Documente Academic

Documente Profesional

Documente Cultură

Atlas Axles: Definitive Guide To

Încărcat de

The_ToecutterTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Atlas Axles: Definitive Guide To

Încărcat de

The_ToecutterDrepturi de autor:

Formate disponibile

Atlas axles

The Atlas is still the axle of choice if youre building a rally car or

big-power street weapon. Heres all you need to know about them.

Definitive guide to

he idea of these features is to bust

myths, uncover secrets and, most

importantly, simplify subjects

that might seem confusing. So a prime

candidate for a definitive guide is the

big power classic Ford favourite: the

Atlas axle.

There seems to be so many variations,

types and sizes that many people are left

dazed, confused and blinded by names

and figures. And then theres the

ongoing debate about how much power

they can take, for how long and whether

you need 18-spline this or fully floating

that. So we decided to tackle this one

head on by going to see the most

respected Atlas experts in the country,

Fostek Engineering.

T

Words Simon Holmes Photos Jon Hill

Theyve been building, uprating

and even engineering their own parts for

these axles for the last 13 years, so its fair

to say theyve got the knowledge when

it comes to definitive answers.

Armed with a notepad, a head full of

questions and a camera, we borrowed

them for a day. We interrogated them

and they gave us the facts...

August 2011 87

Contact

Fostek Engineering

01670 734594

www.fostek.co.uk

Info

defnitive guide: Atlas axles

T

THE MOST COMMON TYPE OF

ATLAS WAS STANDARD IN

ALMOST ALL MK2 AND MK3

CAPRIS, WITH A 1600CC OR

2000CC PINTO ENGINE

CFTECH defnitive guide: Atlas axles

he Atlas axle has come as standard

t in a few different models over the

years, which means theres a variation

of suitable sizes and types. But there were also

a few unusual applications which can only be

used for parts, so here they are explained.

These measurements are taken across the

casing from ange to ange.

Full-width Atlas 52 inches

This is the most common type of Atlas as it

was standard tment in almost all Mk2 and

Mk3 Capris tted with either the 1600cc and

2000cc Pinto engine, or any variation of V6.

Narrow Atlas 50 inches

These came only in the Mk1 3-litre Capris,

which makes them a little rarer. They have

a slightly different pigs head (the main body

that houses the diff and CWP), smaller wheel

bearings and slightly thinner shafts. This

doesnt effect their initial strength though

as the end parts are the same size.

Baby Atlas

48.5 inches

Some very rare European Mk1

Escorts came from the factory

with what is known as a baby Atlas,

which measures the same size as

the common English axle and ts

straight under the standard

arches of an Escort. These

are not to be confused with

the Koln/Cologne axles

though, which appeared

in some European cars.

These look very similar

to Atlas axles from the

outside, but have English

axle internals and are useless

in terms of big power. You can tell

one from the back plate which has a

non-symmetrical bolt pattern and straight

side edges.

The Others

The Cortina Mk3/4/5 2000cc, 2300cc and

the estate model came with an Atlas axle. But

due to their more modern, trailing arm rear

suspension set-up, it makes only the middle

pigs head section useable, which is only ideal

if you need to shorten an axle in the rst place.

The pigs head is also slightly

different, having void-bush

lugs cast into the top of them,

to cater for the Cortinas upper swing

arm suspension.

A variation of Atlas came in the Ford

Transit right up until the late 1980s, but it used

a ve-stud bolt pattern, is much wider and has

a different hub arrangement, which again

means only the centre pigs head section is

of use. Be careful though as other Transit axles

look very similar to Atlas axles, but arent.

So you need to have a good idea of what

youre looking at.

On the same note, P100 pick-ups also

came with a similar axle, but only on the later

Sierra-based examples. They have

a different heavy-duty casting,

but again the stud pattern and hub

arrangement means only the centre

sections are useable. They do come

with the desirable 4.6:1 or 5.1:1

ratio CWP (crown wheel and

pinion) though.

What

different

types of Atlas

are there?

August 2011 89

Full-width, narrow or Baby how do you need yours?

What lengths are used for what cars?

Mk1/Mk2 Escort on standard

arches with a 7J wheel?

A Baby Atlas at 48.5 inches is the size of the

standard English Escort axle, but Fostek prefer

to play it safe when using standard arches

and wider wheels and recommend using a

shortened axle to 47.5 inches to ensure room.

