Documente Academic

Documente Profesional

Documente Cultură

Capacitor Cerâmico 100pfx50v 3

Încărcat de

Anderson Ribeiro CesarinoDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Capacitor Cerâmico 100pfx50v 3

Încărcat de

Anderson Ribeiro CesarinoDrepturi de autor:

Formate disponibile

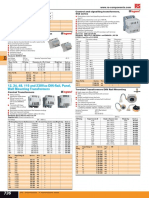

Disc Ceramic Capacitors

Professional Ceramic Capacitors - Class I, II and III

MIL-STD-202F

The professional ceramic disc capacitors were specially

developed for applications in severe environmental conditions, high humidity, temperature, gas, vapor and solvents.

The capacitors are flame retardant epoxy coated, meeting

UL 94-V0 flammability specifications. The capacitors are

100% screened on following electrical parameters:

Capacitance, loss factor, test voltage. After the 100% test,

the capacitors are audited on its electrical and mechanical

parameters with following AQL:

Electrical parameters: 0.065% level II

Mechanical parameters: 0.65% level II

The capacitors withstand the following reliability essays:

Terminal strength: method 211 condition A

Resistance to solvents: method 215

Resistance to soldering heat: method 210 condition B

Solderability: method 208

Thermal shock: method 107 condition A

Humidity (steady state): method 103 condition D

Life (at elevated ambient temperature): method 108

condition D

Operating temperature and storage: -55... +125 C

mm =

0.6 0.1

(0.024) (0.004)

mm = 0.8 0.1

(0.031) (0.004)

Preferred lead spacing F = 5 (0.197)

millimeters (inches)

Lead Spacing

Digit 8

F

2.5 (0.100)

5 (0.200)

6 (0.250)

7.5 (0.300)

10 (0.400)

DIMENSIONS

Digit 9

()

D2

(0.079)

millimeters (inches)

T max.

Available

Lead Spacing

NP0

1pF... 2.7 pF

4.0 (0.157)

3.0 (0.118)

A,B,D,E,O,R

N1500

5.6pF... 8.2 pF

4.0 (0.157)

3.0 (0.118)

A,B,D,E,O,R

4.0 (0.157)

3.0 (0.118)

A,B,D,E,O,R

5.0 (0.197)

6.0 (0.236)

7.0 (0.276)

8.0 (0.315)

9.0 (0.354)

10.0 (0.394)

11.0 (0.433)

13.0 (0.512)

15.0 (0.591)

19.0 (0.748)

3.0 (0.118)

3.0 (0.118)

3.0 (0.118)

3.0 (0.118)

3.0 (0.118)

3.0 (0.118)

3.0 (0.118)

3.5 (0.138)

3.5 (0.138)

4.0 (0.157)

A,B,D,E,O,R,X

A,B,C,D,E,O,R,X

A,B,C,D,E,O,R,X

A,B,C,D,E,O,R,X

A,B,C,E,O,R,X

A,B,C,E,O,R,X

A,B,C,E,O,R,W

B,C,R,W

B,C,R,W

B,C

Others

B

C

D

E

F

G

H

J

K

M

(E), (X), (W): upon request

23

Disc Ceramic Capacitors

General Specifications - Class III Professional

DIELECTRIC - CLASS III

A thin dielectric layer is grown on a disc of conductive

ceramic. Very large capacitances can be obtained due to

reduced thickness of this barrier layer and its inherently

high dielectric constant. Due its small dimensions, they are a

less expensive replacement of multilayer ceramic or polyester capacitors.

DIMENSIONS

Digit 9

of P.N.

()

D2

(0.079)

millimeters (inches)

T max.

Available

Lead Spacing

4.0 (0.157)

3.0 (0.118)

A,B,D,E,O,R

5.0 (0.197)

3.0 (0.118)

A,B,D,E,O,R,X

6.0 (0.236)

3.0 (0.118)

A,B,C,D,E,O,R,X

7.0 (0.276)

3.0 (0.118)

A,B,C,D,E,O,R,X

8.0 (0.315)

3.0 (0.118)

A,B,C,D,E,O,R,X

9.0 (0.354)

3.0 (0.118)

A,B,C,E,O,R,X

10.0 (0.394)

3.0 (0.118)

A,B,C,E,O,R,X

11.0 (0.433)

3.0 (0.118)

A,B,C,E,O,R,W

13.0 (0.512)

3.5 (0.138)

15.0 (0.591)

