Documente Academic

Documente Profesional

Documente Cultură

Boltmasters Pty LTD Recommended Assembly Torques

Încărcat de

Navneet SunilTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Boltmasters Pty LTD Recommended Assembly Torques

Încărcat de

Navneet SunilDrepturi de autor:

Formate disponibile

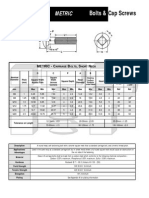

Recommended Assembly Torques

Class 4.6 ISO Metric Coarse Pitch Bolts & Screws

Diameter

M1.6

M2

M2.5

M3

M4

M5

M6

M8

M10

M12

M14

M16

M18

M20

M22

M24

M27

M30

M33

M36

M39

M42

M48

M56

M64

Pitch (mm)

0.35

0.40

0.45

0.50

0.70

0.80

1.00

1.25

1.50

1.75

2.00

2.00

2.50

2.50

2.50

3.00

3.00

3.50

3.50

4.00

4.00

4.50

5.00

5.50

6.00

Bolt Tension

Corresponding to

65% of Proof Load

kN

0.19

0.31

0.50

0.73

1.29

2.08

2.94

5.34

8.45

12.4

16.8

22.9

28.1

35.8

44.3

51.6

67

81.9

101

120

143

164

215

298

393

To convert kN to lbf; Multiply Kn by 224.809

To convert Nm to lbft: Multiply Nm by 0.737562

Surface Condition Torque Adjustment Factors

x 1.0

Plain Steel, as supplied

Plain Steel, degreased

x 2.0

Zinc Plated, as supplied

x 1.0

Zinc Plated, lightly oiled

x 0.9

Galvanised, degreased

x 2.1

Galvanised, lightly oiled

x 1.1

Heavily greased

x 0.7

Recommended

Assembly

Torque

Nm

0.06

0.12

0.25

0.44

1

2.1

3.5

8.5

17

30

47

73

101

143

195

248

362

491

669

864

1115

1378

2064

3338

5030

Recommended Assembly Torques

BSW Mild Steel Bolts & Screws

Diameter

1/4

5/16

3/8

7/16

1/2

5/8

3/4

7/8

1

1.1/8

1.1/4

1.1/2

Threads Per Inch

(TPI)

20

18

16

14

12

11

10

9

8

7

7

6

Bolt Tension

Corresponding to

65% of Proof Load

lbf

Recommended

Assembly

Torque

lbft

736

1208

1786

2451

3176

5206

7705

10641

13943

17566

22473

32334

3

6

11

18

26

54

96

155

232

329

468

808

To convert kN to lbf; Multiply Kn by 224.809

To convert Nm to lbft: Multiply Nm by 0.737562

Surface Condition Torque Adjustment Factors

x 1.0

Plain Steel, as supplied

Plain Steel, degreased

x 2.0

Zinc Plated, as supplied

x 1.0

Zinc Plated, lightly oiled

x 0.9

Galvanised, degreased

x 2.1

Galvanised, lightly oiled

x 1.1

Heavily greased

x 0.7

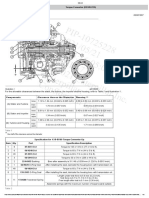

Recommended Assembly Torques

Class 8.8 ISO Metric Coarse Pitch Bolts & Screws

Diameter

M1.6

M2

M2.5

M3

M4

M5

M6

M8

M10

M12

M14

M16

M18

M20

M22

M24

M27

M30

M33

M36

M39

M42

M48

M56

M64

Pitch (mm)

