Documente Academic

Documente Profesional

Documente Cultură

Https Apps - Iveco.com Newsip Pages DispSI

Încărcat de

hevisaseTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Https Apps - Iveco.com Newsip Pages DispSI

Încărcat de

hevisaseDrepturi de autor:

Formate disponibile

Service

Information

2012/0060/3

WARRANTY CAMPAIGN

(IMAGE) I.C. - T87

S 2000; AUTOBUS S 2000

79.41.01

SERVO BRAKE ASSY

Subject

Repair interventions for quality improvements.

Description

To qualitatively improve the product on a limited number of vehicles not delivered to clients yet, some checks have been

specified on the servo brake assy as below:

z Procedure for vehicles with ESP9

z Procedure for vehicles with ABS / ASR / ESP8

Involved Vehicles

29L10 - 29L12 - 29L14 - 35S10 - 35S11 - 35S12 - 35S13 - 35S14 - 35S14G - 35S17 - 35S18 - 35S21 - 35C10 - 35C11 -

35C12 - 35C13 - 35C14 - 35C14G - 35C15 - 35C17 - 35C18 - 35C21

Procedure

PROCEDURE FOR VEHICLES WITH ESP9 (M.Y. 2012):

6.12.2013

Strana 1.(od 6) ParagrafLex

If necessary, connect the battery and make the key on.

Connect EASY to the CAN line as in the photos below and follow the instructions leading to the video page of the braking

system: be careful while correctly identifying the modulation system.

Photo A Photo B

Remove the panel.

Remove the

OBD socket plug (yellow connector)

Photo C

Connection to EASY

6.12.2013

Strana 2.(od 6) ParagrafLex

Start the vehicle and wait 10 seconds so that the vacuum pump obtains the vacuum.

Press the brake pedal no. 5 times with an average load (do not press with your foot to the end).

Wait 20 seconds so that the vacuum stabilises in the servo brake.

Read the "BRAKE OIL PRESSURE" value on EASY. (Photo D)

If the "BRAKE OIL PRESSURE" value (photo D) <0.3 bar the servo brake is compliant.

If the "BRAKE OIL PRESSURE" value (photo D) >= 0,3 bar, disconnect the pipe with the vacuum pump seal valve on

booster and check on the video if the sensor still reads the initial value or if the pressure is decreased. (photo E)

If the pressure value is still the same as the initial one read previously the servo brake is compliant.

If the pressure value is lower than the initial value read previously the servo brake must be replaced.

Re-connect the pipe with the vacuum seal valve and turn the vehicle off, caring to disconnect EASY correctly, then turn

the engine off.

PROCEDURE FOR VEHICLES WITH ABS / ASR / ESP8: (M.Y. 09 - M.Y. 2012)

Photo D

BRAKE OIL PRESSURE value

Photo E

6.12.2013

Strana 3.(od 6) ParagrafLex

If necessary connect the battery, start the vehicle and wait 10 seconds so that the vacuum pump obtains the vacuum.

Press the brake pedal no. 5 times with an average load (do not press with your foot to the end).

Wait 20 seconds so that the vacuum stabilises in the servo brake.

If you have the disk shown in (photos A - B), fit it for the check.

Engage the parking brake and lift the vehicle so that the front wheels are free.

Make three idle turns on each wheel and measure the residual torque, without adjusting the pick-up torque.

The reading must be carried out with the wheel moving, trying to keep a steady effort while rotating: (in photos C - D

you can see a measuring example with torque wrench with display).

If a torque wrench with display is not available, use a wrench with snap adjustment and make the first measurement by

setting the value at 10 Nm, then increase by 5 Nm each time till the wrench snaps.

If you do not have the disk shown in (photos A - B), the residual torque can be measured also applying the torque

wrench directly on the wheel nuts and calculating the value as shown in (photo E).

Photo A Photo B

Replace 3 nuts

with nuts with screw

Fit the disk

as indicated

Photo C Photo D

Apply

the torque wrench

Instrument details

6.12.2013

Strana 4.(od 6) ParagrafLex

Measure on both wheels (excluding the pick-up always) and detect the max. value on the two wheels.

Of the max. value read on both wheels is < 15 Nm (photo D) the servo brake is compliant.

If the max.value read on both wheels is >=15 Nm (pick-up excluded), disconnect the pipe with the vacuum pump seal

valve on the booster (photo F) and measure again the residual torque on both wheels.

If the value read in the second measurement is the same as the one previously measured the servo brake is compliant.

If the value read is lower than the one previously measured replace the servo brake.

Re-connect the pipe with the vacuum seal valve and turn the engine off.

