Documente Academic

Documente Profesional

Documente Cultură

V.k.prasath Woven Sacks Project

Încărcat de

VkprasathMannargudiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

V.k.prasath Woven Sacks Project

Încărcat de

VkprasathMannargudiDrepturi de autor:

Formate disponibile

EXECUTIVE SUMMARY

At shrihari woven sack Pvt. Ltd. I spent good time in learning and was rewarded for

my best efforts, learnt to deal with different situations, had experience of organizations

working environment. Confidence, consistency, hard work, teamwork, seeking success out of

dark, innovation, creativity, organizational survival are the key learnings out of my job And

I would like to say that it will be one of my best skill that would remain with me and help me

in the coming life which offer many challenges. The areas covered during my internship were

wide like was taken to visit the factory, where I observed the process carried on in the factory

and also the manufacturing process. I got to know the various policies and practices of the

company like, their Aims, their vision and mission statements, etc. After getting to know the

company, I even got to know about the auditing aspect and practices. As there was an internal

audit going on in the company, I assisted the Auditor in the Auditing Process. I had the

opportunity to learn a lot of things about Auditing and Taxation.

We also ventured into the topic of Cost Sheet. As its a Manufacturing Company cost

sheet is given a lot of importance. So the Manager gave a brief about the cost sheet and

various cost elements comprising in the Company cost sheet. Later on I was provided with

the Financial Statements i.e. the Balance Sheet and Profit & Loss Statement. With the help of

these I used various Financial Statement Analysis Tools like Comparative Statement

Analysis, Common size Statement Analysis, Ratio Analysis, etc. to analyses the financial

statements. I would like to highlight this, that my experience with the company was very

memorable and full of learning, where I found a lot of positive changes in my attitude,

learning and behavior.

INTRODUCTION

Training is a process of learning, a sequence of programmed behaviour and is an

application of knowledge. It gives people an awareness of rules and procedures to guide the

behaviour and it attempts to improve their performance. Training is a short-term process

utilizing a systematic and organized procedure by which managerial and technical skills are

understood.

Madurai Kamaraj University has incorporated institutional training as a component of

Bachelor of Commerce with Computer Application. This training programme is designed

with a view to enable the students to have an exposure and work experience in the practical

field.

As a student of B.COM.CA, we have undergone training in Madura Steel Industries

(P) Ltd., Dindigul for a period of fifteen days. Here we are submitting the report of the

industrial training in which detailed working experience that we have gained during the

training in various departments in this industry is presented.

Training is the process of increasing the knowledge and skills for doing a particular

job. It is an organised procedure by which people learn knowledge and skills for a definite

purpose. The purpose of training is basically to bridge the gap between job requirements and

completeness of an employee. Training is aimed at improving the behaviour and performance

of a person. It is never ending process. Training is closely related with education and

development but needs to be differentiated from these terms.

INTRODUCTION TO THE TRAINING OPPORTUNITY

DEFINITION

Training is a process by which the attitudes, skills and abilities of employees to perform

specific jobs are increased. On the other hand education is the process of increasing the

general knowledge and understanding of employees.

NECESSITY OF TRAINING

Training is required on account of the following reasons.

OBJECTIVES:

To develop skills in the application of theory to practical work situations.

To develop self-confidence, assertiveness, and basic work habits

To improve my communication skills, especially when dealing with people I

do not know.

To improve my ability to talk with others on a professional level.

To improve my research skills to be more effective and efficient in obtaining

information.

To understand the workplace, operating procedures, the company and its

products, how the firm competes, and other organizational concepts.

To know what it is like to work in a professional environment.

To gain experience and insight in the work field during the internship.

INDUSTRY SECTOR BREIF

PP Woven Sacks, Jute, Paper bags/ box are most widely used packaging systems for

Bulk Commodities. Cement, fertilizer and most of the chemicals are already packed woven

sacks while Food grains and sugar use both woven sacks and jute bags. Plastics are the

material of choice because of inherent advantages of functional performance and cost

benefits. Relative merits with respect to functional requirement for bulk packaging using

these three prime packaging materials are summarized.

Opportunities in Bulk Packaging - Polypropylene Woven Sacks the Ideal

Choice:

Packaging fulfils the diverse role from protecting products, preventing spoilage,

contamination, extending shelf life, ensuring safe storage thereby helping to make them

readily available to consumers. India is one of the largest producers of commodities like food

grains, sugar, fruits, vegetables and tea. Due to varied crop pattern, localized production of

commodities, safe and hygienic storage, transportation and distribution and protection against

wastage, hence packaging is of utmost importance. Huge losses have been observed in

agriculture produce in India. Wastage varies fro5 to 35% depending on nature of crops.

Majority of wastage takes place in each of the above steps viz. storage, transportation and at

retain market due to improper packaging. Bulk Packaging provides a solution for

commodities weighin10 to 50 Kg during handling, storage and transportation.

The present paper describes trends in Bulk Packaging for various commodities,

suitability of Polypropylene (PP) Woven Sacks for packaging of food grains, sugar, tea,

similarly for packaging and transport of vegetables and other horticulture produce PP leno

bag is an effective packaging system. With changing packaging need, optimization of

packaging role of Flexible Intermediate Bulk Container (FIBC) and its future has been

highlighted as trend. PP Woven sacks are worldwide material of choice for bulk packaging of

edible commodities for domestic use and exports.

Production of PP Woven Sacks:

Polypropylene (PP) is used as the basic raw material and is fed to the hopper of

extruder and melted to pass through a T- die in film form which is then slit into tapes, which

are then oriented by stretching and wound in cheese winders. Tapes are then fed into circular

/ flat looms and woven into tubular or flat fabric respectively. These fabrics can then be

laminated based on functional need of the packaging. Finally fabrics are cut into pieces as per

bag specification with stitching in bottom and top as per requirement followed by printing.