= 0.6 0.1

(0.024) (0.004)

4.0 (0.157)

Preferred lead spacing

F = 5 (0.197)

millimeters (inches)

Lead Spacing

F

2.5 (0.100)

B,C,R,W

5 (0.200)

B,C,R,W

6 (0.250)

(E), (X), (W): upon request

7.5 (0.300)

10 (0.400)

PERFORMANCE CHARACTERISTICS CLASS III

Measured at

1.0 kHz / 0.1 Vrms / 25C

CR 22 nF Y5V, Y5U 7.5%

CR > 22 nF Y5V, Y5P 5.0%

Dissipation

Factor

Y5P 20% / -20 +50%

Y5U 20% / -20 +80%

Y5V 20% / -20 +80%

Capacitance

Tolerance

Climatic

Category

55 / 085 / 56

Insulation

Y5P

12 M

Resistance

@ VR

Y5U

4.7 nF...100 nF 10 M

200 nF 1 M

Y5V

100 M

Dielectric Strength

NOTE: Charging

Between

leads

Vt = 1.25 VR

current limited

to 50 mA

Body

insulation

VR = 25V Vt = 100V (DC)

VR = 50V Vt = 150V (DC)

Operating

Temperature

Range (C)

-55... +125 Epoxy Coated

Note: Damp Heat Steady State: 90... 95% R.H. 40C / 21 days. No voltage to be applied.

26

Digit 8 of P.N.

Disc Ceramic Capacitors

Dimension Table

Barrier Layer Capacitors - Class III Professional

EPOXY COATED CAPACITANCE VS. DISC DIAMETER

Class III

C/C (max.)

12%

Temp.

Coefficient

Digits 1,2,3

of P.N.

Rated

Voltage (VR)

CR (pF)

4,700

10,000

22,000

33,000

47,000

50,000

68,000

100,000

200,000

Range

-30... +85C

C/C (max.)

+30 -65%

Y5P

Range

-30... +85C

Y5U

millimeters (inches)

C/C (max.)

+22 -85%

Range

-30... +85C

Y5V

6WF

6WH

6YF

6YH

6ZH

25

50

25

50

50

4.0 (0.157)

6.0 (0.236)

7.0 (0.276)

8.0 (0.315)

4.0 (0.157)

6.0 (0.236)

8.0 (0.315)

9.0 (0.354)

11.0 (0.433)

13.0 (0.512)

15.0 (0.591)

4.0 (0.157)

4.0 (0.157)

5.0 (0.197)

6.0 (0.236)

6.0 (0.236)

7.0 (0.276)

7.0 (0.276)

8.0 (0.315)

13.0 (0.512)

10.0 (0.394)

11.0 (0.433)

13.0 (0.512)

Y5U, Y5V - Preferences

4.0 (0.157)

5.0 (0.197)

7.0 (0.276)

Diameter () = 9th Part Number Digit

27

Disc Ceramic Capacitors

Ordering Code

HOW TO ORDER

5

222

General Purpose

5A = NP0 / I

*5B = P100 / I

*5C = N150 / I

*5D = N220 / I

*5E = N330 / I

*5F = N470 / I

5G = N750 / I

5H = N1500 / I

*5I = N2200 / I

*5J = N4700 / I

5K = SL

5M = Y5E / II

5N = Y5F / II

5O = Y5P / II

*5P = Y5R / II

*5Q = Y5T / II

5S = Y5U / II

5T = Y5V / II

5U = Z5V / II

*5V = Z4V / III

5W = Y5P / III

5Y = Y5U / III

5Z = Y5V / III

Professional Switch Mode

Safety

6A = NP0 / I

*6B = P100 / I

*6C = N150 / I

*6D = N220 / I

*6E = N330 / I

*6F = N470 / I

6G = N750 / I

*6H = N1500 / I

*6I = N2200 / I

6J = N4700 / I

61 = SAFETY

62 = SAFETY

65 = SAFETY

67 = Y5U / SM

68 = Y5V / SM

6L = Y5P / SM

6M = X5E / II

6N = X5F / II

6O = X5P / II

*6P = X5R / II

*6Q = X5T / II

6S = X5U / II

6T = X5V / II

6U = Z5V / II

*6V = Z4V / III

6W = Y5P / III

6Y = Y5U / III

6Z = Y5V / III

Rated Voltage (dc)

