Documente Academic

Documente Profesional

Documente Cultură

PIP STE05121 (Fabrication & Installation of Anchor Bolts)

Încărcat de

bowitchhazelDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

PIP STE05121 (Fabrication & Installation of Anchor Bolts)

Încărcat de

bowitchhazelDrepturi de autor:

Formate disponibile

TECHNICAL CORRECTION

October 2006

Process Industry Practices

Structural

PIP STF05121

Fabrication and Installation of

Anchor Bolts

PURPOSE AND USE OF PROCESS INDUSTRY PRACTICES

In an effort to minimize the cost of process industry facilities, this Practice has

been prepared from the technical requirements in the existing standards of major

industrial users, contractors, or standards organizations. By harmonizing these

technical requirements into a single set of Practices, administrative, application, and

engineering costs to both the purchaser and the manufacturer should be reduced. While

this Practice is expected to incorporate the majority of requirements of most users,

individual applications may involve requirements that will be appended to and take

precedence over this Practice. Determinations concerning fitness for purpose and

particular matters or application of the Practice to particular project or engineering

situations should not be made solely on information contained in these materials. The

use of trade names from time to time should not be viewed as an expression of

preference but rather recognized as normal usage in the trade. Other brands having the

same specifications are equally correct and may be substituted for those named. All

Practices or guidelines are intended to be consistent with applicable laws and

regulations including OSHA requirements. To the extent these Practices or guidelines

should conflict with OSHA or other applicable laws or regulations, such laws or

regulations must be followed. Consult an appropriate professional before applying or

acting on any material contained in or suggested by the Practice.

This Practice is subject to revision at any time.

Process Industry Practices (PIP), Construction Industry Institute, The

University of Texas at Austin, 3925 West Braker Lane (R4500), Austin,

Texas 78759. PIP member companies and subscribers may copy this Practice

for their internal use. Changes, overlays, addenda, or modifications of any

kind are not permitted within any PIP Practice without the express written

authorization of PIP.

PRINTING HISTORY

August 2003 Issued

October 2006 Technical Correction

Not printed with State funds

TECHNICAL CORRECTION

October 2006

Process Industry Practices Page 1 of 6

Process Industry Practices

Structural

PIP STF05121

Fabrication and Installation of

Anchor Bolts

Table of Contents

1. Introduction................................. 2

1.1 Purpose............................................ 2

1.2 Scope............................................... 2

2. References.................................. 2

2.1 Process Industry Practices............... 2

2.2 Industry Codes and Standards......... 2

3. Requirements.............................. 2

3.1 General ............................................ 2

3.2 Materials........................................... 3

3.3 Bolt Callout ....................................... 3

3.4 Fabrication ....................................... 3

3.5 Assemblies....................................... 4

3.6 Installation........................................ 4

Appendix........................................... 5

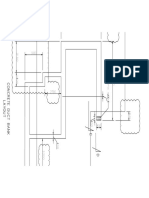

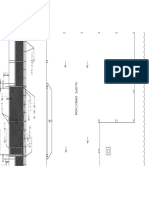

Anchor Bolt Data Table

Anchor Bolt Details

PIP STF05121 TECHNICAL CORRECTION

Fabrication and Installation of Anchor Bolts October 2006

Page 2 of 6 Process Industry Practices

1. Introduction

1.1 Purpose

This Practice provides details and requirements for anchor bolt fabricators and

installers. This Practice also provides information for the design engineer to

standardize bolt lengths. The intent of this Practice is to minimize the use of non-

standard bolt lengths.

1.2 Scope

This Practice provides the details and requirements for anchor bolt fabrication and

installation. Two standard lengths are shown for each diameter anchor bolt. This

Practice also provides requirements for non-standard bolt lengths.

2. References

Applicable requirements in the following Practices and industry codes and standards shall be

considered an integral part of this Practice. The edition in effect on the date of contract

award shall be used, except as otherwise noted. Short titles will be used herein where

appropriate.