Profile PP woven sacks laminated with PP liner have wider applications. PP woven

sacks are much stronger & can withstand much higher impact loads because of PP strips

elongation at break is about 15 to 25% as compared to 30% of Jute. These sacks are much

cleaner & resist fungal attack. PP Woven Sacks can be unlaminated, Laminated and along

with PE liners. The size range for bags made from tubular fabric is from minimum 24 inches

(60 cm.) up to 61 inches (155 cm). Woven Sacks are the best and the most cost effective

packaging solution for Industries like Cement, fertilizer, sugar, chemicals, food grains etc. off

late Woven fabric, which is the first stage of Woven sacks, is a preferred medium for bale

wrapping and rain protection in the form of Tarpaulin.

Salient Features:

Flexible and high strength

Water & dust proof design

Heat/Wave Cut & hemmed top

Flat or anti-slip weaving

Applications:

PP woven sacks with liners are specially designed for the packaging of pulverous &

force flowing materials, which include the following:

Food Products: Flour, Corn, Grain, Sugar, Salt, Animal Feed

Chemicals & Fertilizers: Carbon, Caustic Soda, Potash, Phosphates

Petro chemicals: Polymers, Granules, PVC Compound, Master Batches

Minerals: Cement, Calcium Carbonate, Lime, Sand

Advantages:

Woven sacks of HDPE/PP offer several advantages over other industrial

packaging material. Some of the advantages are:

Moisture Proof: HDPE/PP Bags are inherently moisture repellent

Light Weight: HDPE/PP Bags being light weight, offers easy and cheap

transportation.

Printing: Bright 2/3/4 Color printing offer aggressive marketing prospects

Stack ability: No problems in stacking. Can be gusseted to further improve

stacking

Strength: High Tensile strength and long life.

Economical: Highly economical compared to other alternative packing

material

Woven sacks are rapidly replacing jute bags because they have often various

advantages over the conventional jute fabrics as packaging materials. They have excellent

chemical rsistance; they are light in weight and more suitable for packing of various

chemicals in the form of granules and powder. They are also: stronger and can withstand

much higher impact loads. Their elongation at break is 15 to 25 per cent compared to 3 per

cent for jute; they are much cleaner, both in use and production and can be used to handle

food products as they are resistant to fungal attack. Because of such superior properties of

plastic woven bags, it has high demand everywhere. Cement industry is increasing day by

day.

COMPANY PROFILE ABOUT THE COMPANY

Srihari woven sacks Private Limited is one of the leading woven sack manufacturers

in Tirupur district. They are manufacturing woven sacks since 2009; owing to their

experience they can offer customers the best quality products. Their offer comprises of

various types of sacks.

They make polypropylene woven sacks according to customer's specifications,

concerning dimensions and weights. PP Woven sacks are the traditional bags in packaging

industry due to their wide variety of usage, flexibility and strength. Woven polypropylene

sacks are specializing in packing and transporting bulk commodities. Due to strength,

flexibility, durability and lower cost, woven polypropylene sacks are most popular products

in industrial package, which are widely used in packing cement, grain, feeds, fertilizer, seeds,

powders, sugar, salt, powder, chemical in granulated form.

PP Woven sacks are made according to customers preferred specifications as to

mesh, denier, GSM, and sizes that vary from 25 to 80 cm. widths or depending on the desired

capacity. Shirihari private ltd. are manufacturer of Polypropylene Circular Woven Sacks,

mostly catering to the needs of Cement Industry. And their products are basically used for

packaging of Cement.

ORGANIZATION'S AIM:

We aim to provide the best packaging solutions withcustomer satisfaction, quality

assurance and a congenial working environment.

We strive to offer the finest quality services, timely delivery and competitive prices

to all our client.

We assure our clients the best products within a stipulated time frame

GOAL:

To provide our customers with complete packaging solutions which can help them

enhance their business opportunities.

VISION STATEMENT:

To supply packaging material all over India

MISSION STATEMENT:

To capture 80% of market share in Thirupur,coimbatore for cement packaging

material.

CORE COMPETENCY OF THE COMPANY

Production of finest Quality Woven Sacks.

STATUTORY APPROVALS:

Income Tax Registration: PAN No: AAACJ 5070 A

TIN No.: 28580199316

ECC No.: AAACJ 5070 AXM 002

CIN No.: U25209 AP 1992 PTC 014875

NATURE AND SCOPE OF THE TRAINING

SCOPE OF THE TRAINING

The training gives a knowledge and capacity to the trainee in respective field.

Trainee has been easily placed in the job with one of the job trainings.

The persons are to be motivated and refreshed by training.

LIMITATIONS OF THE TRAINING

Companies are maintaining the secrecy in their financial performance, so trainees are

unable to study the financial matters.

The training period is very short, then not able to have elaborate study.

DESCRIPTION OF BUSINESS

The company is staffed by more than employees. A dynamic team of professionals

trained in merchandising play a pivotal role in co-ordination between clients and factories.

The fabric department is dedicated to source and supply fabrics and fabric designs required to

reproduce international fashion trends. An efficient trim department helps in creating the

right style for the garment by sourcing and developing accessories by tapping both domestic

and international vendors. A strong team of professionals manages global logistics in order to

meet every clients requirement seamlessly.

ORGANIZATIONAL STUCTURE

MANAGING DIRECTOR

DIRECTOR

DIRECTOR

DIRECTOR

FACORY MANAGER

SUPERVISOR Accountant

Store keeper

Quality control

Shift incharge (loom)

Shift incharge (Tabe line)

Workers

Workers

DETAILS OF MANUFACTURING PROCESS

The Polypropylene Tape Making Process:

The polypropylene tapes are manufactured by slitting films of PP or HDPE which are

produced by blown extrusion technique. In this process, the granules of plastic are fed to the

extruder through the hopper. Molten plastics are extruded through circular die and the tube is

inflated by blowing with air to a desired diameter, and pulling it away with a pair of nip rolls.

The extruded PP film is then coded and the bubble is collapsed. The film thus formed is then

slit to desired width. These tapes are stretched in orientation water bath which is at its boiling

point. Alternatively orientation can be carried out by using hot plate. The HDPE/PP tape,

after orientation, is stabilized and then wound on bobbins. The Principle stages involved in

tape manufacture are:

Extrusion of Film

Quenching of Film

Slitting of Film into Tapes

Orientation of Tapes

Annealing of Tapes

Winding

The Polypropylene Fabric Weaving Process

From bobbins carrying polypropylene yarn, fabric is made using warping and yarn

winding machine. The fabric is then woven on looms and finally cut to size and stitched to

sacks of required dimensions. Whenever required, the sacks are screen-printed using

specially prepared ink. In some cases, laminated sacks are required and as such before

stitching and printing the fabric has to be laminated by extrusion coating of LDPE.

