Documente Academic

Documente Profesional

Documente Cultură

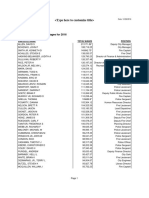

Aditivos Metais

Încărcat de

mauricio_leDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Aditivos Metais

Încărcat de

mauricio_leDrepturi de autor:

Formate disponibile

TheDieselStop.

Com is a source of information, discussion, and help pertaining to the full line of Ford trucks,

SUVs, and vans with International diesels. We cover everything from the original F-250s with 6.9L diesels all

the way up to the newest 2008 Super-Duty trucks with the new 6.4L Power Stroke engine.

Menu

home

contents

forums

calendar

faqs

editors

archives

links

photos

for sale

downloads

therapy

search

utils

contact

advertising

about

ABC's of Oil Analysis

Source:

Kevin Dinwiddie

dinwiddieK@earthlink.net

Kevin is a factory representative for Lubrication Engineers. He has been in the industry for 22 years, is a

Certified Lubrication Specialist by STLE and a 5 year Member of the STLE. (Society of Tribologists and

Lubrication Engineers)

Most everyone has a favorite brand of oil that they use in their car or truck. The question we must ask ourselves

is whether our favorite oil is protecting as well as we think? Oil analysis can answer that question as well as

some others that concern what may be going on in our engines. Oil analysis allows us to receive comprehensive

data in specific categories that are relative to engine wear. Those categories are: wear metals, contaminant

metals, additive metals, non-metallic contaminants, and the lube fluid data. Each individual oil analysis will

give you numeric values that you can compare against unit averages that have been compiled. Furthermore,

each additional sample you have analyzed will tell you more than the previous one because of the trend that you

will establish.

Newest Articles

'05-'06 High Idle by StuartV

Great instructions how to modify an

'05-'06 upfitter switch into an AIC.

6L Shootout Reports by Ralph

Landau

Results and conclusions from Ford

6.0 Liter Shootout held on 9/3/2005 in

Nashville.

1999-2004 $10/$15 AIC by Rob

Milnes

TheDieselStop.Com - www.thedieselstop.com http://www.thedieselstop.com/contents/getitems.php3?ABC's of Oil Analysis

1 de 6 12/12/2013 09:32

Taking the oil sample is easy. First, contact a laboratory close to you (I use CTC at 1-800-524-7848). Ask the

laboratory to send you a sample bottle and information form to provide information on your truck or car.

Depending on the laboratory, the sample analysis will cost between $7.50 and $20.00 for each one. The best

way to retrieve a sample is to suck the oil out from the dipstick hole into the bottle with a suction gun. I

purchased my vampire suction gun from EZ VAC Inc. at 1-423-691-7510 for about $20.00. Another way to get

a sample is from the drain plug. If you decide to take the sample from the drain plug: First, clean off the pan and

plug to keep any contaminants out of the sample. Then, allow some oil to drain out before filling the bottle. If

you take the sample from the oil drain plug, make sure that you indicate where the sample was taken from in the

comment box on the sample information form. Always make sure that you bring the engine up to operating

temperature before you take any sample. Finally, your last step is to seal up the sample bottle and fill out the

information form. Pack it away in the shipping container and send to the lab for analysis.

After your sample has been analyzed you will receive a comprehensive analysis form: The first category you

will look at will be the wear metals category. The wear metals category has 11 elements that are evaluated.

Values for each element are given in parts per million or (ppm). For example a value of 40 for iron would tell

you that you have 40 parts of iron per million parts of oil sample. The 11 wear metals are described below:

Iron: comes from Cylinders, Gears, Rings, Crankshafts, Liners, Bearings, Housings, and Rust. 1.

Chromium: comes from Rings, Roller/Taper Bearing, Rods, and Platings. 2.

Lead: comes from Bearing Overlays, Additive in gear oil and gasoline. 3.

Copper: comes from Bushings, Bearings, Thrust-Washers, Friction Plates, Oil Cooler, and Additives in

oil.

4.

Tin: comes from Bearings, Bushings, Pistons, and Platings. 5.

Aluminum: comes from Pistons, Bearings, Pumps, Blowers, Rotors, and Thrust-Washers. 6.

Nickel: comes from Valves. 7.

Silver: comes from Bearings, Bushings, and Platings. 8.

Manganese: comes from Trace elements in liners and rings, or is an Additive in gasoline. 9.

Titanium: is a trace element. 10.

Vanadium: is also a trace element 11.