2.1 Process Industry Practices (PIP)

PIP STS03001 - Plain and Reinforced Concrete Specification

2.2 Industry Codes and Standards

! American Society of Testing and Materials (ASTM)

ASTM A153/A153M - Standard Specification for Zinc Coating (Hot-Dip) on

Iron and Steel Hardware

ASTM A563 - Standard Specification for Carbon and Alloy Steel Nuts

ASTM F436 - Standard Specification for Hardened Steel Washers

ASTM F1554 - Standard Specification for Anchor Bolts, Steel, 36, 55, and

105-ksi Yield Strength

! American Society of Mechanical Engineers (ASME)

ASME B18.2.1 Square and Hex Bolts and Screws

3. Requirements

3.1 General

3.1.1 Unless a non-standard bolt length is required, the design engineer shall

specify one of the two standard length anchor bolts shown for each anchor

bolt diameter in the Anchor Bolt Data Table.

3.1.2 Non-standard bolt lengths may be required for the following reasons:

TECHNICAL CORRECTION PIP STF05121

October 2006 Fabrication and Installation of Anchor Bolts

Process Industry Practices Page 3 of 6

a. A longer than necessary bolt length may cause the foundation to be

deeper than practical.

b. A longer than necessary bolt length may cause the anchor bolt to project

into the foundation (mat), which would increase construction costs.

c. To properly transfer load to the reinforcing steel, the anchor bolt may

need to be longer than the standard bolt.

3.1.3 If a non-standard bolt length is required, it should be an even dimension (an

even number of inches) and should be significantly different in length than

the standard length bolt (at least 6 inches shorter or longer than the closest

standard length bolt).

3.2 Materials

3.2.1 Bolts shall conform to ASTM F1554, Grade 36, with UNC-2A threads except

as otherwise specified on the design drawing.

3.2.2 Nuts shall conform to ASTM A563, Grade A, heavy hex with UNC-2B

threads. Washers shall be ASTM F436.

3.2.3 Headed bolts (conforming to Section 3.2.1) of at least the same length above

the bottom nut (see Anchor Bolt Details) are an acceptable substitution.

Bolt head style shall be heavy hex in accordance with ASME B18.2.1.

3.3 Bolt Callout

Anchor bolts shall be identified on design drawings as follows:

8 ~ 1 - 1/4" NSL P = 3 - 3/4" W/2 Nuts L = 3' - 8"

Quantity

Diameter

Type

Projection from top of concrete

(called out only if not shown on foundation section)

Nut quantity at top

(shown only if two nuts are required)

Bolt length (shown only if non-standard or if required per note below)

Comment: For record purposes, lengths of standard length anchor bolts shall be

noted either in the call-out or in notes on the drawings. The engineer

may duplicate the Anchor Bolt Data Table (this Practice) on the

design drawing.

3.4 Fabrication

3.4.1 Unless otherwise specified, all bolts (total bolt length), nuts, and washers

shall be hot-dip galvanized after fabrication in accordance with ASTM A153,

Class C.

3.4.2 Excess galvanizing material shall be removed from the threaded portions of

the bolts by the use of a centrifuge or by mechanical chasing of the threads.

PIP STF05121 TECHNICAL CORRECTION

Fabrication and Installation of Anchor Bolts October 2006

Page 4 of 6 Process Industry Practices

3.4.3 The fit of nuts on threads of anchor bolts shall be verified before shipment.

3.5 Assemblies

3.5.1 Type A, B, and N bolt assemblies shall consist of anchor bolt with

tack-welded nut at bottom and nut(s) and washer at top. Refer to Anchor

Bolt Details.

3.5.2 Type ASL, BSL, and NSL bolt assemblies shall consist of anchor bolt

with tack-welded nut at bottom and sleeve, nut(s), and washer at top. Refer

to Anchor Bolt Details.

3.6 Installation

3.6.1 Unless noted otherwise on the design drawings, tolerances shall be as

specified in PIP STS03001.

3.6.2 Unless noted otherwise on design drawings, anchor bolt sleeves for

stationary equipment and structural base plates shall be filled with grout

after the column or equipment is in place and the anchor bolts are aligned.

Water or other loose particles shall not be allowed to collect in the sleeve

before the sleeve is grouted.

