Documente Academic

Documente Profesional

Documente Cultură

U11 CDU Process Variables

Încărcat de

Linh Giang0 evaluări0% au considerat acest document util (0 voturi)

245 vizualizări4 paginiVIETNAM OIL AND GAS CORPORATION (PETROVIETNAM) November 2008 DUNG QUAT REFINERY Rev. : 1 OPERATING MANUAL Chapter : 3 UNIT CDU (011) Page : 30 / 38 Actions: Action Tag No. P&ID No. Service P-1121A / B Tempered water pumps protection (011-UX-024) Purpose: When there is a low low level in the Tempered Water Drum

Descriere originală:

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentVIETNAM OIL AND GAS CORPORATION (PETROVIETNAM) November 2008 DUNG QUAT REFINERY Rev. : 1 OPERATING MANUAL Chapter : 3 UNIT CDU (011) Page : 30 / 38 Actions: Action Tag No. P&ID No. Service P-1121A / B Tempered water pumps protection (011-UX-024) Purpose: When there is a low low level in the Tempered Water Drum

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

245 vizualizări4 paginiU11 CDU Process Variables

Încărcat de

Linh GiangVIETNAM OIL AND GAS CORPORATION (PETROVIETNAM) November 2008 DUNG QUAT REFINERY Rev. : 1 OPERATING MANUAL Chapter : 3 UNIT CDU (011) Page : 30 / 38 Actions: Action Tag No. P&ID No. Service P-1121A / B Tempered water pumps protection (011-UX-024) Purpose: When there is a low low level in the Tempered Water Drum

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 4

VIETNAM OIL AND GAS CORPORATION (PETROVIETNAM) November 2008

DUNG QUAT REFINERY Rev. : 1

OPERATING MANUAL Chapter : 3

UNIT CDU (011) Page : 30/38

Actions:

Action Tag

No.

P&ID No. Service

P-1121A 124 Water pump stopped

P-1121B 124 Water pump stopped

011-FIC-025 124 Condensate flow controller set to manual and

output 0%

This trip is manually reset by 011-UHSR-016

3.1.2.32. P-1122A/B Tempered water pumps protection (011-UX-024)

Purpose: When there is a low low level in the Tempered Water Drum D-1115, the

Tempered Water Pumps are stopped.

Initiators:

Initiator Tag No.

Time

Delay

P&ID No. Cause

011-LXALL-069

0.5

seconds

126 Low low level in D-1115 (Water)

Actions:

Action Tag

No.

P&ID No. Service

P-1122A 126 Tempered Water pump stopped

P-1122B 126 Tempered Water pump stopped

011-FIC-030 126 Tempered Water flow controller set to

manual and output 0%

This trip is manually reset by 011-UHSR-024.

3.1.2.33. H-1101 Purge and Start-up sequence (011-UX-047 to 051)

For detail description of Heater purge, pilot gas, fuel gas, fuel oil and off gas ignition

sequences refer to the following drawing 8474L-011-A3501-0110-001-003, which has been

included in attachment 2.

3.2. OPERATING CONDITIONS

Refer to Process Flow Diagrams, which have been listed in 14.2 Process Flow Diagrams and

Material Selection Diagrams, included in attachment 6.

3.3. PROCESS VARIABLES

This purpose of this chapter is to explain the main variables in Unit control.

The variables described are: CDU feed rate, fired heater outlet temperature, main

fractionator overhead temperature, pumparounds duty and stabilizer bottom temperature.

Simpo PDF Merge and Split Unregistered Version - http://www.simpopdf.com

VIETNAM OIL AND GAS CORPORATION (PETROVIETNAM) November 2008

DUNG QUAT REFINERY Rev. : 1

OPERATING MANUAL Chapter : 3

UNIT CDU (011) Page : 31/38

3.3.1. CDU feed rate

The unit is fed by the crude charge pumps in unit 60. The crude oil flows through the cold

preheat train and enters into the desalter. In order to keep constant the desalter pressure,

the crude oil flow at the crude charge pumps is set to the same flow as the measure at the

fired heaters (011-FIC-069), by the controllers 011-FY-092 and 011-HY-002.

