

Next Offsigners

Next Offsigners

No Days o/b No Rank Days o/b

1 353 1

2 353 2

3 353 3

4 101 4

5 150 5

6 353 6

7 353 7

8 353 8

9 353 9

10 353 10

11 232 11

12 12

13 13

14 14

15 15

16 16

17 17

18 18

19 19

20 20

SYAMSUDDIN.S MASTER MUH.ALI

CHIEF ENGINER

2nd ENGINER

3th ENGINER

A/B

A/B

A/B

FAISAL.TOUWE CHIEF OFFICER

FAISAL 2nd OFFICER

SLAMET S.T

OILER

COOK

POB

Crew Santos

Next Onsigners

Next Onsigners

Name Rank Name

Next Onsigners

Next Onsigners

Next Onsigners

Next Onsigners

Next Onsigners

NAMES

Onsigners

Onsigners

RANK

Onsigners

Onsigners

Onsigners

HERMAN SUARDI

WAHARDI

MOCH.IDRIS.KUSHADI

AJIP PAHRI

YUDIN

SIRATANG

FAJARUDDIN

SLAMET ABADI

Comment

NAME NAME

Onsigners

RANK

Onsigners

Page 2 de 2

Project : Call Out Survey and Personnel Service

Client : 16 November 2012

Prepared by : :

Notes :

Accident Report

DAILY ACTIVITY REPORT

Location : Maleo Field, Madura Strait, Indonesia

: SUPRACO / SANTOS Madura Date

Contract No

16 100

Notes :

NAME TITLE

Today

Man-Hour

Total Man-

Hour

Operation Standby

None

Personnel and Equipment onboard Vessel and Field

PERSONNEL ONBOARD VESSEL AND FIELD EQUIPMENT ONBOARD VESSEL AND FIELD

Previous

Man-Hour

NAME / MODEL

None

Security Report

Amaludin Surveyor 252 12 264 2x GPS Starfix 1 1

Asyhari Surveyor 252 12 264 1x GPS SeaStar VBS 8200 HP 1

Sulaiman Surveyor 252 12 264 2x GPS Trimble DSM 132 1 1

Ariansyah Surveyor 0 0 96 4x GPS Heading Hemisphere 1 3

Sugianto Party Chief 240 12 252 2x GPS Septentrio Aster x2eh 1 1

Yayan Surveyor 108 12 120 8x Radio Telemetry SATELine 4 4

Total = 1260 6x Cable+Antenna ACA 4 2

5x Navigation Computer (Laptop) 1 4

1x Navigation Computer (Desktop) 1

4x LCD Monitor 4

1

2 2

9x DC Power Supply 4 5

2x VGA Splitter 1 1

3x USB Port Bafo 2 1

4x Sunix ComHub 2 2

10x Extention Power Cable 4 6

1x Tripod + Tribrach 1

1x Tool Kit 1

3x Life Jacket 3

1x Printer Canon IP 1300

4x UPS power supply

4x Helmet 4

HSE ACTIVITY

SURVEY ACTIVITY : Continue monitoring AWB.KingFisher position at Mopu platform location.

00:00 KingFisher position 836112.48 E, 9190580.66 N, Heading 163.62

0

, 41m from Mopu platform.

03:00 KingFisher position 836112.84 E, 9190580.46 N, Heading 162.92

0

, 41m from Mopu platform.

05:55 - 06:10 KingFisher moving astern 25m_position 836108.92 E, 9190605.35 N, Heading 165.78

0

, 16m from Mopu platform.

09:00 KingFisher position 836108.92 E, 9190605.35 N, Heading 165.78

0

, 16m from Mopu platform.

Summary of Daily Activities Survey

09:00 KingFisher position 836108.92 E, 9190605.35 N, Heading 165.78 , 16m from Mopu platform.

10:45 - 10:55 Adjusting the KingFisher position for keep the distance gangway.

11:30 - 12:00 Friday praying.

15:00 KingFisher position 836108.85 E, 9190604.94 N, Heading 164.21

0

, 16m from Mopu platform.

