Documente Academic

Documente Profesional

Documente Cultură

Cat CSSV 02 14

Încărcat de

Ali MiladianTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cat CSSV 02 14

Încărcat de

Ali MiladianDrepturi de autor:

Formate disponibile

Cast stainless steel valves

gate, globe, and check

ASME CLASSES 150 600

NPS 24 (DN 15 600)

API 603/ASME B16.34

Corrosion resistant

CAT-CSSV-02-14.indd 1 14-02-10 10:41 AM

2 Velan reserves the right to change this information without notice. 2014 Velan Inc. All rights reserved.

VELANS PROFILE

VELAN AT A GLANCE

History

Founded in 1950

Sales

Over $500 million

People

Over 2,000 employees

Product line

A world-leading range of valves across

all major industrial applications:

Cast steel gate, globe, check,

and ball valves

Forged steel gate, globe, check,

and ball valves

Triple-offset buttery valves

Knife gate valves

Severe service valves

Bellows seal valves

Steam traps

Quality

All major certications and approvals

ASME N stamp and NPT for nuclear

valves (since 1970)

ISO 9001 (since 1991)

Currently certied to ISO 9001:2008

PED

GOST (TR and RTN)

API 6A and API 6D

TA-Luft

Quality programs fully compliant with

ISO-9001, NCA 4000, ASME NQA-1 and

10 CFR 50 Appendix B, surveyed by

ASME and audited by NUPIC, Northrop

Grumman Newport News, DCMA,

utilities, architect/ engineers, and other

organizations from around the world

Headquartered in Montreal, Velan has

several international subsidiaries.

For general inquiries:

Velan head ofce:

7007 Cte de Liesse,

Montreal, QC H4T 1G2 Canada

Tel: +1 514 748 7743

Fax: +1 514 748 8635

Check our website for more

specic contact information.

www.velan.com

Velan is one of the worlds leading

manufacturers of industrial steel valves,

supplying gate, globe, check, ball, triple-

offset butterfly, knife gate, control, and

highly engineered severe service valves

for critical applications in the chemical,

petrochemical, oil and gas, fossil and

nuclear power, cogeneration, pulp and

paper, mining, marine and cryogenic

industries. The company also supplies

actuators and integrated control packages.

Founded in 1950, Velan has earned a

reputation for product excellence and

innovation by bringing to the market superior

products with special emphasis on quality,

safety, ease of operation, and long service

life. Velan valves have an extremely broad

installation base and are approved by major

companies worldwide.

Velan concentrates on one businessthe

design, manufacture and marketing of

steel valves in a broad range of types and

sizes for high performance service in a

wide range of applications. The companys

talented people are focused on Velans

core values of quality, reliability, innovation,

and integrity and mission to be the worlds

leading valve brand.

2014 Velan Inc., Montreal, QC, Canada. All rights reserved. The contents hereof are condential and proprietary

to Velan. Any unauthorized reproduction or disclosure, in whole or in part, is strictly prohibited. Velan reserves the

right to change this information without notice. Velan does not accept any liability or damages arising from the use

of information in this catalog. Velan Valves, Velan, Memoryseal, Securaseal, Torqseal, Velex, Adaxie, and RAMA

are trademarks or registered trademarks of Velan Inc. and/or another Velan company. Stellite is a registered

trademark of Kennametal Stellite, a wholly owned subsidiary of Kennametal Inc. All other trademarks and regis-

tered trademarks are owned by their respective companies.

TABLE OF CONTENTS

Manufacturing Plants ............................. 3

Cast stainless steel API 603 gate

valves, NPS 1 (DN 15 40) .............. 4

Cast stainless steel API 603 gate

valves, NPS 224 (DN 50 600) .............. 5

Cast stainless steel globe valves,

NPS 1 (DN 15 40) ........................... 6

Cast stainless steel globe valves,

NPS 26 (DN 50 150) ............................. 7

Cast stainless steel swing check

valves, NPS 1 (DN 15 40) .............. 8

Cast stainless steel swing check

valves, NPS 212 (DN 50 300) ............ 9

Velan special services cast stainless

steel cryogenic gate, globe, and check

valves, NPS 24 (DN 15 600) ......... 10

How to order cast stainless steel

gate, globe, and check valves .............. 11

B16.34 pressure/temperature table .... 11

Flow coefficient Cv table ....................... 11

North America

Manufacturing plants

Head ofce

Europe Asia

Distribution centers

17 production facilities

5 plants in North America

6 plants in Europe

6 plants in Asia

5 stocking and distribution centers

Hundreds of distributors worldwide

Over 60 service shops worldwide

Williston, VT, U.S.A.

Velan Valve Corp., Plant 3

Lucca, Italy

Velan ABV S.p.A., Plant 1

Lisbon, Portugal

Velan Vlvulas Industriais, Lda.

Montreal, Canada

Velan Inc., Plant 5

Houston, TX, U.S.A.

VelTEX

Willich, Germany

Velan GmbH

Taichung, Taiwan

Velan Valvac Mfg. Co., Ltd.

Suzhou, China

Velan Valve (Suzhou) Co., Ltd.

Coimbatore, India

Velan Valves India Pvt. Ltd.

Granby, Canada

Velan Inc., Plant 4 and 6

Leicester, UK

Velan Valves Ltd.

Marietta, GA, U.S.A.

VelEAST

Ansan City, South Korea

Velan Ltd., Plant 3

Montreal, Canada

Velan Inc., Plant 2 and 7

Mennecy, France

Segault S.A.

Benicia, CA, U.S.A.

VelCAL

Ansan City, South Korea

Velan Ltd., Plant 2

Montreal, Canada

Velan Inc., Plant 1

Lyon, France

Velan S.A.S.

Granby, Canada

VelCAN

Ansan City, South Korea

Velan Ltd., Plant 1

Montreal, Canada

Velan Inc.