If the pressure in the desalter increases the inlet flow from crude charge pumps will be

reduced.

3.3.2. Fired heater outlet temperature

This variable is very important, due to the fact that the column overflash is highly dependent

of this temperature. If an increase in duty is required, the air flow is increased before the fuel

rate is increased. On the other hand, if a decrease in heater duty is required, fuel flow rate is

firstly reduced and secondly air flow rate is reduced. This control scheme ensures that the

fired heater is always operating with an air excess, to ensure a good combustion and avoid

risk of after burning in the stack.

3.3.3. Main fractionator overhead temperature

The overhead vapour temperature is controlled by the amount of heat removed from the top

pumparound circuit. This temperature is important because the overhead product naphtha

end point can be adjusted by changing the set point. If the temperature is higher than the set

point, the top reflux duty will increase. As a result the overhead product end point and

quantity will be reduced. On the other hand, if the temperature is lower than its set point, the

overhead product end point is lower than it should be and the control system will decrease

the top pumparound duty. So, if an increase in the overhead vapour product end point and

quantity is desired, the top pumparound temperature set point will be increased.

3.3.4. Main fractionator pressure.

The column operating pressure depends on the pressure controlled at the main fractionator

accumulator drum D-1103. The operating pressure of a distillation column is related with the

relative volatility of the components to be separated in the different streams. Relative

volatility is a measure of the differences in volatility between 2 components, and hence their

boiling points. It indicates how easy or difficult a particular separation will be. As pressure

increases the relative volatility approaches to one. This means that the vapour pressure

characteristics of the components are more similar, and therefore they are more difficult to

be separated.

In addition, if the remaining variables keep constant, an increase in the column pressure will

decrease the overflash and therefore the internal column flow and the separation achieve will

be lower.

3.3.5. Pumparounds.

Pumparounds must be well controlled to obtain specific products. Pumparound duty control

is essential to keep internal liquid and vapour flow inside the column. The control is acting on

the recycled product flow to the column, and on the total pumparound duty (through duty

controller).

Pumparounds are critical to maintain the optimum vapour/liquid rates in the fractionation of

the column. Inadequate pumparound heat removal and poor pumparound distribution will

result in higher column pressure, poorer fractionation and an increase in the flash zone

pressure. Excessive pumparound heat removal may result in difficulties in maintaining some

end point and may cause internal flooding.

Simpo PDF Merge and Split Unregistered Version - http://www.simpopdf.com

VIETNAM OIL AND GAS CORPORATION (PETROVIETNAM) November 2008

DUNG QUAT REFINERY Rev. : 1

OPERATING MANUAL Chapter : 3

UNIT CDU (011) Page : 32/38

3.3.6. Specification Adjustement.

The principal specifications to which the products from the fractionator can be adjusted are

the boiling point ranges and the flash point. In general, if the fractionation is good, the end

boiling point of a side-cut equals the initial-point of the next heavier product plus a gap. A

gap is the result of a good fractionation; however overlap is more normal and will increase as

fractionation efficiency decrease. Product withdrawal flow rate are adjusted to provide the

required end points for the products and are generally set up from the top of the column

working down.

As a general rule, increasing the drawoff rate will raise the end point of the side stream cut

whilst decreasing the drawoff rate will lower its end point. An indication of the end point is the

draw off temperature of the stream leaving the column. Increasing the product withdrawn,

increases the draw off temperature and the product end point

The flash point of LGO, and HGO products can be modified by adjusting the flow of stripping

steam via, FIC-017 and FIC-019 respectively (to increase the flashpoint the stripping steam

has to be increased). However, the stripping steam can only be increased to the point where

it starts to interfere with the end point of the next higher product. If a further increase in the

flashpoint is required, other changes must be made, allowing an increase of the end point of

the next higher product.

Kerosene flash point can be adjusted by the kerosene stripper reboiler E-1110 duty via 011-

UIC-031 or, in case reboiler E-1110 is out of service, with steam flow via 011-FIC-015.

