Documente Academic

Documente Profesional

Documente Cultură

Biological Approaches For Treatment of Distillery Wastewater

Încărcat de

hohanistTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Biological Approaches For Treatment of Distillery Wastewater

Încărcat de

hohanistDrepturi de autor:

Formate disponibile

Review

Biological approaches for treatment of distillery wastewater: A review

Deepak Pant

a

, Alok Adholeya

a,b,

*

a

Centre of Bioresources and Biotechnology, TERI University, DS Block, India Habitat Centre, Lodhi Road, New Delhi 110 003, India

b

Biotechnology and Management of Bioresources Division, The Energy and Resources Institute, DS Block, India Habitat Centre,

Lodhi Road, New Delhi 110 003, India

Received 12 June 2006; received in revised form 13 September 2006; accepted 25 September 2006

Available online 7 November 2006

Abstract

Euent originating from distilleries known as spent wash leads to extensive soil and water pollution. Elimination of pollutants and

colour from distillery euent is becoming increasingly important from environmental and aesthetic point of view. Stillage, fermenter and

condenser cooling water and fermenter wastewater are the primary polluting streams of a typical distillery. Due to the large volumes of

euent and presence of certain recalcitrant compounds, the treatment of this stream is rather challenging by conventional methods.

Therefore, to supplement the existing treatments, a number of studies encompassing physico-chemical and biological treatments have

been conducted. This review presents an account of the problem and the description of colour causing components in distillery waste-

water and a detailed review of existing biological approaches. Further, the studies dealing with pure cultures such as bacterial, fungal,

algal and plant based systems have also been incorporated. Also, the roles of microbial enzymes in the decolourization process have been

discussed to develop a better understanding of the phenomenon.

2006 Elsevier Ltd. All rights reserved.

Keywords: Colour removal; Distillery euent; Enzymes; Melanoidin; Microorganisms; Wastewater treatment

1. Introduction

Production of ethanol from agricultural materials for

use as an alternative fuel has been attracting worldwide

interest because of the increasing demand for limited

non-renewable energy resources and variability of oil and

natural gas prices. In India this demand is projected to

go up because of a law for mixing 5% ethanol with petrol

and further raising this amount to 10% (The gazette of

India, 2002). Besides this, the other common usages of eth-

anol are in the form of industrial solvent and beverages. In

the year 1999, there were 285 distilleries in India producing

2.7 10

9

L of alcohol and generating 4 10

10

L of waste-

water each year (Joshi, 1999). This number has gone up

to 319, producing 3.25 10

9

L of alcohol and generating

40.4 10

10

L of wastewater annually (Uppal, 2004). Over

the years as the sizes and number of distilleries have grown,

bigger conventional aerobic-treatment plants have been

built to deal with the constantly increasing euent vol-

umes. Space and money to construct these installations

are the biggest hindrances for such investments (Fumi

et al., 1995).

In India, there are a number of large-scale distilleries

integrated with sugar mills. The waste products from

sugar mill comprise bagasse (residue from the sugarcane

crushing), pressmud (mud and dirt residue from juice

clarication) and molasses (nal residue from sugar

crystallization section). Bagasse is used in paper manufac-

turing and as fuel in boilers; molasses as raw material in

distillery for alcohol production while pressmud has no

direct industrial application (Nandy et al., 2002). The eu-

ents from molasses based distilleries contain large amounts

of dark brown coloured molasses spent wash (MSW). In

the distillation process, ethanol ranges from 5% to 12%

0960-8524/$ - see front matter 2006 Elsevier Ltd. All rights reserved.

doi:10.1016/j.biortech.2006.09.027

*

Corresponding author. Address: Biotechnology and Management of

Bioresources Division, The Energy and Resources Institute, DS Block,

India Habitat Centre, Lodhi Road, New Delhi 110 003, India. Tel.: +91 11

24682100/24682111; fax: +91 11 24682144/24682145.

E-mail address: aloka@teri.res.in (A. Adholeya).

Bioresource Technology 98 (2007) 23212334

by volume, hence it follows that the amount of waste varies

from 88% to 95% by volume of the alcohol distilled. An

average molasses based distillery generates 15 L of spent

wash L

1

of alcohol produced (Beltran et al., 2001).

MSW is one of the most dicult waste products to dispose

because of low pH, high temperature, dark brown colour,

high ash content and high percentage of dissolved organic

and inorganic matter (Beltran et al., 1999). The biochemi-

cal oxygen demand (BOD) and chemical oxygen demand

(COD), the index of its polluting character, typically range

between 35,00050,000 and 100,000150,000 mg L

1

,

respectively (Nandy et al., 2002).

Worldwide environment regulatory authorities are set-

ting strict norms for discharge of wastewaters from indus-

tries. In India for instance, distillery industry had been told

to achieve zero discharge of spentwash by December 2005

according to the charter of Central Pollution Control

Board, the apex pollution control authority (CPCB,

2003). It further says that till 100% utilization of spentwash

is achieved, controlled and restricted discharge of treated

euent from lined lagoons during rainy season will be

allowed by SPCBs/CPCB in such a way that the perceptible

colouring of river water bodies does not occur. Physical,

chemical and biological treatment approaches have been

employed for the treatment of distillery wastewater. This

review focuses mainly on lab and eld scale biological

approaches. The overall objective of the work is to present

a literature review on the state of the art in this eld and

address the issues requiring further research.

2. Pollution and toxicity prole of distillery euent

The production and characteristics of spentwash are

highly variable and dependent on feedstocks and various

aspects of the ethanol production process. Wash water

used to clean the fermenters, cooling water blow down,

and boiler water blow down further contributes to its

variability (Duarte et al., 1997). In a distillery, sources of

wastewater are stillage, fermenter and condenser cooling

water and fermenter wastewater. The liquid residues during

the industrial phase of the production of alcohol are:

liquor, sugar cane washing water, water from the condens-

ers and from the cleaning of the equipment, apart from

other residual water. This extract is extremely polluting

as it contains approximately 5% organic material and fertil-

izers such as potassium, phosphorus and nitrogen. The

amount of water used in this process is large, generating

a high level of liquid residues (Borrero et al., 2003).

The MSW is a potential water pollutant in two ways.

First, the highly coloured nature of MSW can block out

sunlight from rivers and streams, thus reducing oxygena-

tion of the water by photosynthesis and hence becomes det-

rimental to aquatic life. Secondly, it has a high pollution

load which would result in eutrophication of contaminated

water courses (FitzGibbon et al., 1998). Due to the pres-

ence of putriciable organics like skatole, indole and other

sulphur compounds, the MSW that is disposed in canals

or rivers produces obnoxious smell (Mahimaraja and

Bolan, 2004). Undiluted euent has toxic eect on shes

and other aquatic organisms. The estimated LC

50

for dis-

tillery spent wash was found to be 0.5% using a bio-toxicity

study on fresh water sh Cyprinus carpio var. communis

(Mahimaraja and Bolan, 2004). Impacts of distillery eu-

ent on carbohydrate metabolism of freshwater sh, C. car-

pio were studied recently by Ramakritinan et al. (2005).

The respiratory process in C. carpio under distillery euent

stress was aected resulting in a shift towards anaerobiosis

at organ level during sublethal intoxication.

Spent wash also leads to signicant levels of soil pollu-

tion and acidication in the cases of inappropriate land dis-

charge. It is reported to inhibit seed germination, reduce

soil alkalinity, cause soil manganese deciency and damage

agricultural crops (Kannabiran and Pragasam, 1993; Agra-

wal and Pandey, 1994). However, eect of distillery euent

on seed germination is governed by its concentration and is

crop-specic. In a study by Ramana et al. (2002) the germi-

nation percent in ve crops decreased with increase in con-

centration of the euent. The germination was inhibited in

all the ve crops studied with concentration exceeding 50%.

At the same time, organic wastes contained in distillery

euent are valuable source of plant nutrients especially

N, P, K and organic substrates if properly utilized (Pathak

et al., 1999). For instance, distillery euent in combination

with bioamendments such as farm yard manure, rice husk

and Brassica residues was used to improve the properties

of sodic soil (Kaushik et al., 2005). The use of fungi for

bioconversion of distillery waste into microbial biomass

or some useful metabolites has been recently reviewed by

Friedrich (2004). The end products of bioconversion are

fungal biomass, ethanol, enzymes etc. and substantially

puried and decolourized euents. Recently enhanced pro-

duction of oyster mushrooms (Pleurotus sp.) using distill-

ery euent as a substrate amendment have been reported

(Pant et al., 2006).