There are only 4 contaminant sources listed on the oil analysis: (also displayed in ppm)

Silicon: is sometimes used as an anti-foam agent, but is most likely airborne dirt and abrasives in the oil.

Silicon can also be from gasket sealer if work has been done recently.

1.

Rob Milnes walks us through building

and installing a $10-15 AIC on a

late-model Power Stroke.

Ceramic Coating by Clive Buttrey

Clive Buttrey (cbuttre835) explains

do-it-yourself ceramic coating on his

1997 Power Stroke.

Proper Tire Inflation by Dave Rais

Dave Rais (Homegrown) explains

how to properly inflate your tires.

More Articles

TheDieselStop.Com - www.thedieselstop.com http://www.thedieselstop.com/contents/getitems.php3?ABC's of Oil Analysis

2 de 6 12/12/2013 09:32

Boron: is in most anti-freeze systems and cooking system inhibitors, but is sometimes used in oil as an

additive.

2.

Sodium: is also in most anti-freeze systems but is also used in some oils to fight off acids. 3.

Potassium: is also in anti-freeze systems but is also used as an additive in gear oil. If your oil analysis

shows the combination of Boron, Sodium and Potassium then you should have your engine looked at for

a coolant leak into your oil.

4.

Additive metals are also reported. These are the "good" metals. They are part of the formula that the oil

companies use to enhance the oil's ability to perform. These values are also going to be given in parts per

million (ppm)

Magnesium, Calcium and Barium: are all dispersant/detergent additives. These additives keep the foreign

particles from sticking together and keep them in suspension for the filter to take them out of the oil.

Zinc, Phosphorus, and Molybdenum: are anti-wear additives and will enhance the oils ability to reduce wear.

When looking for an oil that you want to for extended drains you should look for an oil that uses a lot of

magnesium as well as having a robust zinc phosphorus additive package.

The non-metallic contaminants consist of Fuel, Antifreeze and Water. These values are shown in percentages

(%). For example, a high fuel percentage indicates there is unburned fuel in the oil and may signal an

incomplete combustion problem. Fuel soot may result from incomplete combustion or overextended oil drain

intervals. Water and antifreeze are also non-metallic contaminants and any percentage is not good and should be

investigated.

The lube fluid data is the next category you will find on a good oil analysis. Not all oil analysis companies do

complete lube fluid data. The lube fluid data will consist of a Viscosity value and the TBN or Total Base

Number.

Viscosity is usually measured at 100 degrees Celsius denoted in cSt. The values of cSt for a Specific SAE range

are as follows:

SAE 20 has a cSt range of 5.60 to 9.29.

SAE 30 has a cSt range of 9.30 to 12.49.

SAE 40 has a cSt range of 12.50 to 16.29

SAE 50 has a cSt range of 16.30 to 21.89.

When using multi viscosity oils such as a 15w-40-grade oil, the analysis should show the oil is in the range of a

SAE 40. If not then the oil is out of viscosity grade and should be changed. For example if you were to do an oil

TheDieselStop.Com - www.thedieselstop.com http://www.thedieselstop.com/contents/getitems.php3?ABC's of Oil Analysis

3 de 6 12/12/2013 09:32

analysis on a 15w-40 oil and you received a result of 13.2 cSt then you would be in the middle of the SAE 40

range and clear for extended usage. Conversely, if you were to get a result of 12.5 cSt then you would not want

to go any further on that oil because you would just about be out of spec for a 15w 40 oil or SAE 40 range. The

cSt value gives you more information as to where in the viscosity range your oil is. This allows you to make a

better judgment as to the oils suitability in being used for extended drain intervals. If you use a lab that gives

you a SAE value only then you could be using the oil for extended period when you shouldnt be using it at all.

This is why it is important, if you are doing extended drains, to choose a lab that will give you viscosity values

in cSt rather than SAE range.

The Total Base number is a value that shows the oils ability to fight off acids. TBN is measured as the quantity

of acid fighting additives that a given sample contains. The TBN of new oil should typically range from about 6

to 10 (10 being better) and should not deplete to 50% of the original amount. Hence a 10 should not deplete to

below a 5. I recommend that in diesel applications that the TBN start at 8-10 and not go below a 5. In gasoline

engines I recommend starting with an 8-10 and not going below a 3. In todays diesel engines, using the lower

sulfur diesel fuel that is available for on-road applications, a TBN value over 10 is not necessary even in

extended oil drain situations. Off-Road and high sulfur diesel fuel usage requires oil with higher TBN numbers

to combat the acid produced by the increased sulfur in these fuels. Gasoline engines also need not use oils

exceeding a TBN of 10.