3.6.3 Unless noted otherwise on the design drawings, anchor bolt sleeves for

machinery shall be filled with nonbonding moldable material before

grouting.

3.6.4 Anchor bolt threads shall be covered with duct tape or other suitable means

to keep them clean and to prevent any damage that might occur during the

preparation of the foundation for grouting and the actual grouting of the

foundation.

3.6.5 Unless specified otherwise on design drawings, anchor bolts shall be

tightened to a snug-tight condition, defined as the tightness that is attained

with a few impacts of an impact wrench or with the full effort of a man using

an ordinary spud wrench.

3.6.6 At slide plate locations, two top nuts are required. The lower nut shall be

hand tightened and then backed off a half turn leaving approximately

1/16-inch clearance between lower nut and base plate. The upper nut shall be

installed and jammed against the first nut.

TECHNICAL CORRECTION PIP STF05121

October 2006 Fabrication and Installation of Anchor Bolts

Process Industry Practices Page 5 of 6

Appendix

Anchor Bolt Data Table

Types A, B, N,** ASL, BSL, and NSL** Bolts

(See Anchor Bolt Details for locations of dimensions.)

Bolt

Diameter

do

Allowance for Nuts

Thread

Length

at Top

Sleeve

A &

ASL

Bolts*

B &

BSL

Bolts*

Bolt

Diameter

do

N1 N2 P1 &

Thread

Length

at

Bottom

Shell Size Std. Length

L

Std. Length

L

1/2 1 1 1/2 1 2 1/4 2 x 5 1-0 2-4 1/2

5/8 1 1/4 2 1 2 3/4 2 x 7 1-3 2-5 5/8

3/4 1 1/2 2 1/4 1 1/4 3 2 x 7 1-4 2-6 3/4

7/8 1 1/2 2 1/2 1 1/4 3 1/4 2 x 7 1-5 2-7 7/8

1 1 3/4 2 3/4 1 1/2 3 1/2 3 x 10 1-10 2-11 1

1 1/4 2 1/4 3 1/2 1 3/4 4 1/4 3 x 10 2-0 3-6 1 1/4

1 1/2 2 1/2 4 2 4 3/4 4 x 15 2-8 4-5 1 1/2

1 3/4 3 4 3/4 2 1/4 5 1/2 4 x 15 2-10 5-0 1 3/4

2 3 1/4 5 1/4 2 1/2 6 4 x 18 3-4 5-2 2

2 1/4" 3 3/4 6 2 3/4 6 3/4 4 x 18 3-6 5-5 2 1/4

2 1/2 4 6 1/2 3 7 1/4 6 x 24 4-2 5-7 2 1/2

2 3/4 4 1/2 7 1/4 3 1/4 8 6 X 24 4-4 5-8 2 3/4

3 4 3/4 7 3/4 3 1/2 8 1/2 6" x 24 4-6 6'-0 3

*Note to designer: It is intended that the "A" and "ASL" bolts be used unless a longer length is required. If a

longer length is required, use the "B" and "BSL" bolts. If neither is suitable, designate the

bolt as type N (no sleeves required) or as type NSL (sleeves required), and specify

the required length on the design drawing.

**Note to fabricator: Type N and NSL bolts have no standard length. See the design drawings for anchor

bolt length.

S-ar putea să vă placă și

- Grating DetailsDocument12 paginiGrating DetailsbowitchhazelÎncă nu există evaluări

- Sts 02360Document22 paginiSts 02360Sowjanya VenigallaÎncă nu există evaluări

- PIP STF05511 Fixed Industrial StairsDocument13 paginiPIP STF05511 Fixed Industrial StairsGiammarco Negrini100% (2)

- Pip Stf05521Document16 paginiPip Stf05521joelgir32100% (5)

- Process Industry Practices Structural: PIP STE05530 Grating Design GuideDocument10 paginiProcess Industry Practices Structural: PIP STE05530 Grating Design GuideLumy NastaseÎncă nu există evaluări

- PIP STF05121 Anchor Fabrication and Installation Into ConcreteDocument6 paginiPIP STF05121 Anchor Fabrication and Installation Into Concretecarrimonn11Încă nu există evaluări