3. Colorants in distillery wastewaters

The molasses wastewater from alcoholic fermentation

has a large amount of a brown pigment. The colour is

hardly degraded by the conventional treatments and can

even be increased during anaerobic treatments, due to

repolymerization of compounds. Phenolics (tannic and

humic acids) from the feedstock, melanoidins from Mail-

lard reaction of sugars (carbohydrates) with proteins

(amino groups), caramels from overheated sugars, and

furfurals from acid hydrolysis mainly contribute to the col-

our of the euent (Kort, 1979). During heat treatment, the

Maillard reaction (non enzymatic reaction) takes place

accompanied by formation of a class of compounds known

as Maillard products. The reaction proceeds eectively at

>50 C and it is favored at pH 47 (Morales and Jimnez-

Perez, 2001). Melanoidins are one of the nal products of

the Maillard reaction. They are complex compounds with

their structures not fully understood.

2322 D. Pant, A. Adholeya / Bioresource Technology 98 (2007) 23212334

Melanoidin is one of the biopolymers that is hardly

decomposed by microorganisms and is widely distributed

in nature. Melanoidins have antioxidant properties, which

render them toxic to aquatic micro and macroorganisms

(Kitts et al., 1993). However, melanoidins present in Span-

ish sweet wines were studied by Rivero-Perez et al. (2002)

and they reported that high molecular weight brown pig-

ments (mostly hypothesized to be melanoidins) isolated

by dialysis were correlated with the colour of the wines

but not to their antioxidant activity. Melanoidins, or

related formation products can occur in dierent processes

of beverage manufacture, such as heat concentrated juices

and musts, beers or wines (Kroh, 1994). From studies using

13

C and

15

N CP-NMR spectrometry, Hayase et al. (1986)

conrmed the presence of olenic linkages and conjugated

enamines which were suggested to be important for the

structure of the chromophores in melanoidin. The reduc-

tion in intensity of absorption for the ozonated sample

indicates a cleavage of the C@C on ozonation.

For melanoidins formed from carbohydrates and amino

acids, a new model of a basic melanoidin skeleton mainly

built up from amino-branched sugar degradation products

was suggested by Cammerer et al. (2002). They indicated

that oligo- and polysaccharides reacted in the Maillard

reaction preferentially as complete molecules at the reduc-

ing end under water-free reaction conditions. Another

approach to estimate the chemical structure of melanoidins

was suggested by Kato and Hayase (2002). A blue pigment

(Blue-M1, C

27

H

31

N

4

O

13

) was isolated from the reaction

mixture of D-xylose and glycine in 60% ethanol stored at

26.5 C for 48 h (or 2 C for 96 h) under nitrogen, whose

chemical character was comparable to that of a nondialyz-

able melanoidin preparation obtained from the reaction

mixture of D-xylose and butylamine neutralized with acetic

acid in methanol incubated at 50 C for 7 days. Recently,

the empirical formula of melanoidin has been suggested

as C

1718

H

2627

O

10

N. The molecular weight distribution

is between 5000 and 40,000. It consists of acidic, polymeric

and highly dispersed colloids, which are negatively charged

due to the dissociation of carboxylic acids and phenolic

groups (Manisankar et al., 2004).

4. Spent wash treatment

Biological treatments have been recognized as eective

methods of treatment for highly polluted industrial waste-

waters. Both anaerobic and aerobic systems are commonly

used to treat the wastewaters from agro-industrial plants

including distilleries as well. In the recent years, increasing

attention is also being directed towards utilizing microbial

activity (pure bacteria and fungi) for the decolourization

and mineralization of spent wash. There are several reports

citing the potential of microorganisms for use in this pro-

cess. Moreover, the biologically treated euent could be

used safely and eectively to increase the soil productivity.

This section is discussed in detail as anaerobic and aerobic

treatments.

4.1. Anaerobic treatment

Anaerobic digestion is widely accepted as the rst treat-

ment step in distilleries. Wilkie et al. (2000) have reviewed

the role of anaerobic digestion in stillage (spent wash)

treatment. Anaerobic digestion can convert a signicant

portion (>50%) of the COD to biogas, which may be used

as an inplant fuel, and also saves the energy that would be

required for aeration using aerobic treatment. At present,

the anaerobic biological treatment of distillery euents is

widely applied as an eective step in removing 90% of the

COD in the euent stream (Wolmarans and de Villiers,

2002). During this stage, 8090% BOD removal takes place

and biochemical energy recovered is 8590% as biogas.

A list of common types of anaerobic reactors used for

distillery euent treatment is given in Table 1. Akunna

and Clark (2000) studied the performance of a granular

bed anaerobic baed reactor (GRABR) in the treatment

of a whisky distillery wastewater having COD and BOD

concentrations of 16,60058,000 and 890030,000 mg L

1

,

respectively. The removal of total BOD and COD from

the wastewater were 8092% and 9096%, respectively with

a HRT of 4 days and at a loading rate of 2.37 kg COD

m

3

day

1

.

The highest BOD removal is possible in open lagoon

whereas highest biomethane produced is in upow anaero-

bic sludge blanket (UASB) type bioreactor. The UASB

system has become the most widely applied reactor

technology for high rate anaerobic treatment of industrial

euents. Its relative high treatment capacity compared to

other systems permits the use of compact and economic

wastewater treatment plants. Compared to aerobic system,

it has slow growth rate, mainly associated with methano-

genic bacteria. Therefore, it requires a long retention time,

and also only a small portion of the degradable organic

waste is being synthesized to new cells. Full-scale thermo-

philic (5055 C) anaerobic digestion of wastewater from

an alcohol distillery was reported by Vlissidis and Zoubou-

lis (1993). More than 60% removal of COD was achieved

with 76% of biogas comprising of methane thus making

it a valuable fuel.

Goodwin and Stuart (1994) studied two identical UASB

reactors operated in parallel as duplicates for 327 days for

the treatment of malt whisky pot ale and achieved COD

reductions of up to 90% for inuent concentrations of

352652126 mg L

1

. When the OLRs of 15 kg m

3

day

and above were used, the COD removal eciency dropped

to less than 20%, in one of the duplicate reactors. A meso-

philic two-stage system consisting of an anaerobic lter

(AF) and an UASB reactor was found suitable for anaero-

bic digestion of distillery waste, enabling better conditions

for the methanogenic phase (Blonskaja et al., 2003). The

optimum conditions for the stable work of reactor are:

for the acidogenic stage, organic loading of 24 kg

COD m

3

day

1

at pH 6.0 and for the methanogenic stage,

organic loading of 12 kg COD m

3

day

1

at pH 7.6.

An advanced version of UASB system was reported by

D. Pant, A. Adholeya / Bioresource Technology 98 (2007) 23212334 2323

Driessen and Yspeert (1999), wherein they used an internal

circulation (IC) reactor characterized by biogas separation

in two stages within a reactor with a high weight/diameter

ratio and the gas driven internal euent circulation. This

system could handle high upow liquid and gas velocities

making possible treatment of low strength euents at short

hydraulic retention times as well as treating high strength

euents such as from brewery at very high volumetric

loading rates up to 35 kg COD m

3

. Eect of addition of

macronutrients and micronutrients in the distillery euent

was investigated on the performance of simulated UASB

system by Sharma and Singh (2001). Calcium and phos-

phate were found to be detrimental to treatment eciency.

Uzal et al. (2003) investigated the biochemical methane

potential (BMP) of malt whisky distillery wastewater both

with and without basal medium to observe the eect of

nutrient supplementation. When a COD concentration of

20,920 mg L

1

was maintained in the inuent to the rst

stage, the euent quality of the rst stage began to deteri-

orate. A signicant colour change was observed from black

to brownish black and then to brown, and this was thought

to be due to reduced metabolic activity owing to the toxic

eect of the wastewater on granular biomass, thus increas-

ing oxidation-reduction potential. It was concluded that

two stage UASB reactor conguration is an ecient system

for malt whisky wastewater treatment until up to

33,866 mg L

1

inuent COD concentration. For the over-

all sequential system (anaerobic/aerobic) treatment COD

and BOD removal eciencies were 99.5% and 98.1%,

respectively, for the treatment of malt whisky wastewater.

In aerobic phase, the euent of anaerobic bioreactor is

exposed to atmospheric oxygen in a tank with homogeniz-

ers for proper mixing of the euents. BOD is reduced to

200 and euent diluted with wastewater from bottling

and washer sections and disposed of after clarication

(Ramendra and Awasthi, 1992). The stabilized sludge

serves as a soil conditioner and plant nutrient.

Cost economics of biogas production by anaerobic

treatment was calculated by Ciftci and Ozturk (1995). They

suggested that for every $100 spent for the operation of

full-scale anaerobic aerobic treatment plants in a fermen-

tation industry in Turkey producing bakers yeast from

sugarbeet molasses, the biogas recovery is worth $300.

