Documente Academic

Documente Profesional

Documente Cultură

HSE Management Visit Checklist

Încărcat de

jinyuan7480%(5)80% au considerat acest document util (5 voturi)

2K vizualizări6 paginiHSE VISIT

Titlu original

HSE Management Visit Checklist Template Final

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentHSE VISIT

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

80%(5)80% au considerat acest document util (5 voturi)

2K vizualizări6 paginiHSE Management Visit Checklist

Încărcat de

jinyuan74HSE VISIT

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 6

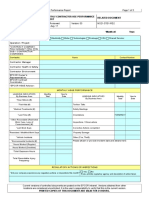

HSE MANAGEMENT VISIT CHECKLIST

Rev. 00 Date: 09/06/12

Page 1 of 6

Well Site: Rig Number: Management Representative (s)

Date:

Item

Nr.

ITEMS VERIFIED Yes No Remedial actions

Due

Date

1. Visible Safety and Induction

1.1

Is there a welcome board with key safety information

posted in high visibility location?

1.2

Did you receive a safety/security induction briefing

on arrival on site?

1.3 If there is POB control, did you receive a T-card?

2. Tool Pusher / Rig Manager Office

2.1

Are the updated HSE policies (Corporate, Company

and Project) posted (in English, Arabic and other

user language)?

2.2

Is the HSE documentation available?

1. HSE Onshore procedures Manual

2. Emergency Procedures Manual

3. HSE Plan and Appendices

4. Health Plan

5. Bridging Document

6. Safety Case

2.3 Are all the folders well organized?

2.4

Is the updated telephone numbers list (including

emergency numbers) posted?

2.5 Is the updated MEDEVAC flowchart posted?

2.6

Is Well Control procedure current?

Is there a kick control work sheet, indicating local

well maximum working pressures, and circulating

rates?

2.7 Is the BOP stack drawing posted?

2.8

Are the records of the BOP test updated and

available?

2.9

Is all certification for rig equipment (mast,

substructure, BOPs, etc) available on site

2.10

Is the technical documentation covering all the

equipment on site?

2.11

Is the Preventive Maintenance System available and

updated?

2.12

Are the Rig layout and the Safety equipment lay out

posted?

2.13

Is there a register of weights for all standard rig

inventory heavy items which may be lifted or

winched?

Are critical or tandem lift procedures / lift plans

available and followed?

2.14

Is the tubular material Rotation Hours Tally

available?

HSE MANAGEMENT VISIT CHECKLIST

Rev. 00 Date: 09/06/12

Page 2 of 6

2.15

Are the minimum of 2 x 2 SCBA sets are available?

Are they functional, and ready to be deployed?

Are they located in opposite corners of the location

so wind direction will not restrict the rescue

capability?

2.16

Does this well require more H2S equipment than

basic minimum, including H2S detection/ alarm

systems as well as air supply for workforce to carry

out operations in a toxic environment?

Is the reserve, resupply or supplied air rescue and

work breathing equipment package available?

Correctly installed on the Rig?

Is it fully supplied with air and equipment functional?

2.17 Is the updated POB posted?

2.18

Is the Work Permit notice board updated with the

Work Permits currently opened?

2.18 Is the Tag out / Lock out key panel available?

2.19

Do mobile cranes have valid certificates of

inspection/acceptance from competent authority by

Intl Standards [LOLER, LEEA equivalent?

2.20

Are lifting accessories slings [soft, wire rope,

chain], shackles, hooks, in good shape?

2.21

Is there a bin/container/ process to quarantine or

destroy, damaged lifting accessories?

2.22

Is the general housekeeping to an acceptable

standard?

3. HSE Supervisor Office

3.1

Are the updated HSE policies posted (in English and

Arabic)?

3.2 Is the Safety Induction folder up to date?

3.3 Are the folders well organized?

3.4

Are all the practicably valuably HSE documentation

available?

1. Hazard Risk Register for work scope

2. JHA / JSA

3. HSE Onshore procedures Manual / Method

statements / Checklists

4. Emergency Procedures Manual

5. Incident Investigation Reporting

6. UA/UC observation tools [Safety Observation cards,

and register]

7. Drills Reports

8. Training Plan and Register

9. Bridging Document

10. HSE Plan and Appendices

11. Health Plan

3.5 Is the housekeeping to an acceptable standard?

3.6

Is there an HSE store with supplies of basic PPE and

tools, [Toolbox talk cards, checklists, PTW system

supplies, LOTO materials, atmosphere testers]?

