Documente Academic

Documente Profesional

Documente Cultură

Tech - 16a2d0707412ca70pct 100 071

Încărcat de

lockas2220 evaluări0% au considerat acest document util (0 voturi)

78 vizualizări2 paginiThe PCT-100 represents a system typically found in the process industry. It consists of Process Units Control Module with power Supply, together with a comprehensive interactive control program. The software has been developed to act as an inclusive PID teaching tool and provides historical data trending features.

Descriere originală:

Titlu original

TECH_16A2D0707412CA70PCT-100-071

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThe PCT-100 represents a system typically found in the process industry. It consists of Process Units Control Module with power Supply, together with a comprehensive interactive control program. The software has been developed to act as an inclusive PID teaching tool and provides historical data trending features.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

78 vizualizări2 paginiTech - 16a2d0707412ca70pct 100 071

Încărcat de

lockas222The PCT-100 represents a system typically found in the process industry. It consists of Process Units Control Module with power Supply, together with a comprehensive interactive control program. The software has been developed to act as an inclusive PID teaching tool and provides historical data trending features.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

Bytronic Ltd PCT-100-071

Process Control Technology

Model: PCT-100

GENERAL DESCRIPTION

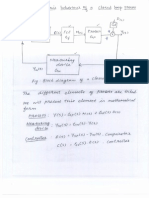

The PCT-100 Process Control Technology unit

represents a system typically found in the process

industry.

The PCT-100 consists of Process Units Control

Module with Power Supply, together with a

comprehensive interactive control program. The

software has been developed to act as an inclusive PID

teaching tool and provides historical data trending

features.

The Control Module contains signal conditioning and

connections to allow both PC and PLC control. There

are also connections provided to allow connection to a

PID controller. The control module also contains a

diagram of the process.

Exercises for the PCT-100 begin with setting up and

executing a process cycle, through to optimising the

PID controllers by estimating P, PI and PID parameters

using Ziegler Nichols process reaction curve or

ultimate cycle methods. Formulation of problems and

resulting solutions coupled with bench-marking are

manifest through tutorials.

Liquid contained in a Sump Tank is pumped around

the process unit to a Process Tank where it can be

heated. The flow rate and the heat input can be

controlled manually, or via a PC, a PLC or a PID

controller.

PT100 temperature sensors are used to determine the

temperature of the liquid in the Sump Tank and the

Process, and a radiator with forced air cooling.

In addition to supplying this data to the controller, it is

also displayed on LCD displays. An impeller type flow

meter is used to determine the flow rate, the data from

which is supplied both to the controller and also to an

LCD display.

Transducers are used to detect the water level and for

pressure measurement within the process tank. Liquid

level measurement is achieved using a magnetostrictive

sensor.

The liquid in the process tank can be heated using a

400W heating element. The power being input from

the heater is shown on an LCD display.

The PCT-100 allows the investigation of:

Control of discrete processes

PID control

Temperature, Level, Pressure and Flow control

Graphical Monitoring of real time processes.

Bytronic Ltd PCT-100-071

Technical Specification

Sump tank volume 7.8 L

Process tank volume 4.2 L

Heating element power 400W

Maximum flow rate 2.2L/min

Indicator lamp ratings T1.5 L.E.S. 24V 1W @ 0.04A

Actuator voltage 24Vdc

Fuse types All 20mm quick blow type

Power Supply Voltage 100-250V AC @ 50/60Hz.

Level Transducer Magnetostrictive

Pressure Transducer Differential

Number of LCD Displays 5

Approximate Weight 42Kg

Approximate Dimensions 91x76x35cm

Ordering Information.

Model Number PC controlled version PCT-100

Consists of:

1 x Process Unit

1 x Control Module with Power Supply

1 x USB Connecting Cable

1 x User Manual

1 x Software CD

1 x Set of Spare Fuses

Notes.

1. Specification is subject to change without notice.

2. All dimensions are in mm unless otherwise stated

Bytronic Ltd., reserves the right to make product improvements at any time and without notice and is not responsible for typographical

errors. Bytronic Ltd., recognise all product names used herein as trademarks or registered trademarks of their respective holders.

