Documente Academic

Documente Profesional

Documente Cultură

Carbs

Încărcat de

nitishghosalDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Carbs

Încărcat de

nitishghosalDrepturi de autor:

Formate disponibile

CARBURETORS

The process of carburetion means to mix air and fuel. The function of the carburetor is to meter

fuel and to proportion air/fuel mixtures, as intake air enters the engine. Carburetors are very

complex and are made of many parts, few of which can be interchanged with any other carburetor.

BERNOULLI'S PRINCIPLE

Daniel Bernoulli discovered in 1738 that there is a relationship between the speed or velocity of a

fluid - either liquid or gas - and the pressure exerted by that fluid. If fluid flow is constant, pressure

is constant. As speed increases, pressure decreases. This is evident in the effect of air on the wing of

an aircraft, the increased speed of air above the wing creates an area of lower pressure. The pressure

of the slower moving air below the wing is greater, applying lift to the wing. The same principle is

used in the design of a venturi in the carburetor.

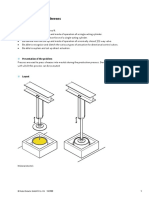

VENTURI

The carburetor operates on the principle of the incoming air drawing the fuel into the air stream. The

carburetor is positioned on the intake manifold and all of the air that is drawn in by the downward

motion of the pistons, must pass through the carburetor This air passes through a narrowing of the

carburetor body. This is called a venturi. The air is forced to change flow characteristics as it

passes through the venturi.

VENTURI CONSTRUCTION

Air passing over the wing of an airplane must travel further than the air under the wing, thus

creating a low-pressure area above the wing, giving it lift. As intake air passes through the venturi,

it must accelerate and travel faster than it was travelling in the larger area of the passage. As the

air passes through at the higher rate of speed, a low-pressure area is created, just as above the

wing of an airplane. This low pressure creates a suction on the gasoline that is present in the

carburetor, and it draws it into the air stream through the discharge tube or nozzle (Bernoulli's

Principle).

The venturi is self-regulating. As the volume of air passing through the venturi rises and falls,

the level of suction on the fuel also rises and falls. The higher the volume of air, the higher the

suction is, and the higher the volume of gasoline that is drawn with it. A constant air fuel mixture

can be maintained this way.

THROTTLE PLATE

If an engine were permitted to draw air in freely, it would accelerate and run uncontrolled at very

high speed. Cutting off or throttling the airflow controls engine speed. When the volume of air is

reduced, engine speed falls accordingly. When air volume is unrestricted, the engine will

produce full power.

The airflow or volume is controlled by the throttle plate, which is placed in the base of the carburetor, below the venturi, and is able to

close the airflow almost completely. The throttle plate, or throttle butterfly, as it is sometimes called, is mounted on a shaft. Rotation

of the shah causes the throttle plate to open or close the air passage. The throttle plate is closed by spring force and opened by foot

pressure from the driver.

BASIC CARBURETOR COMPONENTS

The basic carburetor has the following parts:

1) Carburetor body: the main housing(s), which contain all of the systems and circuits.

2) Air horn: the main air passage. Generally used to describe the upper portion of the passage.

3) Throttle valve: to control airflow.

4) Venturi: the narrowed area of the air passage.

5) Main discharge tube: extends from the fuel bowl into the venturi, carrying fuel to mix with

the air steam.

6) Fuel bowl: stores fuel.

CARBURETOR CIRCUITS

The varying demands and operating conditions of an engine require variations in the

air/fuel mixture. While the venturi and main discharge nozzle are designed to maintain

close to a 15:1 ratio, the engine will require ratios ranging from 8:1 to 18:1. These variations are achieved

through circuits that cope with the needed changes in fueling. The basic carburetor has six major circuits: - float - idle - main metering

- full power or enrichment accelerator - choke

FLOAT CIRCUIT

The float circuit serves to maintain a constant fuel level in the fuel bowl. The float is

mounted with a hinge, and a needle valve is positioned so that the float can close the needle

valve.

When fuel level is low, the needle valve is open. Fuel under pressure from the fuel pump

flows past the needle valve and fills the fuel bowl. As the fuel level rises, the float pushes the

needle valve closed and fuel flow stops.

Some carburetors have two fuel bowls and will therefore require two float circuits. Float level

- the level of the fuel in the float bowl - is adjustable, usually by bending tabs on the float or by

bending the hinge portion of the float. Gauges are often provided with carburetor overhaul kits to

allow precise setting of float levels. The float bowl is vented to the air horn and to the charcoal canister.

IDLE CIRCUIT

An idling engine requires a slightly richer mixture. There is not enough air flowing through the

venturi to draw fuel out of the main discharge tube, so an alternate passage is provided.

