Documente Academic

Documente Profesional

Documente Cultură

The Effects of Tapioca Starch, Oat Fibre and Whey Protein On The Physical and Sensory Properties of Low-Fat Beef Burgers

Încărcat de

ericatorres123Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

The Effects of Tapioca Starch, Oat Fibre and Whey Protein On The Physical and Sensory Properties of Low-Fat Beef Burgers

Încărcat de

ericatorres123Drepturi de autor:

Formate disponibile

. Article No. fs980415 Lebensm.-Wiss. u.-Technol.

, 31, 653657 1998

The Effects of Tapioca Starch, Oat Fibre and

Whey Protein on the Physical and Sensory

Properties of Low-fat Beef Burgers

E. M. Desmond, D. J . Troy* andD. J . Buckley

E. M. Desmond, D. J. Troy: Teagasc, The National Food Centre, Dunsinea, Castleknock, Dublin 15

.

I reland

.

D. J. Buckley: Department of Food Technology, University College, Cork I reland

( )

Receied December 5, 1997; acccepted July 7, 1998

The optimising of the composition of ingredients has a major effect on the properties of low-fat products. The purpose of this research

( ) ( ) was to assess the effects of added tapioca starch ranging from 030 g r kg , oat fibre ranging from 020 g r kg and whey protein

( ) ranging from 020 g r kg on the physical and organoleptic characteristics of low-fat beef burgers. Response surface methodology

( ) RSM was used to study the simultaneous effects of these three ingredients. Significant models of regression were ascertained for

( ) cooking properties yield and water holding capacity , the sensory attributes of tenderness and juiciness, and all mechanical texture

( ) attributes. The leel of tapioca starch TS influenced the models to the greatest extent. Its effect on the cooking properties was highly

significant, positie and linear. The presence of TS had a large negatie linear effect on Warner-Bratzler and Kramer shear forces. For

each significant regression model, TS exerted a linear effect, and in some cases a quadratic effect. Both oat fibre and whey protein had

a limited influence. There was no eidence of interactions among the ariables. The results indicate that as the TS in low-fat beef

burgers increases a succulent and tender low-fat product is obtained.

1998 Academic Press

Keywords: low-fat; ground beef; fat substitutes; response surface methodology

Introduction

Research into low-fat meat products is primarily due to

consumers concerns about health and nutrition, and

the food service industry has made several changes in

.

menus andror methods of preparation 1 . According

.

to Freidman 2 , in the US, hundreds of fat-free, fat-

reduced and low-fat new products have made their way

into virtually every category in the supermarket, as

manufacturers continue to search for ways to provide

indulgent, heart disease conscious consumers with less

fat but same flavour products.

The development of low-fat ground beef products, while

assuring the necessary palatability, is not just as simple

as removing fat. Fat is a calorie-dense nutrient that

provides flavour, juiciness, texture and entraps water in

ground meat products. With excessive fat reduction,

the products become bland and dry and the texture can

.

be hard, rubbery, or mealy 3 . These finding have been

.

supported by other research 48 . Consequently, there

are many low-fat meat systems containing fat substi -

tutes that act as texture-modifying agents in their abil-

ity to bind water. These generally fall into three cate-

* To whom correspondence should be addressed.

.

gories: i nonmeat proteins, for example, soya and milk

.

proteins; ii carbohydrate based, for example, car-

.

rageenan, starches and oat fibres; iii functional

blends which refer to various ingredient blends which

are formulated to achieve particular aims in fat

reduction.

.

Desmond et al. 9 examined 17 ingredients in low-fat

beef burgers and concluded that low-fat beef burgers

containing tapioca starch, oat fibre and whey protein

exhibited improved palatability of the beef burgers.

.

Knight and Perkin 10 reported that low-fat sausages

containing tapioca starch were more succulent and

juicer than sausages containing either soya or potato

starch while the losses during cooking were similar.

The advantages in the use of oat fibre include, its

superior ability to retain moisture and prevent meats

from drying out when cooked, since its mouthfeel imi-

tates fat and it has the ability to retain the natural

. .

flavourings of the meat 11 . El-Magoli et al. 12

concluded that whey protein concentrate may be effec-

tively used as a functional ingredient in low-fat beef

burgers due to its heat gelation and emulsifica-

tion properties, which enhance moisture and fat

entrapment.

Most research into the use of ingredients concentrates

0023-6438r98r070653 q05 $30.00r0 1998 Academic Press

653

. l wtrvol . 31 1998 No. 7 & 8

on one or more adjuncts being used individually. Both

. .

Troutt et al. 13 and Desmond et al. 9 concluded that

improvements in the palatability of low-fat ground beef

may be achieved with the addition of functional ingre-

dients, but more research is needed to optimise the

composition and methods of incorporation. Few studies

deal systematically with the identification of the most

appropriate combinations for producing low-fat beef

burgers or other processed meats. Studies of this kind

are important because the extent to which the

behaviour of any one ingredient influences another by

the presence of varying concentrations of other ingredi-

ents or the medium in which it functions fat, water

.

and protein is unknown. Thus, the quantity of any

ingredient required to achieve a given effect may vary.