D = 16V

F = 25V

H = 50V

K = 100V

N = SAFETY

O = SAFETY

Q = 500V

R = 1000V

S = 2000V

T = 3000V

U = 4000V

V = SAFETY

W = 5000V

*X = 6000V

*Y = 7500V

Capacitance

222 = 2.2 nF

*Upon Request

Capacitance = TPC code

1 pF = 1R0

1.2pF = 1R2

1.5pF = 1R5

1.8pF = 1R8

2.2pF = 2R2

2.7pF = 2R7

3.9pF = 3R9

4.7pF = 4R7

5.6pF = 5R6

6.8pF = 6R8

8.2pF = 8R2

10pF = 100

12pF = 120

15pF = 150

18pF = 180

22pF = 220

27pF = 270

33pF = 330

39pF = 390

47pF = 470

56pF = 560

68pF = 680

82pF = 820

Capacitance = TPC code

100pF = 101

120pF = 121

150pF = 151

180pF = 181

220pF = 221

270pF = 271

330pF = 331

390pF = 391

470pF = 471

560pF = 561

680pF = 681

820pF = 821

1nF = 102

1.2nF = 122

1.8nF = 182

2.2nF = 222

2.7nF = 272

3.3nF = 332

3.9nF = 392

4.7nF = 472

5.6nF = 562

6.8nF = 682

8.2nF = 822

10nF = 103

15nF = 153

22nF = 223

33nF = 333

47nF = 473

100nF = 104

200nF = 204

Disc Ceramic Capacitors

Ordering Code

M

Tolerance

C = 0.25 pF

D = 0.50 pF

J = 5%

K = 10%

M = 20%

S = -20+50%

Z = -20+80%

P = 0+100%

Packaging

Capacitor Diameter

2 (0.079)

A = 4 (0.157)

B = 5 (0.197)

C = 6 (0.236)

D = 7 (0.276)

E = 8 (0.315)

F = 9 (0.354)

G = 10 (0.394)

H = 11 (0.433)

J = 13 (0.512)

K = 15 (0.591)

M* = 19 (0.748)

Cardboard Strips

A=

Bulk

E = 5 (0.197) 1 (0.039) free wire length

C = 10 (0.394) 1 (0.039) free wire length

D = 25 (0.984) 1 (0.039) free wire length

Taping

Avisert

Reel

Panasert

*Wire 0.8 (0.031) recommended

Lead Forming

inches

2.5 0.5

+0.6

5 -0.2

+0.6

6 -0.2

+1

7.5 -0.5

+0.5

10 -1.0

+1

12.5 -0.5

.1 .025

.2 .025

.25 .025

.3 .05

.4 .05

.5 .05

Avisert

Ammo

Pack

mm

M M

Panasert

K M M

Finishing

Diam 9 (0.354) and

F = 5.00 (0.197)

For every other:

Coating does not

surpass the bend

Low Voltage

A = Phenolic

General Q = Waxed phenolic

( Purpose

)

S = Epoxy (Professional) cap. diameter

8 (0.315)

D = Epoxy (Professional) cap. diameter

> 8 (0.315)

High Voltage

F = Measured

from the

center of

leads

0.6 0.1

(0.024) (0.004)

0.8 0.1

I = Epoxy wire diameter

(0.031) (0.004)

L = Phenolic wire diameter 0.6 0.1

(0.024) (0.004)

C = Epoxy wire diameter

Please note that not all code combinations

are either possible or available.

