Documente Academic

Documente Profesional

Documente Cultură

Quick Guide For P&ID Review

Încărcat de

floreda0 evaluări0% au considerat acest document util (0 voturi)

246 vizualizări7 paginiNitrogen Generator Package is composed of one (1) train of Nitrogen Generator (2 x 100%) with Eight (8) unit membrane modules for Produced nitrogen of 97%. Oxygen rich waste is vented off to atmosphere in a safe area via the tie-in point on the skid.

Descriere originală:

Titlu original

Quick Guide for P&ID Review[1]

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentNitrogen Generator Package is composed of one (1) train of Nitrogen Generator (2 x 100%) with Eight (8) unit membrane modules for Produced nitrogen of 97%. Oxygen rich waste is vented off to atmosphere in a safe area via the tie-in point on the skid.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

246 vizualizări7 paginiQuick Guide For P&ID Review

Încărcat de

floredaNitrogen Generator Package is composed of one (1) train of Nitrogen Generator (2 x 100%) with Eight (8) unit membrane modules for Produced nitrogen of 97%. Oxygen rich waste is vented off to atmosphere in a safe area via the tie-in point on the skid.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 7

Quick Guide for Nitrogen Generation Package

Process Description Brief

The System is composed of One (1) train of Nitrogen Generator (2 100%) with Eight (8) unit membrane modules for

Produced Nitrogen of 97%; the description below applies to one train.

Compressed Air is supplied to the Nitrogen Generator Package via the tie-in point. After passing through the Pre-Filter

System and Electrical Heater, the Air is separated into Nitrogen product and Oxygen rich permeate by the separation

Membranes.

The Pre-filtration System consists of Two (2) Coarse Coalescer Filters, and Two (2) Particulate Fine Filters. The air will enter

into the Electrical Heater upon leaving the Pre-filtration System. Air will be heated to 52C before entering Nitrogen

Membranes. Four (4) unit membranes are required for the system of the prescribed Flow Rate of 390 Sm3/h at standard

conditions and Nitrogen purity of 97%.

On the other hand, the Oxygen rich waste is vented off to atmosphere in a safe area via the tie-in point on the skid.

Measuring and Control Instrumentation

Measuring and Control Instrumentation within the Nitrogen Generator Package includes:

- Differential Pressure Indicators across each fine filter,

- Differential Pressure Transmitter across the whole filtration train,

- Feed Air Pressure Gauge,

- Feed Air Temperature Gauge,

- Oxygen Analyzer,

- Produced Nitrogen Pressure Transmitter,

- Produced Nitrogen Flow Transmitter.

All the above signals are wired to Junction Boxes for connection to Clients DCS.

The following parameters are continuously controlled by the Local Control Panel:

- Pressure of Generated Nitrogen, with limitation of Flow in case of excessive demand,

- Cascade control of the Set Point of Generated Nitrogen Flow Controller, based on signal from Oxygen Analyzer.

The discharge Pressure (flow of Nitrogen) is controlled by a Pressure Control Valve and monitored by a Pressure Controller

and a Flow Controller. The Control Valve will adjust the Flow of nitrogen to the Receiver according to the control loop that

generates the lower % opening signal.

In case the product Nitrogen falls outside specification (High Oxygen content), the Set Point of the Flow Controller will be

reduced in order to avoid contamination of the Nitrogen in the Receiver. If the Oxygen content exceeds the High-High

threshold, Pneumatic On/Off Valves will divert the Flow of Nitrogen to atmosphere and the Nitrogen Generator will trip. Said

On/Off Valves are controlled via a solenoid valve that receives a signal from DCS. Manual valves are provided for isolation of

the packages instrumentation, filters and membranes.

Posted 25th May 2013 by Danaraj Chandrasegaran

Labels: Equipment, Quick Guide

25

MAY

0

Add a comment

Quick Guide for Pedestal Cranes

Quick Guide for Pedestal Cranes

Pedestal crane is one of the key equipment installed in an offshore platform and other floating units e.g FPSO, FSO, FPU. Other

than that, it represents significant progress achievement visually during the fabrication period once it is erected at the yard.

Pedestal cranes are usually supplied in accordance to API Spec. 2C. This requirement applies to most part of the world. However,

in European and north sea environment EN13852-1 are used. Most vendors (e.g. NOV, Liebherr, Oil States, Favelle Favco) are able

to cater for both requirements. In addition, Civil Aviation Authority Regulation CAP 437 needs to be implemented as well.