Lucca, Italy

Velan ABV S.p.A., Plant 2

ASME N-stamp accredited manufacturer

CAT-CSSV-02-14.indd 2 14-02-10 10:41 AM

Velan reserves the right to change this information without notice. 2014 Velan Inc. All rights reserved. 3

VELANS GLOBAL NETWORK

North America

Manufacturing plants

Head ofce

Europe Asia

Distribution centers

17 production facilities

5 plants in North America

6 plants in Europe

6 plants in Asia

5 stocking and distribution centers

Hundreds of distributors worldwide

Over 60 service shops worldwide

Williston, VT, U.S.A.

Velan Valve Corp., Plant 3

Lucca, Italy

Velan ABV S.p.A., Plant 1

Lisbon, Portugal

Velan Vlvulas Industriais, Lda.

Montreal, Canada

Velan Inc., Plant 5

Houston, TX, U.S.A.

VelTEX

Willich, Germany

Velan GmbH

Taichung, Taiwan

Velan Valvac Mfg. Co., Ltd.

Suzhou, China

Velan Valve (Suzhou) Co., Ltd.

Coimbatore, India

Velan Valves India Pvt. Ltd.

Granby, Canada

Velan Inc., Plant 4 and 6

Leicester, UK

Velan Valves Ltd.

Marietta, GA, U.S.A.

VelEAST

Ansan City, South Korea

Velan Ltd., Plant 3

Montreal, Canada

Velan Inc., Plant 2 and 7

Mennecy, France

Segault S.A.

Benicia, CA, U.S.A.

VelCAL

Ansan City, South Korea

Velan Ltd., Plant 2

Montreal, Canada

Velan Inc., Plant 1

Lyon, France

Velan S.A.S.

Granby, Canada

VelCAN

Ansan City, South Korea

Velan Ltd., Plant 1

Montreal, Canada

Velan Inc.

Lucca, Italy

Velan ABV S.p.A., Plant 2

ASME N-stamp accredited manufacturer

CAT-CSSV-02-14.indd 3 14-02-10 10:41 AM

4 Velan reserves the right to change this information without notice. 2014 Velan Inc. All rights reserved.

STANDARD MATERIALS

ASME CLASS FIGURE NUMBER

150 0064C13SX or GX

300 1064C13SX or GX

Flanged

ASME CLASS FIGURE NUMBER

600 2064C14SX or GX

Threaded/socket weld

INTEGRAL SEAT, FLANGED, WALL THICKNESS TO ASME B16.34

ASME CLASSES 150, 300, NPS 1 (DN 1540)

FULL PORT, THREADED, SOCKET WELD OR COMBINATION

WALL THICKNESS TO ASME B16.34

ASME CLASS 600, NPS 1 (DN 1540)

VELAN CAST STAINLESS STEEL API 603 GATE VALVES

PART MATERIAL

Body A351 Gr. CF8M

Bonnet A351 Gr. CF8M

Wedge A351 Gr. CF8M

Stem Gr. 316

Gland Gr. 316

Gland flange A351 Gr. CF8M

Handwheel Malleable iron (painted)

Handwheel nut Stainless steel

Body/bonnet cap screw Gr. B8M

Body/bonnet nut Gr. 8M

Gland stud Gr. 304

Gland nut Gr. 8M

Gland packing

SX PTFE

GX Graphite

Gasket

SX PTFE with stainless

GX Graphite with stainless

Name plate Stainless steel

Stem nut Gr. 416

= Center-to-top, open

D

Gate valves with unique flexible wedge

Precision high quality

investment castings

SIZE

NPS

DN

FLANGED, ASME 150 FLANGED, ASME 300 THREADED - SOCKET WELD, ASME 600

A B C D

WEIGHT

lb (kg) A B C D

WEIGHT

lb (kg) A B C D

WEIGHT

lb (kg)

15

4.25

108

8.06

205

4.75

121

0.62

15.7

8

3.6

5.50

140

8.11

206

4.75

121

0.62

15.7

10

4.5

2.88

73

7.97

202

4.75

121

0.62

15.7

6

2.7

20

4.63

118

8.07

205

4.75

121

0.75

19

9

4.1

6.00

152

8.14

207

4.75

121

0.75

19

11

5.0

3.25

83

7.95

202

4.75

121

0.75

19

7

3.2

1

25

5.00

127

8.67

303

4.75

121

1.00

25.4

10

4.5

6.50

165

8.73

222

4.75

121

1.00

25.4

14

6.4

3.50

89

8.55

217

4.75

121

1.00

25.4

8

3.6

1

40

6.50

165

11.91

220

8.00

203

1.50

38.1

23

10.4

7.50

191

11.95

304

8.00

203

1.50

38.1

25

11.3

5.00

127

11.79

300

8.00

203

1.50

38.1

20

9.1

DIMENSIONS AND WEIGHTS

CAT-CSSV-02-14.indd 4 14-02-10 10:41 AM

Velan reserves the right to change this information without notice. 2014 Velan Inc. All rights reserved. 5

SIZE

NPS

DN

FLANGED, ASME 150 FLANGED, ASME 300

A B C D

WEIGHT

lb (kg) A B C D

WEIGHT

lb (kg)

2 7.00 13.89 8.00 2.00 32 8.50 14.66 8.00 2.00 46

50 178 353 203 51 14.5 216 372 203 51 21.9

2 7.50 16.53 8.00 2.50 48 9.50 16.22 8.00 2.50 60

65 191 420 203 64 21.8 241 412 203 64 27.2

3 8.00 18.50 8.00 3.00 52 11.12 18.70 10.00 3.00 86

80 203 470 203 76 23.6 282.45 475 254 76 39.0

4 9.00 21.76 10.00 4.00 80 12.00 23.18 10.00 4.00 134

100 229 553 254 102 36.4 305 589 254 102 60.8

6 10.50 29.06 10.00 6.00 135 15.87 29.52 18.00 6.00 247

150 267 738 254 152 61.2 403 750 457 152 112.07

8 11.50 36.88 14.00 8.00 222 16.50 38.81 18.00 8.00 401

200 292 937 356 203 100.9 419 986 457 203 181.9

10 13.00 45.00 18.00 10.00 324 18.00 47.08 20.00 10.00 630

250 330 1143 457 254 147.3 457 1196 508 254 285.8

12 14.00 53.00 18.00 12.00 472 19.75 55.15 20.00 12.00 880

300 356 1346 457 305 214.1 502 1401 508 305 400.0

14 15.00 61.31 24.00 13.25 800

350 381 1557 610 337 362.9

16 16.00 69.25 24.00 15.25 1000

400 406 1759 610 387 453.6

18 17.00 73.96 24.00 17.25 1300

450 432 1879 610 438 589.6

20 18.00 83.81 30.00 19.25 1500

500 457 2129 762 489 680.3

24

600

INTEGRAL SEAT, FLANGED, WALL THICKNESS TO ASME B16.34

ASME CLASSES 150, 300, NPS 224 (DN 50600)