Is it well organized?

3.7

Is the safety equipment well maintained and ready to

be used?

HSE MANAGEMENT VISIT CHECKLIST

Rev. 00 Date: 09/06/12

Page 3 of 6

3.8

Does the HSE engineer have connection to email or

intranet / internet for contact with Client?

3.9

Are meetings for analysis of the UA/UC Tracking

Log, Event Report Log, and Lessons Learned Log

held on regular basis? [weekly? bi weekly?]

3.10

Are the Event Investigation Reports received from

the Contractors primary support Base available and

presented in the weekly safety meetings with the rig

crew?

3.11

Is there any evidence Contractor has a program of

safety campaigns, and that these campaigns are

communicated to the rig crew if formal presentation

meetings, posted and the presence of personnel to

the presentation of these recorded?

3.12

Is the Daily HSE Tour performed properly, and

distributed to the Contractors Base and/or client on a

daily basis?

3.13

Is the Monthly Rig Inspection check list available and

completed as per the HSE Procedures?

3.14

4. Dog House

4.1 Is the current well shut-in procedure posted?

4.2 Is the Kill sheet updated and available?

4.3

Are the (SCR

1

) recorded?

4.4

Is the current (MAASP

2

) posted beside the

Choke/Kill Control Panel?

4.5 Is the trip sheet updated?

4.6

Is the BHA Tally Book (including drawings, sizes,

type of threads) updated?

4.7 Is the Handovers Register available?

4.8

Are charts / technical data regarding tubulars

available?

4.9

Is the BOP drawing posted and showing the pipe

rams sizes?

4.10

Are all the gauges and pump stroke counter showing

correct values on the Power choke control panel?

4.11 Is the First Aid Box available and completed?

4.12

Is the Crown-O-Matic procedure posted and the tests

carried out as per procedure?

4.13 Is the derrick climbing procedure posted?

4.14 Is racking board rescue procedures posted?

4.15

Has a simulated derrick rescue been performed and

documented once a year?

4.16

Is the condition of harnesses and other fall protection

devices acceptable?

4.17 Is the housekeeping to an acceptable standard?

HSE MANAGEMENT VISIT CHECKLIST

Rev. 00 Date: 09/06/12

Page 4 of 6

1

SCR - Slow Circulating Rate

2

MAASP Maximum Allowable Annular Shut-in Pressure

5. Rig Floor

5.1

Is the inside BOP [Hydraulic] located in easy to

access location, and is valve handle located nearby

in secure location?

5.2 Are all the gauges properly functioning?

53 Is the PVT working properly?

5.4

Is the Kelly hose properly set up with safety lines

& clamps?

5.5 Is the torque indicator working properly?

5.6 Is the RPM indicator working properly?

5.7 Is the Weight Indicator working properly?

5.8

Are draw works controls clearly and correctly

identified, guarded, with provision for locking

devices?

5.9 Are the air winches clearly labeled with the SWL?

5.10

Are the air winches air supply valves functioning

properly?

5.9

Are the air winches controls working properly?

(operating lever must revert to off position when not

operated)

5.10

Are the braided wire rope cables correctly coiled on

all air winches drums?

5.11

Are rotary tongs correctly anchored to prevent

uncontrolled movement

5.12

Are cat heads in place, if so are they covered? There

should be a plan to remove them / replace them with

air tuggers.

5.13 Are all the drilling tools in good shape?

5.14

Are the drilling tongs back up line attaching points

secured with safety pins?

5.15

Are all the gauges showing the correct values on the

remote BOP panel?

Shear rams = 3000 psi; Pipe rams = 1500 psi;

Annular = 1200 psi for drill string or 1500 psi for

casing (cover values)

5.16

Are the lights functioning properly on the remote

BOP panel?

5.17

Are all the pipe rams type and sizes clearly labeled

on the remote BOP panel?

5.18

Are the blind/shear rams properly protected against

accidental operating on the remote BOP panel?

5.19

Is the MATHEY Unit [Wireline] properly functioning

and the meter counter having correct indications?

5.20

Are protective guards in place on all rotating wire

drums? (Hoists & Winches)

5.21

Does the V Door have a barrier chain or gate

deployed across the opening?