The specific gravity is directly related to initial and final product boiling point, so changing the

products yields is required to achieve this specification.

The freeze point is related to chemical composition of the product. As final boiling point

increases, the paraffin content in the product increases too, so the freeze point obtained will

be higher.

If residue entrainment occurs HGO can get black colour. This means that the washing

section (between HGO draw off tray and flash zone) doesnt have enough liquid flow. It is

necessary to increase the overflash or reducing the HGO draw off rate.

3.3.7. Stripping Steam in the Main fractionator column.

Increasing this flow rate, it is possible to decrease the content of lighter fractions still present

in the residue, increasing flash point and the initial boiling point of the residue. The stripping

steam flow, controlled by 011-FV-012 will affect temperature of the flash zone and amount of

overflash.

3.3.8. Overflash

Overflash is that portion of the feed which is vaporized in addition to the overhead and

sidestream products. The overflash condenses on the wash section plates and returns to the

flash zone and bottoms stripping section. Its purpose is to prevent coke deposition in the

wash section plates and preventing entrainment of residue up into HGO section, which

would result in off spec HGO.

The CDU is designed for a minimum of 5% overflash.

3.3.9. Stabilizer temperature

The stabilizer bottom temperature has to be controlled in order to maintain the C4

-

specification in this stream. This control is a cascade loop in which the stabilizer bottom

temperature is controlled by the high pressure steam flow through the desuperheater (DS-

1101). If the bottom temperature decreases, the amount of high pressure steam will

increase, and therefore the reboiler duty, in order to raise the temperature again.

Simpo PDF Merge and Split Unregistered Version - http://www.simpopdf.com

VIETNAM OIL AND GAS CORPORATION (PETROVIETNAM) November 2008

DUNG QUAT REFINERY Rev. : 1

OPERATING MANUAL Chapter : 3

UNIT CDU (011) Page : 33/38

The temperature in the top section at constant pressure defines the quality of the LPG

product; this temperature is controlled on E-1122 (auto variable pitch controller). Settling this

control at a lower temperature will decrease LPG C5 content and will increase the tower

reflux. Increasing this temperature will increase quantity and C5 content in the LPG and will

reduce the reflux rate.

3.4. INTER-UNIT CONTROL SCHEME

3.4.1. Atmospheric Residue from the CDU to the RFCC

3.4.1.1. Objective

The objective of this system is to control the level in the bottom of the Main Fractionator

column and route as much of the outgoing atmospheric residue to the RFCC as is required

3.4.1.2. Description

This description should be read in conjunction with the following:

CDU P&IDs:

- 8474L-011-PID-0021-112

- 8474L-011-PID-0021-125

RFCC P&IDs:

- 8474L-015-PID-0021-301

Schematic 1: Atmospheric residue from CDU to RFCC

The level in the Main Fractionator, T-1101 is controlled by a typical Xxx40 three way split

range level controller 011-LIC-007 (direct acting). In the low range (0-33%) the signal from

011-LIC-007 goes to low selector 011-LY-007B, which selects between 011-LIC-007 and the

feed requirement of the RFCC to control the flow to the RFCC. In the mid range (33-67%)

011-LIC-007 resets the set point of 011-FQIC-026 and in the high range (67-100%) 011-LIC-

007 resets the set point of 011-FQIC-027.

011-FQIC-026 and 011-FQIC-027 are parallel controllers used to regulate the flow of residue

to storage. 011-FV-026 is a smaller valve than 011-FV-027 and will normally be sufficient to

control the amount of residue to storage whilst the RFCC is on-line. In the event that the

RFCC is off-line then 011-FQIC-026 will be fully open and 011-FQIC-027 will control the flow

to storage.

The RFCC feed is controlled by a split range level controller, which takes flow preferentially

from the CDU by cascading onto 011-FQIC-029 via 011-LY-007B. If there is not enough

flow coming from the CDU then flow is taken from storage by acting on a flow controller FIC-

402 in the line from storage.

