Documente Academic

Documente Profesional

Documente Cultură

HACCP

Încărcat de

Kalyankumar KrishnamoorthyDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

HACCP

Încărcat de

Kalyankumar KrishnamoorthyDrepturi de autor:

Formate disponibile

HACCP: A State-of-the-Art Approach to Food Safety

Space-age technology designed to keep food safe in outer space may soon become

standard here on Earth.

Traditionally, industry and regulators have depended on spot-checks of manufacturing

conditions and random sampling of final products to ensure safe food. This approach,

however, tends to be reactive, rather than preventive, and can be less efficient than the

new system.

The new system is known as Hazard Analysis and Critical Control Point, or

HACCP (Pronounced hassip). Many of its principles already are in place in the FDA-

regulated low-acid canned food industry. FDA also established HACCP for the seafood

industry in a final rule December 18, 1995 and for the juice industry in a final rule

released January 19, 2001. The final rule for the juice industry will take effect on

January 22, 2002 for large and medium businesses, January 21, 2003 for small

businesses, and January 20, 2004 for very small businesses.

In 1998, the U.S. Department of Agriculture has established HACCP for meat and

poultry processing plants, as well. Most of these establishments were required to start

using HACCP by January 1999. Very small plants had until Jan. 25, 2000. (USDA

regulates meat and poultry; FDA all other foods.)

FDA now is considering developing regulations that would establish HACCP as the food

safety standard throughout other areas of the food industry, including both domestic

and imported food products.

HACCP has been endorsed by the National Academy of Sciences, the Codex

Alimentarius Commission (an international food standard-setting organization), and the

National Advisory Committee on Microbiological Criteria for Foods.

The Indian standard is based on the revision of the guidelines for the application of

the HACCP system CAC/GL 18-1993 and is identical to it. The revision has now been

included as Annex to the third revision of recommended International Code of Practice--

-General Principles of Food Hygiene [CAC/RCP-1] which was adopted be the codex

Alimentarius Commission, at its twenty second session [ALINORM 97/13 A]

IS No. 2491:1972 Code for hygienic conditions for food processing units

IS /ISO 9001:1994 Quality systems-Model for quality assurance in design,

development, production, installation and servicing

Kamtech Associates Pvt. Ltd.

307,218, Shri Gopal Tower, Nr. Ahinsa Circle, C-scheme, Jaipur 302001

Ph: +91-141-377559,371308, E-mail: kamtech@kamtechassociates.com

What is HACCP?

HACCP involves seven principles:

Analyze hazards. Potential hazards associated with a food and measures to

control those hazards are identified. The hazard could be biological, such as a

microbe; chemical, such as a toxin; or physical, such as ground glass or metal

fragments.

Identify critical control points. These are points in a food's production--from

its raw state through processing and shipping to consumption by the consumer--

at which the potential hazard can be controlled or eliminated. Examples are

cooking, cooling, packaging, and metal detection.

Establish preventive measures with critical limits for each control

point. For a cooked food, for example, this might include setting the minimum

cooking temperature and time required to ensure the elimination of any harmful

microbes.

Establish procedures to monitor the critical control points. Such

procedures might include determining how and by whom cooking time and

temperature should be monitored.

Establish corrective actions to be taken when monitoring shows that a

critical limit has not been met--for example, reprocessing or disposing of

food if the minimum cooking temperature is not met.

Establish procedures to verify that the system is working properly--for

example, testing time-and-temperature recording devices to verify that a cooking

unit is working properly.

Establish effective record keeping to document the HACCP system. This

would include records of hazards and their control methods, the monitoring of

safety requirements and action taken to correct potential problems. Each of

these principles must be backed by sound scientific knowledge: for example,

published microbiological studies on time and temperature factors for controlling

food borne pathogens.

Need for HACCP

New challenges to the U.S. food supply have prompted FDA to consider adopting a

HACCP-based food safety system on a wider basis. One of the most important

challenges is the increasing number of new food pathogens. For example, between

1973 and 1988, bacteria not previously recognized as important causes of food-borne

illness--such as Escherichia coli O157:H7 and Salmonella enteritidis--became more

widespread.

There also is increasing public health concern about chemical contamination of food: for

example, the effects of lead in food on the nervous system.

Kamtech Associates Pvt. Ltd.

