Documente Academic

Documente Profesional

Documente Cultură

Materials-Lateral Expansion-At Cryogenic Temperature

Încărcat de

ManivannanMudhaliar0 evaluări0% au considerat acest document util (0 voturi)

81 vizualizări2 paginiCharpy test

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentCharpy test

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

81 vizualizări2 paginiMaterials-Lateral Expansion-At Cryogenic Temperature

Încărcat de

ManivannanMudhaliarCharpy test

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

Materials & Welding

materials-welding lateral expans

Search this group

lateral expanion

Options

/group/materials-w ce2cbe9e3c31a3

lateral expansion Apr 1, 11:49 am GANESH GANES Materials & Weldi

View profile More options Apr 1, 11:49 am

Friends,

One of our Pqr is failed twice, material stainless stell 316l grade , welded gtaw and smaw. Testing

failed in lateral expansion .

pls suggest a procedure for achieving the lateral expansion.(coupon thickness 25 mm)

Ganesh

Your Mail works best with the New Yahoo Optimized IE8. Get it NOW!

http://downloads.yahoo.com/in/internetexplorer/

Forward

Discussion subject changed to "4664] lateral expansion" by pgoswami

4664] lateral expa Apr 2, 12:38 am "pgoswami" <pgo Materials & Weldi

pgoswami

View profile Translate to Translated (View Original)

More options Apr 2, 12:38 am

Hi Mr. Ganesh,

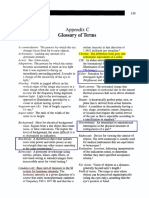

Sec-VIII, DIV-1, UHA 51, elaborates impact test requirements for austenitic S.S base metal, weld

metal and HAZ. Typically as per UHA-51(a) (4)

For 316L weld metals:-

each heat of filler metal used in production shall have a Ferrite Number 5 FN max, as

measured by a ferritescope or magna gauge, which shall be calibrated in accordance with

AWS A4.2, or as determined by applying the chemical composition from the test weld.

notch toughness testing of the base metal, weld metal, and heat affected zone (HAZ) shall be

conducted using a test temperature of 320F (196C); and each of the three specimens

from each test set shall have a lateral expansion opposite the notch not less than 0.021 in.

(0.53 mm).

What was the impact test temperature adopted in PQR qualification?

From my past experience in fabrication of cryogenic tank and other equipments, I could provide the

following guidelines:-

Get the base metal impact tested at the mill at the design temperature or less. Mills could

guarantee impact in 304/304L and 316L S.S down up to 320F (196C);

Similar guidelines should apply for welding consumables also.

Insist on Ferrite 5 FN max for 316L S.S. and consistent impact test results at 320F

(196C);

Should you have problem with 316L S.S. consumables, may think about a switch to 308L S.S,

with a MAX 2.FN. 308L electrodes usually have better impact properties than 316L S.S

electrodes.

Adopt the conventional precautions required for welding austenitic S.S.

If you still face problems, check back with the manufacturers on oxygen content in the weld

metal. However hope this issue should not be major, as S.S weld metals contain enough de-

oxidizers (Cr) to produce a very clean weld metal.

Let me know if it helps.

Thanks.

Pradip Goswami, P.Eng.

Welding & Metallurgical Engineer/Specialist

Ontario Power Generation Inc.

Email-pgoswami@sympatico.ca,pgoswami@quickclic.net

- Show quoted text -

Kobelco-

NC38LT.pdf

115K

Download

2010 Google

S-ar putea să vă placă și

- A-286 Ams 5737Document4 paginiA-286 Ams 5737Kar GayeeÎncă nu există evaluări

- Welding Literature ReviewDocument5 paginiWelding Literature Reviewfvfpvgph100% (1)

- Consumables Corner: Selecting The Right Welding Process and Filler Metal For Repair WorkDocument3 paginiConsumables Corner: Selecting The Right Welding Process and Filler Metal For Repair WorkStateÎncă nu există evaluări

- 516 Vs 515Document2 pagini516 Vs 515Madan YadavÎncă nu există evaluări

- Advanced Pressure Boundary MaterialsDocument23 paginiAdvanced Pressure Boundary MaterialstbmariÎncă nu există evaluări

- Coatings and Overlays For Critical Valve ApplicationsDocument12 paginiCoatings and Overlays For Critical Valve Applicationsnavar001Încă nu există evaluări

