Documente Academic

Documente Profesional

Documente Cultură

Bard Hvac Service Procedures (2100-479)

Încărcat de

bigcee64Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Bard Hvac Service Procedures (2100-479)

Încărcat de

bigcee64Drepturi de autor:

Formate disponibile

Manual 2100-479

Page 1 of 11

Manual No.: 2100-479

Supersedes: NEW

File: Volume I, Tab 1

Date: 03-08-07

Copyright 2007

SERVICING PROCEDURE

R-410A

LEAK TEST EVACUATION

CHARGING

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

Since 1914...Moving ahead, just as planned.

Manual 2100-479

Page 2 of 11

General

Recovery Equipment Rated for R-410A................. 3

Leak Detectors ....................................................... 3

Gauge Manifold ...................................................... 3

Attaching Gauge Manifold ...................................... 3

Attaching Manifold Hose to Schrader Valve .......... 4

Leak Test ................................................................ 4

Evacuation....................................................... 4 & 5

Charging ................................................................. 5

Preliminary Charging Steps.................................... 5

Charging the System by Weight ............................ 5

CONTENTS

Troubleshooting the Mechanical System

Air Conditioning & Heat Pump - Cooling ........... 9

Low Suction Low Head Pressure ...................... 9

High Suction Low Head Pressure...................... 9

Low Suction High Head Pressure...................... 9

High Suction High Head Pressure ..................... 9

Heat Pump - Heating ............................................ 9

Low Suction Low Head Pressure ...................... 9

High Suction Low Head Pressure...................... 9

Low Suction High Head Pressure...................... 9

High Suction High Head Pressure ..................... 9

Figures

Figure 1: Typical AC System Cooling Cycle........... 6

Figure 2: Typical HP System Cooling Cycle .......... 7

Figure 3: Heating Cycle.......................................... 8

Charts

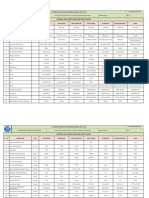

Troubleshooting Chart for Air Conditioners .......... 10

Troubleshooting Chart for Air-to-Air Heat Pumps .. 11

Manual 2100-479

Page 3 of 11

Recovery equipment rated for R-410A refrigerant

R-410A has an ozone depletion potential of zero, but must

be reclaimed due to its global warming potential.

The gauge manifold set is specially designed to withstand

the higher pressure associated with R-410A. Manifold sets

are required to range up to 800 psig on the high side and

250 psig on the low side with a 250 psig low side retard.

All hoses must have a service rating of 800 psig. (This

information will be indicated on the hoses.)

Vacuum Pump and micron gauge must be used when

evacuating a system to 500 microns.

Leak Detectors

An electronic leak detector capable of detecting HFC

refrigerant can be used with R-410A refrigerant.

GENERAL

GAUGE MANIFOLD

A necessary instrument in checking and serving air

conditioning and heat pump equipment is the gauge

manifold. Its purpose is to determine the operating

refrigerant pressures in order for the serviceman to analyze

the condition of the system.

The valving on the manifold is so arranged that when the

valves are closed (front-seated) the center port on the

manifold is closed to the gauges and gauge ports. With the

valves in the closed position, the gauge ports are still open

to the gauges, permitting the gauges to register system

pressures. Opening either valve opens the center port to

that side of the manifold and system.

ATTACHING GAUGE MANIFOLD

For leak testing, purging, checking charge, charging liquid

or evacuating, connect high pressure side of gauge manifold

to Schrader valve on liquid or discharge line. Connect

suction side of gauge manifold to Schrader valve on suction

line. On heat pumps the suction line is between compressor

and reversing valve.

WARNING

The oils used with R-410A refrigerant are

hydroscopic and absorb water from the

atmosphere readily. Do not leave systems

open to the atmosphere for more than 5

minutes. If the system has been open for

more than 5 minutes, change the filter

dryer immediately before evacuation. Then

recharge the system to the factory

specified charge.

WARNING

Gauge manifold must be suitable for use

with R-410A refrigerant and POE oils.

Manual 2100-479

Page 4 of 11

Leak Test

1. Remove gauge port cap from suction and liquid service

valve ports and attach manifold gauge hoses. Connect an

upright R-410A drum to center port of gauge manifold.

Open refrigerant drum valve and manifold high pressure

gauge valve to pressurize system to a positive pressure

with refrigerant vapor. Pressurize the complete system

with dry nitrogen, or CO2 until the pressure reaches 200

psig. Do not exceed 250 psig.