S-ar putea să vă placă și

- PCT100Document2 paginiPCT100lockas222Încă nu există evaluări

- Proses Trainer DatasheetDocument2 paginiProses Trainer DatasheetDenny ChrisnandaÎncă nu există evaluări

- Bytronic SistemDocument6 paginiBytronic SistemSedat IriçÎncă nu există evaluări

- Process Control Lab Experiment on PCT-100 Flow ControlDocument10 paginiProcess Control Lab Experiment on PCT-100 Flow ControlBagas Ghosa HidajatÎncă nu există evaluări

- PCT23MkII _ Process Plant Trainer (Process Control Trainer)Document10 paginiPCT23MkII _ Process Plant Trainer (Process Control Trainer)veronicaÎncă nu există evaluări

- Design and Application of Marine Boiler Control System Based On PLC and Touch ScreenDocument4 paginiDesign and Application of Marine Boiler Control System Based On PLC and Touch ScreenWai Min ThuÎncă nu există evaluări

- Water Level Control System PCT-100Document10 paginiWater Level Control System PCT-100Danang Pradika PurnomoÎncă nu există evaluări

- PID control of tank level using PLC and simulationDocument9 paginiPID control of tank level using PLC and simulationarnisiÎncă nu există evaluări

- Implementation of A Temperature Control Process Trainer Through PID Controller Designed With Siemens S7-1200 PLC and HMI: Proceedings of ICCDN 2018Document9 paginiImplementation of A Temperature Control Process Trainer Through PID Controller Designed With Siemens S7-1200 PLC and HMI: Proceedings of ICCDN 2018mailforfun540Încă nu există evaluări

- Automation and Process Control CRT - Temperature Control and Regulation Study UnitDocument4 paginiAutomation and Process Control CRT - Temperature Control and Regulation Study Unitjoao0honoratoÎncă nu există evaluări

- Pressure Control TrainerDocument1 paginăPressure Control TrainerVirender RanaÎncă nu există evaluări

- Se201 (A4)Document4 paginiSe201 (A4)Mehran Rasheed GorayaÎncă nu există evaluări

- Instruction Manual: Pid Based Pressure Loop TrainerDocument28 paginiInstruction Manual: Pid Based Pressure Loop TrainerKiran BennyÎncă nu există evaluări

- PCT100 PL0214Document2 paginiPCT100 PL0214Wael AhmedÎncă nu există evaluări

- Tech - 09bb259606301e9cpct 200 081Document4 paginiTech - 09bb259606301e9cpct 200 081AhmedAmer1Încă nu există evaluări

- The PROCON PH Process Control System Is Based Around The PH Rig and Is A SelfDocument10 paginiThe PROCON PH Process Control System Is Based Around The PH Rig and Is A Selfmiantahir89Încă nu există evaluări

- Process Control Trainer Technical Specs and SoftwareDocument5 paginiProcess Control Trainer Technical Specs and SoftwareAika CatalanÎncă nu există evaluări

- Electronic PID Controller Design ReportDocument19 paginiElectronic PID Controller Design ReportRatoka LekhemaÎncă nu există evaluări

- Level Control TrainerDocument1 paginăLevel Control TrainerVirender RanaÎncă nu există evaluări

- Control Boiler Operation PLC-SCADADocument26 paginiControl Boiler Operation PLC-SCADAKannan S100% (2)

- PCT-100 Flow Control ExperimentDocument10 paginiPCT-100 Flow Control ExperimentIlham JatiÎncă nu există evaluări

- TBMC12Document10 paginiTBMC12Joel E ValenciaÎncă nu există evaluări

- Kfetrkt: Plant T) Process KeDocument4 paginiKfetrkt: Plant T) Process KeAmogh RÎncă nu există evaluări

- Training on Instrumentation & Controls BasicsDocument28 paginiTraining on Instrumentation & Controls BasicsLe Manh Hai100% (1)

- Ys MilleniumDocument32 paginiYs MilleniumGaraFerrer100% (3)

- Development of A Temperature Control System: Hakan AYKULU 20083263 Department of Computer EngineeringDocument23 paginiDevelopment of A Temperature Control System: Hakan AYKULU 20083263 Department of Computer EngineeringHakan AykuluÎncă nu există evaluări