Lamination should be done from outside. Weaving is done either by using Flat Looms or

Circular Looms, the latter offers the following advantages:

Higher output of fabric

Better retention of mechanical properties

Sack output is higher due to only one side stitching

Savings of 20-25% due to superior quality of tapes

Floor space savings is higher due to less number of operations the woven

fabric is later coated with polymer by the Extrusion coating process.

Cutting:

The woven fabric is feed to the cutting machine which prints and cuts as per set

specifications.

Stitching:

The woven fabric after printing and cutting operation is stitched manually.

Baling:

In order to minimize the storage space occupied by finished sacks, five hundred sacks

are packed to form a bale and pressed in hydraulic baling press and strapped. The sacks are

marked with information as required by the buyer and each bale containing PP Sacks are

marked with standard mark.

Technology/Process Options

The technology is relatively uniform amongst suppliers of machinery. The granules

are fed into the extruder with the color granules and extruded into tape yarn which is then

woven into the fabric with circular looms which produces the fabric in the form of a tube.

TECHNICAL PARAMETERS

Weight

As per Required size

Width

30" to 155"

Denier

350 to 1200

Size

12 TO 90

GSM

40 GSM TO 120 GSM

Length

As per Requirement

Colors

Any Color

Imprint

All

Packing

As per Party Requirement

Bag opening

As per Party Requirement

PE lining

Yes

Laminated/Coated

Yes

Perforated

Yes

Mesh

8 x 8 TO 12 x 12

UV Stabilization

As per customer requirement The Company endeavors to serve the industry with

optimum quality latest products available in the market at the most competitive prices. It is

the quality of the products and the attitude of our company towards its customers that has

helped it in scaling great heights.

Customization of PP Woven Sacks:

Is done on following parameters:

Weave

Material

Draw string or zipper

PE lining

Lamination (Option for un-laminated also available)

Length

Capacity

Weight

Gauge

Seal

Gusset

Handle

Bottom

Customization of woven fabrics:

On the following parameters:

Single or double fold

Laminated / un-laminated

Weave & mesh

Print

Colors

Length

Weight

Gauge

CLIENT SATISFACTION

Hey are a company that strives to match the expectations of our clients in all possible

ways that help us in the betterment of our concern. Consequently, we provide them with

quality PP sacks. These products are prepared using the high-grade material to assure that our

clients receive only the best and excellent range of products. Owing to the transparency in our

business proceedings, we have been able to garner maximum client satisfaction and cater to

the needs of retailers, local authorities, wholesalers, and big & small industries. With this, we

also make a point to supply our products in the set time frame and provide them with hassle-

free transactions addition to this, we attain maximum client satisfaction by offering our

clients our range of products as per the specifications and also offer facility of customized

packaging to them.

Shrihari woven sacks private ltd. - Major clients are

Tirupur Bags - Tirupur.

Bagayalakshmi Bags tirupur.

Sri Narayana industry saravanampatti,Coimbatore.

Srihari polyners chennipalayam,coimbotore.

Agni Backages palladam.

Steps in manufacturing process:

HDPE/PP GRANULES

Tape lines

Winders

Circular Looms

Fabrics Cutting machine

Stitching Machine

Bale packing

Yarn warned on cheese pipes

Tape (flat Yarn)

Woven Fabric

STEPS OR PROCESSES THAT TAKES PLACE IN THE FACTORY

STEP 1: Vendor Quotation:

Procuring the Vendor Quotation and asking for Preforms invoice. If satisfied issue a

Purchase orders. According to it the raw materials are procured and ordered.

STEP 2: Purchase Order Purchase Order Types:

Purchasing provides the following purchase order types: Standard Purchase Order,

Planned Purchase Order, Blanket Purchase Agreement, and Contract Purchase Agreement.

You can use the Document Name field in the Document Types window to change the names

of these documents. For example, if you enter Regular Purchase Order in the Document

Name field for the Standard Purchase Order type, your choices in the Type field in the

Purchase Orders window will be Regular Purchase Order, Planned Purchase Order, Blanket

Purchase Agreement, and Contract Purchase Agreement.

Standard Purchase Orders:

You generally create standard purchase orders for one-time purchase of various items.

You create standard purchase orders when you know the details of the goods or services you

require, estimated costs, quantities, delivery schedules, and accounting distributions. If you

use encumbrance accounting, the purchase order may be encumbered since the required

information is known.

Contract Purchase Agreements:

You create contract purchase agreements with your suppliers to agree on specific

terms and conditions without indicating the goods and services that you will be purchasing.

You can later issue standard purchase orders referencing your contracts, and you can

encumber these purchase orders if you use encumbrance accounting.

Planned Purchase Orders:

A planned purchase order is a long-term agreement committing to buy items or

services from a single source. You must specify tentative delivery schedules and all details

Finished goods

for goods or services that you want to buy, including charge account, quantities, and

estimated cost.

STEP 3:

Issuing of a Purchase Invoice It will have all the specific details like Quantity,

Description, Time, etc.

STEP 4:

Dispatching the Material the materials are then dispatched to the respective Plants and

Machines. Gate entry of transaction is made and the Bill is stamped. Match the Purchase

order and the Invoice.

STEP 5:

Quality Check department all the materials are sent to the Quality Check Department

to check for any short falls. Whether to accept or reject. If its accepted the process is

continued, if its rejected the materials are sent back.

STEP 6:

Stores Department after accepting to quality check it goes to stores, stores ledger

makes an entry. Material receipt note is raised. Finance people enter the invoice in respective

ledger.

STEP 7:

Production Department a note is issued (Issue note) to the respective department and then

material goes to production Department. Then production begins immediately. After the

materials are received the Manufacturing Process begins.