This is especially important if youre changing

to a disc brake set-up as this will space out the

wheels by a further 8 mm each side.

Mk1/Mk2 Escort on bubble

arches or Forest arches?

Ideally, use a 50-inch narrow axle from a Mk1

Capri, as they were the original tment to the

arched works rally cars and most historic rally

cars still use them. It allows 9- or even 10-inch

wide wheels with the right offset. A 52 inch can

be used and are a lot easier to get hold of,

though Fostek say it restricts you to an 8J wheel.

Anglia 105E?

An Anglia needs an axle smaller than even

the Baby Atlas, so nothing will t straight in,

meaning you will need to t new shortened

tubes and shafts to match. If you are going to

the hassle of tting a custom width axle then it

makes sense to make it smaller still to give

some space to t wider wheels, so Fostek

supply a 44- or 45-inch axle to cater for this.

Standard shafts can be shortened to suit by

having them cut and friction welded. But theres

not much difference in price to new upgraded

shafts which can take more power.

The axle rst appeared in the 1960s

in Mk1 Transits and Capris, as the

heavy duty alternative to the English

axle needed to cope with high

performance engines or heavy load

lugging. They used bigger internal

components that were ideal to

ensure reliability, which is why they

were used for rally cars too and they

proved to be so strong the rally

teams didnt even carry a spare!

Ford continued to use them in their

commercial range right up until

the early 1990s.

The History

of the Atlas

Hubs

The outer hub arrangement is the

same for most types of Atlas, unless

it is a Group 4 fully oating axle.

88 August 2011

To put it simply, they are

stronger in every way.

They use a bigger CWP,

with bigger teeth on the

gears, which allows for

more contact area the

most important factor and

where English axles are

heavily let down. Atlas

also have stronger diff

housings and stronger

tubes, making them an

all-round heavy duty axle.

Why are they better than an English axle?

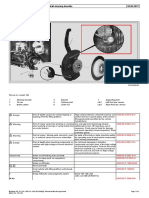

Pigs head

This is the name

given to the centre

section of the axle

which houses

the crown wheel,

pinion (CWP) and

differential. There are

variations of this with

slight differences to

the castings, to cater

for other models.

Tubes

These t into the pigs

head and house the

shafts themselves.

Bracing can be used

to increase strength.

T

CFTECH defnitive guide: Atlas axles

August 2011 91

How much power

can axles take?

How to

improve them

Whats the weakest part of the Atlas axle? Why do CWP ratios

matter? Why is grip the most important factor? And,

how to buy an axle secondhand...

Differentials, casings and shafts... what you need to know.

90 August 2011

he most important factor here

is grip, as the more you have,

the more likely you are to break

something. Generally speaking though

if you were to start with a totally

standard Capri axle in good working

order and drive with moderate care,

then they are usually ne until about

the 300 bhp for a fast road car. After

that, it depends largely on how much

you abuse the car and if its being used

for drag racing or rallying if so,

the shafts will start snapping.

However, with the right uprated

components tted theyve been

proved reliable on 500 bhp YB-powered

fast road, track and strip cars. There

are a couple of points worth knowing

about though...

Differential

The rst thing to do, if you

havent already, is t an LSD, as

the standard open diff isnt ideal

for putting down any kind of

decent power. For a road car,

Fostek suggests using a Quaife

ATB as its easy to maintain and

kind to halfshafts. But they do

advise its considered to be

strictly a road-going diff and

not suited to track or for harsh

driving (which includes

burnouts and doughnuts). If

thats more up your street, or the

car will be spending time at the

track or the strip, then a plated

diff is better suited to your

needs. They are motorsport

orientated items and although

they lock both wheels for

traction in a harsher way, they

can be adjusted through ramp

angles and preloads, to suit a

less aggressive road going

application. Fostek prefer to use

the Gripper diffs, which cost

around 900, as ZF items. They

were very popular but are no

longer available new. Be aware

that the P100 came with an open

diff in a heavy duty casing which

looks like an LSD to the

untrained eye, so be careful

when buying secondhand.