2. Close manifold high pressure gauge valve. Check all

soldered joints, including those on the evaporator coil

with an Electronic Leak Detector suitable for use with

HFC refrigerants or R-410A. If a leak is found which

requires soldering, pressure in the system must be bled

off since it is impossible to solder with unit pressurized.

Be sure all leaks are located and marked before bleeding

pressure from system.

ATTACHING MANIFOLD HOSE TO

SCHRADER VALVE

1. Remove cap from valve.

2. Make sure gauge manifold valves are closed.

3. If hose does not have an unseating pin, a number 395

Superior or equivalent unseating coupler must be used.

4. Make sure coupler is lined up straight with Schrader

valve. Screw coupler on to valve.

5. Open gauge manifold valve slightly and purge air from

hose with refrigerant.

6. Read the suction pressure on compound gauge and heat

pressure on pressure gauge.

7. To remove, push end of hose tight against end of

Schrader valve and hold in place while quickly

unscrewing coupler nut from Schrader valve.

8. Remove coupler from Schrader valve. Replace caps on

valve.

3. Close drum valve and disconnect from center port.

Release nitrogen or CO2 into the atmosphere through

suction line of gauge manifold.

4. Correct any leaks and recheck. When leaks, if any, have

been repaired, system is ready to be evacuated and

charged. Relieve all pressure from the system down to 0

psig.

5. Change the filter dryer. When leaks, if any, have been

repaired, system is ready to be evacuated and charged.

Relieve all pressure from the system down to 0 psig.

EVACUATION

Evacuation

An evacuation to 500 microns is usually sufficient to

remove moisture from a system using R-22 and mineral oil

lubricant. A 500 micron evacuation, however, will not

separate moisture from Polyol Ester oil (POE) in

R-410A systems.

In addition to a 500 micron evacuation, the liquid line filter

dryer (R-410A compatible) must be replaced any time the

system is open. When removing a filter dryer from a

system, do not use a torch; use a tubing cutter to avoid

releasing moisture back into the system.

Older R-22 leak detectors, as well as halide torch leak

detectors, will not detect leaks in R-410A systems. Never

use air and R-410A to leak check, as the mixture may

become flammable at pressures above 1 atmosphere. A

system can be safely leak-checked by using nitrogen or a

trace gas of R-410A and nitrogen.

Remember: Always use a pressure regulator with nitrogen

and a safety valve down stream - set at no more than 150

psig.

1. Evacuate system to less than 500 microns, using a

good vacuum pump and an accurate high vacuum

gauge. Operate the pump below 500 microns for 60

minutes and then close valve to the vacuum pump.

Allow the system to stand for 30 additional minutes to

be sure a 500 micron vacuum or less is maintained.

2. Disconnect charging line at vacuum pump and connect to

refrigerant supply. Crack the cylinder valve and purge

charging line at center on manifold. Then close cylinder

valve.

3. The system is now ready for the correct operating charge

of Refrigerant R-410A.

WARNING

At no time use the compressor to

evacuate the system or any part of it.

WARNING

As a safety measure, it is wise to detach

refrigerant hoses at the lowest pressure

readings on the system. To do this:

A.. Put high pressure hose B on first.

(Unit should not be running.)

B. Put low pressure hose A on second.

(Unit should be running.)

Manual 2100-479

Page 5 of 11

R-410A System Charging

Even though R-410A has a very small fractionation

potential, it cannot be ignored completely when charging.

To avoid fractionation, charging of an air conditioner or

heat pump system incorporating R-410A shall be done with

liquid to maintain optimum system performance. To

insure that the proper blend composition is charged into the

system, it is important that liquid only be removed from the

charging cylinder. Some cylinders supplied by

manufacturers have dip tubes, which allow liquid refrigerant

to be removed from the cylinder when it is in the upright

position. Cylinders without dip tubes have to be tipped

upside down in order for liquid to be removed. The Service

Technician must differentiate between which type of

charging cylinder they are using to avoid removing vapor

refrigerant instead of liquid refrigerant to avoid

fractionation and for safety concerns.

Connect the gauge manifold to the high and low side.

Allow liquid to enter the high side only. The high side will

hold 80-100% of the total charge. When liquid stops

flowing, close high side port. The remainder of the charge

will be added to the low side. Keep in mind two issues:

first, never start the compressor with less than 55 psig of

suction pressure. Secondly, make sure the liquid is

throttled, thus vaporized into the low side of the system to

avoid compressor damage. A throttling valve can be used to

insure that liquid is converted to vapor prior to entering the

system. Proper manipulation (restricting) of the manifold

gauge set can also act as a throttling device to insure liquid

is not entering the compressor.