HSE MANAGEMENT VISIT CHECKLIST

Rev. 00 Date: 09/06/12

Page 5 of 6

5.22

Is the Basket type stretcher available and in good

condition?

5.23 Is the general housekeeping at an acceptable level?

6. Rig Power Supply, Pump House, Mud Mixing Area

6.1

Are all engine exhausts equipped with spark arrestor

and / or water spray?

6.2

Are all electric feeds from main electric control panel

clearly identified and labeled in language of

responsible users?

Are unused electric outlets covered?

6.3

Are all rig power main electric switches capable of

being locked out?

Multiple lockout?

6.4

Are High Voltage signs posted in easily visible

locations?

6.5

Is the mixing area organised, clean, & with

appropriate PPE available?

6.6

Is all rotating machinery equipped with proper

guards?

6.7

Are there any stairs with more than 4 risers, that do

not have hand rails?

6.8 Is there an exhaust fan in mud mixing room?

6.9

Are sufficient fire extinguishers in place on the rig? [4

x 40 or 8 x 20], [ABC or BC]

Securely mounted to protect from damage, and

indicated with high visibility signs?

6.10

Are high pressure mud lines, shock hoses, equipped

with clamps and properly secured?

6.11

Are the mud pits & trip tanks provided with electric

devices that are intrinsically safe as sources of

ignition?

6.12

Are the eye wash stations & showers in good

working order, and easy to access?

6.13

Are all noise hazard areas identified, signs in place,

and PPE available? Used by workforce?

6.14

Is the rig configured to allow one generator to be

designated as an emergency generator?

6.15 Is an emergency lighting system in place?

6.16

Do all alarms, Gas/kick, fire alarm & abandon rig

alarm exist on the rig?

Do they all function?

Can they be heard everywhere? [SCR room, Mud Pump

area, Generator Area, in sub base & BOP area]

7. Clinic

7.1

Is the housekeeping of the clinic to an acceptable

standard?

7.2

Are the updated Medevac procedures and

Contractor Health Plan available?

7.3

Are SCBA inspection and maintenance records

available?

7.4 Is the updated MEDEVAC flowchart posted?

7.5

Are the emergency telephone numbers posted

beside the MEDEVAC flowchart?

HSE MANAGEMENT VISIT CHECKLIST

Rev. 00 Date: 09/06/12

Page 6 of 6

7.6

Is the register of employees treated in the Clinic

available and kept inside the locked drawer?

7.7

Are the personnel medical fitness certificates still

valid?

7.8 Is the Treatment Room access free of obstruction?

7.9

Is the date of last check posted on the Medical

Oxygen Cylinder?

7.10

Is the medical equipment (inclusive stretcher) in

good condition and ready to be used?

7.11

Are copies of water analysis available and up to

date?

7.12 Are copies of weekly camp inspection properly filled?

7.13 Are the First Aid Boxes checked and kept full?

7.14 Are the MEDEVAC drills performed and recorded?

7.15

8. Camp issues

8.1

Are offices and accommodation are located at least

25 meters from well bore?

8.2

Are power cables to trailers from energy supply

suspended or otherwise protected from damage by

machinery?

8.3

All electrical outlets are in good shape and weather

proofed?

Connectors and cables are not damaged, structures

properly grounded?

8.4

Are smoke and fire detectors in each room and

office?

For simple evaluation of the hygiene aspects of the camp, managers and others without specific competence or

qualifications to make the assessment, can use good judgment . . based on humanity . . the basic criteria would

be would I accept to eat and live here?

If it is not good enough for us, then we should be critical of its acceptability for any person who must work under

such extreme adverse conditions as exist in this environment.

8.5 Showers, sinks, toilets?

8.6 Camp dining room?

8.7 Food storage?

8.8 Bedrooms, and bedding?

8.9 Waste disposal, including sewage?

8.10

General comments:

Note: The Tool Pusher shall ensure that the remedial actions (if any) will be carried out and that the due dates

given for closing the remedial actions are respected. Also, the updated check list shall be provided to the Base

Management.