0.35

0.40

0.45

0.50

0.70

0.80

1.00

1.25

1.50

1.75

2.00

2.00

2.50

2.50

2.50

3.00

3.00

3.50

3.50

4.00

4.00

4.50

5.00

5.50

6.00

Bolt Tension

Corresponding to

65% of Proof Load

kN

0.48

0.78

1.28

1.9

3.32

5.35

7.54

13.8

21.9

31.8

43.4

59.2

74.8

95.6

118

138

179

219

270

319

380

437

573

792

1045

To convert kN to lbf; Multiply Kn by 224.809

To convert Nm to lbft: Multiply Nm by 0.737562

Surface Condition Torque Adjustment Factors

x 1.0

Plain Steel, degreased

x 2.0

Zinc Plated, as supplied

x 1.0

Zinc Plated, lightly oiled

x 0.9

Galvanised, degreased

x 2.1

Galvanised, lightly oiled

x 1.1

Heavily greased

x 0.7

Plain Steel, as supplied

Recommended

Assembly

Torque

Nm

0.15

0.31

0.64

1.1

2.7

5

9

22

44

77

122

190

269

372

519

640

967

1314

1782

2297

2970

3671

5500

8870

13376

Recommended Assembly Torques

Class 10.9 ISO Metric Coarse Pitch Bolts & Screws

Diameter

M5

M6

M8

M10

M12

M14

M16

M18

M20

M22

M24

M27

M30

M33

M36

M39

Pitch (mm)

0.80

1.00

1.25

1.50

1.75

2.00

2.00

2.50

2.50

2.50

3.00

3.00

3.50

3.50

4.00

4.00

Bolt Tension

Corresponding to

65% of Proof Load

kN

7.67

10.9

19.8

31.3

45.5

62.1

84.5

103

132

164

190

248

303

371

441

527

To convert kN to lbf; Multiply Kn by 224.809

To convert Nm to lbft: Multiply Nm by 0.737562

Surface Condition Torque Adjustment Factors

x 1.0

Plain Steel, degreased

x 2.0

Zinc Plated, as supplied

x 1.0

Zinc Plated, lightly oiled

x 0.9

Galvanised, degreased

x 2.1

Galvanised, lightly oiled

x 1.1

Heavily greased

x 0.7

Plain Steel, as supplied

Recommended

Assembly

Torque

Nm

8

13

32

63

109

174

270

371

528

722

914

1339

1817

2449

3173

4110

Recommended Assembly Torques

Class 12.9 ISO Metric Coarse Pitch Bolts & Screws

Diameter

M3

M4

M5

M6

M8

M10

M12

M14

M16

M18

M20

M22

M24

M27

M30

M33

M36

Pitch (mm)

0.50

0.70

0.80

1.00

1.25

1.50

1.75

2.00

2.00

2.50

2.50

2.50

3.00

3.00

3.50

3.50

4.00

Bolt Tension

Corresponding to

65% of Proof Load

kN

3.17

5.54

8.97

12.7

23.1

36.6

53.2

72.8

98.8

121

155

191

222

289

354

437

515

To convert kN to lbf; Multiply Kn by 224.809

ly Nm by 0.737562

Surface Condition Torque Adjustment Factors

x 1.0

Plain Steel, degreased

x 2.0

Zinc Plated, as supplied

x 1.0

Zinc Plated, lightly oiled

x 0.9

Galvanised, degreased

x 2.1

Galvanised, lightly oiled

x 1.1

Heavily greased

x 0.7

Plain Steel, as supplied

Recommended

Assembly

Torque

Nm

1.9

4.4

8.9

15

37

73

128

203

316

436

620

840

1066

1561

2124

2884

3708

Recommended Assembly Torques

SAE Grade 5 Bolts & Screws UNF Thread

Diameter

1/4

5/16

3/8

7/16

1/2

9/16

5/8

3/4

7/8

1

1.1/8

1.1/4

1.3/8

1.1/2

Threads Per Inch

(TPI)

28

24

24

20

20

18

18

16

14

12

12

12

12

12

Bolt Tension

Corresponding to

65% of Proof Load

lbf

Recommended

Assembly

Torque

lbft

2010

3180

4840

6560

8840

11240

14170

20600

28100

36600

41100

51600

63200

76000

8

17

30

48

74

105

148

258

410

610

771

1075

1448

1900

To convert kN to lbf; Multiply Kn by 224.809

To convert Nm to lbft: Multiply Nm by 0.737562

Surface Condition Torque Adjustment Factors

x 1.0

Plain Steel, as supplied

Plain Steel, degreased

x 2.0

Zinc Plated, as supplied

x 1.0

Zinc Plated, lightly oiled

x 0.9

Galvanised, degreased

x 2.1

Galvanised, lightly oiled

x 1.1

Heavily greased

x 0.7

Recommended Assembly Torques

SAE Grade 8 Bolts & Screws UNF Thread

Diameter

1/4

5/16

3/8

7/16

1/2

9/16

5/8

3/4

7/8

1

1.1/8

1.1/4

1.3/8

1.1/2

Threads Per Inch

(TPI)