CHARGING

1. Single Package Units Refer to the unit serial plate for

the full operating charge.

PRELIMINARY CHARGING STEPS

If the system has been open to the atmosphere, the filter

dryer should be replaced and then evacuated. Then proceed

as follows:

1. Attach a drum of proper, clean refrigerant to the center

port of the charging manifold with one of the charging

hoses.

2. Attach a second charging hose to the suction gauge (low

pressure) side of the gauge manifold.

3. Remove the cap from the suction line valve.

4. Loosely attach the suction gauge hose to the line valve.

Open the valve on the refrigerant drum and the suction

valve on the charging manifold slightly to purge the air

from the manifold and hoses before tightening the fitting.

5. Attach the third hose to the high pressure side of the

manifold and the liquid line valve. Repeat steps 3 and 4

above.

CHARGING THE SYSTEM BY WEIGHT

1. Connect manifold as instructed.

2. Place refrigerant drum upright on scale and determine

exact weight of the refrigerant and cylinder.

3. With manifold suction valve closed and manifold

discharge valve open, open refrigerant cylinder liquid

valve and allow pressure in system to balance with

pressure of cylinder or 80% of charge is in the unit -

whichever comes first.

4. When there is approximately an 80% charge, front seat

(close) the discharge manifold valve and let the system

stabilize for about five minutes.

5. Start compressor by setting thermostat.

6. Finish charging with liquid by cracking the suction valve.

Open the manifold low pressure valve to allow

refrigerant to flow into the system. Throttle the manifold

valve to keep pressure about 100 psig for R-410A.

7. When the correct weight of refrigerant has been added to

the unit, close refrigerant cylinder valve and allow unit to

run for 30 minutes. Refer to Start-Up Procedure and

Check List for further start-up details.

8. Front seat gauge manifold valves, disconnect charging

and gauge hoses and replace all valve caps.

Manual 2100-479

Page 6 of 11

FIGURE 1

TYPICAL AIR CONDITIONING SYSTEM COOLING CYCLE

MIS-369

Manual 2100-479

Page 7 of 11

FIGURE 2

TYPICAL HEAT PUMP SYSTEM COOLING CYCLE

MIS-368

Manual 2100-479

Page 8 of 11

FIGURE 3

HEATING CYCLE

WARNING

To speed refrigerant flow, it may be

necessary to place refrigerant drum in a

pan of warm water (not greater than 130

F). Remember to either consider the total

weight of the pan of water or remove the

drum for weighing frequently to keep track

of the charging process.

MIS-369

Manual 2100-479

Page 9 of 11

TROUBLESHOOTING THE MECHANICAL SYSTEM

HEAT PUMP HEATING

LOW SUCTION LOW HEAD

PRESSURE

1. Restricted airflow through outdoor coil. (Restricted

water flow through water coil.)

2. Defective outdoor motor. (Defective water pump.)

3. Low outdoor air temperature. (Low water

temperature.)

4. Frozen outdoor coil. (Frozen water coil.)

5. Restricted liquid line, dryer, metering device, etc.

6. Low charge.

7. Low indoor air temperature.

HIGH SUCTION LOW HEAD

PRESSURE

1. Defective or broken valves.

2. IPR valve open.

3. Defective reversing valve.

LOW SUCTION LOW HEAD

PRESSURE

1. Restricted airflow over indoor coil.

2. Defective indoor fan motor.

3. Low indoor temperature

4. Iced indoor coil.

5. Restricted liquid line, dryer, metering device, etc.

6. Low charge.

7. Low ambient entering air temperature. (Low entering

water temperature to water coil.)

HIGH SUCTION LOW HEAD

PRESSURE

1. Defective or broken valves.

2. IPRV valve open.

3. Defective reversing valve.

AIR CONDITIONING AND HEAT PUMP COOLING

LOW SUCTION HIGH HEAD

PRESSURE

1. Partial restriction and then overcharged.

HIGH SUCTION HIGH HEAD

PRESSURE

1. High entering outdoor air temperature. (High entering

water temperature.)

2. Low airflow outdoor coil. (Low water flow.)

3. Overcharged.

4. Air in system.

5. Restricted outdoor coil. (Restricted water coil.)

6. High indoor air temperature.

Water source heat pump.

LOW SUCTION HIGH HEAD

PRESSURE

1. Partial restriction and then overcharged.

HIGH SUCTION HIGH HEAD

PRESSURE

1. High entering outdoor air temperature. (High entering

water temperature.)