Photo E

Residual torque with wrench

applied to wheel nuts

Actual torque = (A + B) / 2

Measurement made horizontally

Photo F

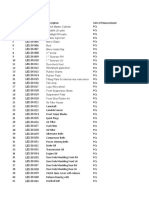

Spare parts

Model re. / Version

Old Part

Number

Old

Q.ty

Description

New Part

Number

New

Q.ty

M.Y. 2012 29L - 35S -

35C

Kit consisting of no. 1 servo

brake

500054883 1

Administrative Definitions

Model re. / Version Description Code

Working units

(WU)

6.12.2013

Strana 5.(od 6) ParagrafLex

M.Y. 2012 29L - 35S -

35C

Checking the servo brake on vehicles with ESP9 79410AT87 2

M.Y. 2012 29L - 35S -

35C

Checking the servo brake on vehicles with ABS - ASR -

ESP8

79410BT87 5

M.Y. 2012 29L - 35S -

35C

Replacing the servo brake on vehicles with ABS - ASR -

ESP9

79410CT87 8

Notes

Attachments

Nr File

1 Chassis-MC10-EN-T87.xls

02 April 2012

6.12.2013

Strana 6.(od 6) ParagrafLex

S-ar putea să vă placă și

- 3007a Je0m f9q Special FeaturesDocument101 pagini3007a Je0m f9q Special FeaturesAdam JohnsonÎncă nu există evaluări

- 02 - Camshaft - Install PDFDocument11 pagini02 - Camshaft - Install PDFNimÎncă nu există evaluări

- Engine Compression Brake Actuator, Replacement, CXU, GU, MP7 2007, 2010Document6 paginiEngine Compression Brake Actuator, Replacement, CXU, GU, MP7 2007, 2010Christian FloresÎncă nu există evaluări

- Special Features of The f5r 740 EngineDocument146 paginiSpecial Features of The f5r 740 EngineBen Van Der MerweÎncă nu există evaluări

- Compression - Test: Shutdown SIS Previous ScreenDocument2 paginiCompression - Test: Shutdown SIS Previous ScreenbejoythomasÎncă nu există evaluări

- Acumulador de FrenoDocument7 paginiAcumulador de FrenoUlises BarreraÎncă nu există evaluări

- Technical Note 3562A XG0NDocument120 paginiTechnical Note 3562A XG0NEeepsÎncă nu există evaluări

- BMW - Puma - 13588845-03 N47 PDFDocument3 paginiBMW - Puma - 13588845-03 N47 PDFjoker63000Încă nu există evaluări

- Seat Ibiza 1400cc-E4-Bbz LPG EngDocument4 paginiSeat Ibiza 1400cc-E4-Bbz LPG EngFlorin MoneaÎncă nu există evaluări

- MR325KANGOO1Document208 paginiMR325KANGOO1Jumbosize100% (1)

- Nissan 2012 Boletin Tecnico - AbsDocument7 paginiNissan 2012 Boletin Tecnico - AbsMarcos PalavecinoÎncă nu există evaluări

- Fuel System - Repair ProceduresDocument48 paginiFuel System - Repair ProcedurescayberrahmadakÎncă nu există evaluări

- Holden VT 2000 Service TechlinesDocument177 paginiHolden VT 2000 Service Techlinescosky071% (7)

- Special Features of The Twingo Fitted With The D7F EngineDocument314 paginiSpecial Features of The Twingo Fitted With The D7F EngineGyula75% (4)

- CVT Audi Installation InstructionsDocument2 paginiCVT Audi Installation Instructionsbox374100% (1)

- Ajuste Freno de MotorDocument8 paginiAjuste Freno de MotorAlvaro Escalona GtzÎncă nu există evaluări

- Brake System Echo/Yaris 2002Document43 paginiBrake System Echo/Yaris 2002Tomas Dominguez100% (1)

- On-Vehicle Inspection: Fuel Tube ConnectorDocument3 paginiOn-Vehicle Inspection: Fuel Tube ConnectordiemnganÎncă nu există evaluări

- VNX - Su Master Propulsion 2003Document469 paginiVNX - Su Master Propulsion 2003cvn2100% (3)

- BMW N54 Turbo Wastegate Rattle TSB / Extended WarrantyDocument8 paginiBMW N54 Turbo Wastegate Rattle TSB / Extended Warrantycheshirecat79100% (2)

- Teste Freio e Acumulador 938HDocument10 paginiTeste Freio e Acumulador 938HCesar AugustoÎncă nu există evaluări

- Calibracion InyectoresDocument4 paginiCalibracion InyectoresWladimir AmaguañaÎncă nu există evaluări

- Gear Group (Rear) - Install: Shutdown SIS Previous ScreenDocument10 paginiGear Group (Rear) - Install: Shutdown SIS Previous ScreenmohamedÎncă nu există evaluări