VELAN CAST STAINLESS STEEL API 603 GATE VALVES

STANDARD MATERIALS

PART MATERIAL

Body A351 Gr. CF8M

Bonnet A351 Gr. CF8M

Wedge A351 Gr. CF8M

Stem Gr. 316

Gland Gr. 316

Gland flange A351 Gr. CF8M

Yoke bushing Gr. 316

Handwheel Malleable iron (painted)

Handwheel nut Carbon steel

Body/bonnet stud Gr. B8M

Body/bonnet nut Gr. 8M

Gland stud Gr. 304

Gland nut Gr. 8M

Spring pin Stainless steel

Gland

packing

SX or SY PTFE

GX or GY Graphite

Gasket

SX or SY

PTFE with stainless

wire mesh

GX or GY

Graphite with stainless

steel foil

Name plate Stainless steel

Stem nut Ni-resist type D-2C

= Center-to-top,

open

D

Gate valves with unique

flexible wedge

Precision high quality

investment castings

DIMENSIONS AND WEIGHTS

ASME CLASS FIGURE NUMBER

150 0064C13SX or GX

300 1064C13SX or GX

Stainless seat

ASME CLASS FIGURE NUMBER

150 0064C13SY or GY

300 1064C13SY or GY

CoCr alloy seat

Optional integral

CoCr alloy seat face

available for longer

service life.

CAT-CSSV-02-14.indd 5 14-02-10 10:41 AM

6 Velan reserves the right to change this information without notice. 2014 Velan Inc. All rights reserved.

STANDARD MATERIALS

ASME CLASS FIGURE NUMBER

150 0074C13SX or GX

300 1074C13SX or GX

Flanged

ASME CLASS FIGURE NUMBER

600 2074C14SX or GX

Threaded/socket weld

INTEGRAL SEAT, FLANGED, WALL THICKNESS TO ASME B16.34

ASME CLASSES 150, 300, NPS 1 (DN 1540)

FULL PORT, THREADED, SOCKET WELD OR COMBINATION

WALL THICKNESS TO ASME B16.34

ASME CLASS 600, NPS 1 (DN 1540)

VELAN CAST STAINLESS STEEL GLOBE VALVES

PART MATERIAL

Body A351 Gr. CF8M

Bonnet A351 Gr. CF8M

Disc A351 Gr. CF8M

Stem Gr. 316

Gland Gr. 316

Gland flange A351 Gr. CF8M

Yoke bushing Gr. 416

Handwheel Malleable iron (painted)

Handwheel nut Stainless steel

Body/bonnet cap screw Gr. B8M

Body/bonnet nut Gr. 8M

Gland stud Gr. 304

Gland nut Gr. 8M

Gland packing

SX PTFE

GX Graphite

Gasket

SX PTFE with stainless

GX Graphite with stainless

Name plate Stainless steel

Stem nut Gr. 416

Globe valves with fully guided disc

Precision high quality

investment castings

SIZE

NPS

DN

FLANGED, ASME 150 FLANGED, ASME 300 THREADED - SOCKET WELD, ASME 600

A B C D

WEIGHT

lb (kg) A B C D

WEIGHT

lb (kg) A B C D

WEIGHT

lb (kg)

15

4.25

108

8.31

211

4.00

102

0.50

13

7

3.2

6.00

152

8.31

211

4.00

102

0.50

13

9

4.1

3.75

95

8.31

211

4.00

102

0.50

13

6

2.7

20

4.63

118

8.31

211

4.00

102

0.75

19

8

3.6

7.00

178

8.31

211

4.00

102

0.75

19

10

4.5

4.25

108

8.31

211

4.00

102

0.75

19

7

3.2

1

25

5.00

127

9.08

230

4.00

102

1.00

25.4

10

4.5

8.00

203

9.08

230

4.00

102

1.00

25.4

12

5.4

5.00

127

9.08

230

4.00

102

1.00

25.4

8

3.6

1

40

6.50

165

11.28

286

8.00

203

1.50

38.1

22

10.0

9.00

229

11.28

286

8.00

203

1.50

38.1

29

13.2

6.00

152

11.28

286

8.00

203

1.50

38.1

18

8.2

DIMENSIONS AND WEIGHTS

= Center-to-top, open

CAT-CSSV-02-14.indd 6 14-02-10 10:41 AM

Velan reserves the right to change this information without notice. 2014 Velan Inc. All rights reserved. 7

DIMENSIONS AND WEIGHTS

SIZE

NPS

DN

FLANGED, ASME 150 FLANGED, ASME 300

A B C D

WEIGHT

lb (kg) A B C D

WEIGHT

lb (kg)

2 8.00 10.25 8.00 2.00 27 10.50 11.27 8.00 2.00 45

50 203 260 203 51 12.3 267 286 203 51 20.4

2 8.50 10.44 10.00 2.50 37 11.50 12.31 10.00 2.50 70

65 216 265 254 64 16.8 292 313 254 64 31.8

3 9.50 12.62 10.00 3.00 53 12.50 13.85 10.00 3.00 87

80 241 321 254 76 24.0 318 352 254 76 39.5

4 11.50 14.92 10.00 4.00 83 14.00 16.29 10.00 4.00 130

100 292 379 254 102 37.6 356 414 254 102 59.0

6 16.00 17.48 10.00 6.00 154 17.50 21.62 14.00 6.00 252

150 406 457 254 152 69.9 445 549 356 152 114.3

INTEGRAL SEAT, FLANGED, WALL THICKNESS TO ASME B16.34

ASME CLASSES 150, 300, NPS 26 (DN 50150)