28

24

24

20

20

18

18

16

14

12

12

12

12

12

Bolt Tension

Corresponding to

65% of Proof Load

lbf

Recommended

Assembly

Torque

lbft

2820

4510

6820

9230

12480

15860

19950

29120

39700

51700

66700

83700

102500

123300

12

23

43

67

104

149

208

364

549

862

1241

1744

2349

3083

SAE Grade 5 & 8 Bolts & Screws 1 SAE

Diameter 1 SAE

Grade 5

Grade 8

Threads Per Inch

(TPI)

14

14

Bolt Tension

Corresponding to

65% of Proof Load

lbf

Recommended

Assembly

Torque

lbft

37500

53000

625

883

To convert kN to lbf; Multiply Kn by 224.809

To convert Nm to lbft: Multiply Nm by 0.737562

Surface Condition Torque Adjustment Factors

x 1.0

Plain Steel, as supplied

Plain Steel, degreased

x 2.0

Zinc Plated, as supplied

x 1.0

Zinc Plated, lightly oiled

x 0.9

Galvanised, degreased

x 2.1

Galvanised, lightly oiled

x 1.1

Heavily greased

x 0.7

Recommended Assembly Torques

Diameter

1/4

5/16

3/8

7/16

1/2

9/16

5/8

3/4

7/8

1

1.1/8

1.1/4

1.3/8

1.1/2

1.3/4

2

2.1/4

2.1/2

2.3/4

3

3.1/4

3.1/2

3.3/4

4

SAE Grade 5 Bolts & Screws UNC Thread

Bolt Tension

Corresponding to

65% of Proof Load

Thread Per Inch

lbf

(TPI)

20

1760

18

2890

16

4290

14

5880

13

7860

12

10070

11

12480

10

18460

9

25550

8

33470

7

36700

7

46600

6

55500

6

67600

5

91300

4.5

120200

4.5

156300

4

192400

4

237100

4

287100

4

341500

4

400600

4

464600

4

532900

To convert kN to lbf; Multiply Kn by 224.809

To convert Nm to lbft: Multiply Nm by 0.737562

Surface Condition Torque Adjustment Factors

x 1.0

Plain Steel, degreased

x 2.0

Zinc Plated, as supplied

x 1.0

Zinc Plated, lightly oiled

x 0.9

Galvanised, degreased

x 2.1

Galvanised, lightly oiled

x 1.1

Heavily greased

x 0.7

Plain Steel, as supplied

Recommended

Assembly

Torque

lbft

7

15

27

43

66

94

130

231

373

558

688

971

1272

1690

2663

4007

5861

8017

10867

14355

18498

23368

29038

35527

Recommended Assembly Torques

Diameter

1/4

5/16

3/8

7/16

1/2

9/16

5/8

3/4

7/8

1

1.1/8

1.1/4

1.3/8

1.1/2

1.3/4

2

2.1/4

2.1/2

2.3/4

3

3.1/4

3.1/2

3.3/4

4

SAE Grade 8 Bolts & Screws UNC Thread

Bolt Tension

Corresponding to

65% of Proof Load

Thread Per Inch

lbf

(TPI)