The aim of this work was to assess the effects of

varying levels of tapioca starch, oat fibre and whey

protein on the physical, texture and sensory character-

istics of low-fat beef burgers. Response Surface

.

Methodology RSM was used for the simultaneous

analysis of the effects. The experimental design also

enables the evaluation of the possible existence of

interactive effects between the ingredients.

MaterialsandMethods

Beef burger formulation

The materials and preparation procedures used in this

investigation into beef burgers are described by

.

Desmond et al. 9 . Appropriate amounts of lean beef

and fat trimmings were combined to manufacture

batches of low-fat beef burgers with fat levels of 100

grkg, each containing combinations of tapioca starch

Tapiocaline EX533, Tipiak Ltd., Pont-Saint-Martin,

.

France , a partially pre-gelatinised starch, oat fibre

TM

Opta Oat Fibre 770, Williamson Fibre Products,

. .

Cork, I reland , and whey protein 35% protein

.

DairyGold Co-Op, Mitchelstown, Cork, I reland as per

.

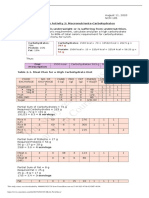

experimental design Table1.

Experimental design

Response Surface Methodology was used to study the

simultaneous effects of three functional ingredients.

The studies were based on a central composite rotat-

. .

able design 14 . Five levels of each factor variable

were chosen in accordance with the principles of the

.

central composite design Table1. The factors studied

.

were: level of tapioca starch ranging from 030 grkg ,

.

level of oat fibre ranging from 020 grkg and level of

.

whey protein ranging from 020 grkg . The assess-

ment of error was derived from the replication of one

treatment combination, as suggested in the design.

Physical traits

The moisture, fat and protein of beef burger samples,

cook yield, water-holding capacity and reduction in

diameter were determined as described by Desmond et

.

al. 9 .

.

Table 1 Levels of tapioca starch grkg , oat fibre

. .

grkg and whey protein grkg making up the 20

systems stipulated in the experimental design

Number Tapioca starch Oat fibre Whey protein

1 15 10 10

2 6 4 16

3 6 16 16

4 24 4 16

5 15 10 20

6 15 10 0

7 6 4 4

8 15 0 10

9 30 10 10

10 24 16 4

11 6 16 4

12 24 4 4

13 15 20 10

14 0 10 10

15 24 16 16

16 15 10 10

17 15 10 10

18 15 10 10

19 15 10 10

20 15 10 10

Sensory analysis

Sensory Analysis was performed using a ten member

in-house taste panel to evaluate the beef burgers for a

number of textural, flavour and overall quality

attributes. The panel was chosen from a pool of 16

assessors selected for their experience in the sensory

analysis of meat products, and on their availability. The

training consisted of treatments presented in three

preliminary sessions to the panellists, to familiarise

them with the characteristics to be evaluated in accor-

dance with the American Meat Science Association

. .

AMSA guidelines 15 . During the preliminary ses-

sions the panellists were presented with examples of

toughrtender beef burgers. Tenderness, moistnessr

juiciness and meat flavour were evaluated using an

eight-point structured scale 8 sextremely tender,

.

juicy and intense; 1 sextremely tough, dry and bland .

Nonmeat flavour, overall flavour, overall texture and

overall acceptability were evaluated using a six-point

structured scale 6 sextremely intense, very good, very

good and extremely acceptable; 1 snone, very poor,

.

very poor and not acceptable . The beef burgers were

.

cooked as described by Desmond et al. 9 and cut into

quarters. Four samples per session were immediately

served to the panellists in random order. The panellists

were instructed to cleanse their palates between the

samples using water. Each sample was coded with

randomly selected three-digit numbers.

Mechanical textural analysis

An I nstron Universal Testing Machine Model 4464,

.

I nstron UK Ltd., Buckinghamshire, UK was used for

the objective evaluation of textural parameters.

Warner-Bratzler and Kramer shear forces were deter-

.

mined as described by Desmond et al. 9 . Five burgers

654

. l wtrvol . 31 1998 No. 7 & 8

per formulation were cooked and then cooled to room

.

temperature ;1 h before sampling.

Instrumental colour

Five raw beef burgers per formulation were removed

from their vacuum packs, and placed on a tray in a

display cabinet at 5 C for a 5 h blooming period. The

light in the cabinet was provided by two fluorescent

bulbs. After the blooming period, the colour of the

samples was measured using the Hunter LAB system

with a tristimulas colorimeter Hunterlab, Model No.

.

D-25, Fairfax, USA . The colorimeter was used with a

25 mm diameter viewing area and Hunter L, a and b

L L

values were measured. Three readings were taken from

each burger.