22

DEC

Classic Flipcard Magazine Mosaic Sidebar Snapshot Timeslide

Engineer Am I?? Engineer Am I??

search

Quick Guide for P&ID Review 01/05/2014

http://danarajc.blogspot.fr/2012/10/quick-guide-for-p-review.html 1 / 7

Hydraulic power units for the pedestal crane could be diesel engine driven or electric motor driven. For diesel engine unit, if there is

cranking time requirement e.g. 3 starts in 1.5 mins., an air receiver need to be an integral part of the crane. Cab design and

operator's interface differs according to supplier's standard design and owner's needs. The more sophisticated and elaborate

interfaces are always available at higher cost.

Construction interfaces that are related to pedestal cranes are:

Structural: Pedestal interface with deck structure, ladders, handrails, aircraft obstruction markings

Piping: Instrument air supply and diesel fuel supply

Electrical: Normal power supply and UPS requirement, aircraft warning lights, JBs

Instrumentation: F&G detectors, windsock, JBs

Telecommunication: Radio unit, antennaes, surge arrestors, Jbs

Installation: Installation procedures, slew bearing change procedure

Testing of the crane unit will be done in accordance to the code and regulations. Usually a witnessed shop test on a fully assembled

crane mounted on a test pedestal shall be required. This test will include a mechanical run of all main and auxiliary machinery,

control panels for a minimum 2 hours under full load test. Prior and post test , the crane and its auxiliaries will be visually inspected

as well. Once the crane's test found satisfactory, a certificate will be issued.

Posted 22nd December 2012 by Danaraj Chandrasegaran

Labels: Equipment, Quick Guide

0

Add a comment

Quick Guide for Pressure Vessel Drawing Review

Quick Guide for Pressure Vessel Drawing Review.

Pressure vessels are among the key items in a mechanical packaged equipment e.g Instrument air package, Nitrogen

generators. Usually, vessel constructions shall comply with ASME Boiler and Pressure Vessel Code (BPVC) Section VIII and

the project specific requirements, including welding specification. For vessel general arrangement drawing review, it should

be completed together with datasheet, calculations and welding document. This would facilitate the consistency check

between documents.

Checklist:

1. Nozzle schedule

2. Design data or equipment data table

3. Bill of material

4. Fabrication (welding) details to be shown:

earthing lugs/ boss

lifting lug

access opening

skirts

nozzles

other attachments

5. Weld details for main circumferential and longitudinal weld line

6. Loading data operating, dry, wind, seismic and transportation

7. Nozzle allowable loads

8. Painting requirements

9. Notes referencing project specifications

References:

ASME codes and standards

A Brief discussion on ASME Section VII Division 1, 2 and the new Division 3

22

OCT

Quick Guide for P&ID Review 01/05/2014

http://danarajc.blogspot.fr/2012/10/quick-guide-for-p-review.html 2 / 7

Posted 22nd October 2012 by Danaraj Chandrasegaran

Labels: Equipment, General, Quick Guide

0

Add a comment

Quick Guide for P&ID Review

Quick Guide for P & ID Review.

Piping and Instrumentation Diagram (P&ID) is one of the key documents that will be reviewed during the course of project execution. It will

be the basis of piping and instrumentation design, as the name implies. Once P&ID is firmed up, secondary drawings such as electrical and

control schematics, bill of material and detailed arrangement can be generated by the engineers. Other than that, P&ID needs to be read in

conjunction with the control philosophy to have the operational overview of the system.

Checklist for P&ID review:

1. Tagging this to be referred against the project tagging philosophy

2. Symbology this to be referred against the project symbols. Otherwise, vendor standard symbol to be listed for referencing.

3. Inlet and outlet design parameters design pressure/ temperature; operating pressure/ temperature

4. Key equipment design parameters design/ operating pressure; design/ operating temperature; material of construction,

corrosion allowance; dimensions

5. Material selection of key components - this to be referred against the project material selection report

6. Line sizing this to be referred against the piping class for material and ratings

7. Valve sizes

8. Valves position during operation or failure

9. Instrumentation suitability for the selected parameters; ranges; alarm set points, trip set points

10. Control panel interfaces signals to/ from main control room and field instruments; hardwired signals; serial linked signals

11. Pressure relief valves sizes

12. Control loops between the instruments and equipment

13. Termination points

14. Notes describing project requirements, exceptions or operational points.

15. Consistency between documents such as instrument index, control philosophy, line list sizing calculations to be reviewed as well.

Posted 11th October 2012 by Danaraj Chandrasegaran

Labels: Equipment, General, Quick Guide

11

OCT

0

Add a comment

Quick Guide for General Arrangement Drawing Review.

Quick Guide for General Arrangement Drawing Review.

General arrangement drawings usually would be the earliest submission by Vendors to the Purchaser ( e.g. EPC

contractor). Since, the GA submission schedule more often than not occurs within 4 weeks from purchase order

placement; Vendor would provide typical arrangement followed up by more details on subsequent revisions.