Disc Ceramic Capacitors

Marking

DIG. 2

Logo: Only in diam. 6mm

O

TC / Class

General Purpose

A = NP0 / I

*B = P100 / I

*C = N150 / I

*D = N220 / I

*E = N330 / I

*F = N470 / I

G = N750 / I

H = N1500 / I

*I = N2200 / I

*J = N4700 / I

K = SL

M = Y5E / II

N = Y5F / II

O = Y5P / II

P = Y5R / II

Q = Y5T / II

S = Y5U / II

T = Y5V / II

U = Z5V / II

V = Z4V / III

*W = Y5P / II

*X = Y5R / II

Y = Y5U / II

Z = Y5V / II

*Upon Request

Professional

A = NP0 / I

B = P100 / I

C = N150 / I

D = N220 / I

E = N330 / I

F = N470 / I

G = N750 / I

H = N1500 / I

I = N2200 / I

J = N4700 / I

7 = Y5U / SM

8 = Y5V / SM

L = Y5P / SM

M = X5E / II

N = X5F / II

O = X5P / II

P = X5R / II

Q = X5T / II

S = X5U / II

T = X5V / II

U = Z5V / II

V = Z4V / III

W = Y5P / III

X = Y5R / III

Y = Y5U / III

Z = Y5V / III

222

OQM

DIG. 3

Q

DIG. 7

M

Rated Voltage

D = 16V

F = 25V

H = 50V

K = 100V

Q = 500V

R = 1000V

S = 2000V

T = 3000V

U = 4000V

W = 5000V

X = 6000V

Y = 7500V

Tolerance

C = 0.25pF

D = 0.5pF

J = 5%

K = 10%

M = 20%

S = -20 +50%

Z = -20 +80%

P = 0 +100%

Capacitance

1pF = 109

1.2pF = 129

1.5pF = 159

1.8pF = 189

2.2pF = 229

2.7pF = 279

3.9pF = 399

4.7pF = 479

5.6pF = 569

6.8pF = 689

8.2pF = 829

10pF = 100

12pF = 120

15pF = 150

18pF = 180

22pF = 220

27pF = 270

39pF = 390

47pF = 470

56pF = 560

68pF = 680

82pF = 820

Safety

Front

Capacitance

As above

EIA

100pF = 101

120pF = 121

150pF = 151

180pF = 181

220pF = 221

270pF = 271

390pF = 391

470pF = 471

560pF = 561

680pF = 681

820pF = 821

1nF = 102

1.2nF = 122

1.8nF = 182

2.2nF = 222

2.7nF = 272

3.9nF = 392

4.7nF = 472

5.6nF = 562

6.8nF = 682

8.2nF = 822

10nF = 103

15nF = 153

22nF = 223

33nF = 333

47nF = 473

100nF = 104

200nF = 204

Type

61V

61V

471M

TC Temperature coefficient.

DIG for better understanding, check pages 3 and 4.

620

65N

Tolerance

As above

Back: (Approval marks)

28

Disc Ceramic Capacitors

Packaging

IDENTIFICATION AND TRACEABILITY

On all TPC ceramic capacitors

packages, you will find a bar code label

with the following information:

Lot number

Manufacturing date

Quantity of parts per packaging

Product part number

TAPED PARTS QUANTITY TABLE

millimeters (inches)

Rated Voltage

(Vr)

Diameter

D

Quantities

Ammopack

Vr <= 500V

D 7 (0.276)

2000

2500

7 < D 11 (0.433)

2000

2000

500V<Vr<=2KV

D 11 (0.433)

1500

2000

2KV<Vr=5KV

D 11 (0.433)

1000

1500

Reel

CARDBOARD STRIPS QUANTITY TABLE

Rated Voltage

(Vr)

Vr <= 500V

500V<Vr<=2KV

2KV<Vr<=5KV

millimeters (inches)

Diameter

D

< = 5 (0.197)

Lead Space

> 5 (0.197)

D 8 (0.315)

2500

1500

8 (0.315) D 11 (0.433)

1500

8 (0.315) D 13 (0.512)

1000

11 (0.433) D 15 (0.591)

1000

13 (0.512) D 19 (0.748)

500

D 19 (0.748)

500

D 9 (0.354)

1500

1000

9 (0.354) D 11 (0.433)

1000

9 (0.354) D 13 (0.512)

1000

11 (0.433) D 19 (0.748)

500

13 (0.512) D 19 (0.748)

500

D 9 (0.354)

1500

D 11 (0.433)

1000

D 13 (0.512)

500

500

Safety

D 6 (0.236)

1500

1500

61V

7 (0.275) D 9 (0.354)

1000

1000

9 (0.354) D

500

500

Safety 65N 62O

Quantities for other package alternative, upon request.

29

Disc Ceramic Capacitors

Tape and Reel Specifications

There are two types of taped disc ceramic capacitors:

Straight or crimped leads.

Both types can be shipped on reels or ammopack.