Shafts

All standard shafts are one-

piece 16 spline and quite small

in diameter, which makes them

the weakest link, so the rst

thing is to upgrade to larger

two-piece 18 spline shafts. To t

larger shafts the casing doesnt

need to be modied, but the

side gears that connect them to

the diff will need to be changed

or machined to suit. Normally,

an LSD will be tted already at

this stage and the side gears

needed to t 18 spline shafts

cost about 150 for the pair. For

the shafts themselves there are

quite a few different brands

available, but Fostek have had

good results from using two

piece shafts from Phil and

Mick Squires at Rally and

Competition Equipment (01782

523664) which are about 125

each. These are known as Group

1 shafts but are in the fact the

same diameter and spline count

as what would be used for a

Group 4 axle. The matching

outer anges, to make them a

two piece shaft, are 70 each

and the new bearings to go with

them are 40 each. New wheel

studs will also be needed for

around 20 a set. The shafts

come in the most common sizes

to cater for baby, narrow and

full-width axles off the shelf

and for more bespoke or

custom applications such

as the slightly shorter

47.5-inch Fostek prefer to

use in un-arched Escorts

can also be supplied. The

quality is outstanding

and will cope with

most high power

applications. But

Fostek do sell an

even heavier

duty, gun-

drilled, rolled-spline version

that come with an unbreakable

guarantee for 1200 a pair,

and can be done to any

length required.

Casing

For the average fast road car no

more needs to be done, or can

be done, to increase the

strength of the axle internals in

terms of power than a good LSD

and a set of uprated shafts.

However, as soon as you start to

use a car in harsh conditions,

rough terrain on a rally stage or

the extreme cornering forces of

a track, thicker tubes and extra

bracing is needed to stop any

ex or twisting of the tubes out

of the pigs head.

Fostek have just had some

brand new castings done for the

pigs head in high grade, high

strength iron, which are even

better than the original Ford

item. They are the rst company

to successfully do this and will

only be supplying them with

their own axles, so will not be

sold separately. Alloy ones are

in the pipeline too, which offer

a big weight

saving.

What CWP ratios are available?

3.09:1

These are the

highest ratios

available and

came in most

V6- engined

Capris. They are

very common,

but generally

useless, as they

are deemed too

lazy for the road.

3.22:1

This was a ratio

found in some Mk1

3-litre Capris and

is very rare. But

sadly, again, pretty

useless in most

road cars as they

are too high.

3.44:1

Ideal for big power

or big torque

YB-engined cars

that wont nd the

slightly high ratio

a problem.

Originally came

on 2-litre Pinto-

powered Capris.

3.75:1

The most desirable

of all the ratios for

a fast road car, as

it offers the best

compromise and

is ideal for the

average YB-

engined car. These

were tted to the

1600cc Pinto-

powered Capris.

4.1:1

This is a rare Ford

Motorsport item

and wasnt tted

to any road car as

standard. Its ideal

for an NA-powered

car and they have

since been

reproduced as

an aftermarket

item by various

companies.

4.6:1

Common on P100

pick-ups and some

Transits, theres

a steady demand

for these from the

rally boys who

regularly use them,

as they are too low

for the road.

5.1:1

These were the

rare standard-t

Transit items for

special vehicles,

such as

Ambulances or

even ice cream

vans. Theres a

high demand from

the rally boys.

Theyre available

as reproduction

items.

Shafts

These are the weakest points of the

Atlas. If youre using standard shafts,

source some from a low mileage car

ones that have been marked to

indicate what side they come from,

as shafts twist marginally over time

and tend to set into position, like a

corkscrew. They are at their strongest

once set, as they become work

hardened, which means if they ever

swap sides for whatever reason then

theyre more likely to break.

CWP

Out the box these are very strong and

rarely break. However, the lower the

ratio, the weaker the pinions become

as the amount of extra teeth that

physically have to t to decrease the

ratio makes them smaller and therefore

weaker. Its also worth noting that the

original Ford items are stronger than

reproduced items and as a result

command more money.

Advantages

Over something like an English,

they use a bigger CWP, bigger

tubes, bigger bearings, have a

stronger casing, use bigger wheel

bearings and theres lots of potential

to improve them to near

indestructible levels. Also

sometimes an English axle isnt

wide enough to t a wide arch car

and nally, now everything has

been re-produced a brand new

axle can be built up from scratch.

Disadvantages

Weight is the main one and the

signicant one; they weigh a fair

bit more than an English axle.

Theres some work and expense

needed to t one, as theres no

readily available off the shelf item

for most cars as it has to be

modied. Due to their bigger size,

a diff tunnel may be needed if the

car is running extra low. Also, in

comparison to the rear loading

English axle, the front loading Atlas

is harder and more time-consuming

to work on, which comes into effect

if you want to change ratios often.