- Process Control Servo SystemDocument16 paginiProcess Control Servo SystemCarlos RamirezÎncă nu există evaluări

- Item Reference Description Qty.: Refrigeration. Medium Module (5 Cai + Cal) Ref: 0911/5SDocument6 paginiItem Reference Description Qty.: Refrigeration. Medium Module (5 Cai + Cal) Ref: 0911/5SA94leo14hsetmaÎncă nu există evaluări

- Procon: Process Control Training SystemsDocument8 paginiProcon: Process Control Training SystemsJunaid AhmadÎncă nu există evaluări

- Item Reference Description Qty.: Refrigeration. Medium Module (20 Cai + Cal) Ref: 0911/20SDocument6 paginiItem Reference Description Qty.: Refrigeration. Medium Module (20 Cai + Cal) Ref: 0911/20SA94leo14hsetmaÎncă nu există evaluări

- PID & PLC Controllers ExplainedDocument4 paginiPID & PLC Controllers ExplainedRadab HameedÎncă nu există evaluări

- Temperature Control Trainer PID TuningDocument17 paginiTemperature Control Trainer PID TuningRohit KalyanÎncă nu există evaluări

- Or As Telecommunications, Water and Waste Control, Energy, Oil and Gas Refining and TransportationDocument5 paginiOr As Telecommunications, Water and Waste Control, Energy, Oil and Gas Refining and TransportationRoshan RaiÎncă nu există evaluări

- Computer Controlled Heat Exchangers Training System with SCADA and PID ControlDocument37 paginiComputer Controlled Heat Exchangers Training System with SCADA and PID ControlMusa MohammadÎncă nu există evaluări

- Item Reference Description Qty.: Heating Module (5 Cai + Cal) Ref: 0940/5SDocument3 paginiItem Reference Description Qty.: Heating Module (5 Cai + Cal) Ref: 0940/5SA94leo14hsetmaÎncă nu există evaluări

- Design PID Controller PLCDocument8 paginiDesign PID Controller PLCankit407Încă nu există evaluări

- Item Reference Description Qty.: Heating Module Ref: 0940Document3 paginiItem Reference Description Qty.: Heating Module Ref: 0940A94leo14hsetmaÎncă nu există evaluări

- PLC Full ReportDocument10 paginiPLC Full ReportJian Jie0% (1)

- TRCVCDocument4 paginiTRCVCedwin dableoÎncă nu există evaluări

- Flow Instrumentation BenchDocument3 paginiFlow Instrumentation Benchadnan0% (1)

- PR Oc Ess Contr OlsDocument8 paginiPR Oc Ess Contr OlsEsteban Vanegas AlvarezÎncă nu există evaluări

- PLC Based Induction Motor Fault Detection TechniqueDocument7 paginiPLC Based Induction Motor Fault Detection Techniquedhaval2430Încă nu există evaluări

- PID CONTROLLER EXPERIMENTDocument13 paginiPID CONTROLLER EXPERIMENTMohd KhairiÎncă nu există evaluări

- Basics of Electrical Ep - 5Document16 paginiBasics of Electrical Ep - 5Dheeraj ChopraÎncă nu există evaluări

- Boiler Control Using SCADADocument9 paginiBoiler Control Using SCADAAdarsh Sunkad0% (1)

- SP1100 50Document6 paginiSP1100 50M-BasicÎncă nu există evaluări

- Computer Controlled Heat Conduction Unit, With SCADA and PID ControlDocument15 paginiComputer Controlled Heat Conduction Unit, With SCADA and PID Controlmohamadreza1368Încă nu există evaluări

- Process and Instrumentation DiagramsDocument8 paginiProcess and Instrumentation DiagramsMehul DeshpandeÎncă nu există evaluări

- FLTP EsDocument2 paginiFLTP EsRoman DominguezÎncă nu există evaluări

- Name of Work: Supply, Installation & Commissioning of PLC Based Control System For Process PlantDocument20 paginiName of Work: Supply, Installation & Commissioning of PLC Based Control System For Process PlantLUATÎncă nu există evaluări