18:00 KingFisher position 836108.85 E, 9190604.94 N, Heading 164.21

0

, 16m from Mopu platform.

20:55 - 21:05 KingFisher moving ahead 27m_position 836113.47 E, 9190578.57 N, Heading 164.65

0

, 43m from Mopu platform.

24:00 KingFisher position 836113.33 E, 9190578.31 N, Heading 162.68

0

, 43m from Mopu platform.

ACTIVITY PLAN : Continue monitoring AWB.KingFisher position at Mopu platform location.

Weather Reports

Period of Time Weather Annotation

Clear

Weather Records : Bright, cloudy, clear, rain

Prepared by : Approved by : Approved by :

GMK Party Chief

Sugianto Rudolf Taufik

Supraco rep. Santos rep.

S-ar putea să vă placă și

- JIGCC Power Block Severe Service Control ValvesDocument21 paginiJIGCC Power Block Severe Service Control ValveszhangÎncă nu există evaluări

- HRD - No-8 Final SettlementDocument1 paginăHRD - No-8 Final SettlementHOSAM HUSSEINÎncă nu există evaluări

- I011a Instrument CalibrationDocument2 paginiI011a Instrument CalibrationEyRa AzyRaÎncă nu există evaluări

- Man Hour Calculation FormDocument152 paginiMan Hour Calculation Formمحمد شافق ابنو شافعتÎncă nu există evaluări

- Employee Final Settlement DetailsDocument1 paginăEmployee Final Settlement DetailsZeeshan MirzaÎncă nu există evaluări

- Boiler House Project ReportDocument12 paginiBoiler House Project ReportKiel CorpuzÎncă nu există evaluări

- Site Weekly Cost Report-MounirDocument50 paginiSite Weekly Cost Report-MounirAna Caroline BritoÎncă nu există evaluări

- Procurement SummaryDocument1 paginăProcurement SummaryRavi Shankar KolluruÎncă nu există evaluări

- Updated B - 209 - MDF - DMS - 20-April-15 - Rev 01Document148 paginiUpdated B - 209 - MDF - DMS - 20-April-15 - Rev 01Nadim JilaniÎncă nu există evaluări

- Instruments: Manufacturer Model RemarksDocument4 paginiInstruments: Manufacturer Model RemarksAnietie UdofiaÎncă nu există evaluări

- Brief General Contract Data Work Progress Summary: Notice To Commence Extension of Time Revised Completion DateDocument4 paginiBrief General Contract Data Work Progress Summary: Notice To Commence Extension of Time Revised Completion Datesidiq7Încă nu există evaluări

- Technical FF PRT C 20181016 171523 PDFDocument851 paginiTechnical FF PRT C 20181016 171523 PDFAayeshaÎncă nu există evaluări

- GANTTDocument14 paginiGANTTManisha ThakurÎncă nu există evaluări

- Aln Group Clearance Form - v4 - Seadweller CorpDocument4 paginiAln Group Clearance Form - v4 - Seadweller CorpJomar FrogosoÎncă nu există evaluări

- Today's Work) Ompleted Location Level ActivityDocument12 paginiToday's Work) Ompleted Location Level ActivityChetan GohilÎncă nu există evaluări

- Principles and Practice of Chiropractic, 3E (2005) (PDF) (UnitedVRG)Document1.246 paginiPrinciples and Practice of Chiropractic, 3E (2005) (PDF) (UnitedVRG)Maikell Moura79% (14)

- Draft ContractDocument342 paginiDraft ContractGema SuryaÎncă nu există evaluări

- CENTRAL GAS PLANT DEBOTTLENECK PROJECT CIVIL WORKSDocument9 paginiCENTRAL GAS PLANT DEBOTTLENECK PROJECT CIVIL WORKSIndra Pandu Prasetyo100% (1)

- Subject: Fire Alarm System's Work Status ReportDocument6 paginiSubject: Fire Alarm System's Work Status ReportJesús Yarleque RamosÎncă nu există evaluări