Garcia-Calderon et al. (1998) reported the application of

the down-ow uidization technology for the anaerobic

digestion of red wine distillery wastewater. The system

achieved 85% TOC removal, at an organic loading rate

of 4.5 kg TOC m

3

day

1

. Perlite was found to be a good

carrier for the anaerobic digestion as it allowed a high

biomass hold-up, with minimum particle wash out, because

of its density.

Immobilization of bacteria in biolm and on bioocs is

a crucial step in anaerobic degradation because of advanta-

ges such as higher activities, higher COD removal percent

at short hydraulic retention times and better tolerance to

disturbances such as toxic and organic shock loadings.

At the same time there are certain disadvantages as well

because in addition to some readily biodegradable matter,

vinasses contain compounds like phenols, which are toxic

to bacteria and inhibit the digestion. Also, due to seasonal

nature of many of these industries and the absence of

microorganisms in vinasses capable of carrying out anaer-

obic digestion, long incubation periods are required for

the start-up stage. Besides, other operational problems in

anaerobic digestion such as low growth rate of anaerobic

bacteria and the loss of biomass in systems with high

hydraulic rates frequently does not achieve a satisfactory

purication of vinasses (Beltran et al., 1999). The for-

mation of H

2

S in anaerobic reactors is the result of the

reduction of oxidized sulphur compounds. Methanogenic

bacteria can tolerate sulphide concentration up to

1000 mg L

1

total sulphide. A complete loss of methane

production occurred at 200 mg L

1

of un-ionized H

2

S dur-

ing digestion of occulent sludge. Anaerobic contact pro-

cess incorporating an ultraltration (UF) unit was used

to treat distillery wastewater characterized by high and

low carbon to nitrogen concentrations. This treatment sys-

tem showed methane yield of up to 0.6 m

3

kg

1

VS and

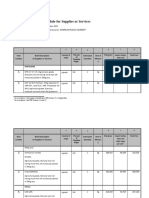

Table 1

Anaerobic methods employed for distillery euent treatment

Reactor type Organic loading rate (OLR)

(kg COD m

3

day

1

)

COD

removal

(%)

BOD

removal

(%)

Retention

time

(days)

Reference

Downow xed-lm reactor 6073 8597 Bories and Ranyal, 1988

Granular bed anaerobic baed

reactor (GRABR)

2.37 9096 8092 4 Akunna and Clark, 2000

Hybrid anaerobic baed reactor 20 70 Boopathy and Tilche, 1991

Upow anaerobic sludge blanket

(UASB) reactor

28 3967 80 Harada et al., 1996

Istanbul UASB reactor 611 90 Akarsubasi et al., 2006

Tekirdag UASB reactor 2.58.5 6080

Diphasic xed-lm reactor with

granular activated carbon (GAC)

as support media

21.3 67.1 4 Goyal et al., 1996

Anaerobic contact lter 19,000 mg L

1

(inuent COD concentration)

7398 4 Vijayaraghavan and

Ramanujam, 2000

2324 D. Pant, A. Adholeya / Bioresource Technology 98 (2007) 23212334

removed up to 80% of the volatile acids (Kitamura et al.,

1996). Two-phase anaerobic digestion of alcohol stillage

proved to be superior to the single-phase process in terms

of substrate loading rate and methane yield, without aect-

ing the treatment performance (Yeoh, 1997). While main-

taining BOD and COD reduction of 85% and 65%

respectively, the two-phase achieved methane yield three

times that of single-phase system.

A number of environmental factors aect the activity of

wastewater microbial populations and the rate of biochem-

ical reactions. Of particular importance are temperature,

pH, nutrients, and inhibiting toxic compounds. Due to

acidic nature of vinasses, pH is one of the most relevant

factors aecting the microbiological activity in the biolog-

ical process. The pH of wastewater increases from 4.0 to

7.5 after anaerobic digestion due to the oxidation of

organic acids to CO

2

and the reaction between the CO

2

and basic compounds to form carbonates and bicarbonates

(Beltran et al., 1999). Because of its high organic load, the

distillery wastewater is often diluted with tap water to sim-

ulate the concentration of a typical industrial euent enter-

ing a wastewater treatment plant. However, spent wash

even after anaerobic treatment does not meet the stringent

euent standards laid down by CPCB, India, in terms of

very high levels of BOD, COD, solids etc. (Asthana

et al., 2001). Also, the secondary spent wash produced by

the anaerobically digested primary molasses spent wash

(DMSW) euent is darker in colour, needing huge vol-

umes of water to dilute it and is currently used in irrigation

water causing gradual soil darkening. The euent there-

fore is released after diluting with fresh water which is a

very dear commodity to industries. Besides, sometimes fail-

ure of the anaerobic digestion threatens the criteria for dis-

charge limit. To overcome this problem either a large

amount of water is used to dilute the wastewater prior to

anaerobic digestion or chemical coagulants are added.

These actions require expansion of the anaerobic digester

volume, large amounts of water for dilution, and addi-

tional costs for coagulants (Kim et al., 1997). Hence aero-

bic treatment is necessary for anaerobically treated nal

euent.

4.2. Aerobic treatment

4.2.1. Bacterial treatment

Microbial treatments employing pure bacterial culture

have been reported frequently in past and recent years. A

detailed list of bacteria tried by dierent researchers for

decolourization of distillery euent is given in Table 2.

Kumar and Viswanathan (1991) isolated bacterial strains

from sewage and acclimatized on increasing concentrations

of distillery waste. These strains were able to reduce COD

by 80% in 45 days without any aeration. The major prod-

ucts left after treatment were biomass, carbon dioxide and

volatile acids. Petruccioli et al. (2000) used an air bubble

column reactor with activated sludge carrying self adapted

microbial population in both free and immobilized on

polyurethane particles for treating aerobic winery wastewa-

ter. The highest COD removal rate was with free activated

sludge in the bubble column reactor. The most prominent

bacterial species isolated from the reactor liquid belonged

to Pseudomonas while Bacillus was isolated mostly from

colonized carriers. Pseudomonas uorescens, decolourized

melanoidin wastewater (MWW) up to 76% under non-ster-

ile conditions and up to 90% in sterile samples (Dahiya

et al., 2001a). The dierence in decolourization might be

due to the fact that melanoidin stability varies with pH

and temperature and at higher temperature during sterili-

zation melanoidin-pigments decompose to low molecular

weight compounds (Ohmomo et al., 1988b). The eect of

immobilization on the decolourization of a melanoidin

solution may be explained by the fact that Lactobacillus hil-

gardii requires a small amount of oxygen for the decolou-

rization and immobilization within Ca-alginate gel leads

to suitably limited aeration, supplying a small amount of

oxygen continuously (Ohmomo et al., 1988a).

Acetogenic bacteria are capable of oxidative decomposi-

tion of melanoidins. Cibis et al. (2002) achieved biode-

gradation of potato slops (distillation residue) by a mixed

population of bacteria under thermophilic conditions up

to 60 C. A COD removal of 77% was achieved under

non-optimal conditions. Marine cyanobacteria such as

Oscillatoria boryna have also been reported to degrade mel-

anoidin due to production of H

2

O

2

, hydroxyl, perhydroxyl

and active oxygen radicals, resulting in the decolourization

of the euent (Kalavathi et al., 2001). 96%, 81% and 26%

decolorisation of distillery euent through bioocculation

by Oscillatoria sp., Lyngbya sp. and Synechocystis sp.

respectively was reported by Patel et al. (2001).

Distillery spent wash, despite carrying high organic

load contains little readily available carbon. Isolation

of bacterial strains capable of degrading recalcitrant com-

pounds of anaerobically digested spent wash from soil of

euent discharge site was reported by Ghosh et al.

(2004). These were Pseudomonas, Enterobacter, Steno-

trophomonas, Aeromonas, Acinetobacter and Klebsiella all

of which could carry out degradation of some component

of spent wash. Maximum 44% COD reduction was

achieved using these bacterial strains either singly or col-

lectively. Sirianuntapiboon et al. (2004) used an acetogenic

bacterium to obtain a decolourization yield of 76.4%

under optimal nutrient conditions. However, this value

was only 7.3%, by using anaerobic pond. Also, it required

sugar, especially glucose and fructose for decolourization

of MWWs. The decolourization activity might be due to

a sugar oxidase.

4.2.2. Fungal treatment

In recent years, several basidiomycetes and ascomycetes

type fungi have been used in the decolourization of natural

and synthetic melanoidins in connection with colour reduc-

tion of wastewaters fromdistilleries. The aimof fungal treat-

ment is to purify the euent by consumption of organic

substances, thus, reducing its COD and BOD, and at the

D. Pant, A. Adholeya / Bioresource Technology 98 (2007) 23212334 2325

same time to obtain some valuable product, such as fungal

biomass for protein-rich animal feed or some specic fungal

metabolite. Filamentous fungi have lower sensitivity to vari-

ations in temperature, pH, nutrients and aeration and have

lower nucleic acid content in the biomass (Knapp et al.,

2001). Several fungi have been investigated for their ability

to decolourise melanoidins and MSW (Table 3).