MACHINERY INFORMATION

Some of the machines that are installed at our unit are as follows:

Extruders

Circular weaving machine

Lamination plant (Tandem and Turn bar) Up to 2600 mm of tubular fabrics

Bale press machine

Automatic cutting & stitching machine

Gusseting machine

EXTRUDERS:

CIRCULAR WEAVING MACHINE:

LAMINATION PLANT:

BALE PRESS MACHINE:

AUTOMATIC CUTTING & STITCHING MACHINE:

GUSSETING MACHINE:

FUNCTIONAL AREAS

DEPARTMENT STRUCTURE

PERSONNEL DEPARTMENT

CORPORATE DAILY POLICY

Shrihari woven sacks Pvt. Ltd.'s Management firmly believes that safety of its

employees and all the stakeholders associated with their project sites and manufacturing

facilities is of utmost importance. Safety is an essential and integral part of all their work

activities which includes planning, design, procurement, fabrication, construction, installation

and commissioning of facilities, products, manufacturing processes and services. They

believe that incidents or accidents and risk to health are preventable through the active

involvement of all the stakeholders, thereby creating a safe and accident free work place.

With regard to safety objectives, the company will:-

Comply with the requirements of all relevant statutory, regulatory and other

provisions.

Create and promote safety awareness to protect all stake holders from fore

seeable work hazards and risks through campaigns and training programs

among employees, business associates and clients.

Provide appropriate level of training and supports to management and

employees to ensure that they are able to fulfill safety responsibilities

Work with major suppliers, business associates and customers to facilitate

their safety performance improvement and also make it obligatory for them to

follow the project site safety rules, procedures, systems and safe practices.

Ensure that appropriate resources are available to fully implement the Safety

Policy and continuously review the policy's relevance with respect to legal and

business development.

ENVIRONMENT CONCERN

With a conscious mind, they undertake Eco-friendly manufacturing processes and

make sure that less effluent and smoke are released. They take the following three concerns

seriously that are defined by some of the well-known regulatory bodies.

Reduction in hazardous environmental release

Recycling of waste products

USE OF ENVIRONMENTALLY PREFERABLE PRODUCTS

For this, they source some of the latest and high performing machines for their unit.

Moreover, the material for fabrication is quality tested and is bio-degradable, which ensures

no hazards to the environment. The range of PP products manufactured by them are

recyclable and do not emit obnoxious fumes, when burned.

What helps them to give an Edge over the competition?

Their experience of 18 years has enabled them to register their capabilities among

their competitors owing to the following factors:

Ethical business practices

Quality range of PP products

Sound manufacturing facilities

Custom designing

Excellent customer service

Wide marketing and distribution network

Timely delivery

Complete client satisfaction

PURCHASE MANAGEMENT

Raw material procurement plan has a very important role to make the production plan

successful. For any procurement, the selection a right supplier, procurement, at right time of right

quantity right price most important. It will control the inventory level of the organization. srihari

woven sacks handle all these areas effectively using following tools:

Material requirement planning

Purchase indent

Tending procedure

Purchase order

Subcontracting purchase order

MATERIAL REQUIREMENT

The raw materials required are: 1.The polypropylene granules that are made into the

tape yarn and then woven into the sacks. The main factors guiding the source of raw material

are:

Quality

Availability

Cost Quality plays a vital role in deciding the choice of raw material supplier. The

cost of the raw material is almost same but it is still a major guiding force behind choice

of the raw material. Availability forms a major guiding force behind the buying decision as

cost and quality being almost same.

shrihari woven sacks private ltd. Major Supplies of Raw Materials are from

the

guratguth

QUALITY MANAGEMENT:

Stringent quality control with proper documentation is the most essential part of woven sacks

industry. Raw material as well as semi-finished/finished items at different stage of production will go

through following quality checking Incoming raw material quality control. Quality report of Tape,

Fabric stage of production .Finished product (Bags) Quality reporting

RESEARCH & DEVELOPMENT

At shrihari woven sacks Pvt. Ltd., they continuously strive to meet the challenging

requirements of the customers. Thus they keep a special focus on Research & Development

to equip the customers with latest products at the most competitive prices. The following has

helped in developing new products & colour master batches for the customers in the shortest

time at the most competitive prices.

To properly understand the needs of the customer.

Close interaction with the suppliers to know what is new in the market.

Maintaining a database of all trials at their end & customers end.

Colour swatches of all master batches in form of granules, film & molded

chips.

Electronic database of standard pigments & end product.

Latest equipments such as Injection molding machines, two roll mills,

hydraulic press, spectrophotometer, imported MFI machines, imported filter

pressure machines and many more.

Small capacity production machines especially dedicated for R&D work.

QUALITY ASSURANCE

Shrihari woven company "Quality" is not an act but it is a habit. Quality Assurance is

in hands of most expert & experienced people in which top management itself is included.

They strictly follow "Quality Assurance System" at different level of Manufacturing

Process...

Raw material Testing--Certified by major manufactures like Reliance, IPCL,

Haldia, GAIL, IOC, etc.

Tape Yarn--Width of yarn--Denier of yarn--Strength and elongation

Fabric--Size of Fabric, Mesh, Strength and elongation, Weight of Fabric in

GSM

Cutting--Weaving Defects, Size of Cutting

Stitching--Seam Strength/Strength of Bag, Weight of Bag, Mass of Sack,

Cleaning and printing matter

Packaging--Counting and Proper Bailing The Groups well-trained and experienced

staff and associates ensures that all the products are made from the finest material and adopts

stringent quality control measures throughout the production process. Quality control is

applied at each and every stage of manufacture and storage, leading to the delivery of top

quality material. An important part of our quality control is minimal wastage of the raw

material. Due to minimum wastage of less than 5% (from tape to bag) gives an opportunity to

keep the price under control.Jakhotia Group has a complete in-house manufacturing & testing

facility that enables it to produce totally flawless and tough products.

PRODUCTION MANAGEMENT

From sales order and sales forecast, production for the period is planed normally on a

thump rule basis where the material requirement is not exactly available as a result the

planned production is seldom srihari woven sacks provides effective solution to optimize

the production plan through:

Bill of material (BoM) of tape fabric and bags

Material requirement planning (MRP) consider availability of granules, colour master

batch, filler master batch, tape fabric and finished bags.