Checklist for GA design review:

1. Footprint dimensions

2. Interface points for piping and structural

3. Interface points for electrical and instrumentation

4. Maintenance access requirements and lifting arrangements

9

OCT

Quick Guide for P&ID Review 01/05/2014

http://danarajc.blogspot.fr/2012/10/quick-guide-for-p-review.html 3 / 7

5. Special protections

6. Human factors requirements

7. Bill of material

8. Weight and load information (dry, operating, seismic and transport)

9. Painting requirements

10. Notes referencing project specifications.

Posted 9th October 2012 by Danaraj Chandrasegaran

Labels: Equipment, General, Quick Guide

0

Add a comment

Wellhead Platform (WHP)

WHP

Awellhead platform includesan integrated deck, utility systems, wellhead systems, living quarters, a helideckand drilling facilities. At times, it could be linked

to Floating, Production, Storage and Offloading (FPSO) vessel or central production platforms. WHPs are normally unmanned. They are designed to be

operated remotely and visited during routine inspection and maintenance activities.

Most times, WHPswould be four legged platforms; consisting of 4 decks. The deckswould be spider deck, cellar deck, main deckand heli deck. It may have 3 to

32 well, depending on the size of WHPs. These wellsare usually drilled by jack-up rigsthat dockswith the WHPs.

Currently market is moving towards minimum facilities installation, whereby minimal engineering activities envisaged and standardization between fields.

Schedule and cost savings can be anticipated by decreasing manhours, fabrication time, streamlining designs and equipment selections. Also, expandable

platformshelpson future field development strategies. Facilitiescould also be designed to accommodate wider design needs. Standardization and streamlining

of design also offersimproved operational requirementse.g. better spare partsmanagement and decrease manned intervention.

Therefore, WHPsdesign and technology development should be interesting to watch in coming years.

16

SEP

Quick Guide for P&ID Review 01/05/2014

http://danarajc.blogspot.fr/2012/10/quick-guide-for-p-review.html 4 / 7

RasGasAl Khaleej GasProject - WHP (By McDermott-Photos)

Posted 16th September 2012 by Danaraj Chandrasegaran

Labels: WHP

0

Add a comment

Quick Guide for Flare Ignition System

Overview: Flare Ignition System

Ignition Method Flame Front Generators

(FFG)

Electronic Ignition Ballistic

Brief FFG creates a mixture of

f u e l gas and air in the

ignition line. Subsequently,

this is ignited. The metering

and mixing process is

accomplished through the

use of small valve trains

placed on the FFG control

panel.

This ignition system uses a

fuel gas line much like other

ignition systems. However,

utilizing the exciter which

produces a high voltage

spark directly in the pilot

nozzle, compared to

conventional FFGs.

Installed at a safe distance

from the flare stack and a

guide lead to the flare tip.

The system is suitable for

all flare tips and may ignite

several flares on one flare

deck. It is easily retrofitted

into existing installations.

Interface Electrical, Fuel, Air Electrical Compressed air

Installation limits <1600m <2000m

Advantages Reliable conventional

system

Instaneous reignition if the

pilot should ever lose its

flame.

No electronic parts or

mo v a b l e parts within

system.

Does not need any pilot

bur ner s, and has no

equipment on the flare deck

that is sensitive to heat,

such as cables,

instrumentation or

electrodes.

Disadvantages Components may require

replacement over its life.

Cabling for electronic

ignition line required.

Ignition detection system

required.

Components may require

replacement over its life.

Only single vendor able to

supply this type i.e.

Hamworthy.

Require guide pipe for the

ignition pellet.

Posted 2nd September 2012 by Danaraj Chandrasegaran

Labels: Equipment, WHP

2

SEP

0

Add a comment

Talent Development: Malaysian Oil & Gas Industries

19

AUG

Quick Guide for P&ID Review 01/05/2014

http://danarajc.blogspot.fr/2012/10/quick-guide-for-p-review.html 5 / 7

TalentDevelopment: Malaysian Oil & Gas Industries

Introduction

Recentannouncement by PETRONAS on several major oil and gas project such asRAPID project in Pengerang and North Malay Basin Development

havecertainly created much excitement in our industry. Other notableoffshore field development within Malaysia that are in thelimelight are Malikai, Rotan and

Kanowit. Also, marginal fields arebeing developed and existing fields will be rejuvenated with enhancedoil recovery system to boost our oil production for

coming years. Allthese developmentsin our local oil and gasindustriesare forecastto create thousandsof skilled jobscomprising of different level ofeducation,

trainings and skill sets. For example, for RAPID project,it is envisaged 40,000 to 50,000 workforce would be needed duringconstruction period (Bernama news,

12 May 2012).

Thequestion that comes to our mind that where do we source all thetechnical personnel and skilled workers that are much needed toexecute and ensure the

successand continuity for all theseprojects. In other words, if the projects concerned do not create themultiplier effect that is needed to boost our overall

economy, itwould be no good at all to all of us, in a nutshell so to speak.