- Linkedin Discussion Pressure VesselDocument2 paginiLinkedin Discussion Pressure VesselAnonymous UoHUagÎncă nu există evaluări

- 2062: Hot Rolled Medium and High Tensile Structural Steel - SpecificationsDocument9 pagini2062: Hot Rolled Medium and High Tensile Structural Steel - SpecificationsKapa SandeepÎncă nu există evaluări

- Soldadura de Hierro ColadoDocument10 paginiSoldadura de Hierro ColadoclnÎncă nu există evaluări

- TestDocument10 paginiTestAnonymous BW1EW9beJqÎncă nu există evaluări

- Spot Welding Research PaperDocument4 paginiSpot Welding Research Paperuzypvhhkf100% (1)

- AstmDocument5 paginiAstmARAVIND PATILÎncă nu există evaluări

- Research Paper On Welding CareerDocument8 paginiResearch Paper On Welding Careerfvgh9ept100% (1)

- Bayu Undan / Darwin LNG Facilities Technical Delivery TermsDocument6 paginiBayu Undan / Darwin LNG Facilities Technical Delivery TermsWidodo MuisÎncă nu există evaluări

- Astm F 136 - 02Document6 paginiAstm F 136 - 02Marcos Verissimo Juca de PaulaÎncă nu există evaluări

- Friction Stir Welding ThesisDocument4 paginiFriction Stir Welding Thesisaflowlupyfcyye100% (2)

- Welding Cast IronDocument10 paginiWelding Cast IronRoberto CordovaÎncă nu există evaluări

- Electric-Resistance-Welded Low-Carbon Steel Pipe For The Chemical IndustryDocument5 paginiElectric-Resistance-Welded Low-Carbon Steel Pipe For The Chemical IndustryAlejandro GonzálezÎncă nu există evaluări

- M02 16019 v44n2p11-16OOIsiaka Nov20161Document7 paginiM02 16019 v44n2p11-16OOIsiaka Nov20161YankeeLeÎncă nu există evaluări

- UT For Duplex Stainless Steel WeldsDocument5 paginiUT For Duplex Stainless Steel WeldsvsnaiduqcÎncă nu există evaluări

- 액화수소저장탱크용스테인리스소재의레이저용접적용을위한기초연구Document8 pagini액화수소저장탱크용스테인리스소재의레이저용접적용을위한기초연구Sungwook KangÎncă nu există evaluări

- Duplex Ss WPSDocument8 paginiDuplex Ss WPSVinu Raveendran100% (1)

- Orbital Welding Research PaperDocument7 paginiOrbital Welding Research Paperaflbskzqa100% (1)

- Wrought Nitrogen Strengthened 11Manganese-17Chromium-3Molybdenum Low-Nickel Stainless Steel Alloy Bar and Wire For Surgical Implants (UNS S29225)Document5 paginiWrought Nitrogen Strengthened 11Manganese-17Chromium-3Molybdenum Low-Nickel Stainless Steel Alloy Bar and Wire For Surgical Implants (UNS S29225)Ahmad Zubair RasulyÎncă nu există evaluări

- ASTM A333 Grade 6 SpecificationDocument9 paginiASTM A333 Grade 6 SpecificationmaldonadohansÎncă nu există evaluări

- Ferrite Content Effect On Autenitic Ss Weld at Cryogenic TempDocument12 paginiFerrite Content Effect On Autenitic Ss Weld at Cryogenic TemparunkumarÎncă nu există evaluări

- A Comparative Study Into The Fracture Toughness Properties of Duplex Stainless SteelsDocument9 paginiA Comparative Study Into The Fracture Toughness Properties of Duplex Stainless Steelscehamos882Încă nu există evaluări

- Friction Stir Welding Thesis PDFDocument8 paginiFriction Stir Welding Thesis PDFcarolinalewiswashington100% (2)

- Friction Stir Welding and Post-Weld Heat Treating of Maraging Steel (Final Report)Document20 paginiFriction Stir Welding and Post-Weld Heat Treating of Maraging Steel (Final Report)scooter_scooterÎncă nu există evaluări

- A 985 - 01 Qtk4ns0wmue - PDFDocument14 paginiA 985 - 01 Qtk4ns0wmue - PDFMung Duong XuanÎncă nu există evaluări