ResultsandDiscussion

Analysis of the results shows the effect of each variable

on the different properties studied. The effect of the

level of tapioca starch added, the level of oat fibre

added and the level of whey protein added on each

.

property was divided into first order linear , second

.

order quadratic and interactive interaction between

.

pairs of variables . The compositional analysis results

are shown in Table 2. The uncooked low-fat beef

burgers had a moisture content ranging from 668704

grkg with a mean value of 684 grkg, a fat content

ranging from 81105 grkg with a mean value of 94

grkg that was close to the target fat level of 100 grkg,

and a protein content ranging from 172196 grkg with

a mean value of 186 grkg.

.

Analysis of variance of the regression models Table3

for the different properties evaluated shows that mod-

.

els were significant P -0.05 for cooking properties

.

cook yield and water holding capacity , the sensory

.

Table 2 Proximate composition grkg of the differ-

ent low-fat beef burgers formulated

Number Moisture Fat Protein

1 685 93 185

2 687 101 187

3 672 103 196

4 678 97 195

5 689 81 192

6 695 88 183

7 689 95 194

8 679 105 186

9 671 93 182

10 670 98 187

11 695 84 181

12 675 101 187

13 668 100 176

14 704 94 188

15 679 89 180

16 690 92 180

17 689 94 185

18 693 90 188

19 689 92 187

20 690 97 172

Table 3 Analysis of variance of regression models

for cooking, sensory, mechanical texture and colour

properties for low-fat beef burgers

b a 2

Attribute Model R S

x

Cooking properties

Cook yield )) 0.729 1.71

% reduction in diameter NS 0.131 2.03

% reduction in thickness NS 0.281 3.40

Water holding capacity ))) 0.839 2.17

Sensory properties

Tenderness ) 0.617 0.28

Moistnessrjuiciness ) 0.536 0.33

Meaty flavour NS 0.069 0.21

Nonmeat flavour NS 0.457 0.24

Overall flavour NS 0.123 0.24

Overall texture NS 0.000 0.26

Overall acceptability NS 0.263 0.22

Mechanical texture properties

Warner-Bratzler peak force )) 0.762 1.36

Warner-Bratzler peak energy ) 0.617 0.02

Kramer shear peak force ))) 0.833 2.12

Kramer shear peak energy ))) 0.824 0.02

Raw colour properties

L value NS 0.118 1.61

a value NS 0.323 0.68

L

b value NS 0.135 0.43

L

a

significant at )))P -0.001, ))P -0.01 and )P -0.05;

n.s.snot significant

b

fitted for degrees of freedom

attributes of tenderness and moistnessrjuiciness and

the mechanical properties Warner-Bratzler shear peak

force and energy, Kramer shear peak force and energy.

.

The models were not significant P )0.05 for the

percentage reduction in diameter and thickness, meat

flavour, nonburger flavour, overall flavour, texture and

acceptability, and for the Hunter colour attributes of L,

.

a and b Table3.

L L

Effect of tapioca starch

.

Tapioca starch TS was the variable that most influ-

enced the various parameters evaluated. The effect on

.

the cook yield and water holding capacity WHC was

.

highly significant P -0.001 , positive and linear, and

no quadratic or interactive effects were observed

.

Table4. As more TS was added, less weight was lost

.

during cooking i.e., an increase in cook yield ; the

WHC increased in the same way as more TS was

added.

The absence of interactive effects on any of the proper-

ties examined indicates that the effects of TS are

.

independent of the other two ingredients Table 4.

There are no studies examining the effect of varying

amounts of tapioca starch on the characteristics of

low-fat beef burgers. I n most cases the influence of

specific amounts or other types of starches have been

analysed. The relationship between TS and cook yield

.

is consistent with the findings of Hart and Price 16

who found that low-fat beef burgers containing TS

655

. l wtrvol . 31 1998 No. 7 & 8

Table 4 Statistically significant regression coefficients from multiple regression analysis

TS OF WP TS=TS OF =OF

Parameter Const. RC P S RC P S RC P S RC P S RC P S

x x x x x

Cook Yield 67.02 3.38 ))) 0.46 0.63 NS 0.46 0.18 NS 0.46 y0.33 NS 0.45 y0.45 NS 0.45

W.H.C. 42.43 5.76 ))) 0.59 1.60 ) 0.59 y0.01 NS 0.59 0.04 NS 0.57 0.04 NS 0.57

Tenderness 6.87 0.45 ))) 0.08 y0.03 NS 0.08 y0.03 NS 0.08 y0.14 NS 0.07 y0.01 NS 0.07

Juiciness 5.89 0.45 ))) 0.09 y0.12 NS 0.09 0.02 NS 0.09 y0.09 NS 0.09 0.02 NS 0.09

WrB Peak Force 14.67 y2.91 ))) 0.37 y0.65 NS 0.37 0.42 NS 0.37 y0.08 NS 0.36 0.20 NS 0.20

WrB Peak Energy 0.14 y0.03 ))) 0.005 y0.01 ) 0.005 0.01 NS 0.005 y0.00 NS 0.004 y0.00 NS y0.00

KS Peak Force 36.55 y5.43 ))) 0.57 0.07 NS 0.57 y1.43 ) 0.57 0.79 NS 0.56 y0.98 NS y0.98

KS Peak Energy 0.224 y0.05 ))) 0.005 0.002 NS 0.005 0.01 NS 0.005 0.000 NS 0.005 y0.00 NS y0.00

TSsTapioca starch content; OF sOat fibre content; WPsWhey Protein Content; RC sRegression coefficient; P sSignificance level;

S sStandard error; significant at )))P -0.001, ))P -0.01, and )P -0.05

x

substantially improved cook yields when compared to

both low- and full-fat controls without added TS.

