Documente Academic

Documente Profesional

Documente Cultură

Hydroelectric Power Plant Guide

Încărcat de

fukscribdTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Hydroelectric Power Plant Guide

Încărcat de

fukscribdDrepturi de autor:

Formate disponibile

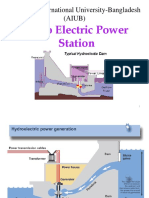

American International University-Bangladesh

(AIUB)

Hydro Electric Power

Station

1

2

3

4

5

6

Hydro Power

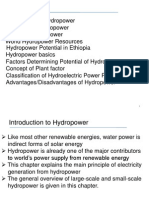

Hydro-electric power is the power obtained from the energy of falling water where

as hydro-electric power plant is the power plant utilizing the potential energy of water at

a high level for the generation of electrical energy.

Hydro-electric power plants, however, can not be located everywhere. Firstly there

must be an ample quantity of water at sufficient head and secondly a suitable site must

be available. The amount of power that can be developed depends on the quantity of

water available, the rate at which it is available, the head etc. The electrical power, P

developed is given by the expression:

P = w Q H 9.81 watts

where w = specific weight of water in kg/m3

Q = rate of flow of water in m3/s

H = height of fall or head in metres

and = efficiency of generation.

In a hydro-electric power station, water head is created by constructing a dam across a

river or lake. The pressure head of water or kinetic energy of water is utilized to drive

the water turbines coupled to alternators and, therefore, generation of electrical power.

7

Ten of the largest hydroelectric producers

Major schemes under construction

Major schemes under construction

Worlds 5 largest dams

Three Gorges Dam, China

Merits of Hydro-electric Power Plants

Hydro-electric power plants offer many distinct advantages over other power plants.

These advantages can be summarized as under:

No fuel is required by such plants as water is the source of energy. Hence

operating costs are low and there are no problems of handling and storage of fuels

and disposal of ash.

The plant is highly reliable and it is cheapest in operation and maintenance.

The plant can be run up and synchronized in a few minutes.

The load can be varied quickly and the rapidly changing load demands can be

met without any difficulty.

Very acute governing is possible with water turbines so such power plants have

constant speed and hence constant frequency.

There are no standby losses in such plants.

Such plants are robust and have got longer life (around 50 years).

The efficiency of such plants does not fall with the age.

It is very neat and clean plant because no smoke or ash is produced.

Highly skilled engineers are required only at the time of construction but later on

only a few experienced persons will be required.

Such plants in addition to generation of electric power also serve other purposes

such as irrigation and flood control.

15

Demerits of Hydro-electric Power Plants

However, the hydro-electric power plants have the following demerits also:

It requires large area.

Its construction cost is enormously high and takes long time for erection

(owing to involvement of huge civil engineering works).

Long transmission lines are required as the plants are located in hilly areas

which are quite away from the load centre.

The output of such plants is never constant owing to vagaries of monsoons

and there dependence on the rate of water flows in a river. Long dry seasons

may affect the power supply.

Hydro-electric power plant reservoir submerges huge areas, uproots large

population and creates social and other problems.

16

Site Selection of Hydro-electric Power Plants

The hydro-electric power plant is only a small part of the whole project. The

power station should be near the dam and storage reservoir. Such a location

reduces the length of the penstock and the loss of head in the penstock. In

view of this, several structures such as dam, intake, surge tank, power house

are involved in the site selection.

The essential requirements for hydro-schemes are: large catchment areas, high

rainfall, step gradients, favorable site for reservoir, solid sub-soil etc.

Many factors have to be considered in the selection but the following are the

most important:

Availability of water

Water storage

Head of water

Geological investigation

Water pollution

Sedimentation

Environmental effects

Access to site

17

Hydrograph:

Hydrograph shows the variation of stream flow in m

3

/sec with

time for a particular river site. The time may be hour, week,

month or year. It is similar to the chronological load curve.

A hydrograph provides the following information:

The discharge at any time during the period under

consideration.

The maximum and minimum run off during the period.

The mean run off during the period.

Total volume of flow up to any time is given by the area under

the curve up to that point.

18

Hydrograph:

J F M A M J J A S A N D

2500

2000

1500

1000

500

0

MONTHS

R

U

N

O

F

F

i

n

m

3

/

s

e

c

J F M A M J J A S A N D

2500

2000

1500

1000

500

0

MONTHS

R

U

N

O

F

F

i

n

m

3

/

s

e

c

J F M A M J J A S A N D

2500

2000

1500

1000

500

0

MONTHS

R

U

N

O

F

F

i

n

m

3

/

s

e

c

J F M A M J J A S A N D

2500

2000

1500

1000

500

0

MONTHS

R

U

N

O

F

F

i

n

m

3

/

s

e

c

Figure: Hydrograph of a flashy river

Figure: Hydrograph of a river

with steady flow

19

Flow Duration Curve

Flow duration curve is a re-

arrangement of all the stream flow

elements of a hydrograph in a

descending order. It is similar to

the load duration curve. Each point

on a flow duration curve shows the

percentage time during the period

when the flow was equal or greater

than the given value. The area

under a flow duration curve gives

the total quantity of run off during

that period.

0 20 40 60 80 100

2500

2000

1500

1000

500

0

PERCENT OF TIME

R

U

N

O

F

F

i

n

m

3

/

s

e

c

0 20 40 60 80 100

2500

2000

1500

1000

500

0

PERCENT OF TIME

R

U

N

O

F

F

i

n

m

3

/

s

e

c

Figure: Flow duration curve

20

Mass Curve

A mass curve indicates the total volume of

run off in cubic metre up to a certain

time. The abscissa can be a day, month

or year. The slope of the curve at any

point shows the rate of flow at that time.

If the rainfall is uniform throughout the

year, the mass curve will be straight

line having a uniform slope. Mass

curves are used in estimating the

capacity of storage reservoir in hydro-

projects.

The ordinate of mass curve can also be

plotted in terms of second-metre-day or

second-metre-month which means the

flow collected at a rate of one cubic

metre per second for one day or one

month respectively.

1 second-metre-month = 1 30 24 60

60

= 25,92,000 cubic metre.

Figure: Mass curve

J F M A M J J A S A N D

12000

10000

8000

6000

4000

2000

0

MONTHS

S

e

c

o

n

d

-

m

e

t

e

r

-

m

o

n

t

h

s

J F M A M J J A S A N D

12000

10000

8000

6000

4000

2000

0

MONTHS

S

e

c

o

n

d

-

m

e

t

e

r

-

m

o

n

t

h

s

21

PROBLEMS TO SOLVE

1. A hydro-electric power plant operates under an effective head of 50 m

and a discharge of 94 m

3

/sec. Determine the power developed.

[46.107 MW]

2. The mean monthly discharge at a particular site is given below:

Month

Discharge

in m

3

/sec

Month Discharge

in m

3

/sec

January

February

March

April

May

June

200

400

600

2400

1200

1800

July

August

September

October

November

December

1600

1200

2000

1200

800

400

Draw the hydrograph, flow duration curve and mass curve.

Determine the average inflow and the power that can be developed at an

effective head of 90 m.

Determine the capacity of the storage reservoir based on the above one

year data neglecting the losses due to seepage, evaporation etc. Assume

overall generation efficiency to be 80%. [1150 m

3

/sec, 812.268 MW,

3350 second-metre-months]

PROBLEMS TO SOLVE

3. A hydro-electric power station is supplied from a reservoir of capacity 3 10

7

m

3

at

a head of 150 m. Determine the total energy available if the overall efficiency of the

plant is 70%. [8.58375 10

6

KWH]

4. A hydro-electric power station is supplied from a reservoir having an area of 50 km

2

and a head of 50 m. If the overall efficiency of the plant be 60%, find the rate at which

the water level will fall when the station is generating 30,000 KW. [7.337 mm/hour]

5. A hydro-electric scheme has a catchment area of 120 sq. km. The available run off is

50% with annual rainfall of 100 cm. A head of 250 m is available on the average.

Efficiency of the power plant is 70%. Find (i) average power produced and (ii) capacity

of the plant assuming the load factor to be 0.6. [(i) 3,266 KW, (ii) 5,443 KW]

6. A hydro-electric power station is supplied from a catchment area of 150 km

2

with an

annual rainfall of 200 cm and effective head of 300 metres. Assuming a yield factor of

60%, calculate (i) the available continuous power, (ii) the rating of the generator

installed [assume the load factor as 0.6] and (iii) net energy available in kwh.

[(i) [12598.46 KW, (ii) 21 MW, (iii) 110.3625 10

6

KWH]

7. A hydro-electric power station is supplied from a catchment area of 480 km

2

with an

annual rainfall of 1100 mm and effective head of 40 metres. 20% of the rainfall is lost

due to evaporation etc. The loss of head in the penstock is estimated to be 10%. The

turbine efficiency is 85% and the generator efficiency is 92%. Find capacity of the

plant assuming the load factor to be 0.6. [6.17 MW]

PROBLEMS TO SOLVE

5. A hydro-electric scheme has a catchment area of 120 sq. km. The available run off is

50% with annual rainfall of 100 cm. A head of 250 m is available on the average.

Efficiency of the power plant is 70%. Find (i) average power produced and (ii) capacity

of the plant assuming the load factor to be 0.6.

6. A hydro-electric power station is supplied from a catchment area of 150 km

2

with an

annual rainfall of 200 cm and effective head of 300 metres. Assuming a yield factor of

60%, calculate (i) the available continuous power, (ii) the rating of the generator

installed [assume the load factor as 0.6] and (iii) net energy available in kwh.

7. A hydro-electric power station is supplied from a catchment area of 480 km

2

with an

annual rainfall of 1100 mm and effective head of 40 metres. 20% of the rainfall is lost

due to evaporation etc. The loss of head in the penstock is estimated to be 10%. The

turbine efficiency is 85% and the generator efficiency is 92%. Find capacity of the

plant assuming the load factor to be 0.6.

PROBLEMS TO SOLVE

2. The mean monthly discharge at a particular site is given below:

Month

Discharge

in m

3

/sec

Month Discharge

in m

3

/sec

January

February

March

April

May

June

200

400

600

2400

1200

1800

July

August

September

October

November

December

1600

1200

2000

1200

800

400

Draw the hydrograph, flow duration curve and mass curve.

Determine the average inflow and the power that can be developed at an

effective head of 90 m.

Determine the capacity of the storage reservoir based on the above one

year data neglecting the losses due to seepage, evaporation etc. Assume

overall generation efficiency to be 80%.

Schematic Arrangement of a Hydro-

Electric Power Plant

The chief requirement for hydro-electric power plant is the availability of

water in huge quantity at sufficient head and this requirement can be met

by constructing a dam across a river or lake. The schematic arrangement

is shown in the following figure.

RESERVOIR

DAM

PRESSURE TUNNEL

SURGE TANK

TAIL

RACE

VALVE

HOUSE

PENSTOCK

POWER HOUSE

RESERVOIR

DAM

PRESSURE TUNNEL

SURGE TANK

TAIL

RACE

VALVE

HOUSE

PENSTOCK

POWER HOUSE

34

Schematic Arrangement of a Hydro-

Electric Power Plant

RESERVOIR

DAM

PRESSURE TUNNEL

SURGE TANK

TAIL

RACE

VALVE

HOUSE

PENSTOCK

POWER HOUSE

RESERVOIR

DAM

PRESSURE TUNNEL

SURGE TANK

TAIL

RACE

VALVE

HOUSE

PENSTOCK

POWER HOUSE

An artificial storage reservoir is formed by

constructing a dam across a river (or lake) and a

pressure tunnel is taken off from the reservoir to the

valve house at the start of the penstock. The valve house

contains main sluice valves for controlling water flow to the

power station and automatic isolating valves for cutting off water

supply in case the penstock bursts. A surge tank is also provided

just before the valve house for better regulation of water pressure in

the system. From the reservoir the water is carried to valve house through

pressure tunnel and from valve house to the water turbine through pipes of

large diameter made of steel or reinforced concrete, called the penstock. The

water turbine converts hydraulic energy into mechanical energy and the

alternator coupled to the water turbine converts mechanical energy into

electrical energy. Water after doing useful work is discharged to the tail race.

35

Important Elements of a Hydro-Electric

Power Plant

A hydro-electric plant consists of a reservoir for storage of water, a diversion dam,

an intake structure for controlling and regulating the flow of water, a conduit

system to carry the water from the intake to the water wheel, the turbines

coupled with generators, the draft tube for conveying water from water wheel to

the tailrace, the tailrace and a power house i.e. is the building to contain the

turbines, generators, the accessories and other miscellaneous items. Few of these

elements are discussed below:

Storage Reservoir

Dam

Forebay

Spillway

Intake

Surge Tank

Penstock

Tail Race

36

37

38

39

40

Classification of Hydro-electric Power Plants

The hydro-electric power plants may be classified according to (i) the extent of

water flow regulation available (ii) the availability of water head and (iii) the

type of load they supply.

(i) According to the extent of water flow regulation available the hydro-electric

power plants may be classified into:

Run-off River Power Plants without Pondage

Run-off River Power Plants with Pondage

Reservoir Power Plants

(ii) According to availability of water head the hydro-electric plants may be

classified into:

Low Head Hydro-electric Power Plants

Medium Head Hydro-electric Power Plants

High Head Hydro-electric Power Plants

(iii) According to the load supplied the hydro-electric power plants may be

classified into:

Base Load Plants

Peak Load Plants

Pumped Storage Power Plants for Peak Load

41

Classification of Hydro-electric Power Plants

Some hydro-power plants are so located that the water is taken

from the river directly, and no pondage or storage is possible.

Such plants are called the run-off river power plants without pondage.

Such plants can use water only as and when available; these can

not be used at any time at will or fit any desired portion of the

load curve. In such plants there is no control on flow of water.

During high flow and low load periods, water is wasted and

during the lean flow periods the plant capacity is very low.

Such plants can be built at a considerably low cost. During the

high flow periods such plants can be employed to supply a

substantial portion of base load.

Run-off River Power Plants without Pondage

42

Classification of Hydro-electric Power Plants

Pondage refers to storage at the plant to take care of hour to

hour fluctuations in load on the station. Pondage increases the

firm capacity of the of the station provided that the floods do

not raise the tail race water level thus reducing the effective

water head and plant output. Such plants can serve as base load

or peak load plants depending on the stream flow. When plenty

of water is available, these plants can be used as base load

plants. When stream flow decreases, these plants can be made

to work as peak load plants.

Run-off River Power Plants with Pondage

43

Classification of Hydro-electric Power Plants

When water is stored in a big reservoir behind a dam, it is

possible to control the flow of water and use it most effectively.

Storage increases the firm capacity of the plant and it can be

used efficiently throughout the year. Such a plant can be used

as a base load plant or as a peak load plant as per requirement

depending the water stored in the reservoir, the rate of inflow

and the system load. Most of the hydro-electric power plants,

everywhere in the world, belong to this category.

Reservoir Power Plants

44

Classification of Hydro-electric Power Plants

When water head is less than 30 m, the plant is called a low

head plant. A dam or barrage across the river creates the

necessary head. The power plant is located near the dam and,

therefore, no surge tank is needed. Either one half of the

barrage has regulating gates for discharge of surplus water

while the plant is in front of the second half or the plant is

constructed by the side of the river. Francis or Kaplan turbines

are used.

Low Head Hydro-electric Power Plants:

45

Classification of Hydro-electric Power Plants

Medium head plants operate at heads between 30 & 100 metres.

An open channel brings water from main reservoir to the

forebay from where penstocks carry water to the turbines.

Francis or Kaplan turbines are used.

Medium Head Hydro-electric Power Plants:

46

Classification of Hydro-electric Power Plants

The plants operating at heads above 100 m are generally

classified as high head plants. The civil works for these plants

include dam, reservoir, tunnel, surge tank and penstock.

Generally Francis turbines are used for heads below 200 m and

Pelton turbines for still higher heads.

High Head Hydro-electric Power Plants:

47

Classification of Hydro-electric Power Plants

They feed the base load of the system. Thus they supply almost

constant load throughout and operate on a high load factor.

Base plants are usually of large capacity. Run-off river power

plants without pondage and reservoir power plants are used as

base load plants. For a plant to be used as base load plant, the

unit cost of energy generated by the plant should be low.

Base Load Plants:

48

Classification of Hydro-electric Power Plants

They are meant to supply the peak load of the system. Run-off

river power plants with pondage can be used as peak load

plants during lean flow periods. Reservoir power plants can, of

course, be used as peak load plants also. Peak load plants have

large seasonal storage. They store water during off-peak

periods and are run during peak load periods. They operate at a

low load factor.

Peak Load Plants:

49

Classification of Hydro-electric Power Plants

This is a unique design of peak load plant in which the plant

pumps back all or a portion of its water supply during low load

period. The usual construction is a tail water pond and a head

water pond connected through a penstock. The plant utilizes

some of the surplus energy generated by the base load plant to

pump the water from the tail water pond into the head water

pond during off peak hours. During peak load period this

water is used to generate power by allowing it to flow from the

head water pond through the water turbine to the tail water.

The capacity of the plant should be such that the plant can

supply the peak load for 4 to 10 hours. The plants can be used

in conjunction with hydro, steam and I.C. engine plants. This

plant is also called a hydraulic accumulator system.

Pumped Storage Power Plants for Peak Load:

50

Classification of Hydro-electric Power Plants

Pumped Storage Power Plants for Peak Load:

DAM

HEAD

WATER

LEVEL

TAIL

WATER

POND

POWER

HOUSE,

TURBINES

AND PUMPS

PENSTOCK

DAM

HEAD

WATER

POND

DAM

HEAD

WATER

LEVEL

TAIL

WATER

POND

POWER

HOUSE,

TURBINES

AND PUMPS

PENSTOCK

DAM

HEAD

WATER

POND

Figure: Pumped Storage Power Plant

51

Classification of Hydro-electric Power Plants

52

Classification of Hydro-electric Power Plants

In the older plants separate motor driven pumps and turbine driven generators

were used. A recent development is a reversible turbine pump. Francis

turbine, which is just the reverse of Centrifugal pump, is normally used.

During peak loads, the turbine drives the alternator and the plant generates

electrical energy. During low loads, the alternator runs as a motor and drives

the turbine which now works as a pump for pumping the water into the head

water pond. This arrangement reduces the capital cost of the plant. The power

for driving the motor is taken from the system.

The efficiency of the plant is around 60 to 70 percent. Some water may

evaporate from the head water pond resulting in the reduction in the stored

energy or there might be run off through the soils. Also there will be some

energy loss in generating and pumping equipment and in power transmission.

Such plant can be operated only in inter-connected systems where other types

of generating plants, such as steam, nuclear, hydro, diesel plants, are available.

In carrying the peak loads of the system, such plants reduces the operating

costs of the steam or nuclear plants working in combination with them by

improving the load factor of the steam or nuclear plant and added capacity to

meet peak loads

Pumped Storage Power Plants for Peak Load:

53

Advantages of Pumped Storage Power Plants

Pumped storage power plants have some very

important advantages. Some of these are given below:

Peak loads can be supplied at lower cost than that when

supplied by steam and nuclear power plants.

The steam and nuclear power plants can be operated at almost

unity load factor which ensures their most efficient and

economic operation.

Because of their ability to take up loads in a very short time

(pumped storage plants need a starting time of only 2-3 seconds

and can be loaded fully in about 15 seconds), the spinning

reserve requirement of the system is reduced.

In the event of extra demand coming up suddenly on the

system, such plants can be immediately switched on to meet

this extra demand.

They can be used for load frequency control.

54

S-ar putea să vă placă și

- Hydro Electric Power PlantDocument61 paginiHydro Electric Power PlantBese MatÎncă nu există evaluări

- Introduction Synopsis Hydro Power PlantDocument7 paginiIntroduction Synopsis Hydro Power PlantSuresh KumarÎncă nu există evaluări

- Chapter 8Document6 paginiChapter 8Paulo AzañeroÎncă nu există evaluări

- Hydraulic Turbine IDocument27 paginiHydraulic Turbine IRam Krishna Singh100% (3)

- Hydropower PlantDocument23 paginiHydropower PlantAsad RazaÎncă nu există evaluări

- Machine Elements L2Document31 paginiMachine Elements L2Julie Ann D. GaboÎncă nu există evaluări

- Ideal Rankine Cycle ExplainedDocument12 paginiIdeal Rankine Cycle ExplainedAarvin GeorgeÎncă nu există evaluări

- Ref Systems Lecture Notes 1Document9 paginiRef Systems Lecture Notes 1Retro GamerÎncă nu există evaluări

- Solar Space Heating and Cooling System For Buildings: Present byDocument14 paginiSolar Space Heating and Cooling System For Buildings: Present byJay KakadiyaÎncă nu există evaluări

- LECTURE NOTES Industrial ProcessessDocument19 paginiLECTURE NOTES Industrial ProcessessjaycobsmillanÎncă nu există evaluări

- A. Otto Cycle (Gasoline Engine)Document22 paginiA. Otto Cycle (Gasoline Engine)John Manuel BautistaÎncă nu există evaluări

- ME 361 Exam 3 problems entropy generation rates refrigerant 134aDocument5 paginiME 361 Exam 3 problems entropy generation rates refrigerant 134aAugi Reader50% (2)

- Engineering EssayDocument2 paginiEngineering EssayMidz SantayanaÎncă nu există evaluări

- Cooling Tower Refrigeration CapacityDocument28 paginiCooling Tower Refrigeration Capacityboj VillanuevaÎncă nu există evaluări

- Speed Measuring InstrumentsDocument7 paginiSpeed Measuring InstrumentsJoshua GarciaÎncă nu există evaluări

- Combined Cycle Power PlantDocument5 paginiCombined Cycle Power PlantarhamÎncă nu există evaluări

- Power Generation PDFDocument59 paginiPower Generation PDFyasinÎncă nu există evaluări

- Magat DamDocument7 paginiMagat DamJennie Vicenta0% (1)

- Internal Combustion Engines GuideDocument16 paginiInternal Combustion Engines GuideAshton SelokaÎncă nu există evaluări

- 2-The Variable LoadDocument14 pagini2-The Variable LoadPotatoFryÎncă nu există evaluări

- Me Lab 3Document27 paginiMe Lab 3Jerome Vega AndesÎncă nu există evaluări

- Chapter 6 - Geothermal Power Plant ReviewerDocument7 paginiChapter 6 - Geothermal Power Plant ReviewerKyle YsitÎncă nu există evaluări

- HEAT TRANSFER: CONDUCTION, CONVECTION & RADIATIONDocument33 paginiHEAT TRANSFER: CONDUCTION, CONVECTION & RADIATIONAlex Philip0% (1)

- Chapter - 3 - Hydraulic TurbinesDocument78 paginiChapter - 3 - Hydraulic TurbinesLauria LavdaÎncă nu există evaluări

- PIPE Ch19Document105 paginiPIPE Ch19JvÎncă nu există evaluări

- CHAP 3 Gas - Power CyclesDocument88 paginiCHAP 3 Gas - Power CyclesMuez GhideyÎncă nu există evaluări

- Thermal Engineering AssignmentsDocument8 paginiThermal Engineering Assignmentsnims1964Încă nu există evaluări

- Bottle Blow Down AnalysisDocument45 paginiBottle Blow Down AnalysisDoctorOberman100% (2)

- Module 5 Gas Power CyclesDocument26 paginiModule 5 Gas Power CyclesJatskinesisÎncă nu există evaluări

- Vapor Power CyclesDocument55 paginiVapor Power CyclesTarikuÎncă nu există evaluări

- Vapor Compression Refrigeration SystemDocument11 paginiVapor Compression Refrigeration Systemm_alodat6144Încă nu există evaluări

- Guide to Developing Small Hydro Power in GeorgiaDocument48 paginiGuide to Developing Small Hydro Power in GeorgiaDawit AbrahamÎncă nu există evaluări

- Boiler Heat Balance BreakdownDocument3 paginiBoiler Heat Balance BreakdownJk Pascii100% (1)

- Thermal Questions KonguDocument9 paginiThermal Questions Konguabu19870% (1)

- Unit Viib Fans and BlowersDocument8 paginiUnit Viib Fans and BlowersRaffy Calamonte CanoyÎncă nu există evaluări

- OBE Syllabus - ME 413 ME Lab 01Document3 paginiOBE Syllabus - ME 413 ME Lab 01Jerico Llovido100% (1)

- Performance Test of A Non-Positive Displacement PumpDocument7 paginiPerformance Test of A Non-Positive Displacement PumpBOSS BabyÎncă nu există evaluări

- Agricultural Power and Energy EngineeringDocument40 paginiAgricultural Power and Energy EngineeringBlack PhanterÎncă nu există evaluări

- Problem Set No 1pdfpdf PDF FreeDocument87 paginiProblem Set No 1pdfpdf PDF FreeMaria Perez100% (1)

- Promlem 1: A) The Discharge Through The Penstock. B) The Mean Annual Energy ProductionDocument4 paginiPromlem 1: A) The Discharge Through The Penstock. B) The Mean Annual Energy ProductionbkkbrazilÎncă nu există evaluări

- Fdocuments - in Otto Cycle PresentationDocument97 paginiFdocuments - in Otto Cycle PresentationUTSAV KUMARÎncă nu există evaluări

- Mechanical Engineers in SocietyDocument17 paginiMechanical Engineers in SocietyMarianneÎncă nu există evaluări

- Hydro Electric Power PlantDocument10 paginiHydro Electric Power PlantShreya ShahÎncă nu există evaluări

- Hydro Electric GeneratorDocument8 paginiHydro Electric Generatoryoichiackerman21Încă nu există evaluări

- Exercise-1: Ans.: 5 MW, 360 MWH, 500 Mwh/DayDocument2 paginiExercise-1: Ans.: 5 MW, 360 MWH, 500 Mwh/DayAbreu Miguel Liliano LilianoÎncă nu există evaluări

- ME 463 Wind Energy AssignmentDocument3 paginiME 463 Wind Energy AssignmentEngr Hafiz Umar100% (1)

- Front Page and Expirement Number 1Document3 paginiFront Page and Expirement Number 1Ron Kristian OpolintoÎncă nu există evaluări

- Hydroelectric Power Plant Set of ProblemsDocument3 paginiHydroelectric Power Plant Set of ProblemsJames Tnecniv Alborte100% (2)

- 2.2.2. Heat Conduction in Cylinders and Spheres: Onduction C Eat H Teady S Wo TDocument9 pagini2.2.2. Heat Conduction in Cylinders and Spheres: Onduction C Eat H Teady S Wo TRaghav SureshÎncă nu există evaluări

- A PROPOSAL On Speed Generation Using Speed BreakerDocument14 paginiA PROPOSAL On Speed Generation Using Speed Breakercobra29190% (1)

- Formulas in Cooling TowerDocument6 paginiFormulas in Cooling TowerGringoÎncă nu există evaluări

- ACE Engineering Academy Mock Test 1 Mechanical Engineering Paper 1Document15 paginiACE Engineering Academy Mock Test 1 Mechanical Engineering Paper 1vidya chakitwarÎncă nu există evaluări

- Theories of failure: Maximum principal stress, shear stress and strain energyDocument2 paginiTheories of failure: Maximum principal stress, shear stress and strain energyBas KaranÎncă nu există evaluări

- Hydro - Power 2020 SpringDocument49 paginiHydro - Power 2020 SpringElisabeth Burnett MartinÎncă nu există evaluări

- Micro-Hydro Power GuideDocument8 paginiMicro-Hydro Power Guidelucas.barravaiteÎncă nu există evaluări

- Introduction to Hydropower OutlineDocument45 paginiIntroduction to Hydropower Outlinekass00488_18085260975% (4)

- Energy ConversionDocument47 paginiEnergy Conversionkass00488_18085260988% (8)

- Module 4 Notes 18ME81Document25 paginiModule 4 Notes 18ME81Zoic GamingÎncă nu există evaluări

- Micro-Hydro Power PDFDocument8 paginiMicro-Hydro Power PDFPedro Teixeira100% (1)

- Tidal Power: Harnessing Energy from Water CurrentsDe la EverandTidal Power: Harnessing Energy from Water CurrentsÎncă nu există evaluări

- Transformer Math FormulaDocument4 paginiTransformer Math FormulafukscribdÎncă nu există evaluări

- Finally, An Easy, Affordable Breath Test For Small Intestine Bacterial Overgrowth (SIBO) !Document1 paginăFinally, An Easy, Affordable Breath Test For Small Intestine Bacterial Overgrowth (SIBO) !fukscribdÎncă nu există evaluări

- Irritable Bowel Syndrome Mechanisms and Dietary ManagementDocument42 paginiIrritable Bowel Syndrome Mechanisms and Dietary ManagementfukscribdÎncă nu există evaluări

- (Arcexam - In) MCQs On Computer by Dr. Alok KumarDocument149 pagini(Arcexam - In) MCQs On Computer by Dr. Alok KumarBalajiÎncă nu există evaluări

- Active Passive+sol 4Document121 paginiActive Passive+sol 4aayushcooolzÎncă nu există evaluări

- Adapted Gaps Intro DietDocument2 paginiAdapted Gaps Intro DietfukscribdÎncă nu există evaluări

- Adapted Gaps Intro DietDocument2 paginiAdapted Gaps Intro DietfukscribdÎncă nu există evaluări

- Idioms New PDFDocument61 paginiIdioms New PDFshothapp100% (2)

- High and Low Fod Map FoodsDocument1 paginăHigh and Low Fod Map FoodsfukscribdÎncă nu există evaluări

- MAPS Diet FoodsDocument1 paginăMAPS Diet FoodsMartin HaynesÎncă nu există evaluări

- Idioms New PDFDocument61 paginiIdioms New PDFshothapp100% (2)

- (Arcexam - In) MCQs On Computer by Dr. Alok KumarDocument149 pagini(Arcexam - In) MCQs On Computer by Dr. Alok KumarBalajiÎncă nu există evaluări

- Active Passive+sol 4Document121 paginiActive Passive+sol 4aayushcooolzÎncă nu există evaluări

- (PDF Download) Design Electrical Comput Engineers Full Online by J. Eric SaltDocument1 pagină(PDF Download) Design Electrical Comput Engineers Full Online by J. Eric SaltfukscribdÎncă nu există evaluări

- Hasbunallahu Wa Nimal Wakeel Nimal Maula Wa Niman Naseer1 PDFDocument12 paginiHasbunallahu Wa Nimal Wakeel Nimal Maula Wa Niman Naseer1 PDFfukscribd100% (2)

- Level I 2016 2017 Program ChangesDocument2 paginiLevel I 2016 2017 Program ChangesIam JaiÎncă nu există evaluări

- (PDF Download) Design Electrical Comput Engineers Full Online by J. Eric SaltDocument1 pagină(PDF Download) Design Electrical Comput Engineers Full Online by J. Eric SaltfukscribdÎncă nu există evaluări

- C CheatsheetDocument74 paginiC CheatsheetRoberto Solano100% (6)

- 42TH BMA SPL COURSE recruitment questionsDocument2 pagini42TH BMA SPL COURSE recruitment questionsLone SparrowÎncă nu există evaluări

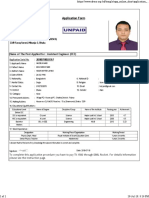

- Application - DESCO Form 2018Document1 paginăApplication - DESCO Form 2018fukscribdÎncă nu există evaluări

- Application - DESCO Form 2018Document1 paginăApplication - DESCO Form 2018fukscribdÎncă nu există evaluări

- Hasbunallahu Wa Nimal Wakeel Nimal Maula Wa Niman Naseer1 PDFDocument12 paginiHasbunallahu Wa Nimal Wakeel Nimal Maula Wa Niman Naseer1 PDFfukscribd100% (2)

- Application - DESCO Form 2018Document1 paginăApplication - DESCO Form 2018fukscribdÎncă nu există evaluări

- Wel Cfa b2b Cfa Level1 Graphic FinalDocument1 paginăWel Cfa b2b Cfa Level1 Graphic FinalDhruv JoshiÎncă nu există evaluări

- 9 10 16 - Civicscitizenship Bangla PDFDocument150 pagini9 10 16 - Civicscitizenship Bangla PDFSharmeen HelalÎncă nu există evaluări

- Shushanta Paul English NoteDocument29 paginiShushanta Paul English NotefukscribdÎncă nu există evaluări

- FASTRAC IC Design Company - 2018Document2 paginiFASTRAC IC Design Company - 2018fukscribdÎncă nu există evaluări

- Austen Jane Pride PrejudiceDocument201 paginiAusten Jane Pride PrejudicefukscribdÎncă nu există evaluări

- Level I 2016 2017 Program ChangesDocument2 paginiLevel I 2016 2017 Program ChangesIam JaiÎncă nu există evaluări

- PizzaDocument164 paginiPizzaGyu Bot100% (3)

- 0 Proposal Form Top Up SUBMITTED BY Markandeya Raju PDFDocument3 pagini0 Proposal Form Top Up SUBMITTED BY Markandeya Raju PDFHOD (MVGR Civil)Încă nu există evaluări

- InkscapePDFLaTeX PDFDocument3 paginiInkscapePDFLaTeX PDFFrancesco ReaÎncă nu există evaluări

- Detection of Phising Websites Using Machine Learning ApproachesDocument9 paginiDetection of Phising Websites Using Machine Learning Approachesshresthabishal721Încă nu există evaluări

- Data Sheet 3VA2225-5HL32-0AA0: ModelDocument7 paginiData Sheet 3VA2225-5HL32-0AA0: ModelJENNYÎncă nu există evaluări

- Intra Cell HODocument10 paginiIntra Cell HOMostafa Mohammed EladawyÎncă nu există evaluări

- Soft ListDocument21 paginiSoft Listgicox89Încă nu există evaluări

- Bus 102 QuestionsDocument4 paginiBus 102 Questionsali2aliyuÎncă nu există evaluări

- Application Letter for Experienced Telecommunications TechnicianDocument5 paginiApplication Letter for Experienced Telecommunications TechnicianRaymondÎncă nu există evaluări

- Tough Turkish TBM Moves Through Fractured and Faulted Rock: Issue 1 + 2014Document8 paginiTough Turkish TBM Moves Through Fractured and Faulted Rock: Issue 1 + 2014sCoRPion_trÎncă nu există evaluări

- Innovative Uses of Housing Lifting Techniques-JIARMDocument16 paginiInnovative Uses of Housing Lifting Techniques-JIARMPOOJA VÎncă nu există evaluări

- DamaDocument21 paginiDamaLive Law67% (3)

- Development Approach PlanDocument15 paginiDevelopment Approach PlanGaurav UpretiÎncă nu există evaluări

- Introduction To Circuit LabDocument8 paginiIntroduction To Circuit LabDaudKhanÎncă nu există evaluări

- Container Stowage Plans ExplainedDocument24 paginiContainer Stowage Plans ExplainedMohd akifÎncă nu există evaluări

- Spjc/Lim Lima-Callao, Peru: .Radar - Minimum.AltitudesDocument41 paginiSpjc/Lim Lima-Callao, Peru: .Radar - Minimum.AltitudesVicente PortocarreroÎncă nu există evaluări

- ASTM D 529 - 00 Enclosed Carbon-Arc Exposures of Bituminous MaterialsDocument3 paginiASTM D 529 - 00 Enclosed Carbon-Arc Exposures of Bituminous Materialsalin2005Încă nu există evaluări

- Globalization of Religion Chapter SummaryDocument2 paginiGlobalization of Religion Chapter SummaryKaye KateÎncă nu există evaluări

- Emergency Incidents AssignmentDocument4 paginiEmergency Incidents Assignmentnickoh28Încă nu există evaluări

- Marine Products Systems CatalogueDocument97 paginiMarine Products Systems CatalogueJhonnatan Quispe Franco100% (1)

- Module 2 - Introduction To A Web-AppDocument17 paginiModule 2 - Introduction To A Web-AppJASPER WESSLYÎncă nu există evaluări

- Competition Patriotism and Collaboratio PDFDocument22 paginiCompetition Patriotism and Collaboratio PDFAngga PrianggaraÎncă nu există evaluări

- Wills and Succession ReviewerDocument85 paginiWills and Succession ReviewerYoshimata Maki100% (1)

- 2 - Brief Report On Logistics Workforce 2019Document39 pagini2 - Brief Report On Logistics Workforce 2019mohammadÎncă nu există evaluări

- TOTO Indonesia Sanitary CatalogDocument40 paginiTOTO Indonesia Sanitary CatalogiaqistiÎncă nu există evaluări

- M100 PD ENDocument2 paginiM100 PD EN윤병택Încă nu există evaluări

- Azubuko v. Motor Vehicles, 95 F.3d 1146, 1st Cir. (1996)Document2 paginiAzubuko v. Motor Vehicles, 95 F.3d 1146, 1st Cir. (1996)Scribd Government DocsÎncă nu există evaluări

- Mining Operational ExcellenceDocument12 paginiMining Operational ExcellencegarozoÎncă nu există evaluări

- Condrada v. PeopleDocument2 paginiCondrada v. PeopleGennard Michael Angelo AngelesÎncă nu există evaluări

- Tucker Northlake SLUPsDocument182 paginiTucker Northlake SLUPsZachary HansenÎncă nu există evaluări

- April 10, 2015 Strathmore TimesDocument28 paginiApril 10, 2015 Strathmore TimesStrathmore TimesÎncă nu există evaluări