20

2470

18

4090

16

6040

14

8320

13

11050

12

14170

11

17610

10

26060

9

36000

8

47200

7

59500

7

75500

6

90000

6

109500

5

148200

4.5

195000

4.5

253500

4

312000

4

384500

4

465600

4

553800

4

649700

4

753400

4

864200

To convert kN to lbf; Multiply Kn by 224.809

To convert Nm to lbft: Multiply Nm by 0.737562

Surface Condition Torque Adjustment Factors

x 1.0

Plain Steel, as supplied

Plain Steel, degreased

x 2.0

Zinc Plated, as supplied

x 1.0

Zinc Plated, lightly oiled

x 0.9

Galvanised, degreased

x 2.1

Galvanised, lightly oiled

x 1.1

Heavily greased

x 0.7

Recommended

Assembly

Torque

lbft

10

21

38

61

92

133

183

326

525

787

1116

1573

2063

2738

4323

6500

9506

13000

17623

23280

29998

37899

47088

57613

S-ar putea să vă placă și

- Service - Specifications Toyota ProboxDocument85 paginiService - Specifications Toyota Proboxcpgmotors83% (6)

- Weld Like a Pro: Beginning to Advanced TechniquesDe la EverandWeld Like a Pro: Beginning to Advanced TechniquesEvaluare: 4.5 din 5 stele4.5/5 (6)

- Service Manual Cat G3416eDocument753 paginiService Manual Cat G3416eUsaha MandiriÎncă nu există evaluări

- Workshop Manual - Daihatsu 3 Cyl 993cc EFIDocument182 paginiWorkshop Manual - Daihatsu 3 Cyl 993cc EFIrhozel201082% (11)

- Unc Unf Metric Thread Chart Northwest FastenerDocument1 paginăUnc Unf Metric Thread Chart Northwest FastenerthailanÎncă nu există evaluări

- Torque Details-Hex Bolt DIN 933Document2 paginiTorque Details-Hex Bolt DIN 933coolkaisy100% (2)

- Ac 036630 001Document1 paginăAc 036630 001navaronefraÎncă nu există evaluări

- Screw Threadlec12 MergedDocument90 paginiScrew Threadlec12 MergedJames EstradaÎncă nu există evaluări

- DBM2000 XS - DBM2000 EV DBM2500 EV - DBM3500 EV: Removal of Both Loader and Drum FromDocument33 paginiDBM2000 XS - DBM2000 EV DBM2500 EV - DBM3500 EV: Removal of Both Loader and Drum FromNicoleta CosteaÎncă nu există evaluări

- DBM Gmec (Ing) MerloDocument87 paginiDBM Gmec (Ing) MerloNicoleta Costea83% (6)

- Method of Statement For R.C.C Jacketing - Rev.0 PDFDocument5 paginiMethod of Statement For R.C.C Jacketing - Rev.0 PDFrobin7Încă nu există evaluări

- Instruction Manual For Installing Turnasure: The Improved and CompleteDocument24 paginiInstruction Manual For Installing Turnasure: The Improved and CompleteNavneet SunilÎncă nu există evaluări

- Wire Mesh Steel Reinforcement BarsDocument6 paginiWire Mesh Steel Reinforcement Barssattar12345Încă nu există evaluări

- Pipe Thread NPT and BSPT Fittings CompatibilityDocument5 paginiPipe Thread NPT and BSPT Fittings CompatibilityEduardoÎncă nu există evaluări

- Jindal - Product Range - H BeamsDocument4 paginiJindal - Product Range - H Beams12december71% (7)

- Ware House 20-70-8 Crane 10 Ton Structural ReportDocument34 paginiWare House 20-70-8 Crane 10 Ton Structural ReportHayman AhmedÎncă nu există evaluări

- G3516e Service Manual (Gas)Document753 paginiG3516e Service Manual (Gas)Сергей Шевченко88% (17)

- Metric (ISO) Fasteners: SMCS - 7553Document5 paginiMetric (ISO) Fasteners: SMCS - 7553Jhon AlejandoÎncă nu există evaluări

- Tightening Torque1Document1 paginăTightening Torque1EngrMuhammadAzizÎncă nu există evaluări

- Test Bank For Physical Rehabilitation 7th Edition Susan B Osullivan Thomas J Schmitz George FulkDocument24 paginiTest Bank For Physical Rehabilitation 7th Edition Susan B Osullivan Thomas J Schmitz George Fulkjenniferhoustonmjcfngpbow100% (44)