307,218, Shri Gopal Tower, Nr. Ahinsa Circle, C-scheme, Jaipur 302001

Ph: +91-141-377559,371308, E-mail: kamtech@kamtechassociates.com

Another important factor is that the size of the food industry and the diversity of

products and processes have grown tremendously--in the amount of domestic food

manufactured and the number and kinds of foods imported. At the same time, FDA and

state and local agencies have the same limited level of resources to ensure food safety.

The need for HACCP in the United States, particularly in the seafood and juice

industries, is further fueled by the growing trend in international trade for worldwide

equivalence of food products and the Codex Alimentarious Commission's adoption of

HACCP as the international standard for food safety.

Advantages

HACCP offers a number of advantages over the current system. Most importantly,

HACCP:

Focuses on identifying and preventing hazards from contaminating food

Is based on sound science & scientific Methods

Permits more efficient and effective government oversight, primarily because the

record keeping allows investigators to see how well a firm is complying with food

safety laws over a period rather than how well it is doing on any given day

Places responsibility for ensuring food safety appropriately on the food

manufacturer or distributor

Helps food companies compete more effectively in the world market

Reduces barriers to international trade.

Some Definitions

CCP Decision Tree:

A sequence of questions to assist in determining whether a control point is a

CCP.

Control:

(a) To manage the conditions of an operation to maintain compliance with

established criteria.

(b) The state where correct procedures are being followed and criteria are being

met.

Control Point:

Any step at which biological, chemical, or physical factors can be controlled.

Corrective Action:

Procedures followed when a deviation occurs.

Kamtech Associates Pvt. Ltd.

307,218, Shri Gopal Tower, Nr. Ahinsa Circle, C-scheme, Jaipur 302001

Ph: +91-141-377559,371308, E-mail: kamtech@kamtechassociates.com

Critical Control Point:

A step at which control can be applied and is essential to prevent or eliminate a

food safety hazard or reduce it to an acceptable level.

Deviation:

Failure to meet a critical limit.

HACCP:

A systematic approach to the identification, evaluation, and control of food safety

hazards.

HACCP Plan:

The written document which is based upon the principles of HACCP and which

delineates the procedures to be followed.

HACCP Team:

The group of people who are responsible for developing, implementing and

maintaining the HACCP system.

Hazard:

A biological, chemical, or physical agent that is reasonably likely to cause illness

or injury in the absence of its control.

Monitor:

To conduct a planned sequence of observations or measurements to assess

whether a CCP is under control and to produce an accurate record for future use

in verification.

Step:

A point, procedure, operation or stage in the food system from primary

production to final consumption.

Verification:

Those activities, other than monitoring, that determine the validity of the HACCP

plan and that the system is operating according to the plan.

Kamtech Associates Pvt. Ltd.

307,218, Shri Gopal Tower, Nr. Ahinsa Circle, C-scheme, Jaipur 302001

Ph: +91-141-377559,371308, E-mail: kamtech@kamtechassociates.com

HACCP PRINCIPLES

HACCP is a systematic approach to the identification, evaluation, and control of

food safety hazards based on the following seven principles:

Principle 1: Conduct a hazard analysis.

Principle 2: Determine the critical control points (CCPs).

Principle 3: Establish critical limits.

Principle 4: Establish monitoring procedures.

Principle 5: Establish corrective actions.

Principle 6: Establish verification procedures.

Principle 7: Establish record-keeping and documentation

procedures.

Education and Training

The success of a HACCP system depends on educating and training management

and employees in the importance of their role in producing safe foods. This

should also include information the control of foodborne hazards related to all

stages of the food chain. It is important to recognize that employees must first

understand what HACCP is and then learn the skills necessary to make it function

properly. Specific training activities should include working instructions and

procedures that outline the tasks of employees monitoring each CCP.

Management must provide adequate time for thorough education and training.

Personnel must be given the materials and equipment necessary to perform

these tasks. Effective training is an important prerequisite to successful

implementation of a HACCP plan.

Kamtech Associates Pvt. Ltd.

307,218, Shri Gopal Tower, Nr. Ahinsa Circle, C-scheme, Jaipur 302001

Ph: +91-141-377559,371308, E-mail: kamtech@kamtechassociates.com

Kamtech Associates Pvt. Ltd.