The standard packaging quantities are shown bellow:

millimeters (inches)

Fig. 1

Fig. 2

Fig. 3

Straight leads

Crimped leads

Maximum pull force during insertion and lead cut

F1

Digit 11

L

M

J H

K I

TPC Code

4 (0.157) D < 6 (0.236)

12N

20N

D 6 (0.236)

20N

25N

Available Tapings

Digit 9

Sizes

4 (0.157) D 11 (0.433)

A... H

Sizes

6 (0.236) D 11 (0.433)

C... H

Digit 11

Packaging

Avisert

Panasert

H

L

L

FIGURE 1 FIGURE 2 FIGURE 3

J

L

L

FIGURE 1 FIGURE 2 FIGURE 3

I

M

M

FIGURE 1 FIGURE 2 FIGURE 3

K

M

M

FIGURE 1 FIGURE 2 FIGURE 3

Reel

Ammopack

Figure 2: Inside Crimp 100V... 1000V

Figure 3: Outside Crimp 1000V

30

F2

Disc Ceramic Capacitors

Tape and Reel Specifications

millimeters (inches)

Straight Leads

Figure 1

A (Avisert)

P (Panasert)

Description of Symbols

Crimped

Figure 2 & 3

Avisert & Panasert

Crimp angle

20...45

Crimp length

1.7 min.

Lead diameter

0.60 0.1

Disc diameter

11 max.

Lead hole diameter

Do

4.0 0.2

Disc thickness

See Catalog

Lead spacing

5.0 +0.6

-0.2

Component alignment, front-rear

01

Height of component from tape center

19.5 0.5

16.5 0.5 - 0

Height from tape center to crimp

Ho

16 + 0.5 - 0

Component height

H1

32.25 max.

Distance from component leads to tape bottom

>23.5

<32.25

12 max.

Tape width

18

Bonding tape width

W3

5.5 min.

Feed hole position

W1

9.0 0.5

Pitch between discs

12.7 1

Feed hole pitch

Po

12.7 0.3

Hole center to lead

P1

3.85 0.7

Feed hole center to component center

P2

6.35 1

Tape + bonding tape thickness

0.7 0.2

Total tape thickness. including lead

t2

1.5 max.

+1

-0.5

SHIPPING CONTAINER

PACKAGING

Ammopack

32.25 max.

Reel

8 Ammopack

5 Reel

This side up

during storage

and transportation

max. stacking: 10 boxes

max. stacking: 10 reels

31

S-ar putea să vă placă și

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Avx Rad Cer ThomsonDocument10 paginiAvx Rad Cer ThomsonΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣÎncă nu există evaluări

- Surface Mount Ceramic Surface Mount Multi - Layer DS: Outline DrawingDocument6 paginiSurface Mount Ceramic Surface Mount Multi - Layer DS: Outline DrawingTim SmithÎncă nu există evaluări

- DSDocument13 paginiDSazmanjamaatÎncă nu există evaluări

- Stps 20 H 100 CTDocument8 paginiStps 20 H 100 CTPablo Cruz ArchundiaÎncă nu există evaluări

- Datasheet PDFDocument11 paginiDatasheet PDFjackass_tÎncă nu există evaluări

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysDe la EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysÎncă nu există evaluări

- DatasheetDocument9 paginiDatasheetloisaomÎncă nu există evaluări

- 110 Waveform Generator Projects for the Home ConstructorDe la Everand110 Waveform Generator Projects for the Home ConstructorEvaluare: 4 din 5 stele4/5 (1)

- HP 450 OptocouplerDocument16 paginiHP 450 Optocoupler1cvbnmÎncă nu există evaluări

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1De la EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Evaluare: 4.5 din 5 stele4.5/5 (3)

- STTA1206D/DI/G: Turboswitch Ultra-Fast High Voltage DiodeDocument9 paginiSTTA1206D/DI/G: Turboswitch Ultra-Fast High Voltage DiodeMarcos AndréÎncă nu există evaluări

- British Commercial Computer Digest: Pergamon Computer Data SeriesDe la EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesÎncă nu există evaluări

- p9nb50 PDFDocument9 paginip9nb50 PDFceftv1Încă nu există evaluări

- SK100GB12T4T: Semitop 3Document5 paginiSK100GB12T4T: Semitop 3Jorge Fernandez EdelmanÎncă nu există evaluări

- TDA7269ADocument7 paginiTDA7269ACojocar FlorinÎncă nu există evaluări

- AV02-2483EN DS ACNV4506 31aug2011Document14 paginiAV02-2483EN DS ACNV4506 31aug2011moabdolyÎncă nu există evaluări

- IRF630 IRF630FP: N - CHANNEL 200V - 0.35 - 9A - TO-220/FP Mesh Overlay MosfetDocument10 paginiIRF630 IRF630FP: N - CHANNEL 200V - 0.35 - 9A - TO-220/FP Mesh Overlay MosfetAlex OreÎncă nu există evaluări