- ThyssenKrupp - XABO 500Document3 paginiThyssenKrupp - XABO 500Yesid Javier Martelo EllesÎncă nu există evaluări

- Weldability Studies and Parameter Optimization of AISI 904L Super Austenitic Stainless Steel Using Friction WeldingDocument18 paginiWeldability Studies and Parameter Optimization of AISI 904L Super Austenitic Stainless Steel Using Friction Weldinggabesh3192Încă nu există evaluări

- Mechanical Testing: Notched Bar or Impact Testing. Part IIDocument4 paginiMechanical Testing: Notched Bar or Impact Testing. Part IIMehmet Soysal100% (1)

- SEP - 1390e 1996 07Document3 paginiSEP - 1390e 1996 07Vijayakumar SamyÎncă nu există evaluări

- F1472Document5 paginiF1472Antonio JÎncă nu există evaluări

- Tig Welding Research PapersDocument8 paginiTig Welding Research Papersfyrj7h9z100% (3)

- Tensile and Chemical Analyses of Selected Steel Bars Produced in NigeriaDocument6 paginiTensile and Chemical Analyses of Selected Steel Bars Produced in NigeriaSalih MohayaddinÎncă nu există evaluări

- Site Cast Tilt Up Concrete Version 18 1Document4 paginiSite Cast Tilt Up Concrete Version 18 1Prakash RajÎncă nu există evaluări

- Steel Castings, Austenitic Manganese: Standard Specification ForDocument2 paginiSteel Castings, Austenitic Manganese: Standard Specification ForJosé Ramón GutierrezÎncă nu există evaluări

- Electric-Resistance-Welded Low-Carbon Steel Pipe For The Chemical IndustryDocument5 paginiElectric-Resistance-Welded Low-Carbon Steel Pipe For The Chemical IndustryRoland CepedaÎncă nu există evaluări

- Lesson X 10.9.3 Coating Moisture Test - The Coating Moisture Test Is Conducted by Removing ADocument1 paginăLesson X 10.9.3 Coating Moisture Test - The Coating Moisture Test Is Conducted by Removing AcrysÎncă nu există evaluări

- Lesson 10 - 13 PDFDocument1 paginăLesson 10 - 13 PDFcrysÎncă nu există evaluări

- A193B7 MaxTemp AllwbleStress - Portland BoltDocument5 paginiA193B7 MaxTemp AllwbleStress - Portland BoltAnonymous nw5AXJqjdÎncă nu există evaluări

- How To Weld Cast Iron - 8 Steps (With Pictures) - WikiHowDocument3 paginiHow To Weld Cast Iron - 8 Steps (With Pictures) - WikiHowzidaaanÎncă nu există evaluări

- AAR TC 128 GR B Weld Failure Analysis - EdittedDocument3 paginiAAR TC 128 GR B Weld Failure Analysis - Edittedamir ghabraeiÎncă nu există evaluări

- Materials System SpecificationDocument13 paginiMaterials System SpecificationMoustafa Bayoumi100% (1)

- F594Document7 paginiF594Gonzalo Guerrero CáceresÎncă nu există evaluări

- Astm A264 (1999)Document8 paginiAstm A264 (1999)Vo Trong ThaiÎncă nu există evaluări

- 3 Edwin NT JongDocument15 pagini3 Edwin NT JongfelixÎncă nu există evaluări

- Welding Research Paper TopicsDocument8 paginiWelding Research Paper Topicscaqllprhf100% (1)

- (Structural) 10 Feb 09 11:34: Hogan666Document3 pagini(Structural) 10 Feb 09 11:34: Hogan666naspauzanÎncă nu există evaluări

- JFE - Clad PlatesDocument26 paginiJFE - Clad PlatestndeshmukhÎncă nu există evaluări

- Astm F837 2008Document8 paginiAstm F837 2008Jesse ChenÎncă nu există evaluări

- Stainless Steel Bolts, Hex Cap Screws, and Studs: Standard Specification ForDocument8 paginiStainless Steel Bolts, Hex Cap Screws, and Studs: Standard Specification ForAlejandro ValdesÎncă nu există evaluări

- Conical ThreadDocument9 paginiConical ThreadAnonymous D5QForitcÎncă nu există evaluări

- Ferrite Limitation For SS316LDocument12 paginiFerrite Limitation For SS316LAntonio PerezÎncă nu există evaluări