- English Proficiency Test: Section 1: Language FunctionsDocument7 paginiEnglish Proficiency Test: Section 1: Language FunctionsWibowo_Wisnu_Nhu_781Încă nu există evaluări

- BM IL Kodya Yogyakarta: Project ScheduleDocument7 paginiBM IL Kodya Yogyakarta: Project ScheduleembundilangitÎncă nu există evaluări

- Equipment Register for Turnkey Petroleum ProjectsDocument222 paginiEquipment Register for Turnkey Petroleum ProjectsEmmanuel IkechukwwuÎncă nu există evaluări

- Sawamlah SS, 3 Weeks Schedule Update Till 21.01.2014Document17 paginiSawamlah SS, 3 Weeks Schedule Update Till 21.01.2014William E. NuevoÎncă nu există evaluări

- Pressure Transmitter Elec: Instrument Calibration ResultDocument2 paginiPressure Transmitter Elec: Instrument Calibration ResultIsaalexÎncă nu există evaluări

- AZITP-J-902-01 Rev 00 Metallic Instrument and Control CableDocument5 paginiAZITP-J-902-01 Rev 00 Metallic Instrument and Control CableVinay YadavÎncă nu există evaluări

- Jawaid Shut Down ResumeDocument4 paginiJawaid Shut Down ResumeRaj AryanÎncă nu există evaluări

- Man Hours HistogramDocument1 paginăMan Hours HistogramMostafa Elkadi0% (1)

- % of Total Pipe Line Cost EstimateDocument1 pagină% of Total Pipe Line Cost EstimateEngFaisal AlraiÎncă nu există evaluări

- Work Done On Today: DCDB (220V-1No &48V-1No) ErectionDocument47 paginiWork Done On Today: DCDB (220V-1No &48V-1No) ErectionGhritachi PaulÎncă nu există evaluări

- Documents Required-Engineering-20210821Document133 paginiDocuments Required-Engineering-20210821Abdelhay MarocainÎncă nu există evaluări

- GE Libya CEMS Inspection PlanDocument31 paginiGE Libya CEMS Inspection PlanZaid RÎncă nu există evaluări

- QAP For Overall Mechanical ActivitiesDocument2 paginiQAP For Overall Mechanical ActivitiesMaheshwar polepallyÎncă nu există evaluări

- TP 09Document6 paginiTP 09Karunanithi NagarajanÎncă nu există evaluări

- Procedure For Preparation of Dry Chemical Wheeled Extinguishers Data SheetDocument5 paginiProcedure For Preparation of Dry Chemical Wheeled Extinguishers Data SheetmÎncă nu există evaluări

- Offer124033 Bom R0Document2 paginiOffer124033 Bom R0t_syamprasad100% (1)

- Edinburgh Napier University HR overtime formDocument2 paginiEdinburgh Napier University HR overtime formRrichard Prieto MmallariÎncă nu există evaluări

- Saudi Aramco Oil Analyzer Specification SheetsDocument10 paginiSaudi Aramco Oil Analyzer Specification Sheetszizu1234Încă nu există evaluări

- NS FFD PACKAGE 2 - PROCUREMENT EQUIPMENTDocument16 paginiNS FFD PACKAGE 2 - PROCUREMENT EQUIPMENTrichardykeÎncă nu există evaluări

- Cosa 9610 Wobbe Analyzer Users ManualDocument44 paginiCosa 9610 Wobbe Analyzer Users ManualEnrique De Haro CortesÎncă nu există evaluări

- Commissioning Schedule 01Document30 paginiCommissioning Schedule 01Srinivasa Rao VenkumahanthiÎncă nu există evaluări

- EDocument66 paginiEAhmed Hussain100% (1)

- Instrument Schedule A40191-R1Document37 paginiInstrument Schedule A40191-R1ash_captchajobsÎncă nu există evaluări

- ASTM A53 B Carbon Steel Pipes - Allowable PressureDocument8 paginiASTM A53 B Carbon Steel Pipes - Allowable PressureAizat Najib100% (1)