- Rohm Lathe ChucksDocument91 paginiRohm Lathe ChucksNebojša ObradovićÎncă nu există evaluări

- Durco 1K 1.5 X 1-82Document9 paginiDurco 1K 1.5 X 1-82jame11inÎncă nu există evaluări

- Part DUNPER Spare Parts Catalog - PDF (TODO)Document631 paginiPart DUNPER Spare Parts Catalog - PDF (TODO)Anibal Muñoz Casas100% (3)

- Weg W21 Fastening Bolt Torque Settings: Calculation DataDocument1 paginăWeg W21 Fastening Bolt Torque Settings: Calculation Datajuanqui20Încă nu există evaluări

- Recommended Assembly Torques 2016Document9 paginiRecommended Assembly Torques 2016Mohamed ElkadyÎncă nu există evaluări

- Torque Figures: The Ralin Group LTD (Bespoke Bolting)Document1 paginăTorque Figures: The Ralin Group LTD (Bespoke Bolting)LLÎncă nu există evaluări

- Steelmasters Torque TableDocument6 paginiSteelmasters Torque TableIbrahim SaidÎncă nu există evaluări

- Maintenance Specifications: 6.1. Tightening TorqueDocument9 paginiMaintenance Specifications: 6.1. Tightening TorqueWshop2 AdminÎncă nu există evaluări

- Eg 00010 PDFDocument7 paginiEg 00010 PDFAnonymous EhdILsAwmsÎncă nu există evaluări

- 1 General Remarks: Original Installation and Maintenance Instructions For Bibby Torque Limiters With ModulesDocument13 pagini1 General Remarks: Original Installation and Maintenance Instructions For Bibby Torque Limiters With ModulesAmirmasoudÎncă nu există evaluări

- Metric (ISO) FastenerDocument4 paginiMetric (ISO) FastenermostafaÎncă nu există evaluări

- Speci Ca Ons, Mechanical Proper Es and Standards For WashersDocument1 paginăSpeci Ca Ons, Mechanical Proper Es and Standards For WashersxxixxussÎncă nu există evaluări

- TOQUES Mms.Document4 paginiTOQUES Mms.jose diego vallejos llamoÎncă nu există evaluări

- Fastenr GradesDocument5 paginiFastenr GradesVipul ShereÎncă nu există evaluări

- 914G Wheel Loader PDF00001-UP (MACHINE) POWERED BY 3054C Engine (SEBP3977 - 42) - DocumentationDocument4 pagini914G Wheel Loader PDF00001-UP (MACHINE) POWERED BY 3054C Engine (SEBP3977 - 42) - DocumentationAsfiannur ade setiawanÎncă nu există evaluări

- Metric (ISO) Fasteners: Torque SpecificationsDocument3 paginiMetric (ISO) Fasteners: Torque SpecificationsSMKN 6 SAMARINDA PANGESTUÎncă nu există evaluări

- Torque Spesification ISODocument2 paginiTorque Spesification ISODania Zataline GusenkaÎncă nu există evaluări

- Service SpecificationDocument95 paginiService SpecificationLoc TruongÎncă nu există evaluări

- 93 Camry SERVICE SPECIFICATIONS - STANDARD BOLTDocument72 pagini93 Camry SERVICE SPECIFICATIONS - STANDARD BOLTdgc513Încă nu există evaluări

- Tightening Torques For Screw JointsDocument6 paginiTightening Torques For Screw JointsTháiSơnTrầnÎncă nu există evaluări

- Metric Carriage ShortneckDocument1 paginăMetric Carriage ShortneckStefan StereaÎncă nu există evaluări

- Torque Specifications Metric BoltsDocument4 paginiTorque Specifications Metric BoltsRoy SilayenÎncă nu există evaluări

- RULAND BeLLOWS coOuplLingsSDocument6 paginiRULAND BeLLOWS coOuplLingsSduxi1981Încă nu există evaluări

- Fasteners Torque Sizes STDDocument15 paginiFasteners Torque Sizes STDyatin888Încă nu există evaluări