Simpo PDF Merge and Split Unregistered Version - http://www.simpopdf.com

S-ar putea să vă placă și

- Statics and Mechanics of Materials 3Rd Edition Full ChapterDocument41 paginiStatics and Mechanics of Materials 3Rd Edition Full Chapterjason.rabil982100% (29)

- Fractionation Tower Controls-Part 1Document38 paginiFractionation Tower Controls-Part 1Rebekah Schmidt100% (1)

- Changeling - The Dreaming 20th Anniversary Edition 9Document1 paginăChangeling - The Dreaming 20th Anniversary Edition 9André Vieira0% (1)

- Science: Quarter 4 - Module 1: Locating Places Using Coordinate SystemDocument28 paginiScience: Quarter 4 - Module 1: Locating Places Using Coordinate SystemJaken Mack100% (5)

- Heater ControlDocument24 paginiHeater Controlmohamedyoussef1Încă nu există evaluări

- 8474L-011-Manual (1-48)Document127 pagini8474L-011-Manual (1-48)tam100% (2)

- Trol/restricted/course/fourth/course/mo Dule3-1.html: Module 3.1: Control of Distillation ColumnsDocument14 paginiTrol/restricted/course/fourth/course/mo Dule3-1.html: Module 3.1: Control of Distillation ColumnsRimeli RoychoudhuryÎncă nu există evaluări

- Main ColumnDocument19 paginiMain ColumnsemÎncă nu există evaluări

- Operator Training System For Hydrocracking Unit PDFDocument7 paginiOperator Training System For Hydrocracking Unit PDFAli Gohar RaoÎncă nu există evaluări

- MagPi70 PDFDocument100 paginiMagPi70 PDFDaniel TuarezÎncă nu există evaluări

- 5 Vasnat KumarDocument108 pagini5 Vasnat Kumarpkgarg_iitkgp100% (1)

- SRU Start-Up Considerations - Shrikant Koli - Black & Veatch PDFDocument26 paginiSRU Start-Up Considerations - Shrikant Koli - Black & Veatch PDFJunghietu DorinÎncă nu există evaluări

- DHDS ProcessDocument9 paginiDHDS ProcessSandeep ChallaÎncă nu există evaluări

- CDU Training PowerpointDocument144 paginiCDU Training Powerpointviettanct92% (13)

- CDU-2 Operating Manual For UpdationDocument192 paginiCDU-2 Operating Manual For UpdationSagar KumarÎncă nu există evaluări

- Reducing Pressure - Increasing Efficiency: PanoramaDocument4 paginiReducing Pressure - Increasing Efficiency: PanoramapsshnkrÎncă nu există evaluări

- Transformation To An Agile and Virtualized World: Operations Center of The FutureDocument1 paginăTransformation To An Agile and Virtualized World: Operations Center of The FuturepinardoÎncă nu există evaluări

- Significance of Debutanizer Reflux RatioDocument2 paginiSignificance of Debutanizer Reflux RatioMuhammadUsmanSaeedÎncă nu există evaluări

- SWS Operating Manual Rev 02Document73 paginiSWS Operating Manual Rev 02Mahesh Kumar Guddeli100% (2)

- Chapter 4 Basic Control System (Updated Aug 2020)Document56 paginiChapter 4 Basic Control System (Updated Aug 2020)Erra ShafiraÎncă nu există evaluări

- Petroleun Refinery Enforcement Manual PDFDocument661 paginiPetroleun Refinery Enforcement Manual PDFiperaltatorres100% (1)

- GBH Enterprises, LTD.: GBHE-PEG-MAS-601Document48 paginiGBH Enterprises, LTD.: GBHE-PEG-MAS-601rahulÎncă nu există evaluări

- Natural Gas Processing from Midstream to DownstreamDe la EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirÎncă nu există evaluări

- Controlling Film Temperature in Fired Heaters PDFDocument4 paginiControlling Film Temperature in Fired Heaters PDFPablo PaganiÎncă nu există evaluări