- RD 15Document9 paginiRD 15primindyaÎncă nu există evaluări

- Irfi 3205 Power MosfetDocument9 paginiIrfi 3205 Power MosfetAndy WilsonÎncă nu există evaluări

- Mosfet p7nc70zfpDocument13 paginiMosfet p7nc70zfptheodoru2014Încă nu există evaluări

- F1010EDocument8 paginiF1010EKamran KhanÎncă nu există evaluări

- Irg 4 PF 50 WDocument8 paginiIrg 4 PF 50 WQuickerManÎncă nu există evaluări

- Disc Ceramic Capacitors: How To OrderDocument2 paginiDisc Ceramic Capacitors: How To OrderJuan GomezÎncă nu există evaluări

- FQPF8N80CDocument11 paginiFQPF8N80CWsad WsadÎncă nu există evaluări

- P 9 NC 60 FPDocument9 paginiP 9 NC 60 FPJulian PascuÎncă nu există evaluări

- Tda 8172Document6 paginiTda 8172perro sÎncă nu există evaluări

- Optoacoplador Integrado 4N25Document7 paginiOptoacoplador Integrado 4N25aureliocsÎncă nu există evaluări

- Fast Speed IGBT with 600V Breakdown and 1.59V Saturation VoltageDocument9 paginiFast Speed IGBT with 600V Breakdown and 1.59V Saturation VoltageKarthikrajan SendhilnathanÎncă nu există evaluări

- Nc7Sz373 Tinylogic Uhs D-Type Latch With 3-State Output: General Description FeaturesDocument9 paginiNc7Sz373 Tinylogic Uhs D-Type Latch With 3-State Output: General Description Featuresgreentea601Încă nu există evaluări

- Datasheet ET1100Document10 paginiDatasheet ET1100Manal FeghaliÎncă nu există evaluări

- TDA7262Document9 paginiTDA7262Nelson PereiraÎncă nu există evaluări

- STPS20H100CT/CF/CG/CR/CFP: High Voltage Power Schottky RectifierDocument8 paginiSTPS20H100CT/CF/CG/CR/CFP: High Voltage Power Schottky RectifierAdeltop4everÎncă nu există evaluări

- Coolmos Power Transistor: Features Product SummaryDocument10 paginiCoolmos Power Transistor: Features Product SummaryJosé Miguel Barbosa HernándezÎncă nu există evaluări

- Semiconductor KIA78D25F/PI 78D15F/PI: Technical DataDocument6 paginiSemiconductor KIA78D25F/PI 78D15F/PI: Technical DatagusguicorÎncă nu există evaluări

- IRF640Document10 paginiIRF640Halil DurmuşÎncă nu există evaluări

- Conductive Polymer Hybrid Aluminum Electrolytic Capacitors CatalogDocument60 paginiConductive Polymer Hybrid Aluminum Electrolytic Capacitors CatalogalltheloveintheworldÎncă nu există evaluări

- DMV1500SDDocument8 paginiDMV1500SDJohnÎncă nu există evaluări

- Stp8Nc50 - Stp8Nc50Fp Stb8Nc50-1: N-Channel 500V - 0.7 - 8A To-220/To-220Fp/I2Pak Powermesh Ii MosfetDocument11 paginiStp8Nc50 - Stp8Nc50Fp Stb8Nc50-1: N-Channel 500V - 0.7 - 8A To-220/To-220Fp/I2Pak Powermesh Ii Mosfetmiguel angel jaramilloÎncă nu există evaluări

- Part Numbering Part Numbering: Chip Monolithic Ceramic CapacitorsDocument4 paginiPart Numbering Part Numbering: Chip Monolithic Ceramic Capacitorsamusin79Încă nu există evaluări

- 2CDC002157D0201Document7 pagini2CDC002157D0201260380sdÎncă nu există evaluări

- STW21NM50N MosfetDocument16 paginiSTW21NM50N MosfetrigowÎncă nu există evaluări

- TEA5101B Ds PDFDocument6 paginiTEA5101B Ds PDFMingo YontoÎncă nu există evaluări

- BIC703M: Bias Controlled Monolithic IC VHF/UHF RF AmplifierDocument11 paginiBIC703M: Bias Controlled Monolithic IC VHF/UHF RF AmplifierRohit SinghÎncă nu există evaluări

- IRG4BC20KD DatasheetDocument11 paginiIRG4BC20KD DatasheetjoaomimaÎncă nu există evaluări