The throttle plate is blocking the majority of intake air, and a high vacuum is present below the

throttle plate. The vacuum draws fuel from the float bowl through a passage that exits below the

throttle plate. Air is drawn through an air bleed passage and mixes with the fuel, before it is

discharged out of the idle port. An idle adjusting screw is located in the idle passage so that flow

of fuel - and consequently engine idle speed - can be adjusted. On late model carburetors the idle

adjustments are set at the factory and sealed, and no adjustments are possible.

Since only a very small amount of air can pass by the throttle plate, a controlled, enriched

mixture enters the engine. As the throttle plate begins to open and the engine comes off idle,

further discharge ports are exposed to vacuum and more fuel air mixture is drawn through these

passages. These ports are called off-idle ports.

The ports may be connected by a transfer slot, or may be individual holes placed above the

throttle plate. The off idle ports provide a smooth transition as the throttle moves from idle to

part throttle, and the fuel flow moves from the idle circuit to the main metering circuit. Vehicle

manufacturers use many variations of idle circuitry.

MAIN METERING CIRCUIT

The main metering circuit provides the fuel metering throughout most of the engine operation.

After the throttle is opened past the off idle ports, there is sufficient airflow to draw fuel through

the main discharge tube. The main metering circuit can maintain normal air/fuel mixture through

all rpm ranges, depending on engine load.

The main discharge nozzle is connected via passages to the fuel float bowl. A metering jet is

placed in this passage to precisely control fuel flow. J ets of various sizes can be interchanged to

affect engine performance.

The passage includes an air bleed that allows air to mix with the fuel as it enters the discharge

tube. A well may be situated in the passage that allows progressively more air to mix with the

fuel and prevent the mixture from becoming too rich as engine speed and air volume increase.

FULL POWER OR ENRICHMENT CIRCUIT

To produce full power, the engine needs a slightly richer

mixture. Since the main metering system tends to provide a

constant air/fuel ratio, an additional circuit is provided to enrich the mixture under full power

operation. There are several designs of circuits for this purpose; the common ones are the metering

rod type, and the power valve.

The metering rod design utilizes mechanical linkage or vacuum to actuate a metering rod that is

placed in the main jets. When full throttle operation is called for, the metering rod lifts out of the

main jet, increasing the area of the opening and subsequently the amount of fuel that can flow.

The power valve design utilizes vacuum or linkage to open an additional metering jet that

permits the flow of additional fuel through the discharge tube.

ACCELERATOR PUMP CIRCUIT

When the engine is accelerated slowly from idle there is a transfer from the idle circuit to the main metering circuit, as discussed

earlier. However if an engine is accelerated quickly, a momentary hesitation will occur. As soon as the throttle plate is opened, air will

flow quickly into the manifold. The flow of gasoline will be slightly delayed however, and that first rush of air/fuel mixture will be

very lean, causing the engine to hesitate or even stall.

The accelerator pump circuit provides a positive charge of fuel that is sufficient to compensate for the amount of air that is drawn in,

before the main metering system begins fuel flow.

The accelerator circuit consists of mechanical linkage connected to a diaphragm

or plunger type pump, and nozzles located in the air horn. Fuel enters the pump

chamber through a one way check valve, and is discharged through a second

check valve, in a manner similar to the fuel pump. As the throttle opens, the

pump is actuated and fuel is discharged from the nozzle(s). The linkage is

generally adjustable, to increase or decrease the amount of fuel that is pumped

into the engine. Hesitation on quick acceleration, is often an indicator of a faulty

accelerator pump.

CHOKE CIRCUIT

Starting a cold engine requires a very rich mixture. To allow the carburetor to deliver this

rich mixture requires the addition of another plate similar to the throttle plate. The choke

plate is capable of closing the airflow into the air horn; this is described as choking the

engine by cutting off its airflow. When the choke plate is closed, the entire carburetor is

subject to the high manifold vacuum. This high vacuum draws large volumes of fuel

through the various passages.

Originally, chokes were manually operated. The driver opened and closed the choke to keep

the engine running at a satisfactory speed and smoothness. To eliminate the inefficiency of a

driver operating the choke, automatic chokes have been used for years. A temperature

sensitive bimetallic spring is connected by linkage to the choke plate. When the engine is

cold, the spring closes the plate, and as the engine heats the bi-metal spring opens the plate.

Many additional devices have been added to automatic chokes to modify the transition from

full choke during engine cranking, to no choke, at normal operating temperature. The choke

plate is offset on its shaft, so that air velocity pulls it partially open as soon as the engine

starts. Intake manifold vacuum is also used to actuate the opening of the choke. As the

engine heats, exhaust gas is directed toward

the bi-metal spring, causing it to respond

more rapidly, and an electric heater may also

be installed to heat up the bi-metal coil.