Once the correctly uprated parts

have been tted to suit the intended

use, they are very strong, reliable

axles. This depends if they have

been built correctly in the rst place,

as its important to check whats

known as the backlash clearance to

ensure its within its tight tolerance.

If it hasnt been done correctly it will

create excess heat, noise and wear.

It needs to be carefully adjusted,

using shims, to make sure theres

good contact between the teeth and

similarly the pinion needs to have a

good mesh with the crown wheel.

This ensures the longevity of the

components and through this kind

of clinical preparation Fostek have

seen axles cope with over 5000

race miles between rebuilds.

Atlas pros

and cons

How reliable

are they?

Ideally get one with as low mileage as possible and in

good working order, although its hard to tell from the

outside, so here are some pointers. If the oil inside the diff

is clean and full to capacity its generally a good sign; the

back plates tend to corrode, leak oil and then they run low

on lubrication, which causes excess wear to the internals.

Its best to spend extra time and money looking for the

right size and ratio for your application, rather than buying

any old axle that comes along and having to spend money

adapting it. Expect to pay around 150 for a 52-inch Atlas

without an LSD and 500-plus for the rare Capri Special

axle which had a plated ZF LSD in it. A narrow 50-inch

Atlas from a Mk1 Capri will normally go for around 300

as its more desirable for the wide arch cars and rally boys.

BUYING

SECONDHAND:

what to look for

CWP

The crown wheel and

pinion ratio can be

changed to give

different acceleration

characteristics.

Plated Diffs

Designed with motorsport in mind,

these are ideal for big power cars.

Open Diffs

Standard in most axles, these

are the rst thing to replace.

1

Atlas axles

wont take

big power? False.

With the right parts

tted they have

been proven on

big power and big

grip cars.

2

Group 4

oating axles

are stronger?

False. The

differences

are only on the

hub arrangement

and not the pigs

head internals.

3

Ford never

made a Baby

Atlas for the Escort?

False. They are

very, very rare,

but they were

tted to some

European cars.

4

An LSD is

stronger than

an open diff? False.

They are as strong

as each other.

5

A standard

axle can cope

with 350 bhp? True.

This has been

known with

gentle road driving

and, importantly,

lower grip levels.

MYTHS

R

un by father and son duo John and Tom

Foster, the company started out around

13 years ago when they were building

themselves a rally car. When it came to the

axle they found no one could supply them

with one. Taking the initiative, they read a few

books and had a go at doing it themselves,

with good results. They were soon doing

another for a friends car and word spread. In

the early days they had to machine and adapt

standard parts, as very little was readily

available. But they now make their own parts,

redesigning items along the way to be both

stronger and lighter. Over time theyve learnt

what works and what doesnt and now turn

out hundreds of axles a year for customers all

over the world for road and competition use.

They quickly established a reputation as being

the leading force and experts in Atlas axles

and their latest development of newly cast

pigs heads means they can now supply

a complete brand new axle from scratch.

So if youve got a big power engine and need

an axle, Fostek are the ones.

ABOUT FOSTEK ENGINEEERING

T

CFTECH

92 August 2011

his is something you hear

being banded about a lot

within rally circles and it

relates to the strength of the hub

arrangement, rather than the

power it can cope with. The heavy

duty upgrades to the hubs allow

for sustained shocks and harsh use

over rough ground such as

rallying. The centre pigs head

section, including the CWP, diff and

shafts, is virtually the same as any

other Group 1 or fast road uprated

item, but the tubes are thicker and

heavily braced. They also use a

stub axle arrangement and

bearing carrier, so the hub itself is

designed to spread the load onto

the tubes and axle. On a normal

axle the shafts and bearings have

to transfer the torque of the engine

as well, taking the wheel load, but

this way its role is reduced to just

transmitting power. This is done by

anchoring the hub, using two

tapered roller bearings, which

stops wheel movement no matter

what the wheel encounters. It also

means that even under very hard

cornering the wheels will always

point in the same direction, which

is ideal for track or circuit based

cars too. As its a fair amount of

work to machine the necessary

end parts, and different shafts are

needed, its not something that can

be done as a kit or as an after

thought once the axles been built.

What is a fully floating

Group 4 axle?

Fostek is a family

run business

which caters

for everything

Atlas related.

Only the outer hubs and shafts are different. On the left is a Group 4, next to a normal axle.