- Explosion in SW Tanks PDFDocument9 paginiExplosion in SW Tanks PDFJaved MohammedÎncă nu există evaluări

- Technip Separations PDFDocument47 paginiTechnip Separations PDFProcess EngineerÎncă nu există evaluări

- Natural Gas FractionationDocument28 paginiNatural Gas Fractionationmohamed100% (1)

- Fired Heater SimulatorDocument11 paginiFired Heater SimulatorNimeshKamatÎncă nu există evaluări

- Four Challenges For Nickel Steam-Reforming CatalystsDocument8 paginiFour Challenges For Nickel Steam-Reforming CatalystsReza Rhi100% (2)

- Process Dynamics and ControlDocument32 paginiProcess Dynamics and ControltapsiiiiÎncă nu există evaluări

- Temperature, Pressure Measurements Solve Column Operating ProblemsDocument5 paginiTemperature, Pressure Measurements Solve Column Operating ProblemsHari PrasadÎncă nu există evaluări

- Functional Description Sulphur Recovery Unit Incinerator: DocumentationDocument19 paginiFunctional Description Sulphur Recovery Unit Incinerator: DocumentationMarian PascuÎncă nu există evaluări

- Yuzuru Hanyu - ThesisDocument6 paginiYuzuru Hanyu - ThesisFatima Esperanza Ortiz Ortiz100% (4)

- Oil Ref Walk ThroughDocument7 paginiOil Ref Walk ThroughSumedh SinghÎncă nu există evaluări

- 09 Heater InstrumentationDocument17 pagini09 Heater InstrumentationTissa1969Încă nu există evaluări

- Muhammad Khaleel C.V - Senior Process Operation Engineer PDFDocument4 paginiMuhammad Khaleel C.V - Senior Process Operation Engineer PDFMuhammad KhaleelÎncă nu există evaluări

- Petroleum Refinery: Fryad Mohammed SharifDocument8 paginiPetroleum Refinery: Fryad Mohammed SharifSander LukeÎncă nu există evaluări

- Troubleshooting Vacuum Unit Revamp - TDocument6 paginiTroubleshooting Vacuum Unit Revamp - TRafeek Emad AbdElkaderÎncă nu există evaluări

- Distillation in RefineryDocument4 paginiDistillation in RefineryMuhammad SultanÎncă nu există evaluări

- Critical Variable in Catalytic Reforming and Unit Monitoring Best PracticesDocument18 paginiCritical Variable in Catalytic Reforming and Unit Monitoring Best Practicesbakhtyar21Încă nu există evaluări

- DsdsDocument10 paginiDsdsLinh GiangÎncă nu există evaluări

- Vacuum Distillation UnitDocument15 paginiVacuum Distillation Unitshaz100% (2)

- Fractionation OnlyDocument27 paginiFractionation OnlymohamedÎncă nu există evaluări

- OPERATING MANUALS - Kerosene Hydrotreater Rev 01 - 3Document13 paginiOPERATING MANUALS - Kerosene Hydrotreater Rev 01 - 3MohamadMostafavi100% (1)

- CDU DesignDocument8 paginiCDU DesignAnonymous DcE7fcjSwÎncă nu există evaluări

- Weak Forms ListDocument2 paginiWeak Forms ListLinh GiangÎncă nu există evaluări

- Weak Forms ListDocument2 paginiWeak Forms ListLinh GiangÎncă nu există evaluări

- CDU Training Powerpoint PDFDocument144 paginiCDU Training Powerpoint PDFnefoussi100% (1)

- Refinery Analytical Techniques Optimize Unit PerformanceDocument8 paginiRefinery Analytical Techniques Optimize Unit PerformanceAlberto Fonseca Uribe100% (1)

- 191 - 197 - Detection of Transaction Fraud Using Deep LearningDocument28 pagini191 - 197 - Detection of Transaction Fraud Using Deep LearningADRINEEL SAHAÎncă nu există evaluări

- Material DesignationDocument34 paginiMaterial DesignationLinh GiangÎncă nu există evaluări