- PIP STF05501 Fixed Ladders and CagesDocument11 paginiPIP STF05501 Fixed Ladders and CagesHowo4Die86% (7)

- PIP STF05520 Details For Pipe Railing For Walking and Working SurfacesDocument13 paginiPIP STF05520 Details For Pipe Railing For Walking and Working SurfacesVivian VijayÎncă nu există evaluări

- Process Industry PracticeDocument12 paginiProcess Industry PracticeRonald George100% (1)

- 000.215.1216 20aug2009Document63 pagini000.215.1216 20aug2009Anonymous ya6gBBwHJFÎncă nu există evaluări

- Pip Arc01016Document12 paginiPip Arc01016Ulises CastroÎncă nu există evaluări

- Process Industry Practices Structural: PIP STS02380 Application of ACI 336.1-01Document8 paginiProcess Industry Practices Structural: PIP STS02380 Application of ACI 336.1-01WÎncă nu există evaluări

- PIP STF05501 Fixed Ladders Fabrication DetailsDocument24 paginiPIP STF05501 Fixed Ladders Fabrication Detailslashara100% (1)

- PIP STC01015 Structural Design CriteriaDocument32 paginiPIP STC01015 Structural Design CriteriaRamesh Ram Hingoranee100% (8)

- Pip STF 05501 - 2012Document17 paginiPip STF 05501 - 2012Денис Пекшуев100% (1)

- Process Industry Practices Structural: PIP STE05121 Anchor Bolt Design GuideDocument55 paginiProcess Industry Practices Structural: PIP STE05121 Anchor Bolt Design GuidemithileshÎncă nu există evaluări

- PIP STF05521 Angle Guards and Handrails Fabrication DetailsDocument43 paginiPIP STF05521 Angle Guards and Handrails Fabrication Detailslashara100% (3)

- PIP STI03310 Concrete General Notes and Typical DetailsDocument16 paginiPIP STI03310 Concrete General Notes and Typical Detailsusotapioca0% (1)

- Pip Ste03350 2008 PDFDocument33 paginiPip Ste03350 2008 PDFNagoya Taycho0% (1)

- PIP STS03001 (Plain & Reinforced Concrete Specification)Document15 paginiPIP STS03001 (Plain & Reinforced Concrete Specification)mobin1978Încă nu există evaluări

- List of Civil PIP CodesDocument1 paginăList of Civil PIP Codesmassive85100% (1)

- Horizontal Vessel Foundation DesignDocument42 paginiHorizontal Vessel Foundation Designhrol31060100% (2)

- PIP STS02380, Application of ACI336.1-01 Specification For The Construction of Drilled PiersDocument9 paginiPIP STS02380, Application of ACI336.1-01 Specification For The Construction of Drilled PiersErik PerezÎncă nu există evaluări

- 000.200.1067 3rd Gen Modular Execution Material Handling Strategy - ZipDocument9 pagini000.200.1067 3rd Gen Modular Execution Material Handling Strategy - ZipMuhammad Fatah ShaikÎncă nu există evaluări

- Pip STS03001Document6 paginiPip STS03001Omisawant100% (1)

- PIP STE03360 Heat Exchanger and Horizontal Vessel Foundation Design Guide PDFDocument42 paginiPIP STE03360 Heat Exchanger and Horizontal Vessel Foundation Design Guide PDFErik PerezÎncă nu există evaluări

- Structural List of PipDocument1 paginăStructural List of Pipstr_designÎncă nu există evaluări

- Pip Vesta002 Atmospheric Storage Tank Specification (Supplement To API Standard 650)Document19 paginiPip Vesta002 Atmospheric Storage Tank Specification (Supplement To API Standard 650)Rajesh PanchalÎncă nu există evaluări

- Pip STF-05520Document7 paginiPip STF-05520mahmoodhassan79563100% (2)

- PIP CVS02830 Chain Link Fence and Gates Installation SpecificationDocument11 paginiPIP CVS02830 Chain Link Fence and Gates Installation Specificationplmo100% (1)

- PIP STE03360 Horizontal Vessel JUL07Document42 paginiPIP STE03360 Horizontal Vessel JUL07Nithirut Kampanya100% (4)