2. Low indoor airflow.

3. Overcharged.

4. Air in system.

5. Restricted air coil.

6. High indoor air temperature.

Water source heat pump.

Manual 2100-479

Page 10 of 11

yl

p

p

u

S

r

e

w

o

P

m

e

t

s

y

S

f

o

e

d

i

S

e

r

u

s

s

e

r

P

h

g

i

H

e

d

i

S

w

o

L

l

a

r

e

n

e

G

e

d

i

S

e

n

i

L

o

t

r

e

t

e

M

r

o

t

c

a

t

n

o

C

f

o

r

o

t

c

a

t

n

o

C

f

o

e

d

i

S

d

a

o

L

l

a

n

i

m

r

e

T

r

o

t

o

M

o

t

t

i

u

c

r

i

C

l

o

r

t

n

o

C

s

r

o

t

o

M

r

o

s

s

e

r

p

m

o

C

n

o

i

t

a

r

e

p

O

m

e

t

s

y

S

r

i

A

r

e

s

n

e

d

n

o

C

r

i

A

r

o

t

a

r

o

p

a

v

E

d

n

a

r

o

s

s

e

r

p

m

o

C

r

o

t

o

m

n

a

f

r

e

s

n

e

d

n

o

c

t

r

a

t

s

t

o

n

ll

i

w

t

u

b

t

r

a

t

s

t

o

n

ll

i

w

r

o

s

s

e

r

p

m

o

C

n

a

f

r

e

s

n

e

d

n

o

c

n

u

r

ll

i

w

r

o

t

o

m

n

a

f

r

e

s

n

e

d

n

o

C

t

r

a

t

s

t

o

n

ll

i

w

t

u

b

"

s

m

u

h

"