If you are going to start oil analysis, you should send a sample of new (unused) oil in for an analysis along with

the used oil. This will give the laboratory a base line to compare the new oil with any other samples of the used

oil you will provide in the future. Many Laboratories already have baseline information on some of the more

common oils on the market. It is a good idea to call the lab first to see if they require the baseline information

on your oil.

Let's talk about some of the things that can confuse us about oil analysis. Let's say that you just worked on your

engine or had someone work on it. If you/they used silicon sealer to seal gaskets or engine components, when

you do an oil analysis high silicon readings may show up. This may send you into a panic for nothing, as it

might not be the dirt that you think it is. On the Analysis form that you submit with your sample there is a

comments section. The comments section is for you to indicate any areas of concern you may have with your

sample. You may want to include in this comments area that the engine has just been worked on. For example,

making the indication Rear main seal replaced. A good analyst should pick up that the silicon level is elevated

due to sealant use.

Another cause of confusion from some trucks is the copper level. Copper is an additive in some oils but you

TheDieselStop.Com - www.thedieselstop.com http://www.thedieselstop.com/contents/getitems.php3?ABC's of Oil Analysis

4 de 6 12/12/2013 09:32

would not know this unless you asked the manufacturer of the oil or sent a new sample of oil in for analysis.

Occasionally copper will show up and it can give you the false impression that you have a bearing problem. A

true bearing problem would show more than an isolated high copper reading. It would more commonly be

found in the company of high Tin and Lead readings. If you only have Copper showing up on your analysis,

then you most likely are seeing copper oxides from an oil cooler or the oil manufacturer uses copper in its

additive package. Some oil companies employ significant amounts of copper in their additive package. Copper

from an oil cooler is not a problem at all. It is most likely an indication of a robust detergent/dispersant package

doing its job. So when you see copper dont panic, you need only be alarmed if you have all three (Copper, Tin

and Lead).

Oil Analysis And Using a By-Pass Filter In Addition To Your Regular Spin-On Filter:

I recommend using a good bypass filter. However, by using a bypass filter you can be fooled into thinking that

your engine is being subjected to less wear. Every oil has a specific wear rate built into it some are lower than

others. You will not get any lower wear rate than when the oil is first out of the bottle. You will however get a

lower wear rate than the average oil if you use a superior oil like Lubrication Engineers Monolec Ultra 8800

15w-40. Here is why

Let's say you use an average oil and don't use a bypass filter. When you do an oil analysis you might see

something like 40ppm of iron in 4,000 miles. Then you install a bypass filter and send an oil analysis in with

4,000 miles on it. You then see a reduction of wear metals that is now giving you a 25ppm of iron reading. You

would think that engine wear has been reduced due to your installing the bypass filter. This might not be true.

You may have the same wear rate, but now the 15 ppm of iron is being collected by the bypass filter instead of

being dropped into the oil. Thus the bypass filter is masking the real wear that is still happening. Fortunately

there is an answer. That is to find an oil with a robust anti friction, anti wear package like the Lubrication

Engineers Monolec Ultra 8800. Lubrication Engineers uses a robust additive package that is made to reduce

wear and friction thus not allowing the particles to get into the oil in the first place. The bypass filter will keep

the oil in better shape longer so you can extend oil drains out farther. The Oil is the key to reducing engine

wear.

If you are interested in purchasing Lubrication Engineers Monolec Ultra 8800 Oil, it can also be purchased at

Mag-Hytec at 1-818-786-8325.

I hope that this information helps you understand oil analysis and take better care of your investment.

TheDieselStop.Com - www.thedieselstop.com http://www.thedieselstop.com/contents/getitems.php3?ABC's of Oil Analysis

5 de 6 12/12/2013 09:32

All trademarks and copyrights on this page are owned by their respective companies.

All else is Copyright 1997-2007 TheDieselStop.Com.

All Rights Reserved

TheDieselStop.Com Privacy Statement

Advertising on TheDieselStop

This site is in no way affiliated with Ford Motor Company or International Truck and Engine Corporation.

