Documente Academic

Documente Profesional

Documente Cultură

10 1018

Încărcat de

Uthayan SPTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

10 1018

Încărcat de

Uthayan SPDrepturi de autor:

Formate disponibile

Section 10

Useful Information

Copyright Metric & Multistandard Components Corp. 2000 10-1018

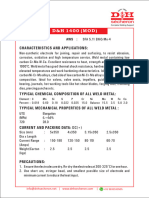

PROPERTY CLASS DATA

Metric Bolts, Screws and Studs

Ref: ISO 898/1-1988

DESIGNATION: Metric Thread Bolts, Screws and Studs are identified by a letter Mfor the thread profile form. The letter Mis followed by the value

of nominal diameter expressed in millimeters and nominal length separated by the sign x. (Example: M 8 x 35)

MATERIALS: The table belowspecifies steels for the different property class of bolts, screws and studs. The minimumtempering temperature

is mandatory for property classes 8.8 to 12.9 in all cases.

CHEMICAL COMPOSITION

PROPERTY

CLASS

MATERIAL AND TREATMENT

CHEMICAL COMPOSITION LIMITS %

TEMPERING

TEMPERATU

RE C MIN.

C P S

min. max. max. max.

4.6, 4.8, 5.8, 6.8* Low or medium carbon steel - 0.55 0.05 0.06 -

8.8 Medium carbon steel quenched, tempered 0.25 0.55 0.04 0.05 425

9.8 Medium carbon steel quenched, tempered 0.25 0.55 0.04 0.05 425

10.9

Medium carbon steel additives e.g. boron, Mn, Cr or

Alloy steel - quenched, tempered

0.20 0.55 0.04 0.05 425

12.9 **Alloy steel - quenched, tempered 0.20 0.50 0.035 0.035 380

*Fee cutting steel is allowed for these classes with the following maximum sulphur, phosphorus and lead content:

S - 0.34% P - 0.11% Lead - 0.35%

**Alloy steel shall contain one or more of chromium, nickel, molybdenum or vanadium

PROPERTY CLASS: Symbols consist of two figures. The first indicates 1/100 of the nominal tensile strength in newtons per mm. The second

figure indicates 10 times the ratio between nominal yield stress and nominal tensile strength. The multiplication of these

two figures will give 1/10 of the nominal yield stress in newtons per mm.

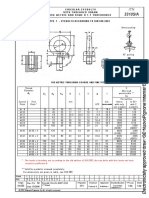

MECHANICAL PROPERTY

PROPERTY CLASS

4.8 5.6 5.8 6.8

8.8

9.8 10.9 12.9 Up to M

16

Over M

16

Tensile Strength

(Rm, N/mm)

nom. 400 500 600 800 900 1000 1200

min. 420 500 520 600 800 830 900 1040 1220

Vickers Hardness

min. 130 155 160 190 250 255 290 320 385

max 250 320 336 360 380 435

Brinell Hardness

min. 124 147 152 181 319 242 266 295 353

max. 238 385 319 342 363 412

Rockwell Hardness

min. HRB 71 79 82 89 -

HRC - - - - 20 23 28 32 39

HRB 95 99 -

max. HRC - - - - 32 34 37 39 44

Yield Stress ReL.

N/mm

nom. 320 300 400 480 -

min. 340 300 420 480 -

Stress at permanent

set limit N/mm

nom. - 640 720 900 1080

min. - 640 660 720 940 1100

S-ar putea să vă placă și

- 421 - Domex 700 MCDocument2 pagini421 - Domex 700 MClalamed21Încă nu există evaluări

- Case Hardening Alloy Steel Bar 6587 Atlas 6587: Colour Code: Signal Red (Band) - BlackDocument3 paginiCase Hardening Alloy Steel Bar 6587 Atlas 6587: Colour Code: Signal Red (Band) - BlackCelsoÎncă nu există evaluări

- WS Hws Hss Asp CPMDocument12 paginiWS Hws Hss Asp CPMGross Meltiade AlexanderÎncă nu există evaluări