- Farm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape MetalDe la EverandFarm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape MetalEvaluare: 4.5 din 5 stele4.5/5 (3)

- The Essentials of Material Science and Technology for EngineersDe la EverandThe Essentials of Material Science and Technology for EngineersEvaluare: 5 din 5 stele5/5 (1)

- Farm and Workshop Welding, Third Revised Edition: Everything You Need to Know to Weld, Cut, and Shape MetalDe la EverandFarm and Workshop Welding, Third Revised Edition: Everything You Need to Know to Weld, Cut, and Shape MetalÎncă nu există evaluări

- Applied Welding Engineering: Processes, Codes, and StandardsDe la EverandApplied Welding Engineering: Processes, Codes, and StandardsÎncă nu există evaluări

- PT PRO FOR ExamDocument3 paginiPT PRO FOR ExamManivannanMudhaliarÎncă nu există evaluări

- The European Pressure Equipment Directive (Ped)Document6 paginiThe European Pressure Equipment Directive (Ped)ManivannanMudhaliarÎncă nu există evaluări

- National Step Tablet Vs Step Wedge Comparision FilmDocument4 paginiNational Step Tablet Vs Step Wedge Comparision FilmManivannanMudhaliarÎncă nu există evaluări

- HAC CrackDocument8 paginiHAC CrackManivannanMudhaliarÎncă nu există evaluări

- PED02Document7 paginiPED02ManivannanMudhaliarÎncă nu există evaluări

- Convex and Concave MirrorDocument2 paginiConvex and Concave MirrorManivannanMudhaliarÎncă nu există evaluări

- Aluminum Welding ProceduresDocument8 paginiAluminum Welding ProceduresManivannanMudhaliar0% (1)

- May 2014 - Risk Assessment - Make It Easier Than It AppearsDocument4 paginiMay 2014 - Risk Assessment - Make It Easier Than It AppearsManivannanMudhaliarÎncă nu există evaluări

- Welder Qualification Test CertificateDocument1 paginăWelder Qualification Test CertificateManivannanMudhaliar100% (1)

- To Avoid Nitride Precepitation in 25% CR Steel:: SL N o Ele Spec Actual Aim Preferred Aim Range PreferredDocument2 paginiTo Avoid Nitride Precepitation in 25% CR Steel:: SL N o Ele Spec Actual Aim Preferred Aim Range PreferredManivannanMudhaliarÎncă nu există evaluări

- Glossary Terms VTDocument5 paginiGlossary Terms VTManivannanMudhaliarÎncă nu există evaluări

- Webinar New Ped 2014 68 EuDocument19 paginiWebinar New Ped 2014 68 EuManivannanMudhaliar100% (1)

- Back To Basics Testing With J1 - Use ReaderDocument4 paginiBack To Basics Testing With J1 - Use ReaderManivannanMudhaliarÎncă nu există evaluări

- Note - Book - School of Applied NDTDocument29 paginiNote - Book - School of Applied NDTManivannanMudhaliarÎncă nu există evaluări

- Cobalt Base Alloy - 6 in Amine ApplicationDocument2 paginiCobalt Base Alloy - 6 in Amine ApplicationManivannanMudhaliarÎncă nu există evaluări

- Metengr: Engg Tips Forum Discussion Reg - Casting PropertiesDocument2 paginiMetengr: Engg Tips Forum Discussion Reg - Casting PropertiesManivannanMudhaliarÎncă nu există evaluări

- Energy Research: at The State University of New YorkDocument10 paginiEnergy Research: at The State University of New YorkdaniÎncă nu există evaluări

- Research Paper Front CoverDocument7 paginiResearch Paper Front Coverorotmbbkf100% (1)

- RFID TechnologyDocument20 paginiRFID TechnologyTamanna ChaudharyÎncă nu există evaluări

- Effects of Online Learning On The Selected First Year Students College of Hospitality and Tourism at Arellano University - Juan Sumulong CampusDocument6 paginiEffects of Online Learning On The Selected First Year Students College of Hospitality and Tourism at Arellano University - Juan Sumulong CampusJohn Lloyd TomacaÎncă nu există evaluări

- Powering Clinical and Operational Excellence at Cleveland Clinic With EPIC and TableauDocument46 paginiPowering Clinical and Operational Excellence at Cleveland Clinic With EPIC and TableauGreg IkeÎncă nu există evaluări