News,opinionshave been generated and discussed regarding the talentissueslately. Here is to focusto a particular industry, which arehigh worth and where we

have the capability to be front runners aswell and may in fact are leading the region at the moment.Nevertheless, considering the significance of oil and gas

industry toour nation'seconomy. It would be prudent to have holistic and longterm approach to addressthe talent issue here, while being cautiouswith external

pull factors.

TalentDevelopment Needsfor Oil & GasIndustry.

Oiland gas industry talent needs differs on a wide magnitude compared toour local manufacturing and construction industry requirements.Equipment

technologiesand safety requirementsdiffersthroughout theworld and dictated by processlicensorsaswell asoil majors. InMalaysian context, the industry iswell

developed to cater for theregional needs. Local vendors has established themselves throughPETRONAS vendor development programme and large

engineeringconsulting group hastheir presence here aswell.

Inorder to move towards wider global audience, much need to be done.Our local engineers need to be well versed with wider technical skillsets in terms of

familiarizing with standardsand other regulatoryrequirementsin other countries. More over, projectsall over theworld are being completed in shorter period and

involving satelliteoffices around the world engaging with multicultural work force,which would require higher degree of English language proficiency andIT

skills.

Alsothe markets are looking for well rounded talents, meaning technicalskills which are complimented with field experience such asfabrication, testing and

commissioning works. Though, this may becommon requirement for most employers. The ground reality is most ofthe workforce are not trained to be well

rounded. Thiswould be apoint that could be taken up by the industry itself.

Talentdevelopment solutions must also cater beyond the engineeringcommunity, such as government officials, logistics service provider,inspection service

providersand procurement personnel. Theadvancement of the industry very much dependsall these partsof theprivate sector and public sector catering to our

oil and gasindustry.

RaisingStandardsof Training & Education

EnsuringMalaysians are capable of meeting the oil and gas industry needs andmarket demands, our workforce needs to be equipped with rightknowledge and

tools. Workforce, not just fresh graduatesneed to befostered to meet market demandsand keep abreast with current marketdevelopments.

Atpresent, there seemsto be a expectationsgap between the industryand educational institutional graduates. Asthe industry wantstheworkforce entrantsto be

job ready but thisnot alwaysthecase. However, stepsare being taken to addressthisissued by boththe private and public sector.

ThoughIEM and BEM hasprescribed path to attain professional qualificationfor engineer, most graduate engineersare either not aware of theprocessor having

lackadaisical attitude towards it. Emphasizingprofessional development for workforce entrant as well as existingshould be the case. Structured learning process

which suitstheindustry, particularly employersmust be part of the workforcedevelopment plan throughout their career with measurable indicators.

Internshipplans such as spearheaded by MOGEC, whereby linking Malaysianresearch universities and major engineering consultancy companiesbased in

Malaysia must be applauded. Solutionssimilar to thisprovideuniversity studentsan early exposure in building oil &gas

industrycapability. Thisisto ensure a smoother transition upon thecompletion of their undergraduate degree in pursuit of a career inthe oil & gasindustry.

Meanwhile,our academic institutions curriculum should be reflective of thespecializations available in the market. Key ideas and industryterminologies should

be familiarized at tertiary education level,which would enhance the confidence level of workforce entrants. Forexamples, subjectsrelated to safety, technology,

industries' codes&standardsor software toolsshould me available to final yearstudentshere.

Boththe industry and academia need to strengthen the collaboration toalign talent development to match the oil and gasindustriesrequirements. Involvement

by industry personnels in designing theacademic curriculum and providing real field or business exposurethrough the sharing of experiences, must be

encouraged and rewarded. More structured learning programme are also needed for existingindustry practitioners to improve themselves. This could be

arrangedvia partnership between industry and academia.

Conclusion

Whiletalent will be a constant issue for the next decade, there is alreadya talent pool in Malaysia that needs to be developed and refined.This may involve a

long term commitmentsfrom both public sector andindustry players. But the benefitsthat could be reaped far outweighsthe effortsthat are needed.