- NissanDocument7 paginiNissanTun Tun Win KseÎncă nu există evaluări

- Chequeo Tiempo Bomba de Inyeccion 3056 CATDocument10 paginiChequeo Tiempo Bomba de Inyeccion 3056 CATAlejandro ValenzuelaÎncă nu există evaluări

- Genius ShockDocument10 paginiGenius ShockRob. Van WaesÎncă nu există evaluări

- Automatic TransmissionDocument382 paginiAutomatic TransmissionYee Leong Yap100% (3)

- Hyundai AT ErrorDocument10 paginiHyundai AT ErrorPerminov SergeyÎncă nu există evaluări

- Calibre Valvulas MP8 s34-5116Document20 paginiCalibre Valvulas MP8 s34-5116Jose AGÎncă nu există evaluări

- Service Manual: Terberg Non-Driven 16T-Tag AxleDocument29 paginiService Manual: Terberg Non-Driven 16T-Tag Axlecarlos venturaÎncă nu există evaluări

- Assembly Compression AirDocument3 paginiAssembly Compression Airaqshal candraÎncă nu există evaluări

- Brake Report 2015Document38 paginiBrake Report 2015Pratyush NagareÎncă nu există evaluări

- AFC Sensor de Presion PDFDocument10 paginiAFC Sensor de Presion PDFCharlie BrownÎncă nu există evaluări

- Brake System Pressure - Test and Adjust: Shutdown SISDocument5 paginiBrake System Pressure - Test and Adjust: Shutdown SISguayanecitroÎncă nu există evaluări

- Clio 2 Factory Repair ManualDocument212 paginiClio 2 Factory Repair Manualagrandi12100% (3)

- Compression Test On 2AZ EnginesDocument4 paginiCompression Test On 2AZ EnginesOlatunde OnakoyaÎncă nu există evaluări

- Turbo ChargersDocument8 paginiTurbo ChargersPhil B.Încă nu există evaluări

- SteeringDocument50 paginiSteeringLoc TruongÎncă nu există evaluări

- CamryShiftFlare TSIBDocument6 paginiCamryShiftFlare TSIBVadim Urupa100% (2)

- гитара передняя С-15 -специфDocument6 paginiгитара передняя С-15 -специфВиталийÎncă nu există evaluări

- Break SistemDocument9 paginiBreak SistemSteven Y.MÎncă nu există evaluări

- Balancines Admision y EscapeDocument6 paginiBalancines Admision y Escapesinger50Încă nu există evaluări

- Ajuste Del EngramDocument6 paginiAjuste Del EngramLuis OcampoÎncă nu există evaluări

- Detroit DD15 Valve AdjustmentDocument3 paginiDetroit DD15 Valve AdjustmentDhanraj Patil94% (32)

- 79 Jeep TSMDocument1.037 pagini79 Jeep TSMJuan Luis Loaiza Correa100% (2)

- Engine Speed Timing Sensor - CalibrateDocument9 paginiEngine Speed Timing Sensor - Calibratewagner_guimarães_150% (2)

- Boletin de Servicio Nissan ABS Well Sensor PDFDocument7 paginiBoletin de Servicio Nissan ABS Well Sensor PDFmaryÎncă nu există evaluări

- Replacing The Turob Pedistal Seals 7.3 DieselDocument3 paginiReplacing The Turob Pedistal Seals 7.3 DieselSt Julian LloydÎncă nu există evaluări

- 2012 Arctic Cat Service Updates and BulletinsDocument470 pagini2012 Arctic Cat Service Updates and BulletinsJuan Carlos SuarezÎncă nu există evaluări

- Automotive - GM SuperchargerManualDocument15 paginiAutomotive - GM SuperchargerManualazrim02Încă nu există evaluări

- Installation Instructions For:: Crank Angle Sensor Replacement For EMS P/N 30-6600Document24 paginiInstallation Instructions For:: Crank Angle Sensor Replacement For EMS P/N 30-6600Ryan FrederickÎncă nu există evaluări

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe la EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceÎncă nu există evaluări

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDe la EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementÎncă nu există evaluări

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)De la EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Încă nu există evaluări

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004De la EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Evaluare: 3 din 5 stele3/5 (1)

- Essex Terraplane Six 1933 Owner's Manual of InformationDe la EverandEssex Terraplane Six 1933 Owner's Manual of InformationÎncă nu există evaluări

- Chevy Differentials: How to Rebuild the 10- and 12-BoltDe la EverandChevy Differentials: How to Rebuild the 10- and 12-BoltEvaluare: 5 din 5 stele5/5 (8)

- Diesel Common Rail Injection Electronic Components ExplainedDe la EverandDiesel Common Rail Injection Electronic Components ExplainedEvaluare: 3.5 din 5 stele3.5/5 (7)

- Condition/Concern: Bulletin No.: PI0631H Date: Apr-2013Document5 paginiCondition/Concern: Bulletin No.: PI0631H Date: Apr-2013Erik CruzÎncă nu există evaluări