- Ptg-tmy-yad2-In-rfq-019 Rev 0 RFQ For Wave Protection For Esv-Sdv & Fo JBDocument15 paginiPtg-tmy-yad2-In-rfq-019 Rev 0 RFQ For Wave Protection For Esv-Sdv & Fo JBAditya PranotoÎncă nu există evaluări

- Progress SummaryDocument1 paginăProgress SummaryIrwan KurniawanÎncă nu există evaluări

- 2.40 Transmittal Log (Po-Pgb-Cab-0002) (PBC)Document10 pagini2.40 Transmittal Log (Po-Pgb-Cab-0002) (PBC)zhangÎncă nu există evaluări

- Project Title: (Company Name) (Project Lead)Document3 paginiProject Title: (Company Name) (Project Lead)Harsha SamagaraÎncă nu există evaluări

- Liquid and Gas Flow Rate CalculatorsDocument4 paginiLiquid and Gas Flow Rate Calculatorshafizi07Încă nu există evaluări

- North Yaran Oil Field Development ClusterDocument4 paginiNorth Yaran Oil Field Development ClustermÎncă nu există evaluări

- Fabrication Inspection Progress ReportDocument4 paginiFabrication Inspection Progress ReportNorman MoralesÎncă nu există evaluări

- PP in Ii 001Document15 paginiPP in Ii 001Dav EipÎncă nu există evaluări

- S - Curve Execution Work Pemasangan 1 Unit Regulator Class 900 CSR PempingDocument1 paginăS - Curve Execution Work Pemasangan 1 Unit Regulator Class 900 CSR PempingWulan Glh100% (1)

- Weather Conditions: Daily Progress ReportDocument2 paginiWeather Conditions: Daily Progress Reportbishu70Încă nu există evaluări

- Cable Products Price ListDocument24 paginiCable Products Price ListPeter BridgeÎncă nu există evaluări

- MS Piping and Fittings Rates ListDocument12 paginiMS Piping and Fittings Rates Listshawanqureshi1706160Încă nu există evaluări

- Notifier Price List 2015 3Document76 paginiNotifier Price List 2015 3juga2013100% (1)

- 04.12.2014 Udated Bar-Chart Common S D - Timeline - Copy12042014Document13 pagini04.12.2014 Udated Bar-Chart Common S D - Timeline - Copy12042014Naushad AhamedÎncă nu există evaluări

- DBRYSDocument2 paginiDBRYSAnshu K MuhammedÎncă nu există evaluări

- KEC - Price List CablesDocument8 paginiKEC - Price List CablesSCM ASA BHANUÎncă nu există evaluări

- Al Ramah Residental C Al Ramah Residental Complexes (Infrastructure)Document5 paginiAl Ramah Residental C Al Ramah Residental Complexes (Infrastructure)anoopvvvÎncă nu există evaluări

- 9 Three Line DiagramDocument1 pagină9 Three Line Diagramapi-302117883Încă nu există evaluări

- Mill Applicable TonnageDocument5 paginiMill Applicable TonnageVijay PalÎncă nu există evaluări

- Definition Endof Line Deflagration Automechanika 2008Document1 paginăDefinition Endof Line Deflagration Automechanika 2008Gema SuryaÎncă nu există evaluări

- CV JUSSI (Updated Januari 2019) - 3Document2 paginiCV JUSSI (Updated Januari 2019) - 3Gema SuryaÎncă nu există evaluări

- Peraturan Menteri Keuangan No. 101-PMK.04-2005-English VersionDocument4 paginiPeraturan Menteri Keuangan No. 101-PMK.04-2005-English VersionGema SuryaÎncă nu există evaluări

- Sensor Networks R170218aDocument5 paginiSensor Networks R170218aGema SuryaÎncă nu există evaluări