Quick Guide for P&ID Review 01/05/2014

http://danarajc.blogspot.fr/2012/10/quick-guide-for-p-review.html 6 / 7

Posted 19th August 2012 by Danaraj Chandrasegaran

Labels: General

0

Add a comment

Intro

Am currently based in Ulsan, South Korea. Working at the largest shipyard in the world. Doing my bit here to share the

knowledge I have accrued all these years. I find that general literature describing the equipment used in the oil & gas

industry etc. lacking on the web. Hence, my effort here to be a starting point the least.

Posted 6th August 2012 by Danaraj Chandrasegaran

Labels: General

6

AUG

0

Add a comment

Quick Guide for P&ID Review 01/05/2014

http://danarajc.blogspot.fr/2012/10/quick-guide-for-p-review.html 7 / 7

S-ar putea să vă placă și

- RSD LinesDocument6 paginiRSD Linesfloreda100% (6)

- 3.plotplan and Equipment LayoutDocument12 pagini3.plotplan and Equipment LayoutAmarKumarÎncă nu există evaluări

- Centrifugal Compressor P&ID GuideDocument4 paginiCentrifugal Compressor P&ID Guidenaveenbaskaran1989100% (1)

- Piping Layout UDLDocument24 paginiPiping Layout UDLLegend Anbu100% (1)

- Pressure Safety ValvesDocument11 paginiPressure Safety ValveschianhhoÎncă nu există evaluări

- Develop Plot Plans for Piping ProjectsDocument9 paginiDevelop Plot Plans for Piping ProjectsTom0% (1)

- Check List - 3D Model ReviewDocument28 paginiCheck List - 3D Model ReviewNikhil ChaundkarÎncă nu există evaluări

- Pressure Vessels and Piping TutorialDocument441 paginiPressure Vessels and Piping TutorialAditya Ranjan Pathak100% (10)

- LR The Theory of Everything RSD NationDocument8 paginiLR The Theory of Everything RSD Nationfloreda100% (1)

- Piping Design BasisDocument26 paginiPiping Design BasisAnjani Prabhakar100% (4)

- Introduction To Piping Engineering PDFDocument6 paginiIntroduction To Piping Engineering PDFKavin KumarÎncă nu există evaluări

- Pipe Stress Analysis - FWDocument32 paginiPipe Stress Analysis - FWmasoud132Încă nu există evaluări

- Checklist For Nozzle OrientationDocument4 paginiChecklist For Nozzle OrientationPhilippe LAVOISIERÎncă nu există evaluări

- Process control modes and tuning methodsDocument23 paginiProcess control modes and tuning methodsMuhammad Ibad AlamÎncă nu există evaluări

- FS HpuDocument11 paginiFS Hpuscribd_thakurÎncă nu există evaluări

- PSV SizingDocument18 paginiPSV SizingGo IELTSÎncă nu există evaluări

- P&id PDFDocument66 paginiP&id PDFFarook MohideenÎncă nu există evaluări

- 1 SS Ci 004Document26 pagini1 SS Ci 004chells.sakthiÎncă nu există evaluări

- For Newbs & Vets Exploration Guide RSD NationDocument8 paginiFor Newbs & Vets Exploration Guide RSD NationfloredaÎncă nu există evaluări

- 16 Habits You Should Do Every DayDocument17 pagini16 Habits You Should Do Every DayfloredaÎncă nu există evaluări

- Engineering Standard for Power, Control and Earthing CablesDocument23 paginiEngineering Standard for Power, Control and Earthing CablesSarah Shibu ThomasÎncă nu există evaluări

- Pi Ups 1004Document39 paginiPi Ups 1004JOEL ARNAO CORTEGANAÎncă nu există evaluări

- Ch.E-403 Chemical Engineering Plant DesignDocument262 paginiCh.E-403 Chemical Engineering Plant DesignAmna EhsanÎncă nu există evaluări

- Chemical Engineering P&ID Review ChecklistDocument7 paginiChemical Engineering P&ID Review ChecklistMayur ParmarÎncă nu există evaluări

- Checklist For Piping Isometrics - P&ID, Layout, Drafting RelatedDocument5 paginiChecklist For Piping Isometrics - P&ID, Layout, Drafting RelatedkarunaÎncă nu există evaluări

- Critical Line ListDocument20 paginiCritical Line ListCristhian Solano Bazalar100% (1)

- C1 The Basic of Plant Layout Design - Process Plant Layout and Piping DesignDocument81 paginiC1 The Basic of Plant Layout Design - Process Plant Layout and Piping Designdung100% (1)

- Hysys Liquid PumpingDocument8 paginiHysys Liquid PumpingEkundayo JohnÎncă nu există evaluări

- Jiangsu Deenpu Petrochemical Machinery Co.,ltdDocument12 paginiJiangsu Deenpu Petrochemical Machinery Co.,ltdJIN WANGÎncă nu există evaluări