Overall, the models for the sensory attributes were not

.

significant P )0.05 except in the case of the tender-

.

ness and juiciness P -0.05 . I n both cases TS had a

. .

significant P -0.001 positive, linear effect Table4.

As the TS was increased the tenderness and juiciness

of the low-fat beef burgers also increased i.e., aiding in

the retention and subsequent release of moisture, re-

. .

sulting in increased succulence . Hart and Price 16

also found that the TS gave more desirable tenderness,

juiciness and textural properties in reduced fat beef

.

burgers. Knight and Perkin 10 reported that the

incorporation of tapioca starch into low-fat sausage

formulations, resulted in a product that was juicier and

softer than the control. I n contrast, Berry and Wergin

.

17 found that a modified pre-gelatinised potato starch

reduced juiciness scores.

The presence of TS had a highly significant, negative

. .

linear, effect P -0.001 on Warner-Bratzler WrB

.

peak force and peak energy Table4, and on Kramer

.

shear peak force and peak energy Table 4. No

significant quadratic or interactive effect on these

mechanical textural parameters was found. I n general,

increasing the TS resulted in lower force or energy

being required to shear the sample. Overall, the regres-

sion model for Kramer shear force was more highly

.

significant P -0.001 when compared to WrB peak

.

force P -0.01 . The regression models indicate, and

.

agree with other studies 13, 17 , that the greater the

amount of starch the lower the force required to shear

.

the low-fat treatments. Troutt et al. 13 found that

potato starch, in combination with polydextrose and

plant fibre ingredients in low-fat beef burgers reduced

peak load and total energy in contrast to 5 and 10% fat

control beef burgers, and had similar values when

compared to 20% fat beef burgers.

Effect of oat fibre

.

Although oat fibre OF had a limited influence on the

parameters measured, its presence resulted in some

variation in WHC, hardness and gumminess. There was

.

a significant P -0.05 influence on WHC in a positive

.

linear fashion Table 4. This shows that as OF was

increased the WHC of the low-fat beef burgers

increased. As with tapioca starch, there are no studies

which deal with the effect of varying amounts of oat

fibre on the properties of low-fat beef burgers. I n most

cases, the influence of specific amounts of ingredient

.

has been analysed. Pszczola 18 reported that oat bran

or fibre has the ability to retain moisture and prevents

.

meats from drying out when cooked. Troutt et al. 13

examined a number of texture-modifying ingredients

and found most of the ingredients, including oat fibre,

were equal to the 20% high fat beef burgers in juici-

ness. These authors also reported that a significant

difference, due to added ingredients including oat

fibre, occurred for the I nstron texture profile analysis

trait of hardness. I n general, beef burgers containing

oat fibre, in combination with polydextrose andror

potato starch, exhibited decreased hardness values

when compared to the low-fat control.

Effect of whey protein

The whey protein affected Kramer shear peak force

.

model in a negative linear manner P -0.05 . As with

the other two variables, the absence of any interactive

effect indicates that the effect of WP is independent of

these variables. I n general, as whey protein is added a

lower Kramer peak force is required to shear the

sample. Few studies have been conducted on varying or

specific amounts of whey in comminuted meat products

such as beef burgers. Most attention has focused on

emulsion-type products such as frankfurters or bologna

sausage.

.

El-Magoli et al. 12 investigated the addition of four

. .

levels 040 grkg of whey protein concentrate WPC

into low-fat beef burger formulations. They found that

with 30 grkg, WPC hardness and chewiness increased,

but at a 40 grkg level these attributes were

reduced. The springiness remained relatively constant

throughout.

Conclusions

The tapioca starch had the greatest effect on the

parameters studied. For each model that was signifi-

cant, the tapioca starch exerted a linear effect and in

some cases a quadratic effect. Both oat fibre and whey

protein had a very limited influence, only exerting a

linear effect on two parameters. This could be due to a

656

. l wtrvol . 31 1998 No. 7 & 8

masking effect by the tapioca starch. The lack of any

interactive effects between the variables shows that the

contribution made by any one ingredient to the charac-

teristics of the low-fat beef burgers was not generally

affected by the others.

The sensory analysis showed that no significant differ-

ence was found for all the attributes, except for tender-

ness and moistnessrjuiciness. Overall, the panellists

rated the beef burgers to be acceptable in flavour and

texture and no off-flavours were detected. All of the

models for the mechanical texture parameters mea-

.

sured on the I nstron were significant P -0.05 .