- sbp1100j (B)Document10 paginisbp1100j (B)PVelozoÎncă nu există evaluări

- Temperature Monitoring System Based On PLCDocument8 paginiTemperature Monitoring System Based On PLCNicoleta ZanăÎncă nu există evaluări

- Process Automation Training System: Base Module: Page 1/3 02/2011Document3 paginiProcess Automation Training System: Base Module: Page 1/3 02/2011neoberoÎncă nu există evaluări

- AnswersDocument22 paginiAnswersVAIBHAV KESHAV MANGARÎncă nu există evaluări

- CTACDocument13 paginiCTACTimothy FieldsÎncă nu există evaluări

- Industrial AutomationDocument28 paginiIndustrial Automation4happy12383% (6)

- Air Compressor Study Unit: SolteqDocument4 paginiAir Compressor Study Unit: Solteqrahulpatel07Încă nu există evaluări

- Advanced Process Control: Beyond Single Loop ControlDe la EverandAdvanced Process Control: Beyond Single Loop ControlÎncă nu există evaluări

- Networked Control System: Fundamentals and ApplicationsDe la EverandNetworked Control System: Fundamentals and ApplicationsÎncă nu există evaluări

- Germany Guideline SBDocument123 paginiGermany Guideline SBlockas222Încă nu există evaluări

- Historic DeLand Building Earns LEED CertificationDocument30 paginiHistoric DeLand Building Earns LEED Certificationlockas222Încă nu există evaluări

- 04 - AbsorbersDocument11 pagini04 - AbsorbersRafael ReyesÎncă nu există evaluări

- MVC Desalination Process Modeling and AnalysisDocument44 paginiMVC Desalination Process Modeling and Analysislockas222Încă nu există evaluări

- PDC Chapter 10.1Document16 paginiPDC Chapter 10.1lockas222Încă nu există evaluări

- Supply Chain QuestionDocument22 paginiSupply Chain Questionlockas22280% (5)

- Green Building RevolutionDocument229 paginiGreen Building Revolutionlockas222Încă nu există evaluări

- Ammonia Plant DesignDocument75 paginiAmmonia Plant Designlockas22288% (16)

- Design of Acetone HYSYSDocument6 paginiDesign of Acetone HYSYSlockas222100% (1)

- 04 - AbsorbersDocument11 pagini04 - AbsorbersRafael ReyesÎncă nu există evaluări

- Chapter 4 Shell and Tube Heat ExchangersDocument45 paginiChapter 4 Shell and Tube Heat Exchangerslockas222Încă nu există evaluări

- PDC CH 10.3 (Problems)Document6 paginiPDC CH 10.3 (Problems)lockas222Încă nu există evaluări

- Manufacturing Process FertilizerDocument14 paginiManufacturing Process FertilizermoentaseerÎncă nu există evaluări

- Chapter 7Document28 paginiChapter 7lockas222Încă nu există evaluări

- Manufacturing Process FertilizerDocument14 paginiManufacturing Process FertilizermoentaseerÎncă nu există evaluări

- Chapter 4Document106 paginiChapter 4lockas222Încă nu există evaluări

- Fluid Mechanics IntroductionDocument49 paginiFluid Mechanics IntroductionIastraÎncă nu există evaluări

- Acetone BDocument9 paginiAcetone BIrdani IdrisÎncă nu există evaluări

- Start AgainDocument1 paginăStart Againlockas222Încă nu există evaluări

- BackgroundDocument9 paginiBackgroundlockas222Încă nu există evaluări

- Start AgainDocument1 paginăStart Againlockas222Încă nu există evaluări

- BackgroundDocument9 paginiBackgroundlockas222Încă nu există evaluări

- Material BalanceDocument42 paginiMaterial Balancealireza_e_20% (1)

- A Summary of Thermodynamic FundamentalsDocument11 paginiA Summary of Thermodynamic Fundamentalslockas222Încă nu există evaluări

- Neraca Massa ATKDocument49 paginiNeraca Massa ATKMuhammad KholidinÎncă nu există evaluări

- Neraca Massa ATKDocument49 paginiNeraca Massa ATKMuhammad KholidinÎncă nu există evaluări