- Stage 1 pipe sizing dataDocument21 paginiStage 1 pipe sizing datasj_scribdÎncă nu există evaluări

- BPL Equiv ChartDocument1 paginăBPL Equiv ChartOscar CruzÎncă nu există evaluări

- Asme Sec Viii Div-2Document31 paginiAsme Sec Viii Div-2Yash Rami100% (3)

- Trg-b1003 Piping Study Column PipingDocument53 paginiTrg-b1003 Piping Study Column Pipingfronjose100% (3)

- Functional Specification For Deck CraneDocument31 paginiFunctional Specification For Deck Craneaiyubi20% (1)

- Technical Specifications - CompDocument57 paginiTechnical Specifications - CompAnonymous gr5Pr9AVÎncă nu există evaluări

- An Overview Of: Plant Layout AND PipingDocument21 paginiAn Overview Of: Plant Layout AND Pipingpuru55980Încă nu există evaluări

- Pressure Relief Safety ValvesDocument52 paginiPressure Relief Safety Valveswah_ma100% (3)

- The #1 Truth About Attracting HOT Women RSD NationDocument8 paginiThe #1 Truth About Attracting HOT Women RSD NationfloredaÎncă nu există evaluări

- Globe control valve fundamentalsDocument14 paginiGlobe control valve fundamentalsSanjay SoniÎncă nu există evaluări

- Rack Piping For A Piping Stress EngineerDocument4 paginiRack Piping For A Piping Stress EngineerFaizal Khan100% (2)

- Korf BrochureDocument1 paginăKorf Brochurelhphong021191Încă nu există evaluări

- Safety Instruction Sheets For Plant Piping and Cross-Country PipelinesDocument35 paginiSafety Instruction Sheets For Plant Piping and Cross-Country PipelinesRaj Bindas50% (2)

- Control Valve FundamentalsDocument241 paginiControl Valve FundamentalsHarpreet SutdharÎncă nu există evaluări

- Basic Engineering PDFDocument17 paginiBasic Engineering PDFvaradarajck893Încă nu există evaluări

- KSB Etanorm CurvesDocument83 paginiKSB Etanorm CurvesEric Fabro100% (5)

- Pipe Stress AnalysisDocument7 paginiPipe Stress AnalysisTushar NaikÎncă nu există evaluări

- LINE SIZING CALCULATIONS GUIDEDocument21 paginiLINE SIZING CALCULATIONS GUIDEjabar sathikÎncă nu există evaluări

- Piping S1Document44 paginiPiping S1Rajkumar AÎncă nu există evaluări

- Typical P&ID Arrangement for Pig Launchers and ReceiversDocument7 paginiTypical P&ID Arrangement for Pig Launchers and ReceiversDHAVAL PANCHAL100% (1)

- 052KP 01 New 24" Gas Transmission Pipeline To Alkhalij Power Generation Station Control /ESD and Operating Philosophy 052KP 01 PHL IN 001, Rev.01Document26 pagini052KP 01 New 24" Gas Transmission Pipeline To Alkhalij Power Generation Station Control /ESD and Operating Philosophy 052KP 01 PHL IN 001, Rev.01Jabel Oil Services Technical DPTÎncă nu există evaluări

- Pipe Stress AnalysisDocument32 paginiPipe Stress Analysisjaky1383100% (3)

- P&ID Drawing Checklist for Equipment, Tags, Lines and TablesDocument3 paginiP&ID Drawing Checklist for Equipment, Tags, Lines and Tablesmohsen2000mÎncă nu există evaluări

- PG Diploma in Oil & Gas Piping Engineering Design and AnalysisDocument28 paginiPG Diploma in Oil & Gas Piping Engineering Design and AnalysisabdullahÎncă nu există evaluări

- Equipment Process Data Sheet ChecklistDocument1 paginăEquipment Process Data Sheet Checklistankur2061Încă nu există evaluări

- PID NotesDocument40 paginiPID Notesmegha ingulkarÎncă nu există evaluări

- Durco - Mark 2 & 3 - Self Priming Pumps - Performance CurvesDocument60 paginiDurco - Mark 2 & 3 - Self Priming Pumps - Performance CurvesDavid Diaz100% (2)

- Model Review Process X5axp5bsDocument8 paginiModel Review Process X5axp5bsNadi Jothidan KLÎncă nu există evaluări

- Tankgauging 131107224507 Phpapp01Document61 paginiTankgauging 131107224507 Phpapp01floredaÎncă nu există evaluări

- Piping PhilosophyDocument15 paginiPiping PhilosophyRagh100% (1)