S-ar putea să vă placă și

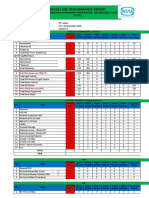

- Nov.2014 Monthly Hse Statistics ReportDocument6 paginiNov.2014 Monthly Hse Statistics ReportSaboor Kabier60% (5)

- Hse Audit Checklist SafetyDocument7 paginiHse Audit Checklist Safetysubhanmusadiq50% (2)

- General HSE Inspection ChecklistDocument5 paginiGeneral HSE Inspection ChecklistBam Handoko80% (5)

- CHINA HARBOUR ENGINEERING LFTZ HSE REPORTDocument21 paginiCHINA HARBOUR ENGINEERING LFTZ HSE REPORTWealth OSIOBE100% (1)

- Company Safety Audit ChecklistDocument7 paginiCompany Safety Audit ChecklistSaddem HadfiÎncă nu există evaluări

- Updated Is 14489 Safety Audit Checklist EhsDocument10 paginiUpdated Is 14489 Safety Audit Checklist EhsUdhayakumar Venkataraman100% (7)

- Hse Action Plan (Final)Document1 paginăHse Action Plan (Final)Rahmat HariÎncă nu există evaluări

- Hse Activity Plan 2010: NO Objek Month January February March April MAYDocument4 paginiHse Activity Plan 2010: NO Objek Month January February March April MAYImanuel MantiriÎncă nu există evaluări

- Annual HSE Program ContohDocument2 paginiAnnual HSE Program ContohSigit WiyonoÎncă nu există evaluări

- Monday Tuesday Wednesday Thursday Friday Saturday Sunday: Monthly Hse Plan For December-2018Document2 paginiMonday Tuesday Wednesday Thursday Friday Saturday Sunday: Monthly Hse Plan For December-2018kalyan1990100% (2)

- HSE Objectives 2015Document2 paginiHSE Objectives 2015Anonymous iI88Lt100% (2)

- Construction QHSE BudgetDocument6 paginiConstruction QHSE Budgetqhse 3dihaji100% (2)

- HWDPDocument15 paginiHWDPjinyuan74Încă nu există evaluări

- Monthly Contractor HSE Performance ReportDocument3 paginiMonthly Contractor HSE Performance Reportpartha80% (5)

- Hse Induction Check ListDocument2 paginiHse Induction Check ListMohammad Anwar Hossain100% (4)

- HSE Monthly Report For XXXX2 ProjectDocument30 paginiHSE Monthly Report For XXXX2 ProjectAhmed Hassan Sabry80% (5)

- Weekly HSE Report Format.Document2 paginiWeekly HSE Report Format.Binay100% (5)

- KIKEH SPAR HSE PLANDocument3 paginiKIKEH SPAR HSE PLANAbdul Hakam Mohamed Yusof100% (2)

- HSE Statistics PDFDocument5 paginiHSE Statistics PDFRashid100% (1)

- Appendix B HSE Plan 2019Document1 paginăAppendix B HSE Plan 2019aymenmoatazÎncă nu există evaluări

- HSE PlanDocument24 paginiHSE PlanDheeraj Menon100% (1)

- Hse Audit Checklist (Safety)Document8 paginiHse Audit Checklist (Safety)mohd_azaruddin100% (4)

- Daily HSE Report 14dec11 0500Document2 paginiDaily HSE Report 14dec11 0500case013100% (5)

- Construction Safety Budget BreakdownDocument3 paginiConstruction Safety Budget BreakdownPerwez2150% (2)

- Project HSE Performance Monitoring ProcedureDocument12 paginiProject HSE Performance Monitoring ProcedureWinnie Eldama0% (1)

- Offshore and Onshore Rig Cables - 1 PDFDocument152 paginiOffshore and Onshore Rig Cables - 1 PDFjinyuan74Încă nu există evaluări

- The Life-Saving Rules (April)Document1 paginăThe Life-Saving Rules (April)jinyuan74Încă nu există evaluări

- Chemistry Revision Pack - 2012Document20 paginiChemistry Revision Pack - 2012api-21735041071% (7)

- The Life-Saving Rules (April)Document1 paginăThe Life-Saving Rules (April)jinyuan74Încă nu există evaluări

- Sterile Operations Quality Risk AssessmentDocument29 paginiSterile Operations Quality Risk Assessmentgbra80100% (1)

- QC Inspection ChecklistDocument2 paginiQC Inspection ChecklistIslam Sahafayat100% (1)

- Manual Uganda CatfishDocument65 paginiManual Uganda CatfishDare Kehinde100% (2)