- 74HC374Document13 pagini74HC374jnax101Încă nu există evaluări

- STP55NE06 STP55NE06FP: N - Channel Enhancement Mode " Single Feature Size " Power MosfetDocument9 paginiSTP55NE06 STP55NE06FP: N - Channel Enhancement Mode " Single Feature Size " Power MosfetLiliana Nadia MarchisÎncă nu există evaluări

- K814P/K824P/K844P: Vishay SemiconductorsDocument8 paginiK814P/K824P/K844P: Vishay SemiconductorsJessica JenkinsÎncă nu există evaluări

- Fast Speed IGBT with 600V Breakdown VoltageDocument8 paginiFast Speed IGBT with 600V Breakdown VoltageLidystonPeronÎncă nu există evaluări

- BDW94CDocument6 paginiBDW94Cjosenicolas12000Încă nu există evaluări

- IRG4BC30K-S: Features Features Features Features FeaturesDocument8 paginiIRG4BC30K-S: Features Features Features Features FeaturesRafael MonzonÎncă nu există evaluări

- Tda 8172Document7 paginiTda 8172dinspekÎncă nu există evaluări

- 2N6027Document9 pagini2N6027mariogizziÎncă nu există evaluări

- MOCD207M, MOCD208M Dual-Channel Phototransistor Small Outline Surface Mount OptocouplersDocument9 paginiMOCD207M, MOCD208M Dual-Channel Phototransistor Small Outline Surface Mount Optocouplershunter73100% (1)

- Analog Engineer S Circuit Cookbook Amplifiers 1683531194Document300 paginiAnalog Engineer S Circuit Cookbook Amplifiers 1683531194eric hudsonÎncă nu există evaluări

- Pandas Data Frame For BeginnersDocument25 paginiPandas Data Frame For Beginnersramnewtown35Încă nu există evaluări

- Machine Learning For Medicine - QRS Detection in A Single Channel ECG Signal (Part 1 - Data-SetDocument8 paginiMachine Learning For Medicine - QRS Detection in A Single Channel ECG Signal (Part 1 - Data-SetAnderson Ribeiro CesarinoÎncă nu există evaluări

- Injeção Eletronica Pajero MPIDocument115 paginiInjeção Eletronica Pajero MPIMarcos OlliveiraÎncă nu există evaluări

- REGRAS PARA PRODUÇÃO DE PCBsDocument28 paginiREGRAS PARA PRODUÇÃO DE PCBsAnderson Ribeiro CesarinoÎncă nu există evaluări

- Machine Learning For Medicine - QRS Detection in A Single Channel ECG Signal (Part 1 - Data-SetDocument8 paginiMachine Learning For Medicine - QRS Detection in A Single Channel ECG Signal (Part 1 - Data-SetAnderson Ribeiro CesarinoÎncă nu există evaluări

- CLUTCHDocument9 paginiCLUTCHjlpjuniorÎncă nu există evaluări

- 13b Fuel SupplyDocument10 pagini13b Fuel SupplyAnderson Ribeiro CesarinoÎncă nu există evaluări

- 00 GeneralDocument48 pagini00 GeneralgilsonbbÎncă nu există evaluări

- PAJERO TR4 11b Engine 4g9-MpiDocument37 paginiPAJERO TR4 11b Engine 4g9-Mpipanhead659370Încă nu există evaluări

- 00 GeneralDocument48 pagini00 GeneralgilsonbbÎncă nu există evaluări

- 11a Engine 4g9-GdiDocument49 pagini11a Engine 4g9-GdiAlexandre Da Silva Pinto100% (1)

- 8051Document14 pagini8051Anderson Ribeiro CesarinoÎncă nu există evaluări

- KA2418Document3 paginiKA2418Jose Valero IlustÎncă nu există evaluări

- 04.3 - Ficha TeÌ C MoÌ Dulo SUN LINK SL220-20M 245 WPDocument2 pagini04.3 - Ficha TeÌ C MoÌ Dulo SUN LINK SL220-20M 245 WPCarlos Manuel FerreiraÎncă nu există evaluări

- Literature Review On Automatic Street Light Control Using LDRDocument5 paginiLiterature Review On Automatic Street Light Control Using LDRfahynavakel2Încă nu există evaluări