- Adaptive PID and Model Reference Adaptive Control SwitchDocument16 paginiAdaptive PID and Model Reference Adaptive Control Switchnarimen lamis rezkiÎncă nu există evaluări

- Wisetherm F/FH: " " " " High Performance Digital Muffle FurnacesDocument1 paginăWisetherm F/FH: " " " " High Performance Digital Muffle FurnacesAnonymous zpNy2bltÎncă nu există evaluări

- ElectronoobsDocument5 paginiElectronoobsTaufiq QurahmanÎncă nu există evaluări

- COOLER MANUAL 2 (Process)Document112 paginiCOOLER MANUAL 2 (Process)YhaneÎncă nu există evaluări

- Vision-Based Guidance and Navigation For Autonomous MAV in Indoor EnvironmentDocument5 paginiVision-Based Guidance and Navigation For Autonomous MAV in Indoor EnvironmentDRathikaÎncă nu există evaluări

- Safe Manual Control of Unstable Systems: Johan ÅkessonDocument57 paginiSafe Manual Control of Unstable Systems: Johan Åkessonjackngare99Încă nu există evaluări

- Presentation On " Free Governor Mode Operation"Document72 paginiPresentation On " Free Governor Mode Operation"Dileep VarmaÎncă nu există evaluări

- Controlador MCCDocument4 paginiControlador MCCJuan RiosÎncă nu există evaluări

- PI500A Series Basic Frequency Inverter User Manual: 1. ForewordDocument16 paginiPI500A Series Basic Frequency Inverter User Manual: 1. ForewordOdali BatistaÎncă nu există evaluări

- 2013 Arduino PID Lab 0Document7 pagini2013 Arduino PID Lab 0Uma MageshwariÎncă nu există evaluări

- Flotation Control and OptimisationDocument11 paginiFlotation Control and OptimisationAmalia PănescuÎncă nu există evaluări

- K Tek At200Document40 paginiK Tek At200mrkssastryÎncă nu există evaluări

- Turbin 1Document27 paginiTurbin 1Durjoy Chakraborty100% (1)

- Chapter 2Document17 paginiChapter 2api-239026214Încă nu există evaluări

- MAQ20Document4 paginiMAQ20raajitaÎncă nu există evaluări

- MM850182-3b MicroCal T500Document35 paginiMM850182-3b MicroCal T500ctmtectrol100% (2)

- Electro Hydraulics: Control Technology ConceptsDocument98 paginiElectro Hydraulics: Control Technology Concepts@nshu_theachiever88% (8)

- Backup Parameter G-TektDocument4 paginiBackup Parameter G-TektTegar PrasetyoÎncă nu există evaluări

- Course OutlineDocument3 paginiCourse OutlineJawwad AhmedÎncă nu există evaluări

- Altronics de 3000 IOI 9 08Document85 paginiAltronics de 3000 IOI 9 08Felix ZavalaÎncă nu există evaluări

- DEMC Programmer's Reference ManualDocument18 paginiDEMC Programmer's Reference ManualRaul Gil BayardoÎncă nu există evaluări

- Load Frequency Control For Power Systems Via DMCDocument6 paginiLoad Frequency Control For Power Systems Via DMCEXPRESS UPDATEÎncă nu există evaluări

- Beko Metpoint Måleteknologi AVS-DanmarkDocument8 paginiBeko Metpoint Måleteknologi AVS-DanmarkLinh NgoÎncă nu există evaluări

- Anyhertz Drive2014811141513711Document6 paginiAnyhertz Drive2014811141513711Jose EspinozaÎncă nu există evaluări

- Frequency Response With MATLAB ExamplesDocument107 paginiFrequency Response With MATLAB ExamplesDisco JockeyÎncă nu există evaluări

- Distillation Absorption StrippingDocument12 paginiDistillation Absorption StrippingLulav BarwaryÎncă nu există evaluări

- Pid Tuning ClassicalDocument18 paginiPid Tuning ClassicalVo Quang HuyÎncă nu există evaluări

- Control Approaches For Magnetic LevitationDocument11 paginiControl Approaches For Magnetic Levitationambachew bizunehÎncă nu există evaluări

- Eet272 Wired CourseDocument10 paginiEet272 Wired CourseJessica RossÎncă nu există evaluări