- Katalog AnkeraDocument20 paginiKatalog AnkeraBosko MiljevicÎncă nu există evaluări

- RITZ Screw Specification PDFDocument12 paginiRITZ Screw Specification PDFThawatchai DanwangkhawÎncă nu există evaluări

- Group 2 Tightening Torque: 1. Major ComponentsDocument3 paginiGroup 2 Tightening Torque: 1. Major ComponentsDenÎncă nu există evaluări

- Metric DIN 609 SpecDocument4 paginiMetric DIN 609 SpecCAT MINING SHOVELÎncă nu există evaluări

- Torque TableDocument1 paginăTorque TableGuido NabaesÎncă nu există evaluări

- NIS Bearing Units Catalogue PDFDocument162 paginiNIS Bearing Units Catalogue PDFMunkhnasan MonaÎncă nu există evaluări

- BP01ADocument6 paginiBP01AElancheliyanÎncă nu există evaluări

- Toyo Rubber CouplingDocument14 paginiToyo Rubber CouplingGreg SanjayaÎncă nu există evaluări

- 1521-Versys X300 Crash Bar PDFDocument4 pagini1521-Versys X300 Crash Bar PDF孙振立Încă nu există evaluări

- 1ZFI209205-437-en - Installation Instructions Tightening TorqueDocument5 pagini1ZFI209205-437-en - Installation Instructions Tightening Torquethomasvicson24Încă nu există evaluări

- Prueba Resorte de EmbragueDocument2 paginiPrueba Resorte de Embraguejohan gomezÎncă nu există evaluări

- Metric (ISO) Fasteners: Torque SpecificationsDocument6 paginiMetric (ISO) Fasteners: Torque SpecificationsOsorio Meza Tavo FernandoÎncă nu există evaluări

- Hexagon Head Bolts/Screws: Metric Series-DimensionsDocument7 paginiHexagon Head Bolts/Screws: Metric Series-DimensionsVishal MistryÎncă nu există evaluări

- How To Specify Fasteners: 3/4 - 10 X 5 Hex Cap Screw Grade 5 Zinc 3/4 - 16 X 5 Hex Cap Screw Grade 5 ZincDocument15 paginiHow To Specify Fasteners: 3/4 - 10 X 5 Hex Cap Screw Grade 5 Zinc 3/4 - 16 X 5 Hex Cap Screw Grade 5 ZincAndré BuysÎncă nu există evaluări

- Group 2 Tightening Torque: 1. Major ComponentsDocument3 paginiGroup 2 Tightening Torque: 1. Major ComponentsSergey MovchanÎncă nu există evaluări

- Group 2 Tightening Torque: 1. Major ComponentsDocument3 paginiGroup 2 Tightening Torque: 1. Major Componentslevinton jose tobias genesÎncă nu există evaluări

- Group 2 Tightening Torque: 1. Major ComponentsDocument3 paginiGroup 2 Tightening Torque: 1. Major ComponentsSergey MovchanÎncă nu există evaluări

- Two Stage Snow Engine Service Manual: Residential ProductsDocument48 paginiTwo Stage Snow Engine Service Manual: Residential ProductsBJ DixÎncă nu există evaluări

- Simranflowtech Catalogue Screw Jack DetailedDocument18 paginiSimranflowtech Catalogue Screw Jack Detailedpushp00Încă nu există evaluări

- Torque-Tightening Metric Machine ScrewsDocument2 paginiTorque-Tightening Metric Machine ScrewsChiranjiv ParidaÎncă nu există evaluări

- Woo Chang Coupling - 112438 - Paqndr oYtYHS8Document14 paginiWoo Chang Coupling - 112438 - Paqndr oYtYHS8Eng-anwer kadhimÎncă nu există evaluări

- Metric (ISO) Fasteners: SmcsDocument4 paginiMetric (ISO) Fasteners: SmcsAnonymous cS9UMvhBqÎncă nu există evaluări

- Transmission and Differential SectionDocument245 paginiTransmission and Differential Sectionbillh@optonline.netÎncă nu există evaluări