Coriolus sp. no. 20, in class basidiomycetes was the rst

strain for the application of its ability to remove melanoi-

dins from MWW (Watanabe et al., 1982). This isolate

did not show any decolourization activity when molasses

pigment was used as carbon source but it showed the activ-

ity when sorbose or glucose was added. In 1985, Ohmomo

et al. used Coriolus versicolour Ps4a for MWW decolouri-

zation and obtained 80% decolourization in darkness

under optimum conditions. Later, Ohmomo et al. (1988b)

used autoclaved mycelium of Aspergillus oryzae Y-2-32

that adsorbed lower weight fractions of melanoidin and

degree of adsorption was inuenced by the kind of sugars

used for cultivation. The wine distilleries produce large vol-

umes of wastewaters having phenolic compounds, which

give a high inhibitory and anti-bacterial activity to this

wastewater, thus slowing down the anaerobic digestion

process. Partial elimination of these phenolics compounds

was obtained by using Geotrichum candidum (Borja et al.,

1993). Rhizoctonia sp. D-90 decolourized molasses mela-

noidin medium and a synthetic melanoidin medium by

87.5% and 84.5% respectively, under experimental growth

conditions. Electron microscopy revealed that the mycelia

absorbed melanoidin pigment, which was in the form of

electron dense material in the cytoplasm. However, mela-

noidin could be eluted from the mycelia by washing in a

Table 2

Bacteria employed for the decolourization of distillery euent

S. no. Name Comments Colour Removal (%) Reference

1 Xanthomonas fragariae All the three strains needed glucose as carbon source and

NH

4

Cl as nitrogen source. The decolourization eciency of

free cells was better than immobilized cells

76 Jain et al., 2002

2 Bacillus megaterium 76

3 Bacillus cereus 82

4 Bacillus smithii Decolourization occurred at 55 C in 20 days under anaerobic

conditions in presence of peptone or yeast extract as

supplemental nutrient. Strain could not use MWW as sole

carbon source

35.5 Kambe et al., 1999

5 Lactobacillus hilgardii Immobilized cells of the heterofermentative lactic acid

bacterium decolourized 40% of the melanoidins solution within

4 days aerobically

40 Ohmomo et al., 1988a

6 Acetobacter acetii The organism required sugar especially, glucose and fructose

for decolourization of MWWs

76.4 Sirianuntapiboon et al.,

2004

7 Pseudomonas

uorescens

This decolourization was obtained with cellulose carrier coated

with collagen. Reuse of decolourized cells reduced the

decolourization eciency

94 Dahiya et al., 2001a

8 Pseudomonas putida The organism needed glucose as a carbon source, to produce

hydrogen peroxide which reduced the colour

60 Ghosh et al., 2002

9 Acinetobacter sp. All these organisms were isolated from an air bubble column

reactor treating winery wastewater after 6 months of

operation. Most isolates from the colonized carriers belonged

to species of the genus Bacillus

Not checked in this

study

Petruccioli et al., 2000

10 Aeromonas sp.

11 Alcaligens faecalis

12 Bacillus sp.

13 Flavobacterium sp.

14 F. meningosepticum

15 Pseudomonas sp.

16 P. paucimobilis

17 P. vescicularis

18 Sphingobacterium

multivorum

19 Bacillus thuringiensis Addition of 1% glucose as a supplementary carbon source was

necessary

22 Kumar and Chandra,

2006

20 Bacillus brevis 27.4

21 Bacillus sp. 27.4

22 Pseudomonas

aeruginosa

The three strains were part of a consortium which decolourized

the anaerobically digested spent wash in presence of basal salts

and glucose

67 Mohana et al., 2007

23 Stenotrophomonas

maltophila

24 Proteus mirabilis

2326 D. Pant, A. Adholeya / Bioresource Technology 98 (2007) 23212334

Table 3

Fungi employed for the decolourization of Distillery euent

S.

no.

Name Comments Colour

Removal (%)

Reference

1 Phanerochaete

chrysosporium

Both the fungi required a readily available carbon source for

melanoidin decolourization while N source had no eect. Maximum

decolourization was observed in 6.25% (v/v) spent wash

53.5 Kumar et al., 1998

2 Coriolus versicolor 71.5

3 Trametes versicolor COD and NNH

4

removal observed in presence of sucrose and

KH

2

PO

4

as nutrient source

82 Benito et al., 1997

4 Geotrichum

candidum

Fungus immobilized on polyurethane foam showed stable

decolourization of molasses in repeated-batch cultivation

80 Kim and Shoda, 1999

5 Coriolus hirsutus A large amount of glucose was required for colour removal but

addition of peptone reduced the decolourizing ability of the fungus

80 Miyata et al., 2000

6 Penicillium sp. All fungi produced decolourization from rst day of incubation,

with maximum being shown byP. decumbens at fourth day with a

reduction of 70% of the phenolic content of the wastewater

30 Jimnez et al., 2003

7 Penicillium

decumbens

41

8 Penicillium

lignorum

28

9 Aspergillus niger 25

10 Aspergillus niger

UM2

Decolourization was more by immobilized fungus and it was able to

decolourize up to 50% of initial euent concentrations

80 Patil et al., 2003

11 Aspergillus

fumigatus G-2-6

Thermophilic strain tried for molasses wastewater decolourization

but colouring compounds hardly degraded

56 Ohmomo et al., 1987

12 Mycelia sterilia Organism required glucose for the decolourizing activity 93 Sirianuntapiboon et al., 1988

13 Aspergillus niger Maximum colour removal was obtained when MgSO

4

, KH

2

PO

4

,

NH

4

NO

3

and a carbon source was added to wastewater

69 Miranda et al., 1996

14 Flavodon avus MSW was decolourized using a marine basidiomycete fungus. It also

removed 68% benzo(a)pyrene, a PAH found in MSW

80 Raghukumar and Rivonkar,

2001; Raghukumar et al., 2004

15 Rhizoctonia sp. D-

90

Mechanism of decolourization of melanoidin involved absorption of

the melanoidin pigment by the cells as a macromolecule and its

intracellular accumulation in the cytoplasm and around the cell

membrane as a melanoidin complex, which was then gradually

decolourized by intracellular enzymes

90 Sirianuntapiboon et al., 1995

16 Coriolus versicolor

Ps4a

Two types of enzymes, sugar-dependent and sugar-independent,

were found to be responsible for melanoidin decolourizing activity

80 Ohmomo et al., 1985

17 Aspergillus oryzae

Y-2-32

The thermophilic strain adsorbed lower molecular weight fractions

of melanoidin and required sugars for growth

75 Ohmomo et al., 1988b

18 Phanerochaete

chrysosporium

JAG-40

This organism decolourized synthetic and natural melanoidins when

the medium was supplemented with glucose and peptone

80 Dahiya et al., 2001b

19 Coriolus hirsutus

IFO4917

Melanoidins present in heat treatment liquor were subjected to

sequencing batch decolourization by the immobilized fungal cells

45 Fujita et al., 2000

20 Aspergillus niveus The fungus could use sugarcane bagasse as carbon source and

required other nutrients for decolourization

56 Angayarkanni et al., 2003

21 Trametes sp. I-62 No colour observed associated with either fungal mycelium or

polysaccharides secreted by the fungus and therefore colour removal

was attributed to fungal degradation and not to a simple physical

binding

73 Gonzalez et al., 2000

22 Aspergillus niger All these organisms were isolated from an air bubble column reactor

treating winery wastewater after 6 months of operation

Not checked

in this study

Petruccioli et al., 2000

23 Candia sp.

24 C. lambica

25 C. lypolitica

26 Fusarium sp.

27 Penicillium sp.

28 P. roquefortii

29 Saccharomyces

cerevisiae

30 Trichoderma

koningii

31 Coriolus sp. no. 20 First strain for the application of its ability to remove melanoidins

from MWW, showed decolourization activity in 0.5% melanoidin

when sorbose or glucose was added as carbon source

80 Watanabe et al., 1982

(continued on next page)

D. Pant, A. Adholeya / Bioresource Technology 98 (2007) 23212334 2327

solution of NaOH and the relative amount of melanoidin

eluted from the mycelia increased with increase in the con-

centration of NaOH (Sirianuntapiboon et al., 1995). Asper-

gillus awamori var. kawachi has been used for production

of single cell protein from Japanese distillery (Shochu)

wastewater after aerobic cultivation (Kida et al., 1995).