Terms of Use

TheDieselStop.Com - www.thedieselstop.com http://www.thedieselstop.com/contents/getitems.php3?ABC's of Oil Analysis

6 de 6 12/12/2013 09:32

S-ar putea să vă placă și

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Odisha State Museum-1Document26 paginiOdisha State Museum-1ajitkpatnaikÎncă nu există evaluări

- HFE0106 TraskPart2Document5 paginiHFE0106 TraskPart2arunkr1Încă nu există evaluări

- Chapter 1Document6 paginiChapter 1Grandmaster MeowÎncă nu există evaluări

- Advertising II Marathi VersionDocument91 paginiAdvertising II Marathi VersionHarsh Sangani100% (1)

- Signature Object Detection Based On YOLOv3Document4 paginiSignature Object Detection Based On YOLOv3Lý Khánh NhưÎncă nu există evaluări

- Automatic Gearbox ZF 4HP 20Document40 paginiAutomatic Gearbox ZF 4HP 20Damien Jorgensen100% (3)

- List of Iconic CPG Projects in SingaporeDocument2 paginiList of Iconic CPG Projects in SingaporeKS LeeÎncă nu există evaluări

- Walking in Space - Lyrics and Chord PatternDocument2 paginiWalking in Space - Lyrics and Chord Patternjohn smithÎncă nu există evaluări

- HRMDocument118 paginiHRMKarthic KasiliaÎncă nu există evaluări

- EAC Inquiry SDCDocument9 paginiEAC Inquiry SDCThe Sustainable Development Commission (UK, 2000-2011)Încă nu există evaluări

- Chemistry Investigatory Project (R)Document23 paginiChemistry Investigatory Project (R)BhagyashreeÎncă nu există evaluări

- Practical Modern SCADA Protocols. DNP3, 60870.5 and Related SystemsDocument4 paginiPractical Modern SCADA Protocols. DNP3, 60870.5 and Related Systemsalejogomez200Încă nu există evaluări

- Measuring Temperature - Platinum Resistance ThermometersDocument3 paginiMeasuring Temperature - Platinum Resistance Thermometersdark*nightÎncă nu există evaluări

- Satish Gujral - FinalDocument23 paginiSatish Gujral - Finalsatya madhuÎncă nu există evaluări

- 2016 W-2 Gross Wages CityDocument16 pagini2016 W-2 Gross Wages CityportsmouthheraldÎncă nu există evaluări

- Product Manual 26086 (Revision E) : EGCP-2 Engine Generator Control PackageDocument152 paginiProduct Manual 26086 (Revision E) : EGCP-2 Engine Generator Control PackageErick KurodaÎncă nu există evaluări

- Facebook: Daisy BuchananDocument5 paginiFacebook: Daisy BuchananbelenrichardiÎncă nu există evaluări

- Draft JV Agreement (La Mesa Gardens Condominiums - Amparo Property)Document13 paginiDraft JV Agreement (La Mesa Gardens Condominiums - Amparo Property)Patrick PenachosÎncă nu există evaluări

- ADC of PIC MicrocontrollerDocument4 paginiADC of PIC Microcontrollerkillbill100% (2)

- Math Review CompilationDocument9 paginiMath Review CompilationJessa Laika CastardoÎncă nu există evaluări

- Axera D06Document2 paginiAxera D06Cristián Fernando Cristóbal RoblesÎncă nu există evaluări

- Faa Data On B 777 PDFDocument104 paginiFaa Data On B 777 PDFGurudutt PaiÎncă nu există evaluări

- Formula:: High Low Method (High - Low) Break-Even PointDocument24 paginiFormula:: High Low Method (High - Low) Break-Even PointRedgie Mark UrsalÎncă nu există evaluări

- Segregation in CastingDocument17 paginiSegregation in CastingAsmaa Smsm Abdallh78% (9)

- TraceDocument5 paginiTraceNorma TellezÎncă nu există evaluări

- Эквивалентная Схема Мотра Теслы с Thomas2020Document7 paginiЭквивалентная Схема Мотра Теслы с Thomas2020Алексей ЯмаÎncă nu există evaluări

- COURTESY Reception Good MannersDocument1 paginăCOURTESY Reception Good MannersGulzina ZhumashevaÎncă nu există evaluări

- Exotic DVM 11 3 CompleteDocument12 paginiExotic DVM 11 3 CompleteLuc CardÎncă nu există evaluări

- Open Letter To Hon. Nitin Gadkari On Pothole Problem On National and Other Highways in IndiaDocument3 paginiOpen Letter To Hon. Nitin Gadkari On Pothole Problem On National and Other Highways in IndiaProf. Prithvi Singh KandhalÎncă nu există evaluări

- Internship Report Format For Associate Degree ProgramDocument5 paginiInternship Report Format For Associate Degree ProgramBisma AmjaidÎncă nu există evaluări