307,218, Shri Gopal Tower, Nr. Ahinsa Circle, C-scheme, Jaipur 302001

Ph: +91-141-377559,371308, E-mail: kamtech@kamtechassociates.com

Conduct a hazard analysis (Principle 1)

Determine critical control points (CCPs)

(Principle 2)

Establish critical limits (Principle 3)

Establish monitoring procedures (Principle 4)

Establish corrective actions (Principle 5)

Establish verification procedures (Principle 6)

Establish record-keeping and documentation

procedures (Principle 7)

HACCP Certification

Assemble the HACCP Team

Describe the Food and its Distribution

Describe the Intended Use and Consumers

of the Food

Develop a Flow Diagram That Describes

the Process

Verify the Flow Diagram

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Standards and SpecificationDocument35 paginiStandards and SpecificationBhaswati PandaÎncă nu există evaluări

- Detailed Lesson Plan in ElectricalDocument7 paginiDetailed Lesson Plan in ElectricalJc Santos0% (1)

- Maj HazDocument60 paginiMaj HazVasant Kumar Varma100% (1)

- IGEM Standards Guide for Gas Industry ProfessionalsDocument9 paginiIGEM Standards Guide for Gas Industry ProfessionalsSenn OdrapmasdÎncă nu există evaluări

- Gail Tender - Volume-Ii-Sow (A) - Pipeline - 20181208 - 122802 PDFDocument612 paginiGail Tender - Volume-Ii-Sow (A) - Pipeline - 20181208 - 122802 PDFChirag ShahÎncă nu există evaluări

- Gail Tender - Volume-Ii-Sow (A) - Pipeline - 20181208 - 122802 PDFDocument612 paginiGail Tender - Volume-Ii-Sow (A) - Pipeline - 20181208 - 122802 PDFChirag ShahÎncă nu există evaluări

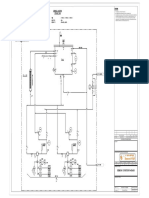

- Chemical Injection SkidDocument1 paginăChemical Injection SkidKalyankumar KrishnamoorthyÎncă nu există evaluări

- C 561Document2 paginiC 561Asep TheaÎncă nu există evaluări

- Exhibit A - Sow (Eal-18-0034)Document54 paginiExhibit A - Sow (Eal-18-0034)Kalyankumar KrishnamoorthyÎncă nu există evaluări

- Underfloor Wheelset Lathe: Operating / Maintenance ManualDocument84 paginiUnderfloor Wheelset Lathe: Operating / Maintenance ManualMinh Canh100% (1)

- Method Statement for Excavation WorksDocument12 paginiMethod Statement for Excavation WorksBasem DoniaÎncă nu există evaluări

- Desalter DesignDocument34 paginiDesalter Designmemon350% (2)

- Indian Petrochemical Plant DataDocument13 paginiIndian Petrochemical Plant DataKalyankumar KrishnamoorthyÎncă nu există evaluări

- SMH Daily Progress Report # 22Document2 paginiSMH Daily Progress Report # 22Kalyankumar KrishnamoorthyÎncă nu există evaluări

- Indian Petrochemical Plant DataDocument13 paginiIndian Petrochemical Plant DataKalyankumar KrishnamoorthyÎncă nu există evaluări

- 02 - RFP Section 2 - List of Contents of RFP (DOP-18-003 Analyse Vibratoire Machines Tournantes) .FR - enDocument1 pagină02 - RFP Section 2 - List of Contents of RFP (DOP-18-003 Analyse Vibratoire Machines Tournantes) .FR - enKalyankumar KrishnamoorthyÎncă nu există evaluări

- Net WorkDocument2 paginiNet WorkKalyankumar KrishnamoorthyÎncă nu există evaluări

- DESALTERDocument2 paginiDESALTERKalyankumar KrishnamoorthyÎncă nu există evaluări

- Resource SheetDocument2 paginiResource SheetKalyankumar KrishnamoorthyÎncă nu există evaluări

- Boiler DataDocument16 paginiBoiler DataKalyankumar KrishnamoorthyÎncă nu există evaluări

- CPMDocument2 paginiCPMKalyankumar KrishnamoorthyÎncă nu există evaluări

- PERT DiagramDocument2 paginiPERT DiagramKalyankumar KrishnamoorthyÎncă nu există evaluări