The supernatant after cultivation could be anaerobically

treated, at a high TOC loading rate, by the addition of

Ni

2+

and Co

2+

. Also, NH

4

, accumulated in the anaerobi-

cally treated wastewater, was eciently removed by utiliza-

tion of residual volatile fatty acids (VFA) as electron

donors during biological denitrication and nitrication,

and the residual organic matter could be removed simulta-

neously. Colour elimination from MSW using Aspergillus

niger was studied by Miranda et al. (1996). Under optimal

nutrient concentration 83% of the total colour removed

was eliminated biologically and 17% by adsorption on

the mycelium. Ohmomo et al. (1988a) concluded that

microbial decolourization of melanoidins is due to two

decomposition mechanisms; in the rst the smaller molecu-

lar weight melanoidins are attacked and in the second the

larger molecular weight melanoidins are attacked.

Under nutrient limiting conditions, fungal cells gener-

ally cannot remain active during a long-term cultivation.

Therefore, the continuous-culture method is not practical

and the semi-batch or repeated-batch method can be an

alternative for long-term cultivation. The immobilization

of the fungus on a solid support is an appropriate means

for controlling the thickness of the biolm. The immobili-

zation of the fungus oers advantages such as short reten-

tion time, easy recovery of the cells and increased activity.

Furthermore, in the presence of the foam matrix, pellet

size is restricted by the size and the physical properties

of the foam (Kim and Shoda, 1999). Miyata et al. (2000)

suggested an inhibitory eect of organic nitrogen on mel-

anoidin decolourization by fungus Coriolus hirsutus. At

Table 3 (continued)

S.

no.

Name Comments Colour

Removal (%)

Reference

32 Williopsis saturnus

strain CBS 5761

Yeast isolates from a rotating biological contactor (RBC) treating

winery wastewater. Only 43% COD removal could be achieved

Not checked

in this study

Malandra et al., 2003

33 Pichia

membranaefaciens

strain IGC 5003

34 Candia intermedia

JCM 1607

35 Eremothecium

gossyphi

36 Saccharomyces

cerevisiae strain J2

37 Hanseniaspora

uvarum

38 Coriolus versicolor

sp no. 20

10% diluted spent wash was used with glucose @ 2% added as carbon

source

34.5 Chopra et al., 2004

39 Phanerochaete

chrysosporium

Sugar renery euent was treated in a RBC using polyurethane foam

and scouring web as support

55 Guimaraes et al. (2005)

40 Pycnoporus

coccineus

Immobilized mycelia removed 50% more colour than free mycelia 60 Chairattanamanokorn et al.,

2005

41 Coriolus versicolor Cotton stalks were added as additional carbon source which stimulated

the decolourization activity of all fungi in 30% vinasses

63 Kahraman and Yesilada,

2003

42 Phanerochaete

chrysosporium

37

43 Funalia trogii 57

44 Pleurotus

pulmonarius

43

45 Aspergillus-UB2 This was with diluted wastewater with optimum values of

supplemented materials

75 Shayegan et al. (2004)

46 Marine

Basidiomycete

NIOCC # 2a

Experiment was carried out at 10% diluted spent wash 100 Dsouza et al. (2006)

47 Phanerochaete

chrysosporium

Molasses medium decolourization was checked in stationary and

submerged cultivation conditions

Thakkar et al., 2006

NCIM 1073 0

NCIM 1106 82

NCIM 1197 76

48 Citeromyces sp.

WR-43-6

Organism required glucose, Sodium nitrate and KH

2

PO

4

for maximal

decolourization

68.91 Sirianuntapiboon et al., 2003

49 Hansenula fabianii The occulant strains could reduce 28.5% TOC from wastewater

without dilution

Not checked

in this study

Moriya et al., 1990

50 Hansenula anomala

2328 D. Pant, A. Adholeya / Bioresource Technology 98 (2007) 23212334

the same time glucose was also required for enhancing

decolourization as the peroxidases require H

2

O

2

, which

is generated by glucose oxidation, to decolourize melanoi-

din. Chopra et al. (2004) reported that absence of addi-

tional nitrogen could not inhibit activity of fungus C.

versicolour sp no. 20 considerably, as signicant decolouri-

zation and COD reduction occurred even in the absence of

it.

Colour removal from distillery euent using a marine

fungus, Flavodon avus has been reported by Raghukumar

and Rivonkar (2001). This fungus was more eective in

decolourizing raw MSW than was the molasses wastewater

collected either after anaerobic treatment or after aerobic

treatment. The oxygen demand of the fungus was quite

high. P. chrysosporium JAG-40 decolourized synthetic

and natural melanoidins present in spentwash up to 80%

(Dahiya et al., 2001b). The larger molecular weight frac-

tions of melanoidin were decolourized rapidly, while the

small molecular weight fractions remained in solution

and were metabolized slowly. Also, the decolourization

was less in sterilized spentwash than in non-sterile solution.

This observation is completely opposite of the one when

Pseudomonas uorescens was used by same authors

(Dahiya et al., 2001a). Kahraman and Yesilada (2003)

reported molasses decolourization in semi solid state

(SSS) cultivation by fungi C. versicolour, Funalia trogii,

P. chrysosporium and Pleurotus pulmonarius with cotton

stalks being used as additional source of carbon. C. versi-

colour decolourized 48% of 30% diluted vinasse without

any additional carbon source which increased to 71% on

addition of cotton stalks. Aspergillus niveus, a litter degrad-

ing fungi was used by Angayarkanni et al. (2003) for the

treatment of distillery euent using paddy straw, sugar-

cane bagasse, molasses and sucrose as carbon source for

growth of fungus in the euent. Sugarcane bagasse at

1% (w/v) concentration resulted in maximum removal of

colour (37%) and COD (91.68%). The decrease in colour

removal in this study might be due to the fact that the eu-

ent taken for study was alkaline (pH 9.0) and the melanoi-

dins responsible for colour were more soluble in the

alkaline pH. In the acidic pH, the melanoidins might be

precipitated and removed easily. Shayegan et al. (2005)

used an Aspergillus species isolated from the soil for

decolourization of anaerobically digested (UASB) and

aerobically treated distillery wastewater. With diluted

wastewater at optimum values of supplemented materials

75% decolourization was achieved which reduced to 40%

on using undiluted wastewater. It was suggested that deco-

lourization by fungi takes place due to the destruction of

coloured molecules and partially because of sorption phe-

nomena. A longer aeration period causes the adsorbed col-

our molecules to be released as a result of endogenous

respiration and cell death, hence reducing decolourization

eciency.

Yeast Citeromyces was used for treating MWW and

high and stable removal eciencies in both colour intensity

and organic matter were obtained. However, the semi-pilot

and pilot-scale experiments are to be tested for checking

the stability of Citeromyces sp. (Sirianuntapiboon et al.,

2003). Malandra et al. (2003) studied the microorganisms

associated with a rotating biological contactor (RBC)

treating winery wastewater. One of the yeast isolates was

able to reduce the COD of synthetic wastewater by 95%

and 46% within 24 h under aerated and non-aerated condi-

tions, respectively. Moriya et al. (1990) used two occulant

strains of yeast, Hansenula fabianii and Hansenula anomala

for treatment of wastewater from beet molasses-spirits pro-

duction and achieved 25.9% and 28.5% removal of TOC

respectively from wastewater without dilution. Dilution

of wastewater was not favourable for practical treatment

of wastewater due to the longer treatment time and higher

energy cost.

4.2.3. Mixed consortium treatment

During last two decades, several attempts have been

made to investigate the possibility of using cell immobili-

zation in the technology of aerobic wastewater treatment

(Fedrici, 1993; Sumino et al., 1985). Early experiments

were restricted to the use of selected pure cultures im-

mobilized on solid supports for the degradation of specic

toxic compounds (Anselmo et al., 1985; Livernoche et al.,

1983). Later, immobilized consortia of two or more

selected strains were employed (Kowalska et al., 1998;

Zache and Rehm, 1989) but of late activated sludge has

been immobilized on dierent carriers and used for waste-

water treatment (Shah et al., 1998). Jet loop reactors

(JLR), the eciency of which has already been shown in

both chemical and biological processes have also been

evaluated for aerobic treatment of winery wastewater. A

JLR of 15 dm

3

working volume was used for the aerobic

treatment of winery wastewater (Petruccioli et al., 2002).