- Remote, Permanently-Installed Wall Thickness Monitoring.: Up To 32 Daisy-Chained Transmitters Per Cable DropDocument2 paginiRemote, Permanently-Installed Wall Thickness Monitoring.: Up To 32 Daisy-Chained Transmitters Per Cable DropGema SuryaÎncă nu există evaluări

- Data Electricity Customer MDocument1 paginăData Electricity Customer MGema SuryaÎncă nu există evaluări

- 1 Using Plaxis On A Network 2 Share The Software: 2.1 Server Installation 2.2 Workstation InstallationDocument9 pagini1 Using Plaxis On A Network 2 Share The Software: 2.1 Server Installation 2.2 Workstation InstallationGema SuryaÎncă nu există evaluări

- IJ-MBON-Rev. Nov 10, 2017-Multi EntityDocument4 paginiIJ-MBON-Rev. Nov 10, 2017-Multi EntityGema SuryaÎncă nu există evaluări

- Personal Detail'S: No Name of Document Number Issued Date Expire DateDocument1 paginăPersonal Detail'S: No Name of Document Number Issued Date Expire DateGema SuryaÎncă nu există evaluări

- Phantom 3 Series Remote Controller Release NotesDocument1 paginăPhantom 3 Series Remote Controller Release NotesGema SuryaÎncă nu există evaluări

- High-TemperatureFlare HTF PDFDocument1 paginăHigh-TemperatureFlare HTF PDFGema SuryaÎncă nu există evaluări

- IJ-MBON-Rev. Nov 10, 2017-Multi EntityDocument4 paginiIJ-MBON-Rev. Nov 10, 2017-Multi EntityGema SuryaÎncă nu există evaluări

- Epc of Well Pad D For Sorik Marapi Geothermal Project Recovery ScheduleDocument1 paginăEpc of Well Pad D For Sorik Marapi Geothermal Project Recovery ScheduleGema SuryaÎncă nu există evaluări

- WWG Construction Activities PDFDocument2 paginiWWG Construction Activities PDFGema SuryaÎncă nu există evaluări

- Schedule SMGP SM-D Re-BaselineDocument1 paginăSchedule SMGP SM-D Re-BaselineGema SuryaÎncă nu există evaluări

- How To Upgrade TP-LINK Wireless N Router&AP (192.168.0.254 Version) PDFDocument2 paginiHow To Upgrade TP-LINK Wireless N Router&AP (192.168.0.254 Version) PDFGema SuryaÎncă nu există evaluări

- Scaffold Proced Erect Dis Man TDocument4 paginiScaffold Proced Erect Dis Man TGema SuryaÎncă nu există evaluări

- TransIt235Manual1r PDFDocument138 paginiTransIt235Manual1r PDFGema SuryaÎncă nu există evaluări

- Phantom 3 Series Remote Controller Release Notes PDFDocument1 paginăPhantom 3 Series Remote Controller Release Notes PDFGema SuryaÎncă nu există evaluări

- Copper RidgeDocument4 paginiCopper RidgeGema SuryaÎncă nu există evaluări

- CBN Jawa Bali 2014Document1 paginăCBN Jawa Bali 2014Tomi KurniaÎncă nu există evaluări

- Phantom 3 Series Remote Controller Release Notes: What's New?Document1 paginăPhantom 3 Series Remote Controller Release Notes: What's New?Gema SuryaÎncă nu există evaluări

- Inerting & BlanketingDocument5 paginiInerting & Blanketingbksree100% (1)

- Explosion-Protected Light Fittings eLLK 92036 eLLK 92036/36: Zone 21/ Zone 22Document1 paginăExplosion-Protected Light Fittings eLLK 92036 eLLK 92036/36: Zone 21/ Zone 22Gema SuryaÎncă nu există evaluări

- Blade CengarDocument1 paginăBlade CengarGema SuryaÎncă nu există evaluări

- CBN Jawa Bali 2014Document1 paginăCBN Jawa Bali 2014Tomi KurniaÎncă nu există evaluări

- GP328 338 Plus-SsDocument2 paginiGP328 338 Plus-SsGema SuryaÎncă nu există evaluări