- Atmospheric Crude Distillation UnitDocument2 paginiAtmospheric Crude Distillation UnitFahmi Ramadhan PutraÎncă nu există evaluări

- Enhanced NGL Recovery ProcessDocument5 paginiEnhanced NGL Recovery ProcessEdgar HuancaÎncă nu există evaluări

- Debottleneck Crude-Unit Preheat Exchanger Network Inefficiencies - Hydrocarbon Processing - February 2012Document8 paginiDebottleneck Crude-Unit Preheat Exchanger Network Inefficiencies - Hydrocarbon Processing - February 2012Srihari KodimelaÎncă nu există evaluări

- Process Control FundamentalsDocument110 paginiProcess Control FundamentalsYoosu NguyenÎncă nu există evaluări

- APC in Lube ProcessingDocument48 paginiAPC in Lube ProcessingHariajahÎncă nu există evaluări

- NHT Furnace OptimisationDocument6 paginiNHT Furnace Optimisationcoolmanyu2k5Încă nu există evaluări

- Unit 3 Steam GenerationDocument30 paginiUnit 3 Steam GenerationkhalimnÎncă nu există evaluări

- Sweetening LPG With AminesDocument8 paginiSweetening LPG With AminessizwehÎncă nu există evaluări

- Filling The Propylene Gap On Purpose TechnologiesDocument12 paginiFilling The Propylene Gap On Purpose Technologiesvajidqc100% (1)

- 18CH036 Hydrotreating ProcessDocument17 pagini18CH036 Hydrotreating ProcessSuleka RanasingheÎncă nu există evaluări

- PSV For Distillation GuidelinesDocument3 paginiPSV For Distillation GuidelinesMubarik AliÎncă nu există evaluări

- Process ManualDocument47 paginiProcess ManualmayankkhÎncă nu există evaluări

- Case Histories of Amine Plant Equipment Corrosion Problems - Part 2Document4 paginiCase Histories of Amine Plant Equipment Corrosion Problems - Part 2jdgh1986Încă nu există evaluări

- Distillation: Prepared By: DEEDAR ALI QURESHI Assist By: PHAIXA ABBASI, Former Student of CHM KU. ReferencesDocument76 paginiDistillation: Prepared By: DEEDAR ALI QURESHI Assist By: PHAIXA ABBASI, Former Student of CHM KU. ReferencesIrshad SheikhÎncă nu există evaluări

- HPCL IT DHDS Block OverviewDocument37 paginiHPCL IT DHDS Block OverviewSrija Mummidi100% (1)

- Jaeger Products, Inc: Superior Performance by DesignDocument18 paginiJaeger Products, Inc: Superior Performance by Designpulse550100% (1)

- Miscellaneous FCC AspectsDocument114 paginiMiscellaneous FCC AspectskotilskÎncă nu există evaluări

- 08 HydroprocessingDocument52 pagini08 HydroprocessingThaiyalNayakiÎncă nu există evaluări

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979De la EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonÎncă nu există evaluări

- Application Bulletin 140Document12 paginiApplication Bulletin 140Maria DazaÎncă nu există evaluări

- DFDFDFDocument5 paginiDFDFDFLinh GiangÎncă nu există evaluări

- Pages From (Piston Valve)Document3 paginiPages From (Piston Valve)Linh GiangÎncă nu există evaluări

- VBFGBDocument1 paginăVBFGBLinh GiangÎncă nu există evaluări

- GggegeegegegDocument131 paginiGggegeegegegLinh Giang100% (1)

- NoName Column ProfilesDocument6 paginiNoName Column ProfilesLinh GiangÎncă nu există evaluări

- Study of Chemical Reactions Effect On The Design and The Performance of An Industrial Secondary Reformer Reactor in The Fertilizers PlantsDocument10 paginiStudy of Chemical Reactions Effect On The Design and The Performance of An Industrial Secondary Reformer Reactor in The Fertilizers PlantsLinh GiangÎncă nu există evaluări