- GM Video Door Phone 2020Document5 paginiGM Video Door Phone 2020jup05Încă nu există evaluări

- Freno Motobomba PDFDocument136 paginiFreno Motobomba PDFEzequiel CeccarelliÎncă nu există evaluări

- HVAC Listing - Addendum #1Document3 paginiHVAC Listing - Addendum #1Jhonny Velasquez PerezÎncă nu există evaluări

- First 2-3 Words of Title 1Document13 paginiFirst 2-3 Words of Title 1Cherise GladneyÎncă nu există evaluări

- MCGGDocument14 paginiMCGGJesica Diaz Rodriguez100% (1)

- TUV ISO Action List 2020Document5 paginiTUV ISO Action List 2020chittineni0% (1)

- GEA - Refrigeration in Oil & Gas Industry - tcm11-33981Document4 paginiGEA - Refrigeration in Oil & Gas Industry - tcm11-33981Dhroov SharmaÎncă nu există evaluări

- Checklist Test Environment: Pass Description RemarksDocument4 paginiChecklist Test Environment: Pass Description RemarksGuru PrasadÎncă nu există evaluări

- Dbms-5-Carol - Advanced Data ModelingDocument45 paginiDbms-5-Carol - Advanced Data ModelingADE FIKRY MUSTOFAÎncă nu există evaluări

- Debug 1214Document2 paginiDebug 1214Ahmad SyifaÎncă nu există evaluări

- Christmas Tree Safety TipsDocument1 paginăChristmas Tree Safety Tipskailashch.msihraÎncă nu există evaluări

- Perrotta 22 ADocument13 paginiPerrotta 22 AZakhan KimahÎncă nu există evaluări

- Hafiz CVDocument6 paginiHafiz CVkashi4ashiÎncă nu există evaluări

- TC600EDocument2 paginiTC600ERadekÎncă nu există evaluări

- Experiment No.: Aim: - To Measure Three Phase Power and Power Factor in A Balanced Three Phase Circuit UsingDocument5 paginiExperiment No.: Aim: - To Measure Three Phase Power and Power Factor in A Balanced Three Phase Circuit Usinggejal akshmiÎncă nu există evaluări

- Multicalor 700.1 MD Multicalor 800.1 MD Multicalor 1000.1 MD Multicalor 1200.1 MDDocument24 paginiMulticalor 700.1 MD Multicalor 800.1 MD Multicalor 1000.1 MD Multicalor 1200.1 MDcristian villegasÎncă nu există evaluări

- Quality Assurance Kamera GammaDocument43 paginiQuality Assurance Kamera GammawiendaintanÎncă nu există evaluări

- William Stallings Computer Organization and Architecture 7 Edition Instruction Sets: Addressing Modes and FormatsDocument45 paginiWilliam Stallings Computer Organization and Architecture 7 Edition Instruction Sets: Addressing Modes and FormatsAlaa YounisÎncă nu există evaluări

- Sap PP Configuration DocumentDocument75 paginiSap PP Configuration DocumentRafaelCasagrandeÎncă nu există evaluări

- S. Kannadhasan (Editor), R. Nagarajan (Editor), Alagar Karthick (Editor) - Intelligent Technologies For Sensors - Applications, Design, and Optimization For A Smart World-ADocument404 paginiS. Kannadhasan (Editor), R. Nagarajan (Editor), Alagar Karthick (Editor) - Intelligent Technologies For Sensors - Applications, Design, and Optimization For A Smart World-ATruong Van HungÎncă nu există evaluări

- Icon Line Trimmer - ICPLT26 Operator ManualDocument10 paginiIcon Line Trimmer - ICPLT26 Operator ManualAnirudh Merugu67% (3)

- Augmented Reality in Medical Education Students Experiences and Learning OutcomesDocument10 paginiAugmented Reality in Medical Education Students Experiences and Learning Outcomesapi-688059491Încă nu există evaluări

- W6!7!304E Skin-Pass Mills ReferencesDocument36 paginiW6!7!304E Skin-Pass Mills Referencesdorin serbanÎncă nu există evaluări

- Dot Net Interview QuestionDocument143 paginiDot Net Interview QuestionBlack JackÎncă nu există evaluări

- Repeater Diagnostics and Control (RDAC) User Guide: November 2017Document150 paginiRepeater Diagnostics and Control (RDAC) User Guide: November 2017Cesar Del Castillo0% (1)