- 000 215 1221 A04 31mar05Document11 pagini000 215 1221 A04 31mar05Felipe FloresÎncă nu există evaluări

- CVC 01017Document15 paginiCVC 01017WÎncă nu există evaluări

- PIP STE03360 Heat Exchanger and Horizontal Vessel FoundationDocument42 paginiPIP STE03360 Heat Exchanger and Horizontal Vessel FoundationUnwanus Sa'adahÎncă nu există evaluări

- STF 05530Document13 paginiSTF 05530aby_abraham5005Încă nu există evaluări

- PIP Ladder & CagesDocument9 paginiPIP Ladder & CagesCarlos Maldonado SalazarÎncă nu există evaluări

- Process Industry Practices Structural: PIP STF05530 Grating Fabrication DetailsDocument13 paginiProcess Industry Practices Structural: PIP STF05530 Grating Fabrication DetailsloukmanÎncă nu există evaluări

- Application of Internal Linings - Sample - PIPDocument15 paginiApplication of Internal Linings - Sample - PIPgbuckley9630100% (1)

- STE05121 - Anchor Bolt Design GuideDocument55 paginiSTE05121 - Anchor Bolt Design GuideMiky Casten100% (2)

- XPIP STE05121 Anchor Bolt Design GuideDocument55 paginiXPIP STE05121 Anchor Bolt Design Guidemacynthia26100% (1)

- PIP STS02360 (Driven Piles Specification)Document22 paginiPIP STS02360 (Driven Piles Specification)Hui LiuÎncă nu există evaluări

- VESV1003 - Fabrication of Welded Vessels and Tanks To Be LinedDocument6 paginiVESV1003 - Fabrication of Welded Vessels and Tanks To Be LinedMuhammad Farukh ManzoorÎncă nu există evaluări

- PIP STE05121 (Anchor Bolt Design Guide)Document55 paginiPIP STE05121 (Anchor Bolt Design Guide)bowitchhazelÎncă nu există evaluări

- PNSC0001Document17 paginiPNSC0001Nasser KunjuÎncă nu există evaluări

- Process Industry Practices ElectricalDocument10 paginiProcess Industry Practices ElectricaljowarÎncă nu există evaluări

- Engineering Brief 83 SignedDocument29 paginiEngineering Brief 83 SignedLabinot KutllovciÎncă nu există evaluări

- Pipe Support Criteria For ASME B31.3 Metallic PipingDocument11 paginiPipe Support Criteria For ASME B31.3 Metallic PipingUsman Naseem100% (4)

- STS05130-B Erection of Structural and Miscellaneous SteelDocument12 paginiSTS05130-B Erection of Structural and Miscellaneous SteelAnaÎncă nu există evaluări

- PNSMV033Document8 paginiPNSMV033craneheadÎncă nu există evaluări

- Agitator SelectionDocument20 paginiAgitator SelectionRamakrishna Koushik100% (2)

- STF05521Document15 paginiSTF05521lingoalvaÎncă nu există evaluări

- PIP - STE05535 Vessel Circular Platform Detail GuidelinesDocument5 paginiPIP - STE05535 Vessel Circular Platform Detail Guidelinescristian_alex9885Încă nu există evaluări

- Functional Specification FOR Chain Pulley BlockDocument9 paginiFunctional Specification FOR Chain Pulley BlockVinayaga MoorthiÎncă nu există evaluări

- PIP StandardDocument32 paginiPIP StandardRitesh Chauhan100% (5)

- Pip Sts05130 PDFDocument12 paginiPip Sts05130 PDFFer PabÎncă nu există evaluări

- ASME B16.11 - Socket Welding and Threaded Forged FittingsDocument71 paginiASME B16.11 - Socket Welding and Threaded Forged FittingspremÎncă nu există evaluări

- Esstd0202scjp Pip Pnfj8000Document71 paginiEsstd0202scjp Pip Pnfj8000Engr Tahir UL HaqÎncă nu există evaluări

- Pip STS05130 2018Document14 paginiPip STS05130 2018Syarief NahdiÎncă nu există evaluări