VELAN CAST STAINLESS STEEL GLOBE VALVES

STANDARD MATERIALS

PART MATERIAL

Body A351 Gr. CF8M

Bonnet A351 Gr. CF8M

Disc A351 Gr. CF8M

Stem Gr. 316

Disc nut A351 Gr. CF8M

Gland pin Gr. 316

Gland Gr. 316

Gland flange A351 Gr. CF8M

Yoke bushing

Austenitic ductile iron

Gr. D-2C

Handwheel Malleable iron (painted)

Handwheel nut Carbon steel

Bonnet stud Gr. B8M

Bonnet nut Gr. 8M

Gland stud Gr. 304

Gland nut Gr. 8M

Gland

packing

SX or SY PTFE

GX or GY Graphite

Gasket

SX or SY PTFE

GX or GY Graphite

Name plate Stainless steel

ASME CLASS FIGURE NUMBER

150 0074C13SX or GX

300 1074C13SX or GX

Stainless seat

ASME CLASS FIGURE NUMBER

150 0074C13SY or GY

300 1074C13SY or GY

CoCr alloy seat

Precision high quality

investment castings

Optional integral

CoCr alloy seat face

available for longer

service life.

= Center-to-top, open

CAT-CSSV-02-14.indd 7 14-02-10 10:41 AM

8 Velan reserves the right to change this information without notice. 2014 Velan Inc. All rights reserved.

INTEGRAL SEAT, FLANGED, WALL THICKNESS TO ASME B16.34

ASME CLASSES 150, 300, NPS 1 (DN 1540)

FULL PORT, THREADED, SOCKET WELD OR COMBINATION

WALL THICKNESS TO ASME B16.34

ASME CLASS 600, NPS 1 (DN 1540)

VELAN CAST STAINLESS STEEL SWING CHECK VALVES

STANDARD MATERIALS

PART MATERIAL

Body A351 Gr. CF8M

Cover A351 Gr. CF8M

Disc A351 Gr. CF8M

Hinge A351 Gr. CF8M

Pin Gr. 316

Disc nut Gr. 8M

Cap screw Gr. B8M

Cover nut Gr. 8M

Gasket

SX PTFE with stainless

GX Graphite with stainless

Name plate Stainless steel

Precision high quality

investment castings

DIMENSIONS AND WEIGHTS

SIZE

NPS

DN

FLANGED, ASME 150 FLANGED, ASME 300 THREADED - SOCKET WELD, ASME 600

A B C D

WEIGHT

lb (kg) A B C D

WEIGHT

lb (kg) A B C D

WEIGHT

lb (kg)

15

4.25

108

3.08

78

2.87

73

0.62

15.7

5

2.3

6.00

152

3.16

80

2.87

73

0.62

15.7

7

3.2

3.75

95

3.03

77

3.03

77

0.62

15.7

4

1.8

20

4.62

117

3.10

79

2.87

73

0.75

19

6

2.7

7.00

178

3.20

81

2.87

73

0.75

19

8

3.6

3.75

95

3.01

76

3.01

76

0.75

19

5

2.3

1

25

5.00

127

3.31

84

3.12

79

1.00

25.4

8

3.6

8.50

216

3.47

88

3.12

79

1.00

25.4

12

5.4

5.00

127

3.26

83

3.26

83

1.00

25.4

7

3.2

1

40

6.00

152

4.56

116

4.00

102

1.50

38.1

16

7.3

9.50

241

4.69

119

4.00

102

1.50

38.1

24

10.9

6.00

152

4.48

114

4.48

114

1.50

38.1

12

15.4

ASME CLASS FIGURE NUMBER

150 0114C13SX or GX

300 1114C13SX or GX

FLANGED

ASME CLASS FIGURE NUMBER

600 2114C14SX or GX

THREADED/SOCKET WELD

D

CAT-CSSV-02-14.indd 8 14-02-10 10:41 AM

Velan reserves the right to change this information without notice. 2014 Velan Inc. All rights reserved. 9

INTEGRAL SEAT, FLANGED, WALL THICKNESS TO B16.34

ASME CLASSES 150, 300, NPS 212 (DN 50300)

VELAN CAST STAINLESS STEEL SWING CHECK VALVES

STANDARD MATERIALS

PART MATERIAL

Body A351 Gr. CF8M

Cover A351 Gr. CF8M

Disc A351 Gr. CF8M

Hinge A351 Gr. CF8M

Pin Gr. 316

Plug Gr. 316

Disc nut Gr. 8M

Washer Gr. 316

Cotter pin Gr. 316

Cover stud Gr. B8M

Cover nut Gr. 8M

Gasket

SX or SY PTFE with stainless wire mesh

GX or GY Graphite with stainless foil

Name plate Stainless steel

ASME CLASS FIGURE NUMBER

150 0114C13SX or GX

300 1114C13SX or GX

Stainless seat

ASME CLASS FIGURE NUMBER

150 0114C13SY or GY

300 1114C13SY or GY

CoCr alloy seat

Precision high quality

investment castings

Optional integral CoCr alloy seat face

available for longer service life.