MRP will also consider bending purchase orders availability production order in the

system

MRP will suggest the production order for tape, fabric , bags and purchase order for

granules, master batchs etc.,

Based on MRP recommendation production order may be creator, it may be creator

manually also

The production order will be realized based on availability of resources like extrusion

machine, looms lamination, machine etc. and manpower

Sub-contracting of WIP at any stage of production

Purchase order may be generated from MRP recommendation or can be created

through manual indent

MANUFACTURING PROCESS

PP Woven Sacks are generally manufactured and printed as per the Customers

demands/needs. The end users adopt different kinds of Color Combinations and Designs in

the Printing of these Sacks to convey the massage(s), characteristic(s), quantity & quality

related details and handling instructions etc. For some kind of specific applications like filling

of Hydroscopic Materials e.g. Chemicals, Fertilizers, Food Products etc. these Woven Sacks

are laminated also. The Process of manufacturing PP Woven Sacks involves following three

steps:

Extrusion

Weaving

Finishing & Stitching

Extrusion:

The process of manufacturing PP woven bags involves mixing raw materials starting

with PP or HDPE pellets and other additives, extruding the raw materials into a yarn PP resin

is heated with feeler of CaCo3 and pigment, melted and extruded as a flat film. It is then slit

into tape yarn by the slitting unit and stretched and annealed. Next, a take-up winder winds

the heat oriented tape yarn onto a bobbin. The Raw Material (PP & Filler) in the Granules

form is fed to a Raffia Tape Manufacturing Plant

To obtain the Raffia Tapes of PP. The Raw Material Mix is prepared in a Tray

adjacent to the Feed Hopper. The prepared Mix is sucked in to the Hopper by Vacuum. The

Raw Material Mix is fetched to the Extruder of the Plant; where the same is melt by applying

controlled External Heat on the Barrel. The Molten Mass is forced out through a Die Head

into a Cooling Tank, in the form of Sheet/Film. The cooled & solidified Sheet/Film is passed

through the Knifes to obtain Raffia Tapes of higher Denier (a Unit by which the fineness of a

Yarn is measured). High Density Polyethylene (HDPE) or Polypropylene (PP) granules are

first converted in to 2.5 mm wide tapes by Extrusion process. The Raffia Tapes received from

the Plant are stretched and annealed. These are then wound on Cheese Pipes with the help of

the Sets of Winders.

Weaving:

Weaving the yarn into a fabric in a process similar to the weaving of textiles. These

flat tapes are then woven into circular fabric by Circular weaving machine. Thus woven

circular fabric is then cut in to required dimension. Thread from the bobbin in the circular

looms creel stand is woven into tubular cloth The Weaving of Raffia Tapes into Cloths is

carried out in Circular Looms, which produce Circular Cloth of desired Width. The process

of Weaving is Automatic and Continuous in nature. Numbers of Circular Looms are installed

so as to match the Effective Output of the Raffia Tape manufacturing Plant. The Cloth

produced by each Loom is continuously wound on Rotating Pipes.

Finishing & Stitching:

The Rolls of Woven Cloth are carried out to the Finishing & Stitching Section of the

Unit. The Cloth is cut into desired size and the printed. After printing the cut pieces are sent

for stitching. Prior to the stitching of the Cloth, a valve is made in one corner of the cut piece,

as per the Customers specification. The Woven Sacks passed through the Quality Control

Test are bundled in 500 or 1000 Nos. and pressed on a Bailing Press. The pressed Woven

Sacks are wrapped, bundled, packed and dispatched. The Quality Control checks are carried

out at each and every step to avoid rejections. The parameters pertaining to the Weight,

Denier, Bursting Strength etc. are strictly adhered to.

FINANCE DEPARTMENT

FINANCIAL STATEMENTS ANALYSIS (What Are Financial

Statements)

Financial statements are documents showing the financial position of a company. The

four main statements are the balance sheet, income statement, cash flow statement, and

statement of retained earnings (or shareholders' equity).

What is Financial Statement Analysis?

Financial statement analysis takes specific line items from a financial statement and

turns them into easy-to-understand data or information.

Why Financial Analysis Is Needed?

Numbers on financial statements can be confusing. Analysis of the numbers gives you

or outside investors a better perspective of how your company is managing money and

operations.

How Are Financial Statements Developed?

Financial statements are a key part of business finances and are used for many

different reasons, primarily as a form of analysis within the company. Outside of the

company, lenders and investors alike study financial statements in order to make key

investment decisions, so preparing financial statements is important even for small business

owners and entrepreneurs. Fortunately, the major financial statements are very common and

there are well-established ways to develop them for most businesses.

Interpreting Financial Statement Analysis

Financial statement ratios must be considered in the context of industry standards.

Ratios should be compared to benchmarks of similar businesses to determine a company's

overall financial health.

Need for Financial Statement Analysis

Companies conduct financial statement analysis to understand their financial health

during the statement period. By using these statements wisely, an individual can gauge the

companys present financial scenario, as well as make projections for the immediate future.

The company also makes extensive use of financial ratios and graphs. With this, one

understands the relation between the company's assets and its productivity. Financial

statement analysis is extremely beneficial for the company's management, its shareholders, its

creditors and the government.

Parties Interested In Financial Statement Analysis

The analysis of financial figures contained in the company's profit and loss account

and balance sheet by employing appropriate technique is known a financial statement

analysis. Financial statement analysis is useful to different parties to obtain the required

information about the organization. Following are the parties interested in financial statement

analysis.

1. Shareholders:

Shareholders are interested in financial statement analysis to know the profitability of

the organization. Profitability shows the growth potentiality of an organization and safety

of investment of shareholders.

2. Investors and Lenders:

Investors and lenders are interested to know the solvency position of an organization.

They analyze the financial statement position to know about the safety of their investment

and ability to pay interest and repayment of principle amount on due date.

3. Creditors:

Creditors are interested in analyzing the financial statements in order to know the

short term liquidity position of an organization. Creditors analyze the financial statement to

know whether the organization is able to pay the amount of short term liabilities on due date

or not.