r

o

s

s

e

r

p

m

o

C

t

r

a

t

s

t

o

n

ll

i

w

d

a

ol

r

e

v

o

n

o

s

el

c

y

c

r

o

s

s

e

r

p

m

o

C

s

el

c

y

c

t

r

o

h

s

r

o

s

s

e

r

p

m

o

C

e

r

u

s

s

e

r

p

w

ol

n

o

o

n

yl

s

u

o

u

n

i

t

n

o

c

s

n

u

r

r

o

s

s

e

r

p

m

o

C

g

n

il

o

o

c

yl

s

u

o

u

n

i

t

n

o

c

s

n

u

r

r

o

s

s

e

r

p

m

o

C

g

n

il

o

o

c

y

s

i

o

n

r

o

s

s

e

r

p

m

o

C

l

i

o

s

e

s

ol

r

o

s

s

e

r

p

m

o

C

h

g

i

h

o

o

t

e

r

u

s

s

e

r

p

d

a

e

H

w

ol

o

o

t

e

r

u

s

s

e

r

p

d

a

e

H

g

n

i

t

a

e

w

s

r

o

g

n

i

t

s

o

r

f

e

n

il

d

i

u

q

i

L

e

r

u

s

s

e

r

p

n

o

i

t

c

u

S

h

g

i

h

o

o

t

w

ol

o

o

t

e

r

u

s

s

e

r

p

n

o

i

t

c

u

S

g

n

i

t

s

o

r

f

r

o

t

a

r

o

p

a

v

E

g

n

i

t

a

e

w

s

r

o

g

n

i

t

s

o

r

f

e

n

il

n

o

i

t

c

u

S

ll

i

w

r

e

w

ol

b

r

o

t

a

r

o

p

a

v

E

t

r

a

t

s

t

o

n

r

o

t

c

a

t

n

o

c

s

n

u

r

r

o

t

o

m

n

a

f

r

e

s

n

e

d

n

o

C

n

i

d

ell

u

p

t

o

n

o

t

k

c

a

b

g

n

i

d

o

ol

f

t

n

a

r

e

g

i

r

f

e

r

d

i

u

q

i

L

r

o

s

s

e

r

p

m

o

c

m

e

t

s

y

s

e

b

u

t

p

a

c

e

r

u

t

a

r

e

p

m

e

t

e

c

a

p

S

h

g

i

h

o

o

t

P o w e r F a i l u r e

B l o w n F u s e s o r T r i p p e d C i r c u i t B r e a k e r s

F a u l t y W i r i n g

L o o s e T e r m i n a l s

L o w V o l t a g e

S i n g l e 1 P H F a i l u r e o f 3 P H

U n b a l a n c e d P o w e r S u p p l y 3 P H

V o l t a g e T o o H i g h

O p e n D i s c o n n e c t S w i t c h

F a u l t y W i r i n g

L o o s e T e r m i n a l

L o w V o l t a g e

D e f e c t i v e C o n t a c t s i n C o n t a c t o r

C o m p r e s s o r O v e r l o a d

P o t e n t i a l R e l a y F a i l s t o O p e n

P o t e n t i a l R e l a y F a i l s t o C l o s e

R u n C a p a c i t o r

S t a r t C a p a c i t o r

F a u l t y W i r i n g

L o o s e T e r m i n a l s

C o n t r o l T r a n s f o r m e r

L o w V o l t a g e

T h e r m o s t a t

C o n t a c t o r C o i l

P r e s s u r e C o n t r o l

C o n d e n s e r F a n R e l a y

E v a p o r a t o r F a n R e l a y

C o m p r e s s o r M o t o r

C o n d e n s e r M o t o r

E v a p o r a t o r M o t o r

C o m p r e s s o r O f f o n I n t e r n a l O v e r l o a d

H o l d D o w n B o l t s

D e f e c t i v e C o m p r e s s o r B e a r i n g s

S e i z e d C o m p r e s s o r

D e f e c t i v e C o m p r e s s o r V a l v e s

C o m p r e s s o r O i l L e v e l

O p e n o r S h o r t M o t o r W i n d i n g s

R e f r i g e r a n t C h a r g e L o w

O v e r c h a r g e o f R e f r i g e r a n t

H i g h H e a d P r e s s u r e

H i g h S u c t i o n P r e s s u r e

L o w S u c t i o n P r e s s u r e

T e m p e r a t u r e s

N o n - C o n d e n s a b l e s ( A i r , e t c . )

E x c e s s i v e L o a d i n S p a c e

L i q u i d V a l v e P a r t i a l l y C l o s e d

C o n d e n s e r F i n s D i r t y o r P l u g g e d

C o n d e n s e r F a n B e l t S l i p p i n g

C o n d e n s e r A i r S h o r t C i r c u i t i n g

L o w C o n d e n s e r A i r V o l u m e

C o n d e n s e r A i r T e m p e r a t u r e L o w

P l u g g e d o r R e s t r i c t e d M e t e r i n g D e v i c e

E v a p o r a t o r F i n s D i r t y o r P l u g g e d

E v a p o r a t o r B e l t S l i p p i n g

L o w E v a p o r a t o r A i r V o l u m e

D i r t y F i l t e r s

D u c t w o r k S m a l l o r R e s t r i c t e d

R e s t r i c t i o n s

T h e r m o s t a t S e t t i n g

T h e r m o s t a t L o c a t i o n

S t r a t i f i e d A i r i n S p a c e

I n c o r r e c t R e f r i g e r a n t P i p i n g

S y s t e m T o o S m a l l

G

e

n

e

r

a

l

l

y

t

h

e

c

a

u

s

e

.

A

l

w

a

y

s

m

a

k

e

t

h

e

s

e

c

h

e

c

k

s

f

i

r

s

t

.

O

c

c

a

s

i

o

n

a

l

l

y

t

h

e

c

a

u

s

e

.

M

a

k

e

t

h

e

s

e

c

h

e

c

k

s

o

n

l

y

i

f

f

i

r

s

t

c

h

e

c

k

s

f

a

i

l

t

o

l

o

c

a

t

e

t

r

o

u

b

l

e

.

R

a

r

e

l

y

t

h

e

c

a

u

s

e

.

M

a

k

e

t

h

i

s

c

h

e

c

k

o

n

l

y

i

f

p

r

e

v

i

o

u

s

c

h

e

c

k

s

f

a

i

l

t

o

l

o

c

a

t

e

t

r

o

u

b

l

e

.

T

R

O

U

B

L

E

S

H

O

O

T

I

N

G

C

H

A

R

T

F

O

R

A

I

R

C

O

N

D

I

T

I

O

N

E

R

S

Manual 2100-479

Page 11 of 11

yl

p

p

u

S

r

e

w

o

P

n

o

i

t

c

e

S

r

o

o

d

t

u

O

n

o

i

t

c

e

S

r

o

o

d

nI

t

a

e

H

.

x

u

A

e

g

a

tl

o

V

e

n

i

L

t

i

u

c

r

i

C

l

o

r

t

n

o

C

r

o

s

s

e

r

p

m

o

C

m

e

t

s

y

S

t

n

a

r

e

g

i

r

f

e

R

t

s

o

r

f

e

D

l

o

r

t

n

o

C

.

v

e

R

e

vl

a

V

k

c

e

h

C

e

vl

a

V

n

a

F

r

o

o

d

t

u

O

l

i

o

C

d

n

a

r

o

t

o

M

r

e

w

ol

B

r

o

o

d

nI

l

i

o

C

d

n

a

r

o

t

o

M

k

c

e

h

C

r

o

t

o

m

n

a

f

.