DIMENSIONS AND WEIGHTS

SIZE

NPS

DN

FLANGED, ASME 150 FLANGED, ASME 300

A B C D

WEIGHT

lb (kg) A B C D

WEIGHT

lb (kg)

2 8.00 4.00 4.00

(1)

2.00 21 10.50 5.61 4.50

(1)

2.00 42

50 203 102 102 51 9.5 267 143 116 51 19.1

2 8.50 5.50 5.50 2.50 30 11.50 5.76 6.50 2.50 55

65 216 140 140 64 13.6 292 146 165 64 24.9

3 9.50 5.88 6.75 3.00 43 12.50 7.00 8.06 3.00 80

80 241 150 172 76 19.5 318 178 205 76 36.4

4 11.50 6.69 8.00 4.00 68 14.00 7.81 9.00 4.00 118

100 292 170 203 102 30.9 356 199 229 102 53.6

6 14.00 10.35 10.00 6.00 128 17.50 11.41 11.19 6.00 212

150 356 203 254 152 58.2 445 290 284 152 96.4

8 19.50 12.19 13.25 8.00 226 21.00 13.70 13.25 8.00 330

200 495 310 337 203 102.7 533 348 337 203 150.0

10 24.50 14.38 16.00 10.00 317 24.50 15.93 17.12 10.00 528

250 622 366 406 254 143.8 622 405 435 254 240.0

12 27.50 16.13 19.00 12.00 530 28.00 18.40 20.34 12.00 802

300 699 410 482 305 240.9 711 468 517 305 364

(1) Square

Eye bolt sizes:

NPS 6-12

(DN 150-300)

D

CAT-CSSV-02-14.indd 9 14-02-10 10:41 AM

10 Velan reserves the right to change this information without notice. 2014 Velan Inc. All rights reserved.

VELAN SPECIAL SERVICES

CAST STEEL CRYOGENIC VALVES

CAST AUSTENITIC STAINLESS STEEL CRYOGENIC GATE,

GLOBE, AND CHECK VALVES, NPS 24 (DN 15 600)

ASME PRESSURE CLASSES 150, 300, AND 600

The production, transport, and storage of liquefied gases such as oxygen,

nitrogen, argon, natural gas, hydrogen, or helium down to -425F (-254C)

presents several technical problems. Velan specially-adapted extended

bonnet cast valves offer safe and efficient service.

MATERIALS

Body and bonnet: Austenitic stainless steel castings used for bodies

and bonnets offer excellent impact strength, minimal heat loss, and

protection against corrosion.

Stem: Austenitic stainless steel. To reduce galling, stems are also

offered in A479 grade XM-19 with high toughness even at extreme low

temperatures, excellent low friction, and galling-free movement at points

of stem contact.

Wetted parts: all Austenitic stainless steel and CoCr alloy.

Stem nut/yoke bushing: Austenitic ductile iron Gr. D-2C.

Packing: PTFE or graphite packing protected from freezing by

a column of insulating gas.

Seating faces: CoCr alloy is used to preventseizing and galling.

When extremely tight shutoff is required, globe and check valves

are supplied with Neoflon, PTFE, or other soft inserts.

Bolting: Strain-hardened Austenitic stainless steel.

Lubrication of stem nut: Exxon Nebula Lubriplate No. 930-AA

or Shell Darina EPI or equivalent.

DESIGN FEATURES

Extended bonnets with sufficient gas column length, usually specified by

customer, are supplied for all valves to keep the stem packing at sufficient

distance away from the cold fluid to remain functional.

Flexible wedges with CoCr alloy seating faces for cryogenic service.

Neoflon inserts are available for gate, globe, and API 594 swing check

valves.

Cleaning: All cryogenic valves are thoroughly degreased and cleaned and

pipe ends are sealed to prevent contamination.

Boiling point Liquid Boiling point Liquid

Type density Type density

C F lb / ft.

3

C F lb / ft.3

Natural gas (LNG) -168 -270 26 Air -194.4 -318 57.87

Methane (CH4) -161.5 -258 26.20 Nitrogen (N2) -195.8 -320 50.45

Oxygen (02) -182.9 -296 71.20 Hydrogen(H2) -252.7 -423 4.43

Argon (Ar) -185.9 -303 87.40 Helium (He) -268.9 -452 7.82

Carbon dioxide (CO2) -78.5 -109 50.60 Absolute zero -273.16 -460 _

TABLE OF LIQUEFIED GASES

NOTE: For more information, see our Cryogenic Valves

catalog (VEL-CRYO) at www.velan.com.

GATE VALVE

GLOBE VALVE

CAT-CSSV-02-14.indd 10 14-02-10 10:41 AM

Velan reserves the right to change this information without notice. 2014 Velan Inc. All rights reserved. 11

The figure numbers shown on this key are designed to cover essential features of Velan valves. Please use figure numbers to ensure

prompt and accurate processing of your order. A detailed description must accompany any special orders.

Example: Flanged NPS 3 (DN 80) Class 150 cast carbon steel full port gate valve with SX trim.

HOW TO ORDER

FLOW COEFFICIENTS CV B16.34 PRESSURE-TEMPERATURE

G

TRIM MATERIAL

F

BODY MATERIAL

E

BODY/BONNET STYLE

D

TYPE

B

SIZE OF CONNECTION PRESSURE RATING

A

TYPE OF CONNECTION

C

F 1 0 0 0 6 4 C 1 3 S X

Size Class 150 Class 300 Class 600

NPS DN Gate Globe Check Gate Globe Check Gate Globe Check

15 13 3 14 13 3 14 13 3 14

20 22 4 16 22 4 16 22 4 16

1 25 34 7 18 34 7 18 34 7 18

1 40 110 11 40 110 11 40 110 11 40

2 50 260 35 95 260 35 95

2 65 420 60 150 420 60 150

3 80 625 92 220 625 60 220

4 100 1,150 180 410 1,150 180 410

6 150 2,650 430 950 2,650 430 950

8 200 4,850 1,750 4,850 1,750

10 250 7,750 2,800 7,750 2,800

12 300 11,500 4,100 11,500 4,100

14 350 14,000

16 400 19,000

18 450 24,000

Kv = Cv x 0.85 20 500 31,000

24 600 45,000

G

TRIM MATERIAL

Wedge/Disc surface

(2)

Seat surface Stem

(2)

Packing Gasket

SX Same as body Integral Same as body PTFE

GX Same as body Integral Same as body Graphite

SY Same as body CoCr alloy

(3)

316 PTFE

GY Same as body CoCr alloy

(3)