Fully

floating

This is something

we hear being used

a lot, but it only

relates to the hub

arrangement, to

give extra strength.

S-ar putea să vă placă și

- Home 302 Stroker InfoDocument10 paginiHome 302 Stroker InfoGypsyRÎncă nu există evaluări

- 2008-32-0073 - Camshaft Design For An Inlet-Restricted FSAE EngineDocument11 pagini2008-32-0073 - Camshaft Design For An Inlet-Restricted FSAE EngineCaio PaimÎncă nu există evaluări

- Choosing The Perfect Performance CamshaftDocument9 paginiChoosing The Perfect Performance CamshaftDesotoJoe100% (1)

- Be The Camshaft ExpertDocument21 paginiBe The Camshaft ExpertRenan100% (1)

- CASE 821F TIER 4 WHEEL LOADER Operator's Manual PDFDocument15 paginiCASE 821F TIER 4 WHEEL LOADER Operator's Manual PDFfjskedmmsme100% (4)

- Timing Belt Replacement ChartDocument1 paginăTiming Belt Replacement Chartbakerman19870% (1)

- Champion Spark Plugs For Proven PerformanceDocument7 paginiChampion Spark Plugs For Proven PerformanceMGD040452100% (1)

- Some Critical Technical Issues On The Steady Flow Testing of Cylinder HeadsDocument16 paginiSome Critical Technical Issues On The Steady Flow Testing of Cylinder HeadsPrateek SinghÎncă nu există evaluări

- Lap Sim EngineDocument5 paginiLap Sim Engineblack_oneÎncă nu există evaluări

- S082252 PDFDocument239 paginiS082252 PDFDanielMarinÎncă nu există evaluări

- 996 gt3 mk1 - mk2Document4 pagini996 gt3 mk1 - mk2Jeff Chin100% (1)

- Ron Iskenderian Cam Session - Minor Cam Timing Inaccuracies Do Not Lost HPDocument3 paginiRon Iskenderian Cam Session - Minor Cam Timing Inaccuracies Do Not Lost HPgaragepunkfan100% (1)

- Type - 9 - Gearbox To Essex v6Document11 paginiType - 9 - Gearbox To Essex v6aakk75Încă nu există evaluări

- Tuning Standard Triumphs VizardDocument159 paginiTuning Standard Triumphs VizardJadera1989100% (1)

- Crash Sensors: Figure 1. Structural Components To An InertiaDocument5 paginiCrash Sensors: Figure 1. Structural Components To An InertiasjramanÎncă nu există evaluări

- Towmotor - ARMY Manual-3Document343 paginiTowmotor - ARMY Manual-3willcham100% (1)

- Operating Instruction PDFDocument43 paginiOperating Instruction PDFnamduong36867% (3)

- CFD Analysis of Non-Symmetrical Intake Manifold For Formula SAE CarDocument11 paginiCFD Analysis of Non-Symmetrical Intake Manifold For Formula SAE CarGtatlisÎncă nu există evaluări

- Design Analysis of The Lotus Seven S4 (Type 60) PDFDocument18 paginiDesign Analysis of The Lotus Seven S4 (Type 60) PDFChristian Villa100% (4)

- Nissan Primera BTCCDocument6 paginiNissan Primera BTCCstefan.vince536100% (2)

- Ford Kent CrossflowDocument6 paginiFord Kent CrossflowSean OsborneÎncă nu există evaluări

- Classic Ford May 2011 Ford Type 9 Five Speed GuideDocument5 paginiClassic Ford May 2011 Ford Type 9 Five Speed GuideDatomarMarquez0% (1)

- Design of Intake ManifoldDocument6 paginiDesign of Intake ManifoldShailendra SinghÎncă nu există evaluări

- Technical Service Department 360 Modena UpdatesDocument328 paginiTechnical Service Department 360 Modena UpdatesDoppel Vergaser100% (1)

- 199R9934 3rev2 PDFDocument16 pagini199R9934 3rev2 PDFbatman2054Încă nu există evaluări

- Selection and Tuning of Weber Dcoe Carburetors 2Document14 paginiSelection and Tuning of Weber Dcoe Carburetors 2Slevinooo100% (5)

- Catalogo Brembo RacingDocument134 paginiCatalogo Brembo Racingblow100% (1)

- Porsche Magazine1Document54 paginiPorsche Magazine1CristianCovaciÎncă nu există evaluări