D

.

O

d

n

a

r

o

s

s

e

r

p

m

o

C

e

t

a

r

e

p

o

t

o

n

o

d

n

u

r

t

o

n

ll

i

w

r

o

s

s

e

r

p

m

o

C

s

n

u

r

r

o

t

o

m

n

a

f

.

D

.

O

t

u

b

"

s

m

u

h

"

r

o

s

s

e

r

p

m

o

C

t

r

a

t

s

t

o

n

ll

i

w

d

a

ol

r

e

v

o

n

o

s

el

c

y

c

r

o

s

s

e

r

p

m

o

C

h

g

i

h

n

o

f

f

o

r

o

s

s

e

r

p

m

o

C

l

o

r

t

n

o

c

e

r

u

s

s

e

r

p

y

s

i

o

n

r

o

s

s

e

r

p

m

o

C

h

g

i

h

o

o

t

e

r

u

s

s

e

r

p

d

a

e

H

w

ol

o

o

t

e

r

u

s

s

e

r

p

d

a

e

H

e

r

u

s

s

e

r

p

n

o

i

t

c

u

S

h

g

i

h

o

o

t

w

ol

o

o

t

e

r

u

s

s

e

r

p

n

o

i

t

c

u

S

t

r

a

t

s

t

o

n

ll

i

w

r

e

w

ol

b

.

D

.I

-

g

n

i

c

i

r

o

g

n

i

t

s

o

r

f

l

i

o

c

.

D

.I

s

p

m

a

r

o

s

s

e

r

p

m

o

c

h

g

i

H

s

n

u

r

r

o

s

s

e

r

p

m

o

C

g

n

il

o

o

c

o

n

yl

s

u

o

u

n

i

t

n

o

c

g

n

i

d

o

ol

f

t

n

a

r

e

g

i

r

f

e

r

d

i

u

q

i

L

r

o

s

s

e

r

p

m

o

c

o

t

k

c

a

b

s

n

u

r

r

o

s

s

e

r

p

m

o

C

g

n

i

t

a

e

h

o

n

yl

s

u

o

u

n

i

t

n

o

c

l

i

o

c

n

o

e

c

i

o

n

s

e

t

a

i

t

i

n

i

el

c

y

c

t

s

o

r

f

e

D

s

e

o

d

e

vl

a

v

g

n

i

s

r

e

v

e

R

t

f

i

h

s

t

o

n

t

r

a

p

r

e

w

ol

n

o

p

u

dl

i

u

b

e

cI

l

i

o

c

.

D

.

O

f

o

g

n

i

d

o

ol

f

t

n

a

r

e

g

i

r

f

e

r

d

i

u

q

i

L

r

o

s

s

e

r

p

m

o

c

o

t

k

c

a

b

.

D

.I

n

o

t

a

e

h

y

r

a

il

i

x

u

A

f

f

o

r

e

w

ol

b

s

t

s

o

c

g

n

i

t

a

r

e

p

o

e

v

i

s

s

e

c

x

E

n

o

e

c

i

e

v

i

s

s

e

c

x

E

l

i

o

c

.

D

.

O

T

R

O

U

B

L

E

S

H

O

O

T

I

N

G

C

H

A

R

T

F

O

R

A

I

R

T

O

A

I

R

H

E

A

T

P

U

M

P

S

P o w e r F a i l u r e

B l o w n F u s e o r T r i p p e d B r e a k e r

F a u l t y W i r i n g

L o o s e T e r m i n a l s

L o w V o l t a g e

S i n g l e 1 P H F a i l u r e o f 3 P H

U n b a l a n c e d 3 P H

D e f e c t i v e C o n t a c t s i n C o n t a c t o r

C o m p r e s s o r O v e r l o a d

P o t e n t i a l R e l a y

R u n C a p a c i t o r

S t a r t C a p a c i t o r

F a u l t y W i r i n g

L o o s e T e r m i n a l s

C o n t r o l T r a n s f o r m e r

L o w V o l t a g e

T h e r m o s t a t

C o n t a c t o r C o i l

P r e s s u r e C o n t r o l o r I m p e d a n c e R e l a y

I n d o o r F a n R e l a y

D i s c h a r g e L i n e H i t t i n g I n s i d e o f S h e l l

B e a r i n g s D e f e c t i v e

S e i z e d

V a l v e D e f e c t i v e

M o t o r W i n d i n g s D e f e c t i v e

R e f r i g e r a n t C h a r g e L o w

R e f r i g e r a n t O v e r c h a r g e

H i g h H e a d P r e s s u r e

L o w H e a d P r e s s u r e

H i g h S u c t i o n P r e s s u r e

L o w S u c t i o n P r e s s u r e

N o n - C o n d e n s a b l e s

U n e q u a l i z e d P r e s s u r e s

S e n s i n g B u l b L o o s e - P o o r l y L o c a t e d

C y c l e T o o L o n g ( C l o c k t i m e r )