- Pip Stf05520 - 2003 Details For BarandalesDocument14 paginiPip Stf05520 - 2003 Details For Barandalesviridiana.noyolaÎncă nu există evaluări

- How to prepare Welding Procedures for Oil & Gas PipelinesDe la EverandHow to prepare Welding Procedures for Oil & Gas PipelinesEvaluare: 5 din 5 stele5/5 (1)

- Reference For Acicode PDFDocument1 paginăReference For Acicode PDFbobmarley20161934Încă nu există evaluări

- Pulse Velocity Using Concrete PropertiesDocument1 paginăPulse Velocity Using Concrete Propertiesbobmarley20161934Încă nu există evaluări

- Reference For Acicode PDFDocument1 paginăReference For Acicode PDFbobmarley20161934Încă nu există evaluări

- Reinforcement Front PageDocument1 paginăReinforcement Front Pagebobmarley20161934Încă nu există evaluări

- Reference For Acicode PDFDocument1 paginăReference For Acicode PDFbobmarley20161934Încă nu există evaluări

- Slip Form Front Page OnlyDocument1 paginăSlip Form Front Page Onlybobmarley20161934Încă nu există evaluări

- Guide To Hot Weather Front Page OnlyDocument1 paginăGuide To Hot Weather Front Page Onlybobmarley20161934Încă nu există evaluări

- Map 1m Below Metro ManilaDocument1 paginăMap 1m Below Metro Manilabobmarley20161934Încă nu există evaluări

- Water Cement RatioDocument1 paginăWater Cement Ratiobobmarley20161934Încă nu există evaluări

- Front Page Design and Control of MixDocument1 paginăFront Page Design and Control of Mixbobmarley20161934Încă nu există evaluări

- Bar Lap Gap SpacingDocument1 paginăBar Lap Gap Spacingbobmarley20161934Încă nu există evaluări

- Construction JointDocument1 paginăConstruction Jointbobmarley20161934Încă nu există evaluări

- Crude OilDocument1 paginăCrude Oilbobmarley20161934Încă nu există evaluări

- Random CheckDocument1 paginăRandom Checkbobmarley20161934Încă nu există evaluări

- A To B 8.250 Meters: Sap2000 Computer ModelDocument4 paginiA To B 8.250 Meters: Sap2000 Computer Modelbobmarley20161934Încă nu există evaluări

- Sample CheckDocument1 paginăSample Checkbobmarley20161934Încă nu există evaluări

- ACI Manual of Concrete Inspection PDFDocument1 paginăACI Manual of Concrete Inspection PDFSushil Dhungana33% (3)

- Concrete Duct BankDocument1 paginăConcrete Duct Bankbobmarley20161934Încă nu există evaluări

- Front FenceDocument1 paginăFront Fencebobmarley20161934Încă nu există evaluări

- Mechanical LoadingDocument1 paginăMechanical Loadingbobmarley20161934Încă nu există evaluări

- Corrosion-Understanding The Basics Front PageDocument1 paginăCorrosion-Understanding The Basics Front Pagebobmarley20161934Încă nu există evaluări

- DL RatioDocument1 paginăDL Ratiobobmarley20161934Încă nu există evaluări

- Commentary Chapter 10Document1 paginăCommentary Chapter 10bobmarley20161934Încă nu există evaluări

- BlurDocument1 paginăBlurbobmarley20161934Încă nu există evaluări

- STAAD Design ParametersDocument8 paginiSTAAD Design Parametersbobmarley20161934Încă nu există evaluări

- Analysis and Design of A Simple Surge TankDocument7 paginiAnalysis and Design of A Simple Surge Tankbobmarley20161934Încă nu există evaluări

- ASCE Steel Penstock Front Page OnlyDocument1 paginăASCE Steel Penstock Front Page Onlybobmarley20161934Încă nu există evaluări

- Hydraulic Structures Front PageDocument1 paginăHydraulic Structures Front Pagebobmarley20161934Încă nu există evaluări

- Sample Hydro PowerDocument2 paginiSample Hydro Powerbobmarley20161934Încă nu există evaluări

- CaptureDocument1 paginăCapturebobmarley20161934Încă nu există evaluări