When an engine is cold and running under

choke, it generally needs to operate with the

throttle plate slightly further open, than at a hot idle.

Idle speed is generally also increased slightly to allow

the engine to run smoothly and avoid the tendency to

stall.

A fast idle device that is incorporated into the choke

linkage accomplishes this. Usually a screw on the

throttle linkage contacts a multi-step cam. When the

choke shaft rotates closed, the throttle opens in

steps, by the actuation of the cam. To engage this feature, the throttle linkage must be depressed

during cranking. In fact, in many cases the choke will not be

closed unless the throttle is depressed before or during

cranking.

A choke break or vacuum break is used to open the choke plate slightly once the engine starts

so that it can breathe. When engine vacuum builds after the engine starts it acts on the break

diaphragm to pull the choke plate open. This amount of opening must be very precise or the

engine will stall. Some manufacturers call for the adjustment to be made using an angle gauge

and others use a specific demension.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Visual Studio C++ TutorialDocument324 paginiVisual Studio C++ TutorialFahadÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The New Fifth Edition of Api 618 For Reciprocating Compressors - Which Pulsation and Vibration Control Philosophy Should You Use?Document14 paginiThe New Fifth Edition of Api 618 For Reciprocating Compressors - Which Pulsation and Vibration Control Philosophy Should You Use?rajurajangam100% (1)

- Suspension 101 by Steve LymanDocument66 paginiSuspension 101 by Steve Lymannitishghosal100% (1)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- FETs DatabookDocument189 paginiFETs DatabookTito Titon0% (1)

- Case Interview Guide PDFDocument13 paginiCase Interview Guide PDFGrand OverallÎncă nu există evaluări

- Course Notes For GeophysicsDocument30 paginiCourse Notes For GeophysicsShivendra Pratap SinghÎncă nu există evaluări

- LRFD Design ExampleDocument698 paginiLRFD Design ExampleCesar RomeroÎncă nu există evaluări

- Cessna 172Document4 paginiCessna 172James DeatoÎncă nu există evaluări

- Manual LDM5 U enDocument3 paginiManual LDM5 U enLuizAugustoMedeirosÎncă nu există evaluări

- TIMO Mock 2019 卷P3fDocument9 paginiTIMO Mock 2019 卷P3fDo Yun100% (1)

- Common RailDocument11 paginiCommon RailnitishghosalÎncă nu există evaluări

- PL/SQL NotesDocument17 paginiPL/SQL NotesnitishghosalÎncă nu există evaluări

- Projectile LoomDocument23 paginiProjectile Loommehedi111560% (5)

- Adam Smith - Wealth of Nations - CondensedDocument86 paginiAdam Smith - Wealth of Nations - CondensedThe_ArkalianÎncă nu există evaluări

- R Cheat Sheet 3 PDFDocument2 paginiR Cheat Sheet 3 PDFapakuniÎncă nu există evaluări

- Brakes by Paul S GrittDocument55 paginiBrakes by Paul S GrittAshok SiddarthÎncă nu există evaluări

- MemoDocument1 paginăMemonitishghosalÎncă nu există evaluări

- Atmosphere 08 00148 v3Document16 paginiAtmosphere 08 00148 v3nitishghosalÎncă nu există evaluări

- Electronic Engine Control Systems Reduce Emissions in DieselsDocument5 paginiElectronic Engine Control Systems Reduce Emissions in DieselsnitishghosalÎncă nu există evaluări

- Diesel Fuel and CharacteristicsDocument19 paginiDiesel Fuel and CharacteristicsnitishghosalÎncă nu există evaluări

- Pages From Lp8semDocument22 paginiPages From Lp8semnitishghosalÎncă nu există evaluări

- Vehicle Dynamics - Thomas DDocument38 paginiVehicle Dynamics - Thomas DJasbir Singh Dhanoa100% (1)

- Combustion in Diesel EngineDocument13 paginiCombustion in Diesel Enginenitishghosal100% (1)

- Conventional InjectorsDocument12 paginiConventional Injectorssameer100% (1)

- Calibration 101 by Kim LyonDocument103 paginiCalibration 101 by Kim LyonnitishghosalÎncă nu există evaluări

- 3 Automotive Chassis Design v2Document62 pagini3 Automotive Chassis Design v2Leela Krishna VegiÎncă nu există evaluări

- Mini BajaDocument31 paginiMini BajanitishghosalÎncă nu există evaluări

- Lab Work 1-4Document27 paginiLab Work 1-4sachingarg1991Încă nu există evaluări

- Tires 101 by Steve LymanDocument21 paginiTires 101 by Steve LymannitishghosalÎncă nu există evaluări