- BoltsDocument6 paginiBoltsJuragan IwalÎncă nu există evaluări

- Thermanit Chromo 9V SMAW enDocument1 paginăThermanit Chromo 9V SMAW ensoft4gsmÎncă nu există evaluări

- Domex 420 MCDocument2 paginiDomex 420 MCHugo RodriguezÎncă nu există evaluări

- Carbon Steel and Alloy Steel FastenersDocument2 paginiCarbon Steel and Alloy Steel FastenersagnisivadasanÎncă nu există evaluări

- Mechanical Properties of Metric Fasteners (Class)Document2 paginiMechanical Properties of Metric Fasteners (Class)Pankaj RaneÎncă nu există evaluări

- 34 CR Ni Mo 6Document1 pagină34 CR Ni Mo 6Bogdan CraciunÎncă nu există evaluări

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 paginiDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelBo WangÎncă nu există evaluări

- Remanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La CarteDocument36 paginiRemanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La Cartepipedown456Încă nu există evaluări

- Domex 700 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 paginiDomex 700 MC Hot Rolled, Extra High Strength, Cold Forming Steelflorin_iacob2001Încă nu există evaluări

- KAMAX - Bolt and Screw CompendiumDocument60 paginiKAMAX - Bolt and Screw Compendiumjzaw65Încă nu există evaluări

- Materials: Mechanical and Physical PropertiesDocument1 paginăMaterials: Mechanical and Physical PropertiespawkomÎncă nu există evaluări

- Gb8417domex500mc PDFDocument2 paginiGb8417domex500mc PDFMario MereniÎncă nu există evaluări

- DIMO 30M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsDocument4 paginiDIMO 30M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsFernando LaraÎncă nu există evaluări

- 34CrMo4 10083 06 ENG 01 PDFDocument1 pagină34CrMo4 10083 06 ENG 01 PDFMarcio CunhaÎncă nu există evaluări

- Parkers: BS EN 10088-3: 1995Document2 paginiParkers: BS EN 10088-3: 1995Sanath WijerathneÎncă nu există evaluări

- Mat 07000-07149 200411Document5 paginiMat 07000-07149 200411Ronaldo Bandeira RodriguesÎncă nu există evaluări

- BS3100 A2Document11 paginiBS3100 A2AlexÎncă nu există evaluări

- EN24 and EN24T SteelDocument3 paginiEN24 and EN24T Steelpatrik710Încă nu există evaluări

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 paginiDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezÎncă nu există evaluări

- 19Mnvs6: Steel GradeDocument3 pagini19Mnvs6: Steel GradeForin PetalÎncă nu există evaluări

- Mechanical Properties of Metric FastenersDocument2 paginiMechanical Properties of Metric Fastenersghostghost123Încă nu există evaluări

- 50 CRV 4Document2 pagini50 CRV 4saptotoÎncă nu există evaluări

- Domex 100 XF Data SheetDocument2 paginiDomex 100 XF Data Sheetzubblwump5063Încă nu există evaluări

- High Tensile: Nearest StandardDocument4 paginiHigh Tensile: Nearest StandardtdfsksÎncă nu există evaluări

- 36NiCrMo16 PDFDocument2 pagini36NiCrMo16 PDFAmy GriffinÎncă nu există evaluări

- SS 6mo - 1.4547Document1 paginăSS 6mo - 1.4547f_riseÎncă nu există evaluări

- GB235 MetalsDocument12 paginiGB235 MetalsAhmet HamamcıoğluÎncă nu există evaluări

- Data Sheet Strenx 700 MCDocument3 paginiData Sheet Strenx 700 MCRoger BandeiraÎncă nu există evaluări

- Cutting Edge BrochureDocument2 paginiCutting Edge BrochureKen SmithÎncă nu există evaluări

- CuAg0,1P PDFDocument8 paginiCuAg0,1P PDFirajfarji2481Încă nu există evaluări

- Strenx 700 MC: Advanced High Strength SteelDocument2 paginiStrenx 700 MC: Advanced High Strength SteeldbaÎncă nu există evaluări

- Structural SteelsDocument1 paginăStructural SteelsrjueiÎncă nu există evaluări

- RO3000 Pour Rogers 3006 PDFDocument4 paginiRO3000 Pour Rogers 3006 PDFTeddy112Încă nu există evaluări

- 316 Tubeing TrisDocument1 pagină316 Tubeing Triscenter steel110Încă nu există evaluări

- Screw CharacteristicsDocument18 paginiScrew CharacteristicsJaokÎncă nu există evaluări

- Cold Rolled 2010 DUNAFER HungriaDocument12 paginiCold Rolled 2010 DUNAFER HungriaBeatriz RizzoÎncă nu există evaluări

- Steel X20Cr13: EN 10250-4:1999, Number: 1.4021Document4 paginiSteel X20Cr13: EN 10250-4:1999, Number: 1.4021AdamÎncă nu există evaluări

- SINOXX 4006 Steel: Designation by StandardsDocument3 paginiSINOXX 4006 Steel: Designation by StandardsKiranÎncă nu există evaluări

- DH 1400modDocument1 paginăDH 1400modGopiNathÎncă nu există evaluări

- Hot Strip Mill Product TolerancesDocument9 paginiHot Strip Mill Product TolerancesAyman Al AnsaryÎncă nu există evaluări

- tcvn1916-1995 VI enDocument16 paginitcvn1916-1995 VI enMohamad SaquibÎncă nu există evaluări

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Weld Like a Pro: Beginning to Advanced TechniquesDe la EverandWeld Like a Pro: Beginning to Advanced TechniquesEvaluare: 4.5 din 5 stele4.5/5 (6)

- Advances in Solid Oxide Fuel Cells and Electronic CeramicsDe la EverandAdvances in Solid Oxide Fuel Cells and Electronic CeramicsÎncă nu există evaluări

- Solution Manual for 100 Genesys Design Examples: Second EditionDe la EverandSolution Manual for 100 Genesys Design Examples: Second EditionÎncă nu există evaluări

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDe la EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášÎncă nu există evaluări

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDe la EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghÎncă nu există evaluări

- TargetDocument219 paginiTargetIqbal.AÎncă nu există evaluări

- Is - 2062.2011 PDFDocument17 paginiIs - 2062.2011 PDFN GANESAMOORTHYÎncă nu există evaluări

- Din en 1563Document2 paginiDin en 1563Tayfun Tezanlar78% (9)

- Company ProfileDocument11 paginiCompany ProfileUthayan SPÎncă nu există evaluări

- Is - 2062.2011 PDFDocument17 paginiIs - 2062.2011 PDFN GANESAMOORTHYÎncă nu există evaluări

- En 10204Document9 paginiEn 10204Uthayan SPÎncă nu există evaluări

- E433Document5 paginiE433Uthayan SPÎncă nu există evaluări

- En 10204Document9 paginiEn 10204Uthayan SPÎncă nu există evaluări

- En 10228-2Document7 paginiEn 10228-2Uthayan SPÎncă nu există evaluări

- Mastercam FullDocument12 paginiMastercam FullAndrew T100% (1)

- En10083 3Document58 paginiEn10083 3Uthayan SP100% (1)

- Is 3589Document19 paginiIs 3589kishor.kokate60% (5)

- Is 3589Document19 paginiIs 3589kishor.kokate60% (5)

- Is 3589Document19 paginiIs 3589kishor.kokate60% (5)

- Autocad 2006Document497 paginiAutocad 2006Uthayan SP100% (1)

- Irs Welded Bridge CodeDocument32 paginiIrs Welded Bridge Codeamawauce67% (3)

- Master Cam Design - Help TopicsDocument257 paginiMaster Cam Design - Help TopicsUthayan SP100% (1)

- Motor TechDocument164 paginiMotor Technricquart100% (1)

- As 1275-1985Document20 paginiAs 1275-1985caimei89Încă nu există evaluări

- Scotch-W Scotch-Weld ProductDocument24 paginiScotch-W Scotch-Weld ProductAnca AnghelÎncă nu există evaluări

- Bollhoff Helicoil Plus Kits and Inserts CatalogueDocument49 paginiBollhoff Helicoil Plus Kits and Inserts CatalogueThor InternationalÎncă nu există evaluări

- Rotary Spray Heads: Since 1922, Precision Made GreatDocument32 paginiRotary Spray Heads: Since 1922, Precision Made GreatLai Ming YihÎncă nu există evaluări

- Pressure-Reducing Valves For Water Systems, ShipboardDocument10 paginiPressure-Reducing Valves For Water Systems, Shipboardreza amiriniaÎncă nu există evaluări

- Ground .: Innovating SupportDocument12 paginiGround .: Innovating SupportAntonio BocanegraÎncă nu există evaluări

- Screws, Fasteners, and The Design of Nonpermanent JointsDocument118 paginiScrews, Fasteners, and The Design of Nonpermanent JointsSOUBHIK ROYÎncă nu există evaluări

- ISO General-Purpose Metric Screw Threads: National ForewordDocument31 paginiISO General-Purpose Metric Screw Threads: National ForewordLORENZOÎncă nu există evaluări

- Thread-Cutting Tools and Procedures: Session 9Document22 paginiThread-Cutting Tools and Procedures: Session 9Rodel M. VasquezÎncă nu există evaluări

- Description Assembly Order No. Static DataDocument29 paginiDescription Assembly Order No. Static DataMROstop.comÎncă nu există evaluări

- GD & T - Training Material Note PagesDocument252 paginiGD & T - Training Material Note Pageslokelooks92% (26)

- TG-73, DS - TM7301 - en - Co - 2146Document15 paginiTG-73, DS - TM7301 - en - Co - 2146Paulkumar RamaiahÎncă nu există evaluări

- 1 Fastening Catalogue 2013 Hi ResDocument30 pagini1 Fastening Catalogue 2013 Hi ResMujjo Sahb100% (1)

- Hydac AccessoriesDocument156 paginiHydac AccessoriesCalo AlcaloÎncă nu există evaluări

- Aeroquip How To Identify Ports and ConnectorsDocument48 paginiAeroquip How To Identify Ports and Connectorsphankhoa83Încă nu există evaluări

- Terraroc Casing Advancement Systems Pipe Roofing Solutions CatalogueDocument12 paginiTerraroc Casing Advancement Systems Pipe Roofing Solutions CatalogueEmrahÎncă nu există evaluări

- ULM User Information No. 8Document5 paginiULM User Information No. 8khemedra patleÎncă nu există evaluări

- Bolts and Power Screws - LongDocument5 paginiBolts and Power Screws - LongAmeeh TorionÎncă nu există evaluări

- Basic Mechanical Engineering ConceptDocument2 paginiBasic Mechanical Engineering Conceptgyanimahato.4345Încă nu există evaluări

- AssignmentDocument5 paginiAssignmentShailesh PrajapatiÎncă nu există evaluări

- Loc LineDocument20 paginiLoc LineVijaymohan KanugulaÎncă nu există evaluări

- Used Machine Tools 4 Sale: BSI ShopDocument3 paginiUsed Machine Tools 4 Sale: BSI ShopnihadbisicÎncă nu există evaluări

- DIN580 Eye BoltDocument7 paginiDIN580 Eye BoltReda El-AwadyÎncă nu există evaluări

- Engineering Drawing: by N. D. BhattDocument6 paginiEngineering Drawing: by N. D. Bhatt71 KaranÎncă nu există evaluări

- Katalog TSP NPTDocument28 paginiKatalog TSP NPThabib TaofikÎncă nu există evaluări

- Asme B18.6.5M 1998Document43 paginiAsme B18.6.5M 1998Jesse ChenÎncă nu există evaluări

- Nut and Bolt TutorialDocument7 paginiNut and Bolt TutorialPraveen Kumar SharmaÎncă nu există evaluări

- CQ2 New Series PDFDocument210 paginiCQ2 New Series PDFsumit_waghmareÎncă nu există evaluări

- Tutorial FastenersDocument2 paginiTutorial FastenersKrm LeoÎncă nu există evaluări