The response surface methodology showed that as tapi-

oca starch increased the low-fat beef burgers had higher

cook yield and higher water retention, resulting in a

more tender and juicy product. Similarly, tapioca starch

was highly significant in influencing the mechanical

texture parameters, thus, the force required to shear or

compress the sample decreased with increasing levels.

The oat fibre also aided in water retention, producing a

more juicy product. Whey protein only influenced the

Kramer shear peak force.

Acknowledgements

The authors wish to thank Teagasc Agricultural and

.

Food Development Authority and the EU AAI R pro-

gram, for the funding of this research Project No.

.

AI R2-CT93-1691 . Also, the companies who supplied

the ingredients as well as technical assistance. Refer-

ence to brand or trade name does not constitute en-

dorsement by The National Food Centre or The

European Union.

References

1 HUFFMAN, D. L. Technology of low fat ground beef.

. Proceedings: Reciprocal Meat Conference, 44, 7379 1991

2 FRI EDMAN, M. New products come alive in 95. Prepared

. Foods, 165, 2532 1996

3 KEETON, J. T. Low-fat meat productsTechnological

problems with processing. Meat Science, 36, 261276

. 1994

4 CROSS, H. R., BERRY, B. W., AND WELLS, L. H. Effects of

fat level and source on the chemical, sensory and cooking

properties of ground beef patties. Journal of Food Science,

. 45, 791793 1980

5 EGBERT, W. R., HUFFMAN, D. L., CHEN, C. M., AND

DYLEWSKI , D. P. Development of low fat ground beef

. Food Technology, 45, 6473 1991

6 BERRY, B. Low fat effects on sensory, shear, cooking and

chemical properties of ground beef patties. Journal of

. Food Science, 57, 537574 1992

7 TROUTT, E. S., HUNT, M. C., JOHNSON, D. E., CLAUS, J.R.,

KASTNER, C.L., KROPF, D. H., AND STRODA, S. Chemical,

Physical and sensory characterisation of ground beef con-

taining 5 to 30 percent fat. Journal of Food Science, 57,

. 2529 1992

8 MI LLER, M. F., ANDERSEN, M. K., RAMSEY, C. B., AND

REAGAN, J. O. Physical and sensory characteristics of low

fat ground beef patties. Journal of Food Science, 58,

. 461463 1993

9 DESMOND, E. M., TROY, D. J., AND BUCKLEY, D. J.

Comparative studies of non-meat ingredients used in the

manufacture of low-fat beef burgers. Journal of Muscle

( ) . Foods, 93, 221241 1998 .

10 KNI GHT, M. K. AND PERKI N, J. The use of tapiocaline in

British sausages. Meat Manufacturing and Marketing, 5,

. 2930 1991

11 MEI NHOLD, N. M. Processed meats with 3875% less fat.

. Food Processing, 52, 105106 1991

12 EL-MAGOLI , S. B., LAROI A, S., AND HANSEN, P. M. T.

Flavour and texture characteristics of low fat ground beef

patties formulated with whey protein concentrate. Meat

. Science, 42, 179193 1996

13 TROUTT, E. S., HUNT, M. C., JOHNSON, D. E., CLAUS, J. R.,

KASTNER, C. L., AND KROPF, D. H. Characteristics of low

fat ground beef containing texture modifying ingredients.

. Journal of Food Science, 57, 1924 1992

14 COCHRAN, W. G. AND COX, G. M. Experimental Designs,

2nd Edn., New York: John Wiley & Sons, I nc. pp. 335369

. 1957

15 AMSA. Guidelines for Sensory, Physical and Chemical

Measurements in Ground Beef. Proc: Repcip. Meat Conf.,

. 36, 221228 1983

16 HART, B. AND PRI CE, K. New potential for low fat beef

. burgers. Food Manufacture, 68, 4243 1993

17 BERRY, B. AND WERGI N, W. P. Modified pregelatinized

potato starch in low fat ground beef patties. Journal of

. Muscle Foods, 4, 305320 1993

18 PSZCZOLA, D. E. Oat-bran based ingredient blend

replaces fat in ground beef and pork sausage. Food

. Technology, 45, 6066 1991

657

S-ar putea să vă placă și

- RRLDocument13 paginiRRLAnonymous MpvABiÎncă nu există evaluări

- Samard Et Al-2019-Journal of The Science of Food and AgricultureDocument9 paginiSamard Et Al-2019-Journal of The Science of Food and Agriculturegiovan ganandyÎncă nu există evaluări

- 10 1016@j Meatsci 2008 03 006Document6 pagini10 1016@j Meatsci 2008 03 006marwa kaddourÎncă nu există evaluări

- AGEs in Meat Products - Food Chemistry PDFDocument6 paginiAGEs in Meat Products - Food Chemistry PDFJOSE DAVID TORRES GONZALEZÎncă nu există evaluări