- Pipe RoutDocument10 paginiPipe Routghkashyap1Încă nu există evaluări

- INST212D Additional topics presentationDocument56 paginiINST212D Additional topics presentationHersang SuprayogiÎncă nu există evaluări

- Aquestia OCV AVIATIONDocument16 paginiAquestia OCV AVIATIONSony Nd AshaÎncă nu există evaluări

- HIPPS Functional Specifications for High Pressure ProtectionDocument8 paginiHIPPS Functional Specifications for High Pressure Protectionscribd_thakurÎncă nu există evaluări

- Specification For LP Gas Reciprocating Compressor PackageDocument25 paginiSpecification For LP Gas Reciprocating Compressor Packageashok100% (1)

- Saudi Aramco Inspection Checklist: Piping / Equipment Internal Cleaning InspectionDocument4 paginiSaudi Aramco Inspection Checklist: Piping / Equipment Internal Cleaning InspectionDilshad Ahemad100% (1)

- SPEC TECH SPEC BRINE CHILLER 0°CDocument17 paginiSPEC TECH SPEC BRINE CHILLER 0°Cdhanu_lagwankar100% (1)

- BS en 13480-1-2017Document22 paginiBS en 13480-1-2017Davide CongiuÎncă nu există evaluări

- Flow InstrumentsDocument38 paginiFlow InstrumentsTirado Melchor Angel Miguel100% (2)

- PRV PetrofacDocument36 paginiPRV PetrofacPradeep MagudeswaranÎncă nu există evaluări

- Advance Pipe Stress Analysis Institute in MumbaiDocument2 paginiAdvance Pipe Stress Analysis Institute in MumbaiSuvidya Institute of TechnologyÎncă nu există evaluări

- Indus - PGD Process Design EngineeringDocument2 paginiIndus - PGD Process Design EngineeringAmarjeet SandhuÎncă nu există evaluări

- Iit MumbaiDocument243 paginiIit MumbaiYogesh JagdaleÎncă nu există evaluări

- Chapter 7: Design and Operation of Steam-Assisted FlaresDocument44 paginiChapter 7: Design and Operation of Steam-Assisted FlaresBre WirabumiÎncă nu există evaluări

- Online Piping and Caesar Course SyllabusDocument10 paginiOnline Piping and Caesar Course Syllabusm 418Încă nu există evaluări

- 300 kW EB Melting Furnace Design and TestingDocument14 pagini300 kW EB Melting Furnace Design and Testingjkhgvdj mnhsnjkhgÎncă nu există evaluări

- Technical Specification for Air Cooled CondenserDocument7 paginiTechnical Specification for Air Cooled CondenserRajendran SrnÎncă nu există evaluări

- Project Standards and Specifications Crude Desalter Systems Rev01Document6 paginiProject Standards and Specifications Crude Desalter Systems Rev01muhammad_asim_10Încă nu există evaluări

- Packaged Outdoor Central StationDocument14 paginiPackaged Outdoor Central StationAbdullah.N FAAliÎncă nu există evaluări

- Icm 400Document19 paginiIcm 400floredaÎncă nu există evaluări

- IcmappgDocument6 paginiIcmappgfloredaÎncă nu există evaluări

- Icm 50Document3 paginiIcm 50floredaÎncă nu există evaluări

- Icm 100Document12 paginiIcm 100floredaÎncă nu există evaluări

- What Is Quality Assurance (QA) - Definition FromDocument3 paginiWhat Is Quality Assurance (QA) - Definition FromfloredaÎncă nu există evaluări

- Quality Assurance - Wikipedia, The Free EncyclopediaDocument5 paginiQuality Assurance - Wikipedia, The Free Encyclopediafloreda100% (1)

- GNL3Z V 455092 80152 0CDocument10 paginiGNL3Z V 455092 80152 0CfloredaÎncă nu există evaluări

- Submersible Pump - Wikipedia, The Free EncyclopediaDocument3 paginiSubmersible Pump - Wikipedia, The Free EncyclopediafloredaÎncă nu există evaluări

- Andy Teach From Graduation To Corporation 3 Per Page Handout-1Document8 paginiAndy Teach From Graduation To Corporation 3 Per Page Handout-1floredaÎncă nu există evaluări

- Submission Confirmation: Entry Received: v12.00.00 Applicant Entry SystemDocument1 paginăSubmission Confirmation: Entry Received: v12.00.00 Applicant Entry SystemfloredaÎncă nu există evaluări

- How To JobborseDocument16 paginiHow To JobborsefloredaÎncă nu există evaluări

- 12 Rules For Learning Foreign Languages in Record Time - TheDocument17 pagini12 Rules For Learning Foreign Languages in Record Time - ThefloredaÎncă nu există evaluări

- Brochure Standard Compliant Switchgear and Controlgear ProductionDocument90 paginiBrochure Standard Compliant Switchgear and Controlgear ProductionjapoesÎncă nu există evaluări

- Custody Transfer - Wikipedia, The Free Encyclopedia PDFDocument6 paginiCustody Transfer - Wikipedia, The Free Encyclopedia PDFfloredaÎncă nu există evaluări

- Submersible Pump - Wikipedia, The Free EncyclopediaDocument3 paginiSubmersible Pump - Wikipedia, The Free EncyclopediafloredaÎncă nu există evaluări

- WWW - Instreng.com Community Threads Selection-Of-Displace PDFDocument8 paginiWWW - Instreng.com Community Threads Selection-Of-Displace PDFfloredaÎncă nu există evaluări

- Intertec Hess Gmbh2Document2 paginiIntertec Hess Gmbh2floredaÎncă nu există evaluări

- Sensor Us Korrektur CorrectedDocument14 paginiSensor Us Korrektur CorrectedfloredaÎncă nu există evaluări

- ChemEngineering - Process Flow DiagramsDocument3 paginiChemEngineering - Process Flow DiagramsfloredaÎncă nu există evaluări

- Critical P & ID Reviews Using HAZOP-LOPA Methodology OverkilDocument3 paginiCritical P & ID Reviews Using HAZOP-LOPA Methodology OverkilfloredaÎncă nu există evaluări

- Cat. HY15-3502CPCDocument56 paginiCat. HY15-3502CPCMaximiliano Dreyer100% (1)

- Flare KO Drum Rev 2Document11 paginiFlare KO Drum Rev 2soufienÎncă nu există evaluări

- Viscous Fluid FlowDocument15 paginiViscous Fluid FlowManander SInghÎncă nu există evaluări

- Stopple ProceduresDocument3 paginiStopple ProceduresBensmatÎncă nu există evaluări

- Piping InputDocument17 paginiPiping InputkarunaÎncă nu există evaluări

- Daily follow-up of PTW systemDocument26 paginiDaily follow-up of PTW systemDie HArdÎncă nu există evaluări

- A 3D Analytical Model For Vortex Velocity Field Based On Spiral Streamline PatternDocument9 paginiA 3D Analytical Model For Vortex Velocity Field Based On Spiral Streamline PatternMohammad BayatlarÎncă nu există evaluări

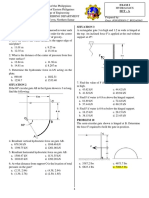

- Republic of The Philippines: Exam 2Document4 paginiRepublic of The Philippines: Exam 2Jan Jan AnoÎncă nu există evaluări

- Lab 5Document9 paginiLab 5Cem UsmangilÎncă nu există evaluări

- Anderson, Modern Compressible Flow SolutionDocument135 paginiAnderson, Modern Compressible Flow SolutionSerkan Demirhan16% (43)

- Optimization of Piping Layout With Respect To Pressure and Temperature Using Caeser-IiDocument6 paginiOptimization of Piping Layout With Respect To Pressure and Temperature Using Caeser-IichabibÎncă nu există evaluări

- NSFMW 2016 - Technical PapersDocument467 paginiNSFMW 2016 - Technical PapersMalouk Cheniouni100% (1)

- In-Line Check Valves: SpecificationsDocument2 paginiIn-Line Check Valves: SpecificationsyorisfmÎncă nu există evaluări

- Chapter 3Document59 paginiChapter 3megaadjiÎncă nu există evaluări

- Hydraulic CalculationDocument46 paginiHydraulic CalculationBader ShrbajiÎncă nu există evaluări

- CFD Analysis of Flow Through Turbine Blade in 2D Cooling Channel With Square Rib TurbulatorsDocument4 paginiCFD Analysis of Flow Through Turbine Blade in 2D Cooling Channel With Square Rib TurbulatorserpublicationÎncă nu există evaluări

- 330D L Excavator Pilot Hydraulic System DocumentationDocument8 pagini330D L Excavator Pilot Hydraulic System DocumentationMiguel Angel Garrido CardenasÎncă nu există evaluări

- Calculate flow rate and pipe sizing for centrifugal pump moving CPODocument25 paginiCalculate flow rate and pipe sizing for centrifugal pump moving CPOEka SafitriÎncă nu există evaluări

- Nozzle Pressure Distribution TestDocument1 paginăNozzle Pressure Distribution TestsaravananiniafiaÎncă nu există evaluări

- Load Control ValvesDocument18 paginiLoad Control ValvesMusa ArysÎncă nu există evaluări