D e f e c t i v e C o n t r o l , T i m e r o r R e l a y

L e a k i n g

D e f e c t i v e V a l v e o r C o i l

S t i c k i n g C l o s e d

L e a k i n g o r D e f e c t i v e

P l u g g e d o r R e s t r i c t e d M e t e r D e v i c e ( H t g )

F i n s D i r t y o r P l u g g e d

M o t o r W i n d i n g D e f e c t i v e

R e c i r c u l a t i o n o r A i r

A i r V o l u m e L o w ( C o o l i n g )

L o w T e m p e r a t u r e C o i l A i r ( C o o l i n g )

P l u g g e d o r R e s t r i c t e d M e t e r i n g D e v i c e ( C l g )

F i n s D i r t y o r P l u g g e d

M o t o r W i n d i n g D e f e c t i v e

A i r V o l u m e L o w

A i r F i l t e r s D i r t y

U n d e r s i z e d o r R e s t r i c t e d D u c t w o r k

S t i c k i n g C l o s e d

L e a k i n g o r D e f e c t i v e

A u x i l i a r y H e a t U p s t r e a m o f C o i l

D

e

n

o

t

e

s

c

o

m

m

o

n

c

a

u

s

e

.

D

e

n

o

t

e

s

o

c

c

a

s

i

o

n

a

l

c

a

u

s

e

.

C o o l i n g

C y c l e

H e a t i n g o r C o o l i n g C y c l e s

H e a t i n g C y c l e

S-ar putea să vă placă și

- MNL 0336Document46 paginiMNL 0336bigcee64Încă nu există evaluări

- Bard WA381 Installation 2100-398Document21 paginiBard WA381 Installation 2100-398bigcee64Încă nu există evaluări

- MNL-0117 1aDocument154 paginiMNL-0117 1abigcee64100% (2)

- TM 9 6115 730 10Document231 paginiTM 9 6115 730 10bigcee64Încă nu există evaluări

- Bard Hvac Warranty (7960-420)Document8 paginiBard Hvac Warranty (7960-420)bigcee64Încă nu există evaluări

- April 16 Report Rev 20091204Document210 paginiApril 16 Report Rev 20091204bigcee64Încă nu există evaluări

- S9086-Gy-Stm-010 (NSTM 221)Document366 paginiS9086-Gy-Stm-010 (NSTM 221)bigcee64100% (3)

- Racial and Ethnic InequalityDocument36 paginiRacial and Ethnic Inequalitybigcee64Încă nu există evaluări

- Bard Hvac User's Guide (2100-034)Document9 paginiBard Hvac User's Guide (2100-034)bigcee64Încă nu există evaluări

- The Leadership ChallengeDocument16 paginiThe Leadership Challengevickram_chandu9526100% (8)

- Va Tech ReportDocument260 paginiVa Tech Reportbigcee64Încă nu există evaluări

- An Evidence-Based Approach To The Practice of Educational LeadershipDocument34 paginiAn Evidence-Based Approach To The Practice of Educational Leadershipbigcee64Încă nu există evaluări

- Everpure SSFM 100M 25 orDocument2 paginiEverpure SSFM 100M 25 orbigcee64Încă nu există evaluări

- Marine Engineering Part1Document65 paginiMarine Engineering Part1bigcee64Încă nu există evaluări

- Basic Electrical Principles & Test Equipment GuideDocument33 paginiBasic Electrical Principles & Test Equipment Guidebigcee64Încă nu există evaluări

- Reintjes Marine Reduction Gear Operating ManualDocument72 paginiReintjes Marine Reduction Gear Operating Manualbigcee6496% (24)

- North Star Model 13000 TFG, Item #165939 Triple Fuel GeneratorDocument40 paginiNorth Star Model 13000 TFG, Item #165939 Triple Fuel Generatorbigcee6467% (3)