- Food ScienceDocument4 paginiFood Scienceandry pratamaÎncă nu există evaluări

- A Comparison of Physicochemical Characteristics, Texture, and Structure of Meat Analogue and MeatsDocument8 paginiA Comparison of Physicochemical Characteristics, Texture, and Structure of Meat Analogue and MeatsYanuar Metriks MutiaraÎncă nu există evaluări

- ANSDocument78 paginiANSNikita KerkarÎncă nu există evaluări

- Ahmad Et Al., 2012Document10 paginiAhmad Et Al., 2012Hussain Ahmad QadriÎncă nu există evaluări

- Processing of Buffalo Meat Nuggets Utilizing Different BindersDocument7 paginiProcessing of Buffalo Meat Nuggets Utilizing Different BindersDilip GuptaÎncă nu există evaluări

- Quality and Acceptability of Value-Added Beef BurgerDocument7 paginiQuality and Acceptability of Value-Added Beef BurgerDilip GuptaÎncă nu există evaluări

- Utilization of Some Food Processing Wastes As A Fat Replacers in CakesDocument12 paginiUtilization of Some Food Processing Wastes As A Fat Replacers in CakesBanuraspatiÎncă nu există evaluări

- 03ce PDFDocument7 pagini03ce PDFJessa Baguio EullaranÎncă nu există evaluări

- JFQ Soy FiberDocument10 paginiJFQ Soy Fiberpaulocampagnol7934Încă nu există evaluări

- PHD Isabelle Kalmar Wageningen - 17 Maart 2011Document172 paginiPHD Isabelle Kalmar Wageningen - 17 Maart 2011Alan Niemies100% (1)

- Variable Fat in Pie CrustsDocument11 paginiVariable Fat in Pie CrustsMaryl Ecla BithaoÎncă nu există evaluări

- WMP đến xx gàDocument12 paginiWMP đến xx gàThúy ViÎncă nu există evaluări

- Utilization of Banana Peel As A Functional Ingredient in Yellow NoodleDocument9 paginiUtilization of Banana Peel As A Functional Ingredient in Yellow NoodleKim GosengÎncă nu există evaluări

- Tabaldo-Tucar 2019 J. Phys. Conf. Ser. 1254 012017Document9 paginiTabaldo-Tucar 2019 J. Phys. Conf. Ser. 1254 012017Jennifer DabalosÎncă nu există evaluări

- Analisis TeksturDocument11 paginiAnalisis Teksturrifqi siedÎncă nu există evaluări

- Development of Low-Fat Mayonnaise Containing Polysaccharide Gums As Functional IngredientsDocument7 paginiDevelopment of Low-Fat Mayonnaise Containing Polysaccharide Gums As Functional IngredientsKhati NguyenÎncă nu există evaluări

- 17 IFRJ 19 (04) 2012 NurulDocument7 pagini17 IFRJ 19 (04) 2012 NurulViko Azi CahyaÎncă nu există evaluări

- Pengaruh Penambahan Berbagai Ekstrak Bahan Pewarna Merah Alami Terhadap Daya Terima Sosis Ikan LeleDocument7 paginiPengaruh Penambahan Berbagai Ekstrak Bahan Pewarna Merah Alami Terhadap Daya Terima Sosis Ikan LelefaycadyanaÎncă nu există evaluări

- Balb/c Mouse. Thirty Two Mice, Consisted of 16 Male and 16 Female of A 28-Day Old, WereDocument14 paginiBalb/c Mouse. Thirty Two Mice, Consisted of 16 Male and 16 Female of A 28-Day Old, WereIndria YulandaraÎncă nu există evaluări

- 8934-16457-1-PB-English (1) AlesDocument15 pagini8934-16457-1-PB-English (1) AlesViskaÎncă nu există evaluări

- Paper y Mapa (Unidos) - Extrusión - Chicana, Cusi, HuamánDocument10 paginiPaper y Mapa (Unidos) - Extrusión - Chicana, Cusi, HuamánWILSON DANIEL CHICANA ZAPATAÎncă nu există evaluări

- Meat Preservation Research PaperDocument8 paginiMeat Preservation Research Papernikuvivakuv3100% (1)

- Comparisons of Volatile Compounds Released During Consumption of Cheddar Cheeses by Different ConsumersDocument8 paginiComparisons of Volatile Compounds Released During Consumption of Cheddar Cheeses by Different ConsumersgeorgianaÎncă nu există evaluări

- Thesis Meat ProcessingDocument6 paginiThesis Meat Processingdwt3zbkq100% (2)

- Process Optimization and Characterization of Cereal Based Ready-To-Eat Extruded Snack FoodDocument8 paginiProcess Optimization and Characterization of Cereal Based Ready-To-Eat Extruded Snack FoodTJPRC PublicationsÎncă nu există evaluări

- 17 IFRJ 19 (04) 2012 Nurul PDFDocument7 pagini17 IFRJ 19 (04) 2012 Nurul PDFVivy Nefriady ChaniagoÎncă nu există evaluări