- Group 1 Mk2 EscortDocument6 paginiGroup 1 Mk2 EscortPhilip RiddlesÎncă nu există evaluări

- Randy Leffingwell - Porsche Turbo - The Inside Story of Sttutgart's Turbocharged Road and Race Cars-Motorbooks (2015)Document259 paginiRandy Leffingwell - Porsche Turbo - The Inside Story of Sttutgart's Turbocharged Road and Race Cars-Motorbooks (2015)Hrvoje Rodic100% (1)

- Formula SAE Performance Exhaust DesignDocument65 paginiFormula SAE Performance Exhaust Designpaulo negaoÎncă nu există evaluări

- Adjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersDocument13 paginiAdjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersJ.d. LangleyÎncă nu există evaluări

- Transmision 0AW A6FwdDocument128 paginiTransmision 0AW A6FwdCarlos Garcia Godoy78% (23)

- Cosworth StoryDocument32 paginiCosworth StoryTanoV12-Formula1AmarcordÎncă nu există evaluări

- Tuning Standard Triumphs VizardDocument159 paginiTuning Standard Triumphs Vizardvanapeer100% (3)

- Mikuni AgulhasDocument4 paginiMikuni AgulhasJaKa1Încă nu există evaluări

- 911 and Porsche World Issue 318 January 2021Document118 pagini911 and Porsche World Issue 318 January 2021Florin StratulatÎncă nu există evaluări

- Theissen 10 Years of BMW F1 EnginesDocument17 paginiTheissen 10 Years of BMW F1 EnginesBlaze123xÎncă nu există evaluări

- Ferrari Mondial PDFDocument11 paginiFerrari Mondial PDFBennyLouPlummerÎncă nu există evaluări

- Porsche 356: The Engine Handbook: An Engine Assembly GuideDe la EverandPorsche 356: The Engine Handbook: An Engine Assembly GuideÎncă nu există evaluări

- Porsche 914 6Document2 paginiPorsche 914 6AlexeIonutÎncă nu există evaluări

- Puma Race Engines - Peugeot 205 8 Valve Engine Tuning Guide: Blocks and CranksDocument11 paginiPuma Race Engines - Peugeot 205 8 Valve Engine Tuning Guide: Blocks and Cranksspidermaan67% (3)

- Pinto+Doc Med+ResDocument20 paginiPinto+Doc Med+ResSirRD80% (5)

- Vodou Auto Kits VR5 Variations From Book PlansDocument19 paginiVodou Auto Kits VR5 Variations From Book PlansTully MoreÎncă nu există evaluări

- 2016 Nissan GTRDocument32 pagini2016 Nissan GTRMark100% (1)

- Ford PushrodDocument7 paginiFord PushrodLouise Ellis-Rix50% (2)

- Elan 5 SPDDocument6 paginiElan 5 SPDslipsittinÎncă nu există evaluări

- The Dodge Viper 8.4 L V10Document6 paginiThe Dodge Viper 8.4 L V10znamÎncă nu există evaluări

- Allied 2008 CatalogDocument306 paginiAllied 2008 CatalogEvilJay20% (1)

- Puma Race Engines - Cylinder Head Modifications - Part 1: Valve SeatsDocument4 paginiPuma Race Engines - Cylinder Head Modifications - Part 1: Valve SeatsRobert DennisÎncă nu există evaluări

- GP N Brochure ProdriveDocument7 paginiGP N Brochure ProdriveTc Mrt Çap TmlÎncă nu există evaluări

- Cam Selection - Jim McFarland HRM March 1966Document3 paginiCam Selection - Jim McFarland HRM March 1966garagepunkfanÎncă nu există evaluări

- SOHC Head Flow Data + CarburetorsDocument62 paginiSOHC Head Flow Data + CarburetorsVincenzo SepeÎncă nu există evaluări

- Porsche 911: Navigation SearchDocument19 paginiPorsche 911: Navigation SearchaffaqÎncă nu există evaluări

- Scuderia Topolino - Technical AdviceDocument130 paginiScuderia Topolino - Technical AdviceNikÎncă nu există evaluări

- Multi Valve SynopsisDocument11 paginiMulti Valve SynopsisiampiyushsahuÎncă nu există evaluări

- Design and Analysis of Camshafts (DOHC)Document23 paginiDesign and Analysis of Camshafts (DOHC)Esaam Jamil0% (3)