- HSE Monthly ReportDocument11 paginiHSE Monthly ReportAlfredo Medina Cano100% (7)

- HSE Meeting HSE ProcedureDocument13 paginiHSE Meeting HSE Procedureloveson709Încă nu există evaluări

- HSE Action PlanDocument5 paginiHSE Action PlansantosoÎncă nu există evaluări

- Form Weekly HSE Performance Report Subcont... - 1Document19 paginiForm Weekly HSE Performance Report Subcont... - 1indra brotowali0% (1)

- 2013 HSE Annual Report - Web FINAL PDFDocument74 pagini2013 HSE Annual Report - Web FINAL PDFarunradÎncă nu există evaluări

- Weekly HSE ReportDocument4 paginiWeekly HSE ReportJeremia Samosir100% (4)

- Supervisors - HSE ChecklistDocument2 paginiSupervisors - HSE Checklistchikkam50% (4)

- EHS Alert 009 - Traffic Safety AlertDocument1 paginăEHS Alert 009 - Traffic Safety AlertAbdulKather100% (1)

- HSE DocumentsDocument20 paginiHSE DocumentsVelmurugan Balasubramanian100% (3)

- PT Hon Chuan Indonesia K3 Program 2015Document1 paginăPT Hon Chuan Indonesia K3 Program 2015Suharto Ari100% (3)

- Monthly HSE Performance Report April 2018-AD 540Document70 paginiMonthly HSE Performance Report April 2018-AD 540Mohamed ThowfeekÎncă nu există evaluări

- Att 1 HSE Objectives & TargetsDocument1 paginăAtt 1 HSE Objectives & TargetsAbdul Hakam Mohamed Yusof100% (1)

- CS8 Hse Weekly Meeting #04Document18 paginiCS8 Hse Weekly Meeting #04Omer Khazal100% (2)

- Monthly HSE Report April .2013Document8 paginiMonthly HSE Report April .2013sakthivelÎncă nu există evaluări

- Model For HSSE ReportDocument2 paginiModel For HSSE ReportMidha Neer50% (2)

- Kpi Hse - MsiDocument12 paginiKpi Hse - MsiRobby Damanik0% (1)

- 423-02 HSE Plan Checklist EditableDocument16 pagini423-02 HSE Plan Checklist Editablepolosantiomvery100% (4)

- PTW Audit ChecklistDocument2 paginiPTW Audit ChecklistHasanuddin HAMID100% (1)

- Internal HSE Audit ProcedureDocument5 paginiInternal HSE Audit ProcedureGOWRI M MÎncă nu există evaluări

- Project Hse Plan Contract No. C.: Description Action BY A. TrainingDocument6 paginiProject Hse Plan Contract No. C.: Description Action BY A. TraininglithronicÎncă nu există evaluări

- ALSA VAPOUR RECOVERY COMPRESSOR MODIFICATION AND PLANT UPGRADESDocument2 paginiALSA VAPOUR RECOVERY COMPRESSOR MODIFICATION AND PLANT UPGRADESsauspy100% (1)

- HSE InductionDocument16 paginiHSE InductionChethan100% (4)

- HSE PlanDocument80 paginiHSE Planpandaprasad88% (8)

- Annexure - IV - Contractor HSE Capability Assessment Sheet - Rev 00 - VibrantDocument4 paginiAnnexure - IV - Contractor HSE Capability Assessment Sheet - Rev 00 - VibrantGovindKrishnanÎncă nu există evaluări

- National Housing Program HSE ReportDocument9 paginiNational Housing Program HSE ReportfarrukhÎncă nu există evaluări

- HSE Monthly Statisctical Report February 2016Document2 paginiHSE Monthly Statisctical Report February 2016naveed566100% (2)

- Daily HSE Report/Job Safety Analysis: Date: Location: Doc. Ref. No. Project Name: Date: Total ManpowerDocument14 paginiDaily HSE Report/Job Safety Analysis: Date: Location: Doc. Ref. No. Project Name: Date: Total Manpowersaad100% (1)

- HSE Statistics (Monthly) - Package I November-2016Document182 paginiHSE Statistics (Monthly) - Package I November-2016makdelÎncă nu există evaluări

- HSE Management Meeting Highlights Drilling Activity and Safety ActionsDocument7 paginiHSE Management Meeting Highlights Drilling Activity and Safety Actionsrasnowmah2012Încă nu există evaluări