- TM-048 90kW Generator, Northern Lights Model OM2-4, OperatorDocument28 paginiTM-048 90kW Generator, Northern Lights Model OM2-4, Operatorbigcee6450% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hydraulic Machines Lab Report Characteristic CurvesDocument11 paginiHydraulic Machines Lab Report Characteristic CurvesBaran ShafqatÎncă nu există evaluări

- Safety Valve ListDocument3 paginiSafety Valve ListYair Alexis Muñoz RojasÎncă nu există evaluări

- Service: ManualDocument53 paginiService: ManualFlorian Leordeanu100% (1)

- Posicionador SP400 - Válvula de ControlDocument2 paginiPosicionador SP400 - Válvula de ControlLINA MARIA GARCIA CRUZÎncă nu există evaluări

- Topic 1 Valve and Instrumentation SymbolsDocument8 paginiTopic 1 Valve and Instrumentation SymbolshatiniÎncă nu există evaluări

- Assembly Manual Series (Am200 & Am250) Ver.1.11Document53 paginiAssembly Manual Series (Am200 & Am250) Ver.1.11palas100% (1)

- Automatically Balanced Combination Valves Ab-Qm: Data SheetDocument12 paginiAutomatically Balanced Combination Valves Ab-Qm: Data SheetbatazivoÎncă nu există evaluări

- Manual de Bombas PomacDocument46 paginiManual de Bombas PomacChemicalProgrammer100% (1)

- Method Statement For Installation, TESTING, COMISNNING of F.FDocument16 paginiMethod Statement For Installation, TESTING, COMISNNING of F.FdemdiinÎncă nu există evaluări

- G58 Maintenance ManualDocument20 paginiG58 Maintenance ManualNathaniel LuraÎncă nu există evaluări

- Pressure Drop Compressible FlowDocument14 paginiPressure Drop Compressible Flowdilip matalÎncă nu există evaluări

- Udcf04 01GBDocument336 paginiUdcf04 01GBEjaz EjazÎncă nu există evaluări

- Air StarterDocument6 paginiAir StarterParvizÎncă nu există evaluări

- All Safety Inspection ChecklistsDocument30 paginiAll Safety Inspection ChecklistsSagar Sharma50% (2)

- MM RT Flex84t D - WECS 9520 - Dynex - 2014 07 PDFDocument610 paginiMM RT Flex84t D - WECS 9520 - Dynex - 2014 07 PDFsaw ba htoo100% (1)

- As 1200 2015 Pressure EquipmentDocument53 paginiAs 1200 2015 Pressure EquipmentShanfan Luo100% (2)

- 01 BQ-PLUMBING (Draft Ketiga)Document11 pagini01 BQ-PLUMBING (Draft Ketiga)Biggie ColdAngelÎncă nu există evaluări

- Manual de Instalación Bomba Quintuplex Pentair MA-300Document32 paginiManual de Instalación Bomba Quintuplex Pentair MA-300zayagoraÎncă nu există evaluări

- Magnetic Level GaugesDocument23 paginiMagnetic Level Gaugesniginp100% (1)

- BOE Intview Questions & Answers-2 PDFDocument19 paginiBOE Intview Questions & Answers-2 PDFRahul NigamÎncă nu există evaluări

- Piston & Ball Check ValvesDocument8 paginiPiston & Ball Check Valveswilasn1Încă nu există evaluări

- P & I DiagramsDocument20 paginiP & I DiagramsYash PatelÎncă nu există evaluări

- Case 430 Series 3 Skid Steer PDFDocument1.724 paginiCase 430 Series 3 Skid Steer PDFAny Rayli100% (3)

- SOP - Eyewash and Safety Shower (Signed)Document2 paginiSOP - Eyewash and Safety Shower (Signed)yusuf al aziz100% (1)

- Scanwill Pressure IntensifierDocument12 paginiScanwill Pressure IntensifierÁlvaro Conti FilhoÎncă nu există evaluări

- Neutralizing-Mineralizing Filter & Berson UV-watersterilizerDocument40 paginiNeutralizing-Mineralizing Filter & Berson UV-watersterilizerDimitry SilinshÎncă nu există evaluări

- HPB Datos TecnicosDocument30 paginiHPB Datos TecnicosRenzzo B NamucheÎncă nu există evaluări

- 03-2 N Series Hydraulic Section PDFDocument115 pagini03-2 N Series Hydraulic Section PDFusuario29000100% (3)

- Anatomy SluicegateDocument13 paginiAnatomy Sluicegatepir8s_xÎncă nu există evaluări

- Anderson Greenwood: Manifolds and AccessoriesDocument162 paginiAnderson Greenwood: Manifolds and AccessoriesSales DIGIHUÎncă nu există evaluări