- Net WorkDocument2 paginiNet WorkKalyankumar KrishnamoorthyÎncă nu există evaluări

- GantDocument2 paginiGantKalyankumar KrishnamoorthyÎncă nu există evaluări

- Predict Pipe4 1 PINDocument4 paginiPredict Pipe4 1 PINKalyankumar KrishnamoorthyÎncă nu există evaluări

- Roof access safety proceduresDocument2 paginiRoof access safety proceduresAnonymous y1pIqcÎncă nu există evaluări

- Fire Prevention Week 2021 Safety Tip SheetDocument1 paginăFire Prevention Week 2021 Safety Tip SheetepraetorianÎncă nu există evaluări

- NEBOSH International Diploma Unit IC Mock ExamDocument5 paginiNEBOSH International Diploma Unit IC Mock ExamЮрий СиливончикÎncă nu există evaluări

- Root Cause Analysis Chart 1Document1 paginăRoot Cause Analysis Chart 1sk sajidÎncă nu există evaluări

- UK Civil Aviation Authority Strategic Plan ConsultationDocument38 paginiUK Civil Aviation Authority Strategic Plan ConsultationAbdelgafor AwadÎncă nu există evaluări

- Iosh Noise at Work Risk Assessment CourseDocument7 paginiIosh Noise at Work Risk Assessment Coursebcqv1trr100% (2)

- Appendix DDocument6 paginiAppendix DShafiqulHasanÎncă nu există evaluări

- Propyl Paraben MSDS: Section 1: Chemical Product and Company IdentificationDocument5 paginiPropyl Paraben MSDS: Section 1: Chemical Product and Company Identificationperqs BeautyisjoyÎncă nu există evaluări

- SDS UltraSnap US en 1 - 0Document14 paginiSDS UltraSnap US en 1 - 0IG ChannelÎncă nu există evaluări

- Ijires 1138 FinalDocument12 paginiIjires 1138 FinalCharlotte Mae IgleciaÎncă nu există evaluări

- HP Steam Superheater 2 Intermediate Tube Sheets Repair JSADocument1 paginăHP Steam Superheater 2 Intermediate Tube Sheets Repair JSAVIctor OdususiÎncă nu există evaluări

- Guidelines For Good Practice - Storage of Chemicals PDFDocument27 paginiGuidelines For Good Practice - Storage of Chemicals PDFYanka IlarionovaÎncă nu există evaluări

- Food Safety, Security and Bioterrorism - LinkedInDocument7 paginiFood Safety, Security and Bioterrorism - LinkedInJessa Beth GarcianoÎncă nu există evaluări

- Disaster Risk Reduction and Management Plan of Selected Public Schools in Marikina CityDocument20 paginiDisaster Risk Reduction and Management Plan of Selected Public Schools in Marikina CityAbigailÎncă nu există evaluări

- Critical Systems Validation: ©ian Sommerville 2004Document45 paginiCritical Systems Validation: ©ian Sommerville 2004Cecep Kurnia SastradiprajaÎncă nu există evaluări

- Fire Safety Fundamentals and Fire Extinguisher ClassificationsDocument3 paginiFire Safety Fundamentals and Fire Extinguisher ClassificationsGangapuram SrikanthÎncă nu există evaluări

- Case StudyDocument5 paginiCase StudyMil Albert Batiquin TorresÎncă nu există evaluări

- Leonardo, Trisha Lou C. Lesson PlanDocument3 paginiLeonardo, Trisha Lou C. Lesson PlanTrish LeonardoÎncă nu există evaluări

- Gardner Denver ESM 30 Original User ManualDocument60 paginiGardner Denver ESM 30 Original User ManualFernando ValadãoÎncă nu există evaluări

- Cutmaster 120Document126 paginiCutmaster 120Berling Encarnacion RosarioÎncă nu există evaluări

- Food Safety in The WorkplaceDocument4 paginiFood Safety in The WorkplaceKatÎncă nu există evaluări

- Machine GuardingDocument20 paginiMachine GuardingJohnCWilson100% (2)

- Revised Guidelines For Denr Accreditation of Third Party Source Emission Testing Firms Dao-2013-26Document11 paginiRevised Guidelines For Denr Accreditation of Third Party Source Emission Testing Firms Dao-2013-26Maria Teresa Alarcos BuluranÎncă nu există evaluări