COD removal eciency higher than 90% was achieved

with an organic load of the nal euents that ranged

between 0.11 and 0.3 kg COD m

3

. Most isolates belong

to the genus Pseudomonas and the yeast Saccharomyces

cerevisiae. Later, Eusibio et al. (2004) reported the opera-

tion of a JLR for more than one year treating winery

wastewater collected in dierent seasons and achieved an

average COD removal eciency of 80%. JLR have higher

oxygen transfer rates at lower energy costs. They also

observed Bacillus apart from Pseudomonas and the yeast

Saccharomyces cerevisiae. Adikane et al. (2006) studied

decolourization of molasses spent wash in absence of

any additional carbon or nitrogen source using soil as

inoculum. A decolourization of 69% was obtained using

10% (w/v) soil and 12.5% (v/v) MSW after 7 days

incubation.

4.2.4. Phytoremediation approach

Algal growth potential bioassay is a standard assay to

determine the potential of water bodies, natural waters

and wastewaters, to support or inhibit the microalgae

growth. Algae growth potential was determined in distill-

ery wastewater pretreated by anaerobic processes and by

D. Pant, A. Adholeya / Bioresource Technology 98 (2007) 23212334 2329

a combined anaerobic-aerobic system. The biologically

treated distillery wastewater provided satisfactory condi-

tions for microalgae growth (Travieso et al., 1999). Billore

et al. (2001) used Phragmites kharka in a constructed wet-

land for treatment of wastewater from the same industry

and obtained 36% removal of total Kjeldahl nitrogen and

48% removal of total suspended solids (TSS). Enhanced

decolourization was achieved by phytoremediation of

distillery euent by a macrophyte, Spirodela polyrrhiza

(L.) Schliden pretreated with Bacillus thuringiensis (Kumar

and Chandra, 2004). Recently, macrophyte Potamogeton

pectinatus was used for bioaccumulating heavy metals from

distillery euent (Singh et al., 2005). Increasing concentra-

tion of the euent greatly reduced the biomass of the plant

with maximum accumulation of Fe being recorded in

plants growing in 100% euent. In another study Trivedy

and Nakate (2000) employed Typha latipholia for distillery

euent treatment in a constructed wetland. The system

resulted in 78% and 47% reduction in COD and BOD

respectively in a period of 10 days. Using a combined treat-

ment with Lemna minuscula and Chlorella vulgaris Valder-

rama et al. (2002) reported 52% colour removal from

distillery euent. The microalgal treatment removed nutri-

ents and organic matter from wastewater and produced

oxygen for other organisms. The macrophyte removed

organic matter and eliminated the microalgae form treated

wastewater. However, despite the potential of aquatic mac-

rophytes in cleaning wastewaters the use of these plants in

designing a low cost treatment system is still at experimen-

tal stage and is considered to be a potentially important

area of environmental management.

5. Role of enzymes in euent decolourization

Although the enzymatic systemrelated with decolouriza-

tion of melanoidins is yet to be completely understood, it

seems greatly connected with fungal ligninolytic mech-

anisms. The white-rot fungi have a complex enzymatic

system which is extracellular and non-specic, and under

nutrient-limiting conditions is capable of degrading ligno-

lytic compounds, melanoidins, and polyaromatic com-

pounds that cannot be degraded by other microorganisms

(Benito et al., 1997). A large number of enzymes from a

variety of dierent plants and microorganisms have been

reported to play an important role in an array of waste

treatment applications.

Several studies regarding degradation of melanoidins,

humic acids and related compounds using basidiomycetes

have also suggested a participation of at least one laccase

enzyme in fungi belonging to Trametes (Coriolus) genus.

The role of enzymes other than laccase or peroxidases in

the decolourization of melanoidins by Trametes (Coriolus)

strain was reported during the 1980s. Several reports

claimed that intracellular sugar-oxidase- type enzymes (sor-

bose-oxidase or glucose-oxidase) had melanoidin-decolou-

rizing activities. It was suggested that melanoidins were

decolourized by the active oxygen (O

2

; H

2

O

2

) produced

by the reaction with sugar oxidases (Watanabe et al.,

1982). Decolourization by microbial methods includes the

enzymatic breakdown of melanoidin and occulation by

microbially secreted substances. Ohmomo et al. (1985) used

C. versicolour Ps4a, which decolourized molasses wastewa-

ter 80% in darkness under optimum conditions. Decolouri-

zation activity involved two types of intracellular enzymes,

sugar-dependent and sugar-independent. One of these

enzymes required no sugar and oxygen for appearance of

the activity and could decolourize MWW up to 20% in

darkness and 1117% of synthetic melanoidins. Thus, the

participation of these H

2

O

2

producing enzymes as a part

of the complex enzymatic system for melanoidin degrada-

tion by fungi should be taken into account while designing

any treatment strategy. One of the more complete enzy-

matic studies regarding melanoidin decolourization was

reported by Miyata et al. (1998). Colour removal of syn-

thetic melanoidin by C. hirsutus involved the participation

of peroxidases (MnP and MIP) and the extracellular H

2

O

2

produced by glucose-oxidase, without disregard of a partial

participation of fungal laccase. Mansur et al. (1997)

obtained a maximum decolourization of around 60% on

day 8 after inoculating with fungus Trametes sp. I-62. Here

euent was added at a nal concentration of 20% (v/v)

after 5 days of fungal growth, the time at which high levels

of laccase activity were detected in the extracellular

mycelium.

The white-rot basidiomycete T. versicolour is an active

degrader of humic acids as well as of melanoidins. A mel-

anoidin mineralizing 47 kDa extracellular protein corre-

sponding to the major mineralizing enzyme system from

T. versicolour was isolated by Dehorter and Blondeau

(1993). This Mn

2+

dependent enzyme system required oxy-

gen and was described to be as peroxidase. Uniform, small

and spongy pellets of the fungus T. versicolour were used as

inoculum for colour removal using dierent nutrients such

as ammonium nitrate, manganese phosphate, magnesium

sulphate and potassium phosphate and also sucrose as car-

bon source (Benito et al., 1997). Maximum colour removal

of 82% and 36% removal of NNH

4

was obtained on using

low sucrose concentration and KH

2

PO

4

as the only nutri-

ent. Some studies have identied the lignin degradation

related enzymes participating in the melanoidin decolouri-

zation. Intracellular H

2

O

2

producing sugar oxidases have

been isolated from Coriolus strains. Also, C. hirsustus have

been reported to produce enzymes that catalyze melanoidin

decolourization directly without additions of sugar and O

2

.

Miyata et al. (1998) used C. hirsutus pellets to decolourize a

melanoidin-containing medium. It was elucidated that

extracellular H

2

O

2

and two extracellular peroxidases, a

manganese-independent peroxidase (MIP) and manganese

peroxidase (MnP) were involved in decolourization

activity.

Lee et al. (2000) investigated the dye-decolourizing per-

oxidase by cultivating Geotrichum candidum Dec1 using

molasses as a carbon source. Components in the molas-

ses medium stimulated the production of decolourizing

2330 D. Pant, A. Adholeya / Bioresource Technology 98 (2007) 23212334

peroxidase but inhibited the decolourizing activity of the

puried enzyme. It was found that the inhibitory eect of

molasses can be eliminated at dilution ratios of more than

25. Recently Dsouza et al. (2006) reported 100% decolou-

rization of 10% spent wash by a marine fungal isolate

whose laccase production increased several folds in the

presence of phenolic and non-phenolic inducers.

A combined treatment technique consisting of enzyme

catalyzed in situ transformation of pollutants followed by

aerobic biological oxidation was investigated by Sangave

and Pandit (2006a) for the treatment of alcohol distillery

spent wash. It was suggested that enzymatic pretreatment

of the distillery euent leads to in situ formation of the

hydrolysis products, which have dierent physical proper-

ties and are easier to assimilate than the parent pollutant

molecules by the microorganisms, leading to faster initial

rates of aerobic oxidation even at lower biomass levels.

In another study, Sangave and Pandit (2006b) used irradi-

ation and ultrasound combined with the use of an enzyme

as pretreatment technique for treatment of distillery waste-

water. The combination of the ultrasound and enzyme

yielded the best COD removal eciencies as compared to

the processes when they were used as stand-alone treatment

techniques. Enzymatic decolourization of molasses med-

ium has also been tried using P. chrysosporium (Thakkar

et al., 2006). Under stationary cultivation conditions, none

of the strains could decolourize molasses nor produce

enzymes lignin peroxidase, manganese peroxidase and lac-

case. All of them could produce lignin peroxidase and man-

ganese peroxidase when cultivated in at bottom glass

bottles under stationary cultivation conditions.

6. Conclusions

For industries using large quantities of water such as

distilleries, it is essential to treat and reuse their wastewater.

However, most of the times, the discharge standards

applied to most agro-industries, including distilleries are

often too stringent and below the levels that can be

achieved with appropriate biological treatment technolo-

gies. It has been observed and often reported that the use

of an individual process alone may not treat the wastewater

completely. A combination of these processes is necessary

to achieve the desirable goal. An anaerobic, or chemical

coagulation/oxidation pretreatment followed by aerobic

biological oxidation is a common technique used for decol-

orizing wastewater. But as discussed above, these processes

are not ecient enough to treat these large volumes of col-

oured wastewaters. A combination of dierent treatment

processes including a decolourization step could result in

an eective bioremediation of the molasses wastewaters.