- What's NewDocument5 paginiWhat's NewLinh GiangÎncă nu există evaluări

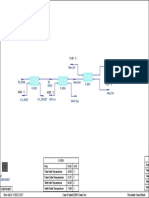

- 78.00 C 71.69 1.507e+004 C KG/H: Tue Jul 25 09:01:02 2017 Case: E:/desk/E3001/TEST - KSC Flowsheet: Case (Main)Document1 pagină78.00 C 71.69 1.507e+004 C KG/H: Tue Jul 25 09:01:02 2017 Case: E:/desk/E3001/TEST - KSC Flowsheet: Case (Main)Linh GiangÎncă nu există evaluări

- 78.00 C 71.69 1.507e+004 C KG/H: Tue Jul 25 09:01:02 2017 Case: E:/desk/E3001/TEST - KSC Flowsheet: Case (Main)Document1 pagină78.00 C 71.69 1.507e+004 C KG/H: Tue Jul 25 09:01:02 2017 Case: E:/desk/E3001/TEST - KSC Flowsheet: Case (Main)Linh GiangÎncă nu există evaluări

- SLIDE2Document1 paginăSLIDE2Linh GiangÎncă nu există evaluări

- O.H.T.C W/m2.K: Sun Jul 30 14:40:55 2017 Case: E:/desk/E3001/TEST E3004.ksc Flowsheet: Case (Main)Document1 paginăO.H.T.C W/m2.K: Sun Jul 30 14:40:55 2017 Case: E:/desk/E3001/TEST E3004.ksc Flowsheet: Case (Main)Linh GiangÎncă nu există evaluări

- Extended Abstract PDFDocument10 paginiExtended Abstract PDFLinh GiangÎncă nu există evaluări

- Petro SIM PrintDocument1 paginăPetro SIM PrintLinh GiangÎncă nu există evaluări

- 090768.231 3.00 100 A BDocument1 pagină090768.231 3.00 100 A BLinh GiangÎncă nu există evaluări

- Job Application FormDocument2 paginiJob Application FormLinh GiangÎncă nu există evaluări

- TTCL Vietnam Corporation LimitedDocument4 paginiTTCL Vietnam Corporation LimitedLinh GiangÎncă nu există evaluări

- Job Application Letter: Mr. Hoang Minh AiDocument1 paginăJob Application Letter: Mr. Hoang Minh AiLinh GiangÎncă nu există evaluări

- Leave, Keep, Get, Drive, Bake, Pack, Push, Pull, Put, Paint, Dye, Sweep, Wipe, Set, Declare, Break, Bury, Report, Shoot, Think, Imagine, Consider, Take, Prove (CH NG Minh), Find, Feel, SeeDocument26 paginiLeave, Keep, Get, Drive, Bake, Pack, Push, Pull, Put, Paint, Dye, Sweep, Wipe, Set, Declare, Break, Bury, Report, Shoot, Think, Imagine, Consider, Take, Prove (CH NG Minh), Find, Feel, SeeLinh GiangÎncă nu există evaluări

- Answer Key ADocument15 paginiAnswer Key ALinh GiangÎncă nu există evaluări

- Design-Expert Software, Version 7.0: Optimize Your Product or Process With Design of Experiments (DOE)Document4 paginiDesign-Expert Software, Version 7.0: Optimize Your Product or Process With Design of Experiments (DOE)leninkathirÎncă nu există evaluări

- 19 Pdfsam 92974093 Gas Processing Campball PDFDocument1 pagină19 Pdfsam 92974093 Gas Processing Campball PDFHoàng Minh ÁiÎncă nu există evaluări

- 34 Pdfsam 92974093 Gas Processing Campball PDFDocument1 pagină34 Pdfsam 92974093 Gas Processing Campball PDFHoàng Minh ÁiÎncă nu există evaluări

- 34 Pdfsam 92974093 Gas Processing Campball PDFDocument1 pagină34 Pdfsam 92974093 Gas Processing Campball PDFHoàng Minh ÁiÎncă nu există evaluări

- 151 Pdfsam 92974093 Gas Processing Campball PDFDocument1 pagină151 Pdfsam 92974093 Gas Processing Campball PDFLinh GiangÎncă nu există evaluări