316 Graphite

A TYPE OF CONNECTION

C Combination (socket weld/threaded) U Undrilled anges

F Flanged B16.5 (B16.47 series A) W Socket weld

S Threaded NPT

D VALVE TYPE

06 Full port gate 08 Stop check 11 Swing check

07 Stop globe 09 Needle

B SIZE OF CONNECTION

Customers have the choice of specifying valve size as part of the

valve figure number (B) using the numbers below, or indicating

valve size separately. Sizes shown in NPS (DN)

EXAMPLES:

B16-3054P-02TS (valve size is part of figure number)

NPS 10 B-3054P-02TS (valve size is shown separately)

03 (15) 09 2 (65) 14 6 (150) 20 16 (400)

04 (20) 10 3 (80) 15 8 (200) 21 18 (450)

05 1 (25) 11 3 (90) 16 10 (250) 22 20 (500)

07 1 (40) 12 4 (100) 18 12 (300) 23 22 (550)

08 2 (50) 13 5 (125) 19 14 (350) 24 24 (600)

C PRESSURE RATING

0 150 1 300 2 600

F BODY MATERIAL

11 S/S F304, CF8 13 S/S F316, CF8M

(1)

15 S/S F347, CF8C

12 S/S F304L, CF3 14 S/S F316L, CF3M 28 S/S F317, CG8M

Note: CoCr alloy as used throughout this catalog refers to cobalt chrome

hardfacing alloys as supplied by Kennametal Stellite, and other

approved manufacturers.

E BODY / BONNET STYLE

4 Vertical

C Bolted bonnet (cast)

E Extended bonnet (cryogenic) cast valve

(1) Not suitable for temperatures above 1000F (538C).

(2) Base material is either the same as the body or solid trim at manufacturers option.

(3) CoCr alloy refers to cobalt-chrome alloys in Grade 6 (e.g. AWS CoCr-A, UNS 30006 & 30106) or

Grade 21 (e.g. AWS CoCr-E, UNS 30021). Use of Grade 6 or 21 is at Velan's option.

Class 150 300 600 900 1500

PN 20 50 110 150 260

PN and Class designations are not exact equivalents and are provided

for comparison purposes only, based on API 600/ISO 10434 2006 edition.

A351 Gr. CF8M

(1)

Temp. F

psig

150 300 600

20 to 100 275 720 1,440

200 235 620 1,240

300 215 560 1,120

400 195 515 1,025

500 170 480 955

600 140 450 900

650 125 440 885

700 110 435 870

750 95 425 855

800 80 420 845

850 65 420 835

900 50 415 830

950 35 385 775

1,000 20 365 725

1,050 20 360 720

1,100 20

(2)

305 610

1,150 20

(2)

235 475

1,200 20

(2)

185 370

1,250 20

(2)

145 295

1,300 20

(2)

115 235

1,350 20

(2)

95 190

1,400 20

(2)

75 150

1,450 20

(2)

60 115

1,500 15

(2)

40 85

(1) At temperatures over 538C, use only when

the carbon content is 0.04% or higher.

(2) Flanged-end valve ratings terminate at

1,000F (538C).

WORKING PRESSURES BY CLASS

Temp. C

bar

150 300 600

29 to 38 19 49.6 99.3

50 18.4 48.1 96.2

100 16.2 42.2 84.4

150 14.8 38.5 77

200 13.7 35.7 71.3

250 12.1 33.4 66.8

300 10.2 31.6 63.2

325 9.3 30.9 61.8

350 8.4 30.3 60.7

375 7.4 29.9 59.8

400 6.5 29.4 58.9

425 5.5 29.1 58.3

450 4.6 28.8 57.7

475 3.7 28.7 57.3

500 2.8 28.2 56.5

538 1.4 25.2 50

550 1.4

(2)

25 49.8

575 1.4

(2)

24 47.9

600 1.4

(2)

19.9 39.8

625 1.4

(2)

15.8 31.6

650 1.4

(2)

12.7 25.3

675 1.4

(2)

10.3 20.6

700 1.4

(2)

8.4 16.8

725 1.4

(2)

7 14

750 1.4

(2)

5.9 11.7

775 1.4

(2)

4.6 9

800 1.2

(2)

3.5 7

816 1.0

(2)

2.8 5.9

CAT-CSSV-02-14.indd 11 14-02-10 10:41 AM

BRO-FLB SAS-FLB ABV-FLB VEL-PS CAT-CSV

CAT-BV VEL-MS CAT-PBV BRO-CBV CAT-GPBV

CAT-CSSV CAT-SFV CAT-BG CAT-KGV CAT-DPCV

CAT-BF SAS-CCV VEL-BS VEL-CRYO CAT-ST

2014 Velan Inc., Montreal, QC, Canada. All rights reserved. The contents hereof are condential and proprietary

to Velan. Any unauthorized reproduction or disclosure, in whole or in part, is strictly prohibited. The material in this

catalog is for general information only and shall not be used for specic performance data and material selection

without rst consulting Velan. Velan reserves the right to change this information without notice. Velan does not

accept any liability or damages arising from the use of information in this catalog. Velan Valves, Velan, Memoryseal,

Torqseal, Velex, Adaxie, and RAMA are trademarks or registered trademarks of Velan Inc. and/or another Velan

company. Stellite is a registered trademark of Kennametal Stellite, a wholly owned subsidiary of Kennametal Inc.

All other trademarks and registered trademarks are owned by their respective companies.

Headquartered in Montreal, Canada, Velan has several

international subsidiaries. For general inquiries:

Velan head ofce

7007 Cte de Liesse, Montreal, QC H4T 1G2 Canada

Tel: +1 514 748 7743 Fax: +1 514 748 8635

Check our website for more specic contact information.

www.velan.com

Printed in Canada

ASME pressure classes 1504500 in carbon, alloy, and stainless steel

The most comprehensive line of industrial forged and cast steel

gate, globe, check, ball, butterfly, and knife gate valves and steam traps.