In general, microbial decolourization is an environ-

ment-friendly and cost-competitive alternative to chemical

decomposition process. However, the problem still persists

because several organisms that have been shown to degrade

melanoidin are not best suited for treating MSW. This is

because they deplete oxygen in the euent and further,

higher fungi are not easily adopted for aquatic habitats.

The investigations so far can be seen as an initial step

toward solving the problem. Moreover, most of these

microbial decolourization studies required euent dilution

for optimal activity. While using microorganisms, use of

media supplement pose extra burden on overall euent

treatment process.

The use of cellulose carriers for microbial treatment

oers an alternative method for cell immobilization.

Gel entrapment has been conventional process of cell

immobilization. However, in processes like wastewater

treatment where large volumes are involved, entrapment

in gel beads is not as practical and economic when used

on an industrial scale. Further, the emerging treatment

methods like enzymatic treatment have technological

advantages and yet are in its infancy, requiring economical

considerations in order to apply it on the plant scale. Cap-

ital and operating costs of the available physicochemical

and biological treatment processes of distillery waste

stream are inevitably high thus making these processes less

lucrative to the industry. Nevertheless, the feasibility of

application of the process to full-scale would need further

research in this continuous culture set-up, in order to min-

imize the added nutrients and extend the biomass activity

for a longer period. An understanding of complete prole

of the euent and the structures of coloring compounds

would also be helpful in achieving the appropriate treat-

ment solutions.

Acknowledgements

Authors wish to thank Dr. R. K. Pachauri, Director-

General, TERI, New Delhi, India for support in research.

Financial assistance from University Grants Commission,

New Delhi in form of Senior Research Fellowship to the

rst author is duly acknowledged.

References

Adikane, H.V., Dange, M.N., Selvakumari, K., 2006. Optimization of

anaerobically digested distillery molasses spent wash decolourization

using soil as inoculum in the absence of additional carbon and nitrogen

source. Biores. Technol. 97, 21312135.

Agrawal, C.S., Pandey, G.S., 1994. Soil pollution by spentwash discharge:

Depletion of manganese (II) and impairment of its oxidation. J.

Environ. Biol. 15, 4953.

Akarsubasi, A.T., Ince, O., Oz, N.A., Kirdar, B., Ince, B.K., 2006.

Evaluation of performance, acetoclastic methanogenic activity and

archaeal composition of full-scale UASB reactors treating alcohol

distillery wastewaters. Process Biochem. 41, 2835.

Akunna, J.C., Clark, M., 2000. Performance of a granular-bed anaerobic

baed reactor (GRABBR) treating whisky distillery wastewater.

Biores. Technol. 74, 257261.

Angayarkanni, J., Palaniswamy, M., Swaminathan, K., 2003. Biotreat-

ment of distillery euent using Aspergillus niveus. Bull. Environ.

Contam. Toxicol. 70, 268277.

Anselmo, A.M., Mateus, M., Cabral, J.M.S., Novais, J.M., 1985.

Degradation of phenol by immobilized cells of Fusarium occiferum.

Biotechnol. Lett. 7, 889894.

D. Pant, A. Adholeya / Bioresource Technology 98 (2007) 23212334 2331

Asthana, A., Mishra, S.K., Chandra, R., Guru, R., 2001. Treatment of

colour and biochemical oxygen demand of anaerobically treated

distillery euent by aerobic bacterial strains. Ind. J. Environ. Prot.

21, 10701072.

Beltran, F.J., Garcia-Araya, J.F., Alvarez, P.M., 1999. Wine distillery

wastewater degradation 2. Improvement of aerobic biodegradation by

means of an integrated chemical (ozone)-biological treatment. J. Agric.

Food Chem. 47, 39193924.

Beltran, F.J., Alvarez, P.M., Rodriguez, E.M., Garcia-Araya, J.F., Rivas,

J., 2001. Treatment of high strength distillery wastewater (cherry

stillage) by integrated aerobic biological oxidation and ozonation.

Biotechnol. Prog. 17, 462467.

Benito, G.G., Miranda, M.P., Santos, D.R., 1997. Decolourization of

wastewater from an alcoholic fermentation process with Trametes

versicolor. Biores. Technol. 61, 3337.

Billore, S.K., Singh, N., Ram, H.K., Sharma, J.K., Singh, V.P., Nelson,

R.M., Dass, P., 2001. Treatment of a molasses based distillery euent

in a constructed wetland in central India. Water Sci. Tech. 44, 441

448.

Blonskaja, V., Menert, A., Vilu, R., 2003. Use of two-stage anaerobic

treatment for distillery waste. Adv. Environ. Res. 7, 671678.

Boopathy, R., Tilche, A., 1991. Anaerobic digestion of high strength

molasses wastewater using hybrid anaerobic baed reactor. Water

Res. 25, 785790.

Bories, A., Ranyal, J., 1988. Anaerobic digestion of high-strength distillery

wastewater (cane molasses stillage) in a xed-lm reactor. Biol.

Wastes. 23, 251267.

Borja, R., Martin, A., Luque, M., Duran, M.M., 1993. Enhancement of

the anaerobic digestion of wine distillery wastewater by the removal of

phenolics inhibitors. Biores. Technol. 45, 99104.

Borrero, M.A.V., Pereira, J.T.V., Miranda, E.E., 2003. An environmental

management method for sugar cane alcohol production in Brazil.

Biomass Bioenergy. 25, 287299.

Cammerer, B., Jalyschkov, V., Kroh, L.W., 2002. Carbohydrate structures

as part of the melanoidins skeleton. Int. Congress Series 1245, 269

273.

Chairattanamanokorn, P., Imai, T., Kondo, R., Sekine, M., Higuchi, T.,

Ukita, M., 2005. Decolourization of alcohol distillery wastewater by

thermotolerant white rot fungi. Appl. Biochem. Microbiol. 41, 583

588.

Chopra, P., Singh, D., Verma, V., Puniya, A.K., 2004. Bioremediation of

melanoidins containing digested spent wash from cane-molasses

distillery with white rot fungus, Coriolus versicolour. Ind. J. Microbiol.

44, 197200.

Cibis, E., Kent, C.A., Krzywonos, M., Garncarek, Z., Garncarek, B.,

Miskiewicz, T., 2002. Biodegradation of potato slops from a rural

distillery by thermophilic aerobic bacteria. Biores. Technol. 85, 57

61.

Ciftci, T., Ozturk, I., 1995. Nine years of full-scale anaerobic-aerobic

treatment experiences with fermentation industry euents. Water Sci.

Technol. 32, 131139.

CPCB, 2003. Charter on corporate responsibility for environmental

protection. Workshop organized at Mumbai by MPCB on 03.01.2003.

<http://cpcb.nic.in//Charter/charter5.htm>.

Dahiya, J., Singh, D., Nigam, P., 2001a. Decolourisation of molasses

wastewater by cells of Pseudomonas uorescens immobilized on porous

cellulose carrier. Biores. Technol. 78, 111114.

Dahiya, J., Singh, D., Nigam, P., 2001b. Decolourisation of synthetic and

spentwash melanoidins using the white-rot fungus Phanerochaete

chrysosporium JAG-40. Biores. Technol. 78, 9598.

Dehorter, B., Blondeau, R., 1993. Isolation of an extracellular Mn-

dependent enzyme mineralizing melanoidins from the white rot fungus

Trametes versicolour. FEMS Microbiol. Lett. 109, 117122.

Driessen, W., Yspeert, P., 1999. Anaerobic treatment of low, medium and

high strength euent in agro-industry. Water Sci. Technol. 40, 221

228.

Dsouza, D.T., Tiwari, R., Sah, A.K., Raghukumar, C., 2006. Enhanced

production of Laccase by a marine fungus during treatment of

coloured euents and synthetic dyes. Enzyme Microb. Technol. 38,

504511.

Duarte, E., Martins, M., Carvalho, E., Costa, S., Spranger, I., 1997. An

integrated approach for overcoming the environmental impacts of

wineries wastewaters a Portuguese case study. In: Proceedings of

International Symposium of the Vine and wine, 0710 October,

1997. Yangling, China, pp. 15.

Eusibio, A., Petruccioli, M., Lageiro, M., Fedrici, F., Duarte, J.C., 2004.

Microbial characterization of activated sludge in jet-loop bioreactors

treating winery wastewaters. J. Ind. Microbiol. Biotechnol. 31, 2934.