- RP PagadanDocument19 paginiRP PagadanEujay Martirez AnieteÎncă nu există evaluări

- Thawing Effects On The Quality of Animal and Plant Based Sausage PattiesDocument8 paginiThawing Effects On The Quality of Animal and Plant Based Sausage PattiesHerald Scholarly Open AccessÎncă nu există evaluări

- Fish SausageDocument8 paginiFish Sausagefizah_rahmanÎncă nu există evaluări

- Mosambi Peel Powder Incorporation in Meat ProductsDocument10 paginiMosambi Peel Powder Incorporation in Meat ProductsAliyya SyahminaÎncă nu există evaluări

- N Uckles 1990Document4 paginiN Uckles 1990mekdes abebeÎncă nu există evaluări

- SPF Kibble Palatability 1309PETpalDocument6 paginiSPF Kibble Palatability 1309PETpalenquiry3042Încă nu există evaluări

- A Chemical Analysis of Samples of Crude Glycerol F PDFDocument9 paginiA Chemical Analysis of Samples of Crude Glycerol F PDFFina Mustika SimanjuntakÎncă nu există evaluări

- Rajkumr Daun KariDocument7 paginiRajkumr Daun KariHajarulAsyuraÎncă nu există evaluări

- Effects of Dietary L-Arginine On Growth Performance, Nutrient Digestibility, Gas Emission, and Meat Quality in Finishing PigsDocument8 paginiEffects of Dietary L-Arginine On Growth Performance, Nutrient Digestibility, Gas Emission, and Meat Quality in Finishing PigsthamesÎncă nu există evaluări

- Grain and Milling Quality of Barley and Their Suitability For Preparation of Traditional South Indian ProductsDocument5 paginiGrain and Milling Quality of Barley and Their Suitability For Preparation of Traditional South Indian ProductsIOSR Journal of PharmacyÎncă nu există evaluări

- Gambar Tepung Ketan PDFDocument12 paginiGambar Tepung Ketan PDFNafta PutraÎncă nu există evaluări

- Ostrich Meat Protein Quality and DigestibilityDocument5 paginiOstrich Meat Protein Quality and DigestibilitysuperboysingurÎncă nu există evaluări

- J Meatsci 2009 10 012Document7 paginiJ Meatsci 2009 10 012JonathanRicoVelasqueÎncă nu există evaluări

- Genetic Related Effects On Sheep Meat Quality: Small Ruminant ResearchDocument13 paginiGenetic Related Effects On Sheep Meat Quality: Small Ruminant ResearchAndreea MarinÎncă nu există evaluări

- Biochemistry Critique Paper #1Document2 paginiBiochemistry Critique Paper #1Sharmaine MararacÎncă nu există evaluări

- Effects of Guanidinoacetic Acid Supplementation in Broiler Chicken Diet On Carcass CharacteristicsDocument8 paginiEffects of Guanidinoacetic Acid Supplementation in Broiler Chicken Diet On Carcass CharacteristicsIJAR JOURNALÎncă nu există evaluări

- 144 252 1 PBDocument6 pagini144 252 1 PBUchazhu Ummu Zuhry SecondlyÎncă nu există evaluări

- 11 127 PDFDocument7 pagini11 127 PDFjokylove aceroÎncă nu există evaluări

- (NOODLE) Sung & Stone (2004) - Characterization of Legume Starches and Their Noodle QualityDocument8 pagini(NOODLE) Sung & Stone (2004) - Characterization of Legume Starches and Their Noodle QualityEduard TethoolÎncă nu există evaluări

- IRJET V3I6223paper4Document7 paginiIRJET V3I6223paper4reply25siddharthÎncă nu există evaluări

- Quality Evaluation of Chicken Nugget Formulated WiDocument8 paginiQuality Evaluation of Chicken Nugget Formulated WijazzzÎncă nu există evaluări

- Gelatine TexturDocument6 paginiGelatine TexturDanielÎncă nu există evaluări

- CATFISH THESIS CHAPTER Sobrang Lapit NaDocument69 paginiCATFISH THESIS CHAPTER Sobrang Lapit Napreddienelguevarrayahoo.comÎncă nu există evaluări

- PDF 14802Document10 paginiPDF 14802Mc KobaÎncă nu există evaluări

- 67 2017campagnolDocument9 pagini67 2017campagnolNguyen Minh TrongÎncă nu există evaluări

- Evaluation of Chemical Properties CroissantDocument4 paginiEvaluation of Chemical Properties CroissantSzénási KrisztiÎncă nu există evaluări

- 1324-Article Text-2222-1-10-20190703Document11 pagini1324-Article Text-2222-1-10-20190703Amaliatul KhusnaÎncă nu există evaluări

- Foods 12 00312Document15 paginiFoods 12 00312willy yashilvaÎncă nu există evaluări

- Reference Method For Water Holding Capacity AssessmentDocument5 paginiReference Method For Water Holding Capacity AssessmentFaysa UtbaÎncă nu există evaluări