CAT-CSSV-02-14

CAT-CSSV-02-14.indd 12 14-02-10 10:41 AM

S-ar putea să vă placă și

- VálvulasDocument44 paginiVálvulasCarlos LópezÎncă nu există evaluări

- A World-Leading Valve Product Range: VelanDocument12 paginiA World-Leading Valve Product Range: VelanDiego PadillaÎncă nu există evaluări

- Coker Ball Valve of Velan PDFDocument8 paginiCoker Ball Valve of Velan PDFmujeebtalibÎncă nu există evaluări

- Cat CSVDocument36 paginiCat CSVaqhammamÎncă nu există evaluări

- Cat VelanDocument28 paginiCat VelanRick FayÎncă nu există evaluări

- Velan Triple Offset Butterfly L - BF - 2006aDocument24 paginiVelan Triple Offset Butterfly L - BF - 2006amfcramerÎncă nu există evaluări

- Securaseal Metal-Seated Ball Valves: ASME Classes: 150 - 4500 Sizes: - 24" (15 - 600 MM)Document28 paginiSecuraseal Metal-Seated Ball Valves: ASME Classes: 150 - 4500 Sizes: - 24" (15 - 600 MM)ANILÎncă nu există evaluări

- Cat AXCATDocument80 paginiCat AXCATgazwang478Încă nu există evaluări

- Vel PQCV Web Catalogo Velan Duo CheckDocument21 paginiVel PQCV Web Catalogo Velan Duo Checkel_apache10Încă nu există evaluări

- VIP Red CatalogueIntroduction This catalogue will provide you with an idea of range, which now includes a huge selection of plumbing products and pumps to complement our already extensive engineering range. - our service is constantly reviewed and we aim to offer our customers excellence in all areas. About Us Formed in 1985, we have earned a reputation for setting standards in quality, service and reliability. We supply a wide range of industries including:Document28 paginiVIP Red CatalogueIntroduction This catalogue will provide you with an idea of range, which now includes a huge selection of plumbing products and pumps to complement our already extensive engineering range. - our service is constantly reviewed and we aim to offer our customers excellence in all areas. About Us Formed in 1985, we have earned a reputation for setting standards in quality, service and reliability. We supply a wide range of industries including:aco1970Încă nu există evaluări

- CAT DewranceDocument93 paginiCAT DewranceHorvatAladar100% (1)

- Velan Valves Catalog PDFDocument12 paginiVelan Valves Catalog PDFJavierfox98Încă nu există evaluări

- Valvula para CoqueDocument12 paginiValvula para CoqueKerry DillonÎncă nu există evaluări

- Complete Valve Solutions: For The Refining and Petrochemical IndustriesDocument16 paginiComplete Valve Solutions: For The Refining and Petrochemical Industriesfranz_passariniÎncă nu există evaluări

- API 6A and 6D Ball ValvesDocument27 paginiAPI 6A and 6D Ball ValveszayerirezaÎncă nu există evaluări

- Velan ABV: Delivering Value Through PerformanceDocument16 paginiVelan ABV: Delivering Value Through PerformanceAnanto Yusuf WÎncă nu există evaluări

- Wellhead CatalogueDocument78 paginiWellhead CatalogueAminÎncă nu există evaluări

- APV-LLK-2 Ball Valve BrochureDocument13 paginiAPV-LLK-2 Ball Valve BrochureHeri SetyantoÎncă nu există evaluări

- Velan Bellows SealDocument19 paginiVelan Bellows SealdscribddevoreÎncă nu există evaluări

- Cryogenic Valves: Gate, Globe, Check, Ball & Butterfly ValvesDocument24 paginiCryogenic Valves: Gate, Globe, Check, Ball & Butterfly ValvesisaithberdugoÎncă nu există evaluări

- Bellow Seal ValvesDocument36 paginiBellow Seal ValvesJake SparrowÎncă nu există evaluări

- Ball Valve StandarDocument32 paginiBall Valve StandartavolenÎncă nu există evaluări

- APV Plug Valve CatalogueDocument40 paginiAPV Plug Valve CatalogueVeerapandianÎncă nu există evaluări

- Velan ProquipDocument21 paginiVelan ProquipISHAN VERMAÎncă nu există evaluări

- TrunnionBallValveBrochure 6D EBROCHURE 091514Document40 paginiTrunnionBallValveBrochure 6D EBROCHURE 091514Marlon TurnerÎncă nu există evaluări

- BRO NUC 09 13 0d54Document12 paginiBRO NUC 09 13 0d54aike_5Încă nu există evaluări

- Velan Butterfly Valves PDFDocument24 paginiVelan Butterfly Valves PDFTushar Lanjekar100% (1)

- AloycoDocument32 paginiAloycoSidney RiveraÎncă nu există evaluări

- Lanus ValvesDocument55 paginiLanus Valvesdjole112Încă nu există evaluări

- Europa Valve Non Slam Check ValvesDocument16 paginiEuropa Valve Non Slam Check ValvesBryan KellyÎncă nu există evaluări

- KORVAL Catalogue (11년 5월)Document44 paginiKORVAL Catalogue (11년 5월)bertyli67% (3)

- Ball Valve KnowledgeDocument40 paginiBall Valve KnowledgeMeanRat100% (1)

- Aloyco Stainess Steel ValvesDocument26 paginiAloyco Stainess Steel Valvescristi_molins100% (1)

- VelanDocument36 paginiVelanIslam Hosny MohamedÎncă nu există evaluări

- Velan Forged Steel CatalogueDocument26 paginiVelan Forged Steel CatalogueJuan Carlos Ojeda RamirezÎncă nu există evaluări

- Valvulas Velan bv6d Web PDFDocument36 paginiValvulas Velan bv6d Web PDFAndres CortezÎncă nu există evaluări

- Brida MafDocument2 paginiBrida MafmisaelzaÎncă nu există evaluări

- VEL BS 2001aDocument20 paginiVEL BS 2001aritoh8657Încă nu există evaluări

- Vel Api603 99 WebDocument10 paginiVel Api603 99 Webvermaakash22Încă nu există evaluări