4. Management:

Management is interested to analyze the financial statement for measuring the

effectiveness of its policies and decisions. It analyze the financial statements to know short

term and long term solvency position, profitability, liquidity position and return on

investment from the business.

5. Government:

Government is interested to analyze the financial position in determining the amount

of tax liability. It also helps for formulating effective plans and policies for economic growth.

Objectives of Financial Statement Analysis:

The major objectives of financial statement analysis are as follows

1. Assessment of Past Performance:

Past performance is a good indicator of future performance. Investors or creditors are

interested in the trend of past sales, cost of goods sold, operating expenses, net income, cash

flows and return on investment. These trends offer a means for judging management's past

performance and are possible indicators of future performance.

2. Assessment of current position:

Financial statement analysis shows the current position of the firm in terms of the

types of assets owned by a business firm and the different liabilities due against the

enterprise.

3. Prediction of profitability and growth prospects:

Financial statement analysis helps in assessing and predicting the earning prospects

and growth rates in earning which are used by investors while comparing investment

alternatives and other users in judging earning potential of business enterprise

4. Prediction of bankruptcy and failure:

Financial statement analysis is an important tool in assessing and predicting

bankruptcy and probability of business failure.

5. Assessment of the operational efficiency:

Financial statement analysis helps to assess the operational efficiency of the

management of a company. The actual performance of the firm which is revealed in the

financial statements can be compared with some standards set earlier and the deviation of any

between standards and actual performance can be used as the indicator of efficiency of the

management.

Methods or Techniques Of Financial Statement Analysis

Financial statement analysis can be performed by employing a number of methods or

techniques. The following are the important methods or techniques of financial statement

analysis.

1. Ratio Analysis:

Ratio analysis is the analysis of the interrelationship between two financial figures.

2. Cash Flow Analysis:

Cash flow analysis is the analysis of the change in the cash position during a period.

3. Comparative Financial Statements:

Comparative financial statement is a analysis of financial statements of the company

for two years or of the two companies of similar types.

4. Common-size Financial Statements:

Common-size financial statement is a analysis of financial statements of the

company, where there is a base element taken from the financial statement and every other

elements are taken as a percentage of that base element.

5. Trend Analysis:

Trend analysis is the analysis of the trend of the financial ratios of the company over

the years. The methods to be selected for the analysis depend upon the circumstances and the

users' need. The user or the analyst should use appropriate methods to derive required

information to fulfill their needs.

Limitations of Financial Statement Analysis

Although analysis of financial statement is essential to obtain relevant information for

making several decisions and formulating corporate plans and policies, it should be carefully

performed as it suffers from a number of the following limitations.

1. Mislead the user:

The accuracy of financial information largely depends on how accurately financial statements

are prepared. If their preparation is wrong, the information obtained from their analysis will

also be wrong which may mislead the user in making decisions.

2. Not useful for planning:

Since financial statements are prepared by using historical financial data, therefore,

the information derived from such statements may not be effective in corporate planning, if

the previous situation does not prevail.

3. Qualitative aspects:

Then financial statement analysis provides only quantitative information about the

companys financial affairs. However, it fails to provide qualitative information such as

management-labor ration, customers satisfaction, and management skills and so on which

are also equally important for decision making.

4. Comparison not possible:

The financial statements are based on historical data. Therefore comparative analysis

of financial statements of different years cannot be done as inflation distorts the view

presented by the statements of different years.

5. Wrong judgment:

The skills used in the analysis without adequate knowledge of the subject matter may

lead to negative direction. Similarly, biased attitude of the analyst may also lead to wrong

judgment and conclusion. The limitations mentioned above about financial statement analysis

make it clear that the analysis is a means to an end and not an end to itself. The users and

analysts must understand the limitations before analyzing the financial statements of the

company.

MARKETING MANAGEMENT

The critical problem faced by marketing is to predict the delivery date to customer

due to non-availability of correct stock states or resources loading. The production executive

is also not aware of exact order booking position or sales target to plan the production due to

the lack of integration between the sales and production plan.

At any point of the time srihari woven sacks provides were house wise/ material wise

inventory balance quantity available to promise, production plan, production at shop floor

witch is relevant to marketing people. srihari woven sacks also provides the order status aft

any point of time. srihari woven sacks also provides the tools that allow manufacture to

capture product service, business knowledge increasing overall productivity. Is increases

sales effectiveness and profitability making it easier and less costly.

CONCLUSION

Internship as a Learning Process

Working in an organization does not limit ones experience to just one department that

one is assigned with, but actually the organization is running with a systematic collaboration

of the departments and hence requires communications and Interaction. Well thats the point

that one should not ignore, and always keep ones Mind and heart open for the experience. If

one is in a situation and have interactions, ones studies are being implemented in practical

environment there .Youre not by passing your boss, because you Understand that

organizational hierarchy is defined and proper communication channels are available which

should be used. OR. You won show resistance to Change cause you studied that change is

the only constant and hence necessary for organizational development and employees

survival. Experience & learning: Having an experience of a good organization has one huge

advantage, it makes you more professional and professionalism is the key to success.

Internships have main emphasis on factors like:

Communication skills

Professionalism

Presentation abilities and Confidence

Handling the stressful situations Working with the Company added a great value to my skills

knowledge and abilities and hence gave me a chance to relate my studies in the practical

working environments , my communication skills improved and the I feel more confident

then I was and this experience helped me broaden my vision and more practical.