- 14 Pdfsam 92974093 Gas Processing Campball PDFDocument1 pagină14 Pdfsam 92974093 Gas Processing Campball PDFLinh GiangÎncă nu există evaluări

- 10 Pdfsam 92974093 Gas Processing Campball PDFDocument1 pagină10 Pdfsam 92974093 Gas Processing Campball PDFLinh GiangÎncă nu există evaluări

- WSU Presentation 20220407Document63 paginiWSU Presentation 20220407debapriyoÎncă nu există evaluări

- PHASE TEST PHYSICS Fiitjee Class 8Document3 paginiPHASE TEST PHYSICS Fiitjee Class 8SahejÎncă nu există evaluări

- Form Cor Eng Pip 002 e R01Document1 paginăForm Cor Eng Pip 002 e R01Uri SanchezÎncă nu există evaluări

- Cross-Cultural Validation of The Scales For Outcomes in Parkinson's Disease-Psychosocial Questionnaire (SCOPA-PS) in Four Latin American CountriesDocument7 paginiCross-Cultural Validation of The Scales For Outcomes in Parkinson's Disease-Psychosocial Questionnaire (SCOPA-PS) in Four Latin American Countriesfozia hayyatÎncă nu există evaluări

- Introduction & BiomoleculesDocument50 paginiIntroduction & BiomoleculesAshrul NasirÎncă nu există evaluări

- Xii Chemistry MCQ (Haloalanes & Haloarenrs)Document7 paginiXii Chemistry MCQ (Haloalanes & Haloarenrs)SanjanasanjuÎncă nu există evaluări

- Kinetic Energy Recovery SystemDocument2 paginiKinetic Energy Recovery SystemInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- BMTC 132Document16 paginiBMTC 132Deepak Chaudhary JaatÎncă nu există evaluări

- Confidence IntervalDocument22 paginiConfidence Intervallloyd balinsuaÎncă nu există evaluări

- 3g3JX InverterDocument262 pagini3g3JX InverterdatdttvuÎncă nu există evaluări

- 1.bitwise OperatorsDocument2 pagini1.bitwise OperatorsPaul kollamÎncă nu există evaluări

- Quadratic Equation - MATH IS FUNDocument8 paginiQuadratic Equation - MATH IS FUNChanchan LebumfacilÎncă nu există evaluări

- Formula SheetDocument3 paginiFormula SheetgogogogoÎncă nu există evaluări

- m1100 s12 v1.1f en - Fender - DesignDocument48 paginim1100 s12 v1.1f en - Fender - Designdzul fiqarÎncă nu există evaluări

- How Do Bodies MoveDocument28 paginiHow Do Bodies Movedeme2411Încă nu există evaluări

- Integrating Theory, Experiments, and FEA To Solve Challenging Nonlinear Mechanics ProblemsDocument17 paginiIntegrating Theory, Experiments, and FEA To Solve Challenging Nonlinear Mechanics ProblemsBodieTechÎncă nu există evaluări

- 310 011 SDocument34 pagini310 011 SvigneshwaranmÎncă nu există evaluări

- Dynamic Group Number Assignment (DGNA)Document16 paginiDynamic Group Number Assignment (DGNA)afkaeÎncă nu există evaluări

- Week 4.damping ElementsDocument5 paginiWeek 4.damping ElementsTrophie NilemoaÎncă nu există evaluări

- Asco Series 042 Gas Shutoff CatalogDocument4 paginiAsco Series 042 Gas Shutoff CatalogRoqueNetÎncă nu există evaluări

- Chapter 4 Structure EditedDocument9 paginiChapter 4 Structure Editedyeshi janexoÎncă nu există evaluări

- STP10NK80Z - STP10NK80ZFP STW10NK80ZDocument11 paginiSTP10NK80Z - STP10NK80ZFP STW10NK80ZAnkitÎncă nu există evaluări

- DigfiltDocument237 paginiDigfiltJuhi SinghÎncă nu există evaluări