- Hse Goals and TargetsDocument4 paginiHse Goals and TargetsVICTOR100% (1)

- HSE Plan - IRQ-HPM-V1 - Mar 2021Document22 paginiHSE Plan - IRQ-HPM-V1 - Mar 2021amjed naama100% (2)

- Safety Department Checklist FormatDocument32 paginiSafety Department Checklist Formatrockyvinoo100% (18)

- HSE Training Matrix 2019Document1 paginăHSE Training Matrix 2019Sigit Wiyono100% (2)

- 2013 HSE Annual Report Web FINALDocument74 pagini2013 HSE Annual Report Web FINALThiếu Nhiều Thứ100% (1)

- HSE Induction NewDocument16 paginiHSE Induction Newredbire100% (2)

- Visible Safety and Induction: Hse Management Visit ChecklistDocument6 paginiVisible Safety and Induction: Hse Management Visit ChecklistHARSHALÎncă nu există evaluări

- DC 4.75Document11 paginiDC 4.75jinyuan74Încă nu există evaluări

- Fire PumpDocument1 paginăFire Pumpjinyuan74Încă nu există evaluări

- DPDocument19 paginiDPMohammad HusanÎncă nu există evaluări

- Mud HopperDocument2 paginiMud Hopperjinyuan74Încă nu există evaluări

- LAKELAND Chemical Resistant ApronDocument4 paginiLAKELAND Chemical Resistant Apronjinyuan74Încă nu există evaluări

- FIS Services Spec BookDocument22 paginiFIS Services Spec BookLuis A G. C.Încă nu există evaluări

- Rotary and Handling Tools Catalog PDFDocument190 paginiRotary and Handling Tools Catalog PDFjinyuan74100% (3)

- CG - Eng .223 Drill Pipe Care and HandlingDocument12 paginiCG - Eng .223 Drill Pipe Care and Handlingjinyuan74Încă nu există evaluări

- Ellk92led CsaDocument12 paginiEllk92led Csajinyuan74Încă nu există evaluări

- DME Exhaust Catalog 2013 PDFDocument72 paginiDME Exhaust Catalog 2013 PDFjinyuan74Încă nu există evaluări

- Osborn Loadrunners English PDFDocument92 paginiOsborn Loadrunners English PDFjinyuan74Încă nu există evaluări

- PR-1947 - Electrical Safety RulesDocument58 paginiPR-1947 - Electrical Safety Rulesjinyuan74Încă nu există evaluări

- Flfe Series Lighting Fixtures For Fluorescent Tubes-1Document5 paginiFlfe Series Lighting Fixtures For Fluorescent Tubes-1jinyuan74Încă nu există evaluări

- MHD56251 Ed4Document152 paginiMHD56251 Ed4jinyuan74100% (1)

- Physics Notes RevisionDocument43 paginiPhysics Notes RevisionMatthew LiÎncă nu există evaluări

- HL Series Addendum - 08-26-14Document1 paginăHL Series Addendum - 08-26-14jinyuan74Încă nu există evaluări

- 50Hz UP5 11, UP5 15, UP5 18, UP5 22 60Hz UP6 15, UP6 20, UP6 25, UP6 30Document10 pagini50Hz UP5 11, UP5 15, UP5 18, UP5 22 60Hz UP6 15, UP6 20, UP6 25, UP6 30jinyuan74Încă nu există evaluări

- Material Safety Data Sheet: Effective Date 15.11.2011Document7 paginiMaterial Safety Data Sheet: Effective Date 15.11.2011jinyuan74Încă nu există evaluări

- Loc TiteDocument2 paginiLoc Titejinyuan74Încă nu există evaluări

- Lufkin CatalogDocument48 paginiLufkin Catalogjinyuan74Încă nu există evaluări

- Product Compare: Products OverviewDocument2 paginiProduct Compare: Products Overviewjinyuan74Încă nu există evaluări

- Ball ValveDocument12 paginiBall ValvemohamedfirozÎncă nu există evaluări

- Loc TiteDocument2 paginiLoc Titejinyuan74Încă nu există evaluări

- Lewis Oilfield ProductsDocument4 paginiLewis Oilfield Productsjinyuan74Încă nu există evaluări