S-ar putea să vă placă și

- What Would Billionaires Do Quickstart GuideDocument36 paginiWhat Would Billionaires Do Quickstart GuideRich Diaz100% (24)

- Bloomberg ReferenceDocument112 paginiBloomberg Referencephitoeng100% (1)

- Project Report On Pu Foam MattressDocument5 paginiProject Report On Pu Foam MattressEIRI Board of Consultants and PublishersÎncă nu există evaluări

- Internship ReportDocument46 paginiInternship ReportDisha Ganatra100% (7)

- Nike Cost of CapitalDocument23 paginiNike Cost of CapitalSaahil Ledwani100% (1)

- Accounting For InventoriesDocument15 paginiAccounting For Inventoriesrichardchan001Încă nu există evaluări

- Hdpe PP Woven Sacks Using Circular LoomsDocument2 paginiHdpe PP Woven Sacks Using Circular LoomsRishi Patel100% (2)

- MSME Disposable SyringesDocument24 paginiMSME Disposable SyringesNaveenbabu SoundararajanÎncă nu există evaluări

- Plastic Jerry CanDocument26 paginiPlastic Jerry CanSivaratnam NavatharanÎncă nu există evaluări

- Raffia Tape Line ProcessDocument20 paginiRaffia Tape Line ProcessSumeet Rathor100% (12)

- Socks Manufacturing (Brief Project Report)Document2 paginiSocks Manufacturing (Brief Project Report)arunlal100% (2)

- Draft 1Document47 paginiDraft 1Viral BhogaitaÎncă nu există evaluări

- Configuring FICO Lawrence RebelloDocument148 paginiConfiguring FICO Lawrence Rebellobaburam100% (8)

- Ad Star Handbook 10 2015 PDFDocument40 paginiAd Star Handbook 10 2015 PDFmatt60% (5)

- Non Woven Bags - FinalDocument28 paginiNon Woven Bags - FinalOlivia Jackson75% (12)

- Woven Sacks For Fertilizers: Profile No.: 49 NIC Code: 22209Document8 paginiWoven Sacks For Fertilizers: Profile No.: 49 NIC Code: 22209Aparesh GantaitÎncă nu există evaluări

- Lgu-Baler Ordinance No 009-2012Document16 paginiLgu-Baler Ordinance No 009-2012PatbauÎncă nu există evaluări

- Project On The Production of Woven PP BagsDocument29 paginiProject On The Production of Woven PP BagsZeyinu Ahmed Moh100% (2)

- PP Woven Bag Making Plant Zemera TradingDocument14 paginiPP Woven Bag Making Plant Zemera TradingEndayenewMollaÎncă nu există evaluări

- The Nature of Small BusinessDocument33 paginiThe Nature of Small BusinessRae MorganÎncă nu există evaluări

- Project Profile - Mat Products ManufactuingDocument6 paginiProject Profile - Mat Products Manufactuingmadhusudhans100% (1)

- Disposal of SubsidiaryDocument9 paginiDisposal of SubsidiaryCourage KanyonganiseÎncă nu există evaluări

- P.P. Sack Thesis - EeDocument55 paginiP.P. Sack Thesis - EeAl AminÎncă nu există evaluări

- Thakur PP Woven Sacks Bags PVT - LTDDocument6 paginiThakur PP Woven Sacks Bags PVT - LTDVinod Singh ThakurÎncă nu există evaluări

- Skill Training For Raffia Sector TTRC LOHIA CORP April 2016Document29 paginiSkill Training For Raffia Sector TTRC LOHIA CORP April 2016rkd274350% (2)

- Plastic Woven SacksDocument42 paginiPlastic Woven Sacksaldiabl50% (4)

- Project Report On Hdpe/pp Woven BagsDocument6 paginiProject Report On Hdpe/pp Woven BagsEIRI Board of Consultants and Publishers0% (1)

- Neha Anand Final Report (SIP)Document35 paginiNeha Anand Final Report (SIP)Saurabh KhareÎncă nu există evaluări

- Reward Management Closing Growing SayDo GapDocument28 paginiReward Management Closing Growing SayDo GapSophia Babkov100% (1)

- Circular WeavingDocument28 paginiCircular Weavinggovardhan6rao50% (2)

- Summer Training Report by Rahul CipetDocument111 paginiSummer Training Report by Rahul Cipetshivi100% (2)

- Manufacturing Process of PP Woven BagsDocument17 paginiManufacturing Process of PP Woven Bagsollata kalano50% (2)

- Profile On The Production of Woven PP Bags MulugetaDocument29 paginiProfile On The Production of Woven PP Bags MulugetaEndayenewMolla50% (2)

- Summer Training New 1Document43 paginiSummer Training New 1ROHIT KUMAR100% (2)

- Project Profile-HDPE Bottles & ContainersDocument7 paginiProject Profile-HDPE Bottles & ContainersHetal Patel0% (2)

- Polypropylene Woven Bags Manufacturing UnitDocument23 paginiPolypropylene Woven Bags Manufacturing UnitIjaz AhmadÎncă nu există evaluări

- Woven Bags-Project ProfileDocument6 paginiWoven Bags-Project ProfileBalas43100% (2)

- HDPEPPWoven Sacks 2010 SKADocument18 paginiHDPEPPWoven Sacks 2010 SKAAanand SharmaÎncă nu există evaluări

- Summer Training ReportDocument41 paginiSummer Training ReportKeith Shaw67% (3)

- Loaia Star Linger MachineryDocument30 paginiLoaia Star Linger MachinerySaif MastoiÎncă nu există evaluări

- Nonwoven Bags Project Report DubaiDocument54 paginiNonwoven Bags Project Report Dubaisugaimpax80% (10)

- PP BAGS Factory ListsDocument1 paginăPP BAGS Factory ListsFasil 1 BekeleÎncă nu există evaluări

- Plastic RopesDocument6 paginiPlastic RopesSamy VishnuÎncă nu există evaluări

- Internship Project ReportDocument3 paginiInternship Project Reportazizah kamaruddin lowÎncă nu există evaluări

- Lohia Corps Limited ReportDocument23 paginiLohia Corps Limited ReportAnkit Patel100% (1)

- TapelineDocument4 paginiTapelineusmankhawaja100% (1)

- Summer Training Repot by Shubham MishraDocument114 paginiSummer Training Repot by Shubham MishraAnkit Singh100% (1)

- Profile On The Production of Woven PP Bags614Document30 paginiProfile On The Production of Woven PP Bags614Hailu MiÎncă nu există evaluări

- Project Profile On Tyre RetreadingDocument5 paginiProject Profile On Tyre RetreadingBinu Balakrishnan100% (2)

- MSME Project ReportDocument8 paginiMSME Project Reportchaudhary1604Încă nu există evaluări