- High Pressure Ball Valves 150119Document5 paginiHigh Pressure Ball Valves 150119Nilesh MistryÎncă nu există evaluări

- Mainternal Interval 3406Document3 paginiMainternal Interval 3406Sandy Sanjaya100% (1)

- (Manual) StraightLine HDD 2462 Parts ManualDocument65 pagini(Manual) StraightLine HDD 2462 Parts ManualCường Nguyễn QuốcÎncă nu există evaluări

- Machinery and Machine Guarding ProgramDocument35 paginiMachinery and Machine Guarding ProgramBenson Harison MajabeÎncă nu există evaluări

- Replacing A Head Gasket 5A-FEDocument1 paginăReplacing A Head Gasket 5A-FE985wtz8rcjÎncă nu există evaluări

- Sec5a4 Abs AsrDocument94 paginiSec5a4 Abs AsrNguyễn Hữu Hà88% (8)

- Curva de Carga Grua 60 Ton LINK BELTDocument24 paginiCurva de Carga Grua 60 Ton LINK BELTFelipe García ValdebenitoÎncă nu există evaluări

- Isuzu N-Series 4JJ1 Engine Control System Lg4jjed-We - 4jj1 Euro 5 With DPDDocument379 paginiIsuzu N-Series 4JJ1 Engine Control System Lg4jjed-We - 4jj1 Euro 5 With DPDMircea Gilca93% (57)

- Installation Manual MT-502: I. Accessory PartsDocument5 paginiInstallation Manual MT-502: I. Accessory PartshashemÎncă nu există evaluări

- Toyota ABC AnalysisDocument27 paginiToyota ABC AnalysisRiya RaiÎncă nu există evaluări

- Anna University Exams Regulation 2017 Anna University Semester Exam Important QuestionsDocument3 paginiAnna University Exams Regulation 2017 Anna University Semester Exam Important QuestionsBairaviPerumalVigneswaranÎncă nu există evaluări

- GR-900XL: 90 Ton Capacity (81.6 Metric Tons) Hydraulic Rough Terrain CraneDocument16 paginiGR-900XL: 90 Ton Capacity (81.6 Metric Tons) Hydraulic Rough Terrain CraneMiguel Eduardo Parra GutierrezÎncă nu există evaluări

- RT 200 Manual de Operación y MantenimientoDocument342 paginiRT 200 Manual de Operación y MantenimientoLuis Enrique Peña100% (1)

- Turbine Dir PDFDocument11 paginiTurbine Dir PDFsppramÎncă nu există evaluări

- VW PP MBPDocument5 paginiVW PP MBPjulio ortegaÎncă nu există evaluări

- Liebherr L544-443 Wheel Loader Service Repair Manual SN 7477 PDFDocument45 paginiLiebherr L544-443 Wheel Loader Service Repair Manual SN 7477 PDFjfjksekdmeik67% (3)

- DC Motor WikiDocument55 paginiDC Motor Wikisupratim05Încă nu există evaluări

- Degradation Effects On Industrial Gas Turbines - Rainer KruzDocument7 paginiDegradation Effects On Industrial Gas Turbines - Rainer KruzhrsotherÎncă nu există evaluări

- BUILDING UTILITIES 2 Building HVAC SystemsDocument142 paginiBUILDING UTILITIES 2 Building HVAC Systemsjona serranoÎncă nu există evaluări

- Craftsman TillerDocument33 paginiCraftsman TillerJeff KelleyÎncă nu există evaluări

- Job Cost in V 03112012Document52 paginiJob Cost in V 03112012govindvbÎncă nu există evaluări

- 150 7125 Dana 32000 TransmissionDocument156 pagini150 7125 Dana 32000 TransmissionFred Javier Melendez Garcia83% (18)

- Cummins QSB6.7 Engine Spare Parts Catalog: Part Number DescriptionDocument12 paginiCummins QSB6.7 Engine Spare Parts Catalog: Part Number DescriptionsanouÎncă nu există evaluări

- 938G Wheel Loader: Service Repair ManualDocument24 pagini938G Wheel Loader: Service Repair ManualAbdelbagi50% (2)

- Manual Motor Hidráulico EATON PDFDocument8 paginiManual Motor Hidráulico EATON PDFalexiqqclÎncă nu există evaluări

- Steam EngineDocument4 paginiSteam EngineimgopalÎncă nu există evaluări

- Double Vane Type PumpDocument4 paginiDouble Vane Type PumpMiguel VlntìnÎncă nu există evaluări

- Use of Basic Tools Tve 7 ModuleDocument13 paginiUse of Basic Tools Tve 7 ModuleJocelyn C. DinampoÎncă nu există evaluări

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-2-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)