Documente Academic

Documente Profesional

Documente Cultură

Conveyor Scale Kit Installation

Încărcat de

Samir BoradDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Conveyor Scale Kit Installation

Încărcat de

Samir BoradDrepturi de autor:

Formate disponibile

METTLER TOLEDO

Installation Instructions

PS90 Scale

Conveyor Scale Drop-In Kit

CHG:02 - 04/08

2007 Mettler-Toledo, Inc.

Page 1 of 5

Model: PS90 Scale Document Number: 64058111

Kit Number: 64058112 Revision: 02

Description: Conveyor Scale Drop-In Kit Release Date: 04/08

Introduction

This kit allows a PS90 scale to be integrated into a standard gravity conveyor. The kit is designed for

standard conveyors that use 1.9 diameter rollers on a frame that supports 1.5 spacing increments. The kit

can be used with conveyors between 22 and 32 in width. The scale can be mounted lengthwise or

transverse in the conveyor frame.

!

WARNING! DO NOT ATTEMPT TO INSTALL THIS KIT IN A POWERED CONVEYOR.

This kit supports both the ball-top and roller-top platter options for the PS90 scale. The ball-top platter

allows packages to be rotated easily when on the scale. This option is commonly used when packages

have labels that must be scanned at the shipping station. The roller-top platter is commonly used when

packages are significantly larger than the scale. The PS90 should always be mounted lengthwise when

used with the roller-top platter.

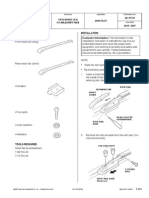

Length-wise Mounting, Roller-Top Platter Transverse Mounting, Ball-Top Platter

Parts List

Included in this kit are:

Two adjustable hanger assemblies

Eight M10x20 screws, lock washers and nuts

Four tall scale legs (for use with ball top platters)

Tools Required

The following tools are required to perform this installation procedure:

One flat head screwdriver A bubble level 24 or longer

Two M17 wrenches or one wrench and one socket Gloves are recommended

A tape measure

METTLER TOLEDO

PS90 Scale

Conveyor Scale Drop-In Kit

Installation Instructions

Page 2 of 5 Document: 64058111 - CHG:02 - 04/08 Kit number 64058112

Preparation for Assembly

The scale must be mounted level and adequately elevated above the rollers so that the longest package will

not rest on the conveyor on either side of the scale. Use particular care with gravity conveyors that are

sloped slightly so that packages roll down the conveyor without assistance. The in-feed conveyor will be

higher and interfere with longer packages. It is recommended that the in-feed side of the conveyor adjacent

to the scale be level, or have a slope of no more than a 1 inch drop per 10 feet of conveyor.

Identify a position in the conveyor to install the scale. If possible, the scale should be mounted no

more than two feet from the legs that support the conveyor.

For 10 foot conveyor sections, an extra set of legs should be installed so that the scale has support

immediately on either side.

When used with the CNS810 static dimensioner, make sure there is adequate space above and

below the conveyor for the dimensioner and its stand.

There should be no cross bars within the envelope of the scale.

Lengthwise Mounting Transverse Mounting

For lengthwise mounting of the scale (shown at left in the figure above) with roller-top or ball-top platters:

1. Remove the rollers in a 24 section of the conveyor.

2. Mark a hole at least 3 from the roller on the in-feed side.

3. Mark the hole that is 19.5 away from this hole. The two marked holes will be the outer mounting

holes of the two hangers.

When the PS90 scale is used with a ball-top platter, the scale may be mounted transverse (width-wise) in

the conveyor (at right in the figure above). For this orientation:

1. Remove rollers in a 20 section of the conveyor.

2. Mark a hole at least 3 from the roller on the in-feed side.

3. Mark the hole that is 16.5 down the conveyor from this hole. The two marked holes will be the

outer mounting holes of the two hangers.

METTLER TOLEDO

Installation Instructions

PS90 Scale

Conveyor Scale Drop-In Kit

Kit number 64058112 Document: 64058111 - CHG:02 - 04/08 Page 3 of 5

Hanger Installation

1. Place the adjustable hangers on a flat surface. If necessary, loosen the screws on the bottom of the

hangers, and pull the sides apart until the bracket width is the same as the conveyor rail inside

spacing. Adjust the center channel so that it is an equal distance from each end bracket.

Adjust to inside width between conveyor rails

Adjust for equal length at each end of channel bar

Hanger Adjustment

2. Finger tighten the screws on the bottom of each hanger, but do not tighten them completely at this

time.

Hanger Assembly Screws

3. Position each of the hangers into the conveyor opening with the outside hole of the hanger aligned

with the mark previously placed on the conveyor rail.

4. Secure with (4) M10x20 screws, inserting the screws from the inside of the conveyor rails and

installing the lock washer and nut from outside the rails, as seen in the photograph below. Make

sure the hangers are vertical, and tighten the screws.

Hanger Mounted to Conveyor Rail

5. Verify that the channel bar is still centered between the hangers, and then tighten the four screws on

the bottom of each of the hangers.

METTLER TOLEDO

PS90 Scale

Conveyor Scale Drop-In Kit

Installation Instructions

Page 4 of 5 Document: 64058111 - CHG:02 - 04/08 Kit number 64058112

Scale Installation

1. Remove the platter from the PS90 scale.

2. If the ball-top platter is being used, the supplied set of four longer feet must be installed. Turn the

scale frame upside down, remove the feet and install the new legs. (The photograph below shows

one of the standard, shorter, feet installed.) Turn the scale over so that it is resting on its feet.

Scale Foot with Jam Nut Scale Foot Resting on Hanger

3. Place the scale on the hangers in