- Vagm 22Document4 paginiVagm 22AONLAÎncă nu există evaluări

- CapacitorDocument17 paginiCapacitorzainabamara1427Încă nu există evaluări

- Fault Tracing: FMI 3: Checking The Sensor CircuitDocument1 paginăFault Tracing: FMI 3: Checking The Sensor Circuituser1Încă nu există evaluări

- DC& Transient ResponseDocument36 paginiDC& Transient ResponseThi Nguyen Duy ManhÎncă nu există evaluări

- Project ProposalDocument4 paginiProject ProposalSushrut BhatÎncă nu există evaluări

- IR2117 ApplicationDocument24 paginiIR2117 ApplicationBhaskar KharviÎncă nu există evaluări

- Experiment No 5 Single-Phase Current Transformer: ObjectiveDocument3 paginiExperiment No 5 Single-Phase Current Transformer: ObjectiveMr Hassan RazaÎncă nu există evaluări

- RC Snubber Circuit Design For Thyristor Using Turn-Off Model in PspiceDocument5 paginiRC Snubber Circuit Design For Thyristor Using Turn-Off Model in PspiceIjsrnet EditorialÎncă nu există evaluări

- Electrical Installation Guide Chapter on LV Distribution SchemesDocument8 paginiElectrical Installation Guide Chapter on LV Distribution SchemesMidhun VargheseÎncă nu există evaluări

- Bac HD 230 Holiday Detector: FeaturesDocument1 paginăBac HD 230 Holiday Detector: FeaturesAhmed MagdiÎncă nu există evaluări

- Silicon Zener Diodes Voltage and Power SpecsDocument2 paginiSilicon Zener Diodes Voltage and Power SpecsFabian BordaÎncă nu există evaluări

- Osram P-Vip PDFDocument57 paginiOsram P-Vip PDFtantra_lover2005Încă nu există evaluări

- Abb Acs310-1Document50 paginiAbb Acs310-1osrinivas1234Încă nu există evaluări

- Method of Statement ElectricalDocument30 paginiMethod of Statement ElectricalNaveed70% (10)

- Relation between turns ratio and voltage ratio in a transformerDocument11 paginiRelation between turns ratio and voltage ratio in a transformerNikita100% (1)

- A400.4 Dragonfly 4-Channel 120W Power Amplifier Schematic and ManualDocument24 paginiA400.4 Dragonfly 4-Channel 120W Power Amplifier Schematic and ManualmundomusicalmeriaÎncă nu există evaluări

- Lesson 11: DC Transient AnalysisDocument81 paginiLesson 11: DC Transient AnalysisJoshua JapitanÎncă nu există evaluări

- Transformers: 12, 24, 48, 115 and 230vac DIN-Rail, Panel, Wall Mounting TransformersDocument1 paginăTransformers: 12, 24, 48, 115 and 230vac DIN-Rail, Panel, Wall Mounting TransformersЛеха ЯнчукÎncă nu există evaluări

- Training Contactor PDFDocument11 paginiTraining Contactor PDFAnonymous JBF08eAbtÎncă nu există evaluări

- Experiment No. 4 - Impedance of RLC CircuitsDocument2 paginiExperiment No. 4 - Impedance of RLC CircuitsDeanneLaylay100% (1)

- Navsea S9 84-Ac-Mmo-010/lst-1í79 CLDocument306 paginiNavsea S9 84-Ac-Mmo-010/lst-1í79 CLfrancisco xavier palma ramirezÎncă nu există evaluări

- Technical Specification For 20 MVA Transformer PDFDocument21 paginiTechnical Specification For 20 MVA Transformer PDFamulya00428100% (10)

- Choosing A Replacement TransistorDocument2 paginiChoosing A Replacement TransistorRafael CossÎncă nu există evaluări

- 2 (1) .DIODE APPLICATIONS - FinalDocument37 pagini2 (1) .DIODE APPLICATIONS - FinalSanjana HaqueÎncă nu există evaluări

- Electrical Engineering FundamentalsDocument1 paginăElectrical Engineering FundamentalsTheophilus PhenomenonÎncă nu există evaluări

- HPS2D Operation ManualDocument33 paginiHPS2D Operation Manualsanjeewa12Încă nu există evaluări

- Step Motor M42SP-4 - Mitsumi PDFDocument2 paginiStep Motor M42SP-4 - Mitsumi PDFHjac CarvalhoÎncă nu există evaluări

- Peee Notes Unit IIIDocument49 paginiPeee Notes Unit IIIPujita JÎncă nu există evaluări