- 1907 - T - CardDocument1 pagină1907 - T - Cardjinyuan74Încă nu există evaluări

- Construction Claim Books & LinkDocument7 paginiConstruction Claim Books & LinkAfrath_nÎncă nu există evaluări

- Process Validation ProtocolDocument10 paginiProcess Validation ProtocolDivya SekarÎncă nu există evaluări

- AP Electrical Safety SWPDocument12 paginiAP Electrical Safety SWPjvigforuÎncă nu există evaluări

- Common SAP Testing Terminology Ensures Project UnderstandingDocument8 paginiCommon SAP Testing Terminology Ensures Project UnderstandingZelimir KovacevicÎncă nu există evaluări

- Rotorcraft Forecast Sample - R013Document14 paginiRotorcraft Forecast Sample - R013Genaire LimitedÎncă nu există evaluări

- Clearing Pending TransactionsDocument10 paginiClearing Pending TransactionsVinay ChughÎncă nu există evaluări

- JBT GreenDocument3 paginiJBT GreenRagu VenkatÎncă nu există evaluări

- Case Study On Ford Motor CompanyDocument5 paginiCase Study On Ford Motor CompanySteveÎncă nu există evaluări

- North Sea AtlasDocument483 paginiNorth Sea Atlasjacek_sawicz100% (2)

- ZARGES K 470 Universal Box - 40678Document3 paginiZARGES K 470 Universal Box - 40678Phee Beng HweeÎncă nu există evaluări

- 1 Drilling Engineering IIDocument235 pagini1 Drilling Engineering IIKarwan Dilmany100% (7)

- Steam Nozzles: Prepared by Venkat Chintala Asst. Prof. S.G. Mechanical Engg. Deptt., UPESDocument50 paginiSteam Nozzles: Prepared by Venkat Chintala Asst. Prof. S.G. Mechanical Engg. Deptt., UPESRaj NarayanÎncă nu există evaluări

- Company Profile Prima VistaDocument10 paginiCompany Profile Prima VistaInche Helmi Dori DoriÎncă nu există evaluări

- Professional Resume (HVAC & Utilities Manager) - 1Document3 paginiProfessional Resume (HVAC & Utilities Manager) - 1Mujtaba AliÎncă nu există evaluări

- Astm E11-13Document9 paginiAstm E11-13OmarMageedÎncă nu există evaluări

- C-157: Three Coat Epoxy Coating Spec for Seawater ImmersionDocument11 paginiC-157: Three Coat Epoxy Coating Spec for Seawater ImmersionKong Hu LeeÎncă nu există evaluări

- Brochure Ec380d Ec480d t2 t3 en 30 20030338 DDocument32 paginiBrochure Ec380d Ec480d t2 t3 en 30 20030338 DJose Martin Rodriguez YarlequeÎncă nu există evaluări

- Jonathan Baeza's Resume - Java Consultant & IT Co-FounderDocument5 paginiJonathan Baeza's Resume - Java Consultant & IT Co-FounderJonathan BaezaÎncă nu există evaluări

- Metro RailDocument59 paginiMetro Railகீர்த்திவாசன் தமிழன்50% (2)

- Contract for Sale of Electricity to Steel PlantDocument2 paginiContract for Sale of Electricity to Steel PlantAleli Manimtim-CorderoÎncă nu există evaluări

- Materials Engineering SpecificationDocument2 paginiMaterials Engineering SpecificationRonald AraujoÎncă nu există evaluări

- NCAR AIP 2010 AerodromeDocument170 paginiNCAR AIP 2010 AerodromeAbhishek Man ShresthaÎncă nu există evaluări

- Assembly Manual For50ccDocument42 paginiAssembly Manual For50ccfRANCÎncă nu există evaluări

- Microsign PresentationDocument27 paginiMicrosign PresentationMicrosign ProductsÎncă nu există evaluări

- NO Nama Produk AKL Produk Code Size Principal Keterangan QTY Harga Harga + PPN 10% Lumbal SystemDocument2 paginiNO Nama Produk AKL Produk Code Size Principal Keterangan QTY Harga Harga + PPN 10% Lumbal SystemIndraSuryadibrataÎncă nu există evaluări

- JSW Steel Coated Products Test CertificatesDocument10 paginiJSW Steel Coated Products Test CertificatesBernice AkotoÎncă nu există evaluări

- Trada 2Document2 paginiTrada 2rdobeidatÎncă nu există evaluări