- Series 4200: Safety Valves For ASME Code Section I Boiler ApplicationsDocument16 paginiSeries 4200: Safety Valves For ASME Code Section I Boiler ApplicationsjimycantrellÎncă nu există evaluări

- Catalog (1) API 600 GATE VALVES PDFDocument140 paginiCatalog (1) API 600 GATE VALVES PDFMohsen HalweniÎncă nu există evaluări

- L&T Aquaseal Butterfly Check ValvesDocument24 paginiL&T Aquaseal Butterfly Check ValvesSohail PathanÎncă nu există evaluări

- Canalta Parts Catalogue PDFDocument25 paginiCanalta Parts Catalogue PDFZohaib MaqboolÎncă nu există evaluări

- Nve NBR 1003Document48 paginiNve NBR 1003nricquartÎncă nu există evaluări

- American ValveDocument12 paginiAmerican Valveviller_lpÎncă nu există evaluări

- Efcv PDFDocument20 paginiEfcv PDFSudarshan ChandraÎncă nu există evaluări

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsEvaluare: 4.5 din 5 stele4.5/5 (10)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDe la EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryÎncă nu există evaluări

- Valve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationDe la EverandValve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationEvaluare: 4.5 din 5 stele4.5/5 (21)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1De la EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Evaluare: 3.5 din 5 stele3.5/5 (3)

- The Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingDe la EverandThe Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingÎncă nu există evaluări

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsDe la EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsEvaluare: 4 din 5 stele4/5 (6)

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsDe la EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsÎncă nu există evaluări

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDe la EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingEvaluare: 5 din 5 stele5/5 (3)

- Rotational Lining SystemDocument11 paginiRotational Lining SystemMubeenÎncă nu există evaluări

- Failure Analysis of A Machinable Brass Connector in A Boiler Unit InstallationDocument6 paginiFailure Analysis of A Machinable Brass Connector in A Boiler Unit InstallationAnnisa RakhmawatiÎncă nu există evaluări

- REHS3819-02 Procedure For Troubleshooting and Cleaning The Oil Rail System For The HEUIDocument8 paginiREHS3819-02 Procedure For Troubleshooting and Cleaning The Oil Rail System For The HEUImoises100% (2)

- MSDS - Fuel-Protect, Keep Clean Solution, For Diesel InjectorDocument5 paginiMSDS - Fuel-Protect, Keep Clean Solution, For Diesel InjectorDaniel OlanoÎncă nu există evaluări

- BR PDFDocument240 paginiBR PDFMisha KulibaevÎncă nu există evaluări

- Groth 7618 7628Document16 paginiGroth 7618 7628Julian GaleanoÎncă nu există evaluări

- 8295780Document34 pagini8295780Tong BbmÎncă nu există evaluări

- Hexion Vodnye Otverditeli I Smoly EngDocument6 paginiHexion Vodnye Otverditeli I Smoly EngCloudy DayÎncă nu există evaluări

- Transmission Towers DetailingDocument38 paginiTransmission Towers DetailingFeleki AttilaÎncă nu există evaluări

- Daikin Download Link (070915)Document6 paginiDaikin Download Link (070915)Sam Wing HongÎncă nu există evaluări

- 2020-03-17 Pine Wood SpecsDocument4 pagini2020-03-17 Pine Wood SpecsSandesh KumarÎncă nu există evaluări

- ASME B 16.5 InterpretationsDocument24 paginiASME B 16.5 InterpretationsM.AwadAltayib100% (1)

- CFBC Boiler Bed MaterialDocument2 paginiCFBC Boiler Bed MaterialmkoelrealÎncă nu există evaluări

- Taper Bushes: Instructions - Installation and RemovalDocument2 paginiTaper Bushes: Instructions - Installation and RemovaldesetekÎncă nu există evaluări

- Mechanical FailureDocument52 paginiMechanical FailureDirkPons100% (5)

- Chapter 4 - Plasticity of SoilDocument15 paginiChapter 4 - Plasticity of SoilHussein EssaÎncă nu există evaluări

- Product Catalogue (ARZTECH SOLUTION) PDFDocument5 paginiProduct Catalogue (ARZTECH SOLUTION) PDFAzizy YusofÎncă nu există evaluări

- IB HL Chemistry Assessment Statements Topic 7Document3 paginiIB HL Chemistry Assessment Statements Topic 7AndrewÎncă nu există evaluări

- Village of Fredonia Inspection Report 2015Document16 paginiVillage of Fredonia Inspection Report 2015WGRZ-TV100% (1)

- Arihant Brochure 2016 PDFDocument148 paginiArihant Brochure 2016 PDFSachinÎncă nu există evaluări

- Builder MotionDocument13 paginiBuilder MotionShailendra Mishra100% (2)

- NDT Product ListDocument24 paginiNDT Product ListdarouichÎncă nu există evaluări

- Brosur Blend SeventyDocument2 paginiBrosur Blend SeventyLilianti AzwarÎncă nu există evaluări

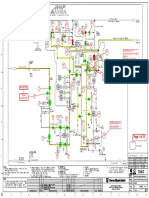

- Sample of P&ID Marked Up DrawingDocument11 paginiSample of P&ID Marked Up DrawingToniÎncă nu există evaluări

- PMDG 737Ngx Groundwork: Fuel System Lesson IntroductionDocument9 paginiPMDG 737Ngx Groundwork: Fuel System Lesson IntroductionJoãoPaulodeAlmeidaÎncă nu există evaluări

- Greenhouse Structural ComponentsDocument26 paginiGreenhouse Structural Componentsnadiahikhlas50% (2)

- Wiper BladeDocument3 paginiWiper Bladeghyd artiagaÎncă nu există evaluări

- 1,1,6 Precalciner KilnsDocument39 pagini1,1,6 Precalciner KilnsMohamed Saad100% (1)

- Industrial Product Guide: Quality Service IntegrityDocument138 paginiIndustrial Product Guide: Quality Service IntegrityLilia MijangosÎncă nu există evaluări

- DevelopmentsDocument8 paginiDevelopmentsPaige RobsonÎncă nu există evaluări