- Construction Issue Report: Page 1 of 2Document2 paginiConstruction Issue Report: Page 1 of 2Navneet SunilÎncă nu există evaluări

- Bonding Procedures BookletDocument29 paginiBonding Procedures BookletLeDzungÎncă nu există evaluări

- 13-1160 - Hhs Bolt, H.h.nut & Washer A490Document1 pagină13-1160 - Hhs Bolt, H.h.nut & Washer A490Navneet SunilÎncă nu există evaluări

- Tips Critical Crane Lift PDFDocument7 paginiTips Critical Crane Lift PDFb_wooÎncă nu există evaluări

- Fun MathDocument29 paginiFun MathGanesh AlkariÎncă nu există evaluări

- Metric Thread Dimensions - Bolt Sizes Chart For M1.6 To M69 Screws - AccuDocument3 paginiMetric Thread Dimensions - Bolt Sizes Chart For M1.6 To M69 Screws - AccuGaurav VatsÎncă nu există evaluări

- Milton Roy: Ga Drawing of CP250V225Document1 paginăMilton Roy: Ga Drawing of CP250V225Zainuddin CIEÎncă nu există evaluări

- Misturador - RC 150, 160 E 170 ESTACIONÁRIO - (7R026ATL E)Document33 paginiMisturador - RC 150, 160 E 170 ESTACIONÁRIO - (7R026ATL E)xuneviskÎncă nu există evaluări

- 2.thread GaugesDocument28 pagini2.thread GaugesAshlin SreedharÎncă nu există evaluări

- 1DIN 6921-10.9 Hex Flange Bo.Document2 pagini1DIN 6921-10.9 Hex Flange Bo.Sunil BaliÎncă nu există evaluări

- 06 Haesl LatheDocument43 pagini06 Haesl LatheKike DavilaÎncă nu există evaluări

- OriginalDocument28 paginiOriginalPatrick JanssensÎncă nu există evaluări

- Syj 100 TF SKFDocument2 paginiSyj 100 TF SKFronny ArdiansyahÎncă nu există evaluări

- 10.9 Metric Hex Head Cap Screws PamphletDocument5 pagini10.9 Metric Hex Head Cap Screws PamphletnotengofffÎncă nu există evaluări

- LC-1000 (2009)Document23 paginiLC-1000 (2009)samuel velayosÎncă nu există evaluări

- PS Conceptual DrawingDocument4 paginiPS Conceptual Drawing• Mushroom Plays Games•Încă nu există evaluări

- B18 2 1 1996Document86 paginiB18 2 1 1996phani u4meÎncă nu există evaluări

- Non Preload Bs en 15048 CeDocument3 paginiNon Preload Bs en 15048 CeAnamaria SuzanaÎncă nu există evaluări

- GTS300i 維修手冊 (車身) PDFDocument31 paginiGTS300i 維修手冊 (車身) PDFCHI SANG TANGÎncă nu există evaluări

- Safety Tying WireDocument4 paginiSafety Tying WireMico Rahmat WibowoÎncă nu există evaluări

- Pt. Tata Bara Utama-Ca3077Document7 paginiPt. Tata Bara Utama-Ca3077Andy A.S.Încă nu există evaluări

- Fastener Weight & Count ChartDocument12 paginiFastener Weight & Count ChartaselabollegalaÎncă nu există evaluări

- BN 8699Document2 paginiBN 8699bcsf01Încă nu există evaluări

- SPARES LIST Cessna 172-June 2022Document2 paginiSPARES LIST Cessna 172-June 2022mmÎncă nu există evaluări

- C. Emsco FB-1600 Parts ListDocument14 paginiC. Emsco FB-1600 Parts Listluis mateosÎncă nu există evaluări

- Willy NillyDocument11 paginiWilly NillyPeter RodriguesÎncă nu există evaluări

- Parts Manual: MODEL 3000 Rigid Frame PlanterDocument158 paginiParts Manual: MODEL 3000 Rigid Frame PlanterAlexey petrovichÎncă nu există evaluări