- Hub Centres SteeringDocument29 paginiHub Centres SteeringSudheesh Kumar EÎncă nu există evaluări

- SSP 341 4.2l V8 5V EngineDocument41 paginiSSP 341 4.2l V8 5V EngineAcorda Iacanga SPÎncă nu există evaluări

- Spyder NEWDocument6 paginiSpyder NEWwchenowethÎncă nu există evaluări

- LAMPIRAN I (Lanjutan)Document8 paginiLAMPIRAN I (Lanjutan)GalÎncă nu există evaluări

- Leaflet All New Voxy 170222Document6 paginiLeaflet All New Voxy 170222Admin Aono Pack IndonesiaÎncă nu există evaluări

- Speed Sensing SteeringDocument2 paginiSpeed Sensing Steeringgeorge josephÎncă nu există evaluări

- Hyundai Elantra BrochureDocument10 paginiHyundai Elantra Brochuretarun PathivadaÎncă nu există evaluări

- Golf-June-2002 PDFDocument44 paginiGolf-June-2002 PDFCaroline PuckettÎncă nu există evaluări

- Index OF BOOKDocument26 paginiIndex OF BOOKSunny BhatiaÎncă nu există evaluări

- 2000 Buick Regal Localizacion de FusiblesDocument8 pagini2000 Buick Regal Localizacion de FusiblesRubenÎncă nu există evaluări

- Configuration Diagrams: Group 80Document28 paginiConfiguration Diagrams: Group 80Stasio PiwowarskiÎncă nu există evaluări

- L958FDocument2 paginiL958Fabdelhadi houssinÎncă nu există evaluări

- AISIN Fully Synthetic ATF (AFW+) : Premium Synthetic Multi-Vehicle Automatic Transmission FluidDocument3 paginiAISIN Fully Synthetic ATF (AFW+) : Premium Synthetic Multi-Vehicle Automatic Transmission FluidminaryÎncă nu există evaluări

- GoMechanic OrderHealthCard 202201224307939Document3 paginiGoMechanic OrderHealthCard 202201224307939Amar nathÎncă nu există evaluări

- Rcak 16V256 6961Document2 paginiRcak 16V256 6961Anonymous GF8PPILW5Încă nu există evaluări

- Daftar Spare Part PDFDocument80 paginiDaftar Spare Part PDFManiso MnsÎncă nu există evaluări

- Unicorn 150Document2 paginiUnicorn 150Nirmal GoreÎncă nu există evaluări

- Audi A6 3.0 TDI (230kW) Quattro S Tronic Tehnilised Andmed PDF Formaadis (Inglise Keeles)Document1 paginăAudi A6 3.0 TDI (230kW) Quattro S Tronic Tehnilised Andmed PDF Formaadis (Inglise Keeles)Marusca Sergiu VladÎncă nu există evaluări

- Radius Magazine Issue 36Document33 paginiRadius Magazine Issue 36Pearson PublishingÎncă nu există evaluări

- Hiace: Delivering ProfessionalismDocument3 paginiHiace: Delivering ProfessionalismalfonsxxxÎncă nu există evaluări

- CVT Apr.06E A4-1Document2 paginiCVT Apr.06E A4-1Thang Nguyen HuuÎncă nu există evaluări

- R&I Steering Knuckle FrontDocument4 paginiR&I Steering Knuckle FrontTzvetan DimitrovÎncă nu există evaluări

- Vehicle Safety RegulationsDocument24 paginiVehicle Safety RegulationsMathusuthanan MariilayarajaÎncă nu există evaluări

- 466: Drive Shaft, Constant Velocity Joint, Drive Shaft Gear, B4164T, MPS6 Drive Shaft RightDocument4 pagini466: Drive Shaft, Constant Velocity Joint, Drive Shaft Gear, B4164T, MPS6 Drive Shaft RightojopodoabeÎncă nu există evaluări

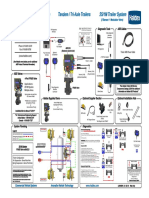

- PLC Select System 2S/1M Trailer System Tandem / Tri-Axle TrailersDocument1 paginăPLC Select System 2S/1M Trailer System Tandem / Tri-Axle TrailersDimaÎncă nu există evaluări

- Fuller Heavy Duty Transmissions TRDR0500: Driver InstructionsDocument20 paginiFuller Heavy Duty Transmissions TRDR0500: Driver InstructionsBart JohnÎncă nu există evaluări