- NEWEST BYOYL 2017 Optimized PDFDocument37 paginiNEWEST BYOYL 2017 Optimized PDFpitulusaÎncă nu există evaluări

- David Perlmutter Focus Autoimmune PDFDocument23 paginiDavid Perlmutter Focus Autoimmune PDFutpal_thakar100% (6)

- DiverticulosisDocument49 paginiDiverticulosisJewelyn Alafriz AngelesÎncă nu există evaluări

- UsanaDocument9 paginiUsanamaryÎncă nu există evaluări

- Tl.e 10 Week 7&8Document18 paginiTl.e 10 Week 7&8Christian BastonaÎncă nu există evaluări

- Corra 2016Document15 paginiCorra 2016Benito, BodoqueÎncă nu există evaluări

- Effects of A Low Fat High Fiber Diet and Exercise Program On Breast Cancer Risk Factors in Vivo and Tumor Cell Growth and Apoptosis in VitroDocument8 paginiEffects of A Low Fat High Fiber Diet and Exercise Program On Breast Cancer Risk Factors in Vivo and Tumor Cell Growth and Apoptosis in VitroCodyÎncă nu există evaluări

- Name: Muhammad Fakhrurrazi Bin Riduan CLASS: 203 Subject: ScienceDocument18 paginiName: Muhammad Fakhrurrazi Bin Riduan CLASS: 203 Subject: ScienceFathilah OsmanÎncă nu există evaluări

- Nutriciously Vegan Breakfast Meal PrepDocument20 paginiNutriciously Vegan Breakfast Meal PrepJÎncă nu există evaluări

- A4 Quantitative Study of Acceptability of Coconut CHPTR 1&2Document16 paginiA4 Quantitative Study of Acceptability of Coconut CHPTR 1&2Adiyan100% (2)

- 105 Meal PlanDocument4 pagini105 Meal PlanAisha MarieÎncă nu există evaluări

- Nutrition and Diet Therapy Summary of BookDocument17 paginiNutrition and Diet Therapy Summary of BookMabes100% (2)

- BurtonFreeman Reimers2011Document12 paginiBurtonFreeman Reimers2011Della FitriaÎncă nu există evaluări

- EatRight Diet Analysis 7d QuestionsDocument8 paginiEatRight Diet Analysis 7d QuestionsBundi Gonzalez MartinÎncă nu există evaluări

- The Lyon Protocol Dr. Gabrielle LyonDocument20 paginiThe Lyon Protocol Dr. Gabrielle LyonIvan Farkaš100% (2)

- 2017 Libro AlimentaryDocument341 pagini2017 Libro AlimentaryreinpolyÎncă nu există evaluări

- SAMPLE RobRiches UltraLean LR NEW PDFDocument16 paginiSAMPLE RobRiches UltraLean LR NEW PDFTilak Raj0% (1)

- Radishes Offer A Lot of Health BenefitsDocument11 paginiRadishes Offer A Lot of Health BenefitsashivaramakrishnaÎncă nu există evaluări

- 7th Science English PDFDocument173 pagini7th Science English PDFJithinAbrahamÎncă nu există evaluări

- Global Nutrition Philosophy Presentation NoVideo U.S.English PDFDocument187 paginiGlobal Nutrition Philosophy Presentation NoVideo U.S.English PDFMuthu KumarÎncă nu există evaluări

- Calorie ChartDocument6 paginiCalorie Chartvijai daniel75% (4)

- Cereal (Major Staple and Panacea To Food Insecurity in Nigeria)Document18 paginiCereal (Major Staple and Panacea To Food Insecurity in Nigeria)Ekoh EnduranceÎncă nu există evaluări

- Ray PeatDocument10 paginiRay PeatCosti Sorescu100% (2)

- PHG111 AssignmentDocument7 paginiPHG111 AssignmentKermina Elkomos Wissa Azmy FanousÎncă nu există evaluări

- Journal of Functional Foods: Isabel Aranda-Olmedo, Luis A. RubioDocument13 paginiJournal of Functional Foods: Isabel Aranda-Olmedo, Luis A. RubioAndrés Felipe Zapata MurielÎncă nu există evaluări

- Nutritional Aspects of CerealsDocument32 paginiNutritional Aspects of CerealsFlorinÎncă nu există evaluări

- CODEX STAN 234-1999 Métodos de Análisis y Muestreo Recomendados (60pp)Document60 paginiCODEX STAN 234-1999 Métodos de Análisis y Muestreo Recomendados (60pp)Juan Igor Astorga SalinasÎncă nu există evaluări

- Functional Properties of Fruits & Vegetable BeveragesDocument28 paginiFunctional Properties of Fruits & Vegetable Beveragesb_danish2100% (2)

- Nutrition Weight Loss Guide™ - PhenQ DocumentDocument18 paginiNutrition Weight Loss Guide™ - PhenQ DocumentFurman PourosÎncă nu există evaluări

- Medical Nutrition TherapyDocument11 paginiMedical Nutrition TherapyVanessa Bullecer67% (3)