Fedrici, F., 1993. Potential applications of viable, immobilized fungal cell

systems. World J. Microbiol. Biotechnol. 9, 495502.

FitzGibbon, F., Singh, D., McMullan, G., Marchant, R., 1998. The eect

of phenolics acids and molasses spent wash concentration on distillery

wastewater remediation by fungi. Process Biochem. 33, 799803.

Friedrich, J., 2004. Bioconversion of distillery waste. In: Arora, D.K.

(Ed.), Fungal biotechnology in agriculture, food and environmental

applications. Marcel Dekker Inc., New York, pp. 431442.

Fujita, M., Era, A., Ike, M., Soda, S., Miyata, N., Hirao, T., 2000.

Decolourization of heat-treatment liquor of waste sludge using

polyurethane foam-immobilized white rot fungus equipped with an

ultramembrane ltration unit. J. Biosci. Bioeng. 90, 387394.

Fumi, M.D., Parodi, G., Parodi, E., Silva, A., 1995. Optimization of

long-term activated-sludge treatment of winery wastewater. Biores.

Technol. 52, 4551.

Garcia-Calderon, D., Buere, P., Moletta, R., Elmaleh, S., 1998.

Anaerobic digestion of wine distillery wastewater in down-ow

udized bed. Water Res. 32, 35933600.

Ghosh, M., Ganguli, A., Tripathi, A.K., 2002. Treatment of anaerobically

digested distillery spentwash in a two-stage bioreactor using Pseudo-

monas putida and Aeromonas sp. Process Biochem. 7, 857862.

Ghosh, M., Verma, S.C., Mengoni, A., Tripathi, A.K., 2004. Enrichment

and identication of bacteria capable of reducing chemical oxygen

demand of anaerobically treated molasses spent wash. J. Appl.

Microbiol. 96, 12781286.

Gonzalez, T., Terron, M.C., Yague, S., Zapico, E., Galletti, G.C.,

Gonzalez, A.E., 2000. Pyrolysis/gas chromatography/ mass spectro-

metry monitoring of fungal biotreated distillery wastewater using

Trametes sp. I 62 (CECT 20197). Rapid Commun. Mass Spectrom. 14,

14171424.

Goodwin, J.A.S., Stuart, J.B., 1994. Anaerobic digestion of malt whisky

distillery pot ale using upow anaerobic sludge blanket reactor. Biores.

Technol. 49, 7581.

Goyal, S.K., Seth, R., Handa, B.K., 1996. Diphasic xed-lm biometh-

anation of distillery spentwash. Biores. Technol. 56, 239244.

Guimaraes, C., Porto, P., Oliveira, R., Mota, M., 2005. Continuous

decolourization of a sugar renery wastewater in a modied rotating

biological contactor with Phanerochaete chrysosporium immobilized on

polyurethane foam discs. Process Biochem. 40, 535540.

Harada, H., Uemura, S., Chen, A.C., Jayadevan, J., 1996. Anaerobic

treatment of a recalcitrant distillery wastewater by a thermophilic

UASB reactor. Biores. Technol. 55, 215221.

Hayase, F., Kim, S., Kato, H., 1986. Analyses of the chemical structures

of melanoidins by

13

C and

15

N CP-MAS NMR spectrophotometry.

Agric. Biol. Chem. 50, 19511957.

Jain, N., Minocha, A.K., Verma, C.L., 2002. Degradation of predigested

distillery euent by isolated bacterial strains. Ind. J. Exp. Bot. 40, 101

105.

Jimnez, A.M., Borja, R., Martin, A., 2003. Aerobic-anaerobic biodegra-

dation o beet molasses alcoholic fermentation wastewater. Process

Biochem. 38, 12751284.

Joshi, H.C., 1999. Bio-energy potential of distillery euents. Bio. Energy

News. 3, 1015.

Kahraman, S., Yesilada, O., 2003. Decolourization and bioremediation of

molasses wastewater by white-rot fungi in a semi-solid state condition.

Folia Microbiol. 48, 525528.

Kalavathi, D.F., Uma, L., Subramanian, G., 2001. Degradation and

metabolization of the pigment-melanoidin in distillery euent by the

2332 D. Pant, A. Adholeya / Bioresource Technology 98 (2007) 23212334

marine cyanobacterium Oscillatoria boryana BDU 92181. Enzyme

Microb. Technol. 29, 246251.

Kambe, T.N., Shimomura, M., Nomura, N., Chanpornpong, T., Naka-

hara, T., 1999. Decolourization of molasses wastewater by Bacillus sp.

under thermophilic and anaerobic conditions. J. Biosci. Bioeng. 87,

119121.

Kannabiran, B., Pragasam, A., 1993. Eect of distillery euent on seed

germination, seedling growth and pigment content of Vigna mungo (L.)

Hepper (CVT9). Geobios. 20, 108112.

Kato, H., Hayase, F., 2002. An approach to estimate the chemical

structure of melanoidins. Int. Congress Series 1245, 37.

Kaushik, A., Nisha, R., Jagjeeta, K., Kaushik, C.P., 2005. Impact of long

and short term irrigation of a sodic soil with distillery euent in

combination with bioamendments. Biores. Technol. 96, 1860

1866.

Kida, K., Morimiura, S., Abe, N., Sonoda, Y., 1995. Biological treatment

of Shochu distillery wastewater. Process Biochem. 30, 125132.

Kim, S.J., Shoda, M., 1999. Batch decolourization of molasses by

suspended and immobilizes fungus of Geotrichum candidum Dec 1.

J. Biosci. Bioeng. 88, 586589.

Kim, J.S., Kim, B.G., Lee, C.H., Kim, S.W., Jee, H.S., Koh, J.H., Fane,

A.G., 1997. Development of clean technology in alcohol fermentation

industry. J. Cleaner Prod. 5, 263267.

Kitamura, Y., Maekawa, T., Tagawa, A., Hayashi, H., Farrell-Poe, K.L.,

1996. Treatment of strong organic, nitrogenous wastewater by an

anaerobic contact process incorporating ultraltration. Appl. Eng.

Agric. ASAE 12, 709714.

Kitts, D.D., Wu, C.H., Stich, H.F., Powrie, W.D., 1993. Eects of

glucose-glycine maillard reaction products on bacterial and mamma-

lian cells mutagenesis. J. Agric. Food Chem. 41, 23532358.

Knapp, J.S., Vantoch-Wood, E.J., Zhang, F., 2001. Use of wood-rotting

fungi for the decolourisation of dyes and industrial euents. In: Gadd,

G.M. (Ed.), Fungi in Bioremediation. British Mycological Society.

Cambridge University Press, p. 242.

Kort, M.J., 1979. Colour in the sugar industry. In: de Birch, G.G., Parker,

K.J. (Eds.), Science and Technology. Applied Science, London, pp.

97130.

Kowalska, M., Bodzek, M., Bohdziewicz, J., 1998. Biodegradation of

phenols and cyanides with immobilized microorganisms. Process

Biochem. 33, 189197.

Kroh, L.W., 1994. Caramelisation in food and beverages. Food Chem.

51, 373379.

Kumar, P., Chandra, R., 2004. Detoxication of distillery euent through

Bacillus thuringiensis (MTCC 4714) enhanced phytoremediation

potential of Spirodela polyrrhiza (L.) Schliden. Bull. Environ. Contam.

Toxicol. 73, 903910.

Kumar, P., Chandra, R., 2006. Decolurisation and detoxication of

synthetic molasses melanoidins by individual and mixed cultures of

Bacillus spp. Biores. Technol. 97, 20962102.

Kumar, S., Viswanathan, L., 1991. Production of biomass, carbon

dioxide, volatile acids, and their interrelationship with decrease in

chemical oxygen demand, during distillery waste treatment by bacterial

strains. Enzyme Microb. Technol. 13, 179186.

Kumar, V., Wati, L., Nigam, P., Banat, I.M., Yadav, B.S., Singh, D.,

Marchant, R., 1998. Decolourization and biodegradation of anaero-

bically digested sugarcane molasses spent wash euent from biometh-

anation plants by white-rot fungi. Process Biochem. 33, 8388.

Lee, T.H., Aoki, H., Sugano, Y., Shoda, M., 2000. Eect of molasses on

the production and activity of dye-decolourizing peroxidase from

Geotrichum candidum Dec 1. J. Biosci. Bioeng. 89, 545549.

Livernoche, D., Jurasek, L., Desrochers, M., Dorica, J., 1983. Removal of

colour from kraft mill wastewaters with cultures of white-rot fungi and

immobilized mycelium of Coriolus versicolour. Biotechnol. Bioeng. 25,

20552065.

Mahimaraja, S., Bolan, N.S., 2004. Problems and prospects of agricultural

use of distillery spentwash in India. SuperSoil 2004. 3

rd

Australian