- Leno 4: Circular LoomDocument4 paginiLeno 4: Circular Loomss_abbu0% (1)

- Proj Profile For Cement With TL600KGDocument6 paginiProj Profile For Cement With TL600KGVISHALAG10Încă nu există evaluări

- Grain Bag Manufacturing Feasibility StudyDocument53 paginiGrain Bag Manufacturing Feasibility StudyCalvawell MuzvondiwaÎncă nu există evaluări

- Non Woven BegDocument23 paginiNon Woven BegTeja SreeÎncă nu există evaluări

- P.P. Sack Thesis - EeDocument58 paginiP.P. Sack Thesis - EeNoor Ibne SalehinÎncă nu există evaluări

- Woven SacksDocument27 paginiWoven Sacksbig johnÎncă nu există evaluări

- Sergical Absorbent CottonDocument11 paginiSergical Absorbent Cottonzeine100% (1)

- Coc Project FinalDocument46 paginiCoc Project FinalMYTHRIYA DEVANANDHANÎncă nu există evaluări

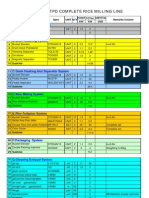

- 200tpd Rice MillDocument5 pagini200tpd Rice MillAzim KowshikÎncă nu există evaluări

- Organization Study (12354Document39 paginiOrganization Study (12354Gobs Mix100% (1)

- Polypropylene Woven Bags ManufacturingDocument2 paginiPolypropylene Woven Bags ManufacturingFITIWIÎncă nu există evaluări

- My Food Roller Flour Factory PVT - LTDDocument54 paginiMy Food Roller Flour Factory PVT - LTDSandeep Nair67% (3)

- Jaicorp Summer Training REPORT ELECTRICAL ENGINEERINGDocument62 paginiJaicorp Summer Training REPORT ELECTRICAL ENGINEERINGSourabh KhandelwalÎncă nu există evaluări

- Weekly Report No. 1 & 2 N FULLDocument68 paginiWeekly Report No. 1 & 2 N FULLnikhil baidÎncă nu există evaluări

- Project Report of Industrial TrainingDocument59 paginiProject Report of Industrial TrainingTushant Garg67% (3)

- KPL 2nd Yr Internship PDFDocument41 paginiKPL 2nd Yr Internship PDFPriyansh ChoudharyÎncă nu există evaluări

- THE Winter Project ON Organisatonal Studies AT Saber Flexipack PVT LTDDocument45 paginiTHE Winter Project ON Organisatonal Studies AT Saber Flexipack PVT LTDHardik JaniÎncă nu există evaluări

- Packraft Corrugate India Pvt. LTD Internship ReportDocument21 paginiPackraft Corrugate India Pvt. LTD Internship ReportSushant ChauhanÎncă nu există evaluări

- S.No Particulars Page No. Chapter-I: 1 1.1 Introduction of The Study 1.2 Industry Profile 1.3 Company ProfileDocument36 paginiS.No Particulars Page No. Chapter-I: 1 1.1 Introduction of The Study 1.2 Industry Profile 1.3 Company ProfileR.SenthilÎncă nu există evaluări

- Trading Account PDFDocument9 paginiTrading Account PDFVijayaraj Jeyabalan100% (1)

- Accountancy Paper Class XiDocument13 paginiAccountancy Paper Class Xinishtha chachanÎncă nu există evaluări

- SBO Solution BriefDocument4 paginiSBO Solution BriefroyshahanaÎncă nu există evaluări

- Fin3n Cap Budgeting Quiz 1Document1 paginăFin3n Cap Budgeting Quiz 1Kirsten Marie EximÎncă nu există evaluări

- Team Based Compensation: Made By: Prashansa Madan Pragya SabharwalDocument18 paginiTeam Based Compensation: Made By: Prashansa Madan Pragya SabharwalVijay AnandÎncă nu există evaluări

- Case Study 101Document29 paginiCase Study 101Michael100% (1)

- (Group 9) Can Sears Reinvent ItselfDocument5 pagini(Group 9) Can Sears Reinvent ItselfAmbika Sharma0% (1)

- Krugman Summary International Chapter ThreeDocument87 paginiKrugman Summary International Chapter ThreeGennifer InghamÎncă nu există evaluări

- The Economy of Andhra Pradesh PDFDocument326 paginiThe Economy of Andhra Pradesh PDFurike rajÎncă nu există evaluări

- Promise To Purchase (PP)Document7 paginiPromise To Purchase (PP)catsdeadnowÎncă nu există evaluări

- Business Plan Format For Msmes (Manufacturing Industries)Document10 paginiBusiness Plan Format For Msmes (Manufacturing Industries)Shaikh WasimaÎncă nu există evaluări

- Chapter 11 - Computation of Taxable Income and TaxDocument22 paginiChapter 11 - Computation of Taxable Income and TaxMichelle Tan100% (1)

- Accounting 1 ValeDocument13 paginiAccounting 1 ValeAhmadnur JulÎncă nu există evaluări

- Intermediate Accounting 3 Second Grading Quiz: Name: Date: Professor: Section: ScoreDocument2 paginiIntermediate Accounting 3 Second Grading Quiz: Name: Date: Professor: Section: ScoreGrezel NiceÎncă nu există evaluări

- Republican Party of Arkansas State by LawsDocument54 paginiRepublican Party of Arkansas State by LawsAlex MartinezÎncă nu există evaluări

- Quiz - iCPADocument15 paginiQuiz - iCPAJericho PedragosaÎncă nu există evaluări

- Financial Statement AnalysisDocument98 paginiFinancial Statement AnalysisDrRitesh PatelÎncă nu există evaluări

- SFP ProblemDocument2 paginiSFP ProblemTerryjay Catama69% (13)

- Chap 013Document60 paginiChap 013zeidÎncă nu există evaluări

- Financial Position of The STCDocument13 paginiFinancial Position of The STCSalwa AlbalawiÎncă nu există evaluări

- Full PVC FootwearDocument5 paginiFull PVC Footwearpradip_kumarÎncă nu există evaluări