- Emissions Control Technologies To Meet Current and Future European Vehicle Emissions LegislationDocument11 paginiEmissions Control Technologies To Meet Current and Future European Vehicle Emissions LegislationnitishghosalÎncă nu există evaluări

- Academic Calander 2012-2013Document5 paginiAcademic Calander 2012-2013sidharth2505Încă nu există evaluări

- Presented By: Nitish Ghosal Amit RaiDocument25 paginiPresented By: Nitish Ghosal Amit RainitishghosalÎncă nu există evaluări

- (Final) Electrical Lab ManualDocument37 pagini(Final) Electrical Lab ManualnitishghosalÎncă nu există evaluări

- Data Representation in A ComputerDocument13 paginiData Representation in A ComputernitishghosalÎncă nu există evaluări

- Student Rank List by Branch (Top 10Document1 paginăStudent Rank List by Branch (Top 10nitishghosalÎncă nu există evaluări

- Symmetric GroupDocument13 paginiSymmetric GroupPriyanka PatelÎncă nu există evaluări

- House of CardsDocument2 paginiHouse of CardsHello misterÎncă nu există evaluări

- RPGS Complete Lecture Note1 Inpdf Compressed1Document203 paginiRPGS Complete Lecture Note1 Inpdf Compressed1Purusottam PandeyÎncă nu există evaluări

- The Windows Process Journey v6 0 Aug2023 1691726739Document53 paginiThe Windows Process Journey v6 0 Aug2023 1691726739blakboukiÎncă nu există evaluări

- Electrochemical Cleaningof Artificially Tarnished SilverDocument11 paginiElectrochemical Cleaningof Artificially Tarnished SilverRahmi Nur Anisah Nasution 2003114489Încă nu există evaluări

- Model For Calculating The Refractive Index of DiffDocument5 paginiModel For Calculating The Refractive Index of DiffNANÎncă nu există evaluări

- Cognac Brandies From A Region of France, Cognac Are Called Cognac. They Are Known To Be The Best Types of Brandies in The WorldDocument3 paginiCognac Brandies From A Region of France, Cognac Are Called Cognac. They Are Known To Be The Best Types of Brandies in The Worldmanuk193Încă nu există evaluări

- Exercise 1: Pressing Cheeses: Cheese ProductionDocument8 paginiExercise 1: Pressing Cheeses: Cheese ProductionAhmed HusseinÎncă nu există evaluări

- Explorer - Help RESCODocument18 paginiExplorer - Help RESCOTomás Oteros OrdóñezÎncă nu există evaluări

- WWW Mathworks inDocument7 paginiWWW Mathworks inRagini SharmaÎncă nu există evaluări

- GMAT Practice QuestionsDocument8 paginiGMAT Practice QuestionswithraviÎncă nu există evaluări

- BRINELL BH3000 - WilsonHardnessDocument2 paginiBRINELL BH3000 - WilsonHardnessKhoa Bui AnhÎncă nu există evaluări

- Sensitivity Analysis: Enter Base, Minimum, and Maximum Values in Input CellsDocument5 paginiSensitivity Analysis: Enter Base, Minimum, and Maximum Values in Input CellsSajid IqbalÎncă nu există evaluări

- Welding robot aviation plug terminal definitionDocument4 paginiWelding robot aviation plug terminal definitionPhươngNguyễnÎncă nu există evaluări

- Laminar Flow Reactor ProblemDocument6 paginiLaminar Flow Reactor ProblemAileen Banua Añonuevo100% (1)

- LEMBARAN KERJA BI TAHUN 4 (m7-10) PDPRDocument9 paginiLEMBARAN KERJA BI TAHUN 4 (m7-10) PDPRnurulwaznahÎncă nu există evaluări

- Crowd Puller FinalDocument10 paginiCrowd Puller FinalJanette Tibayan CruzeiroÎncă nu există evaluări

- Quiz6 AnswerDocument8 paginiQuiz6 AnswerTrí Tạ MinhÎncă nu există evaluări

- 1 Gauss SeidelDocument20 pagini1 Gauss SeidelYanes Kristianus HediÎncă nu există evaluări

- JavaDocument20 paginiJavaSivasakthi MarimuthuÎncă nu există evaluări

- CCR Load Calculator 2014-03-13Document35 paginiCCR Load Calculator 2014-03-13Danielle FowlerÎncă nu există evaluări

- Atlas Copco Compressed Air Manual: 8 EditionDocument25 paginiAtlas Copco Compressed Air Manual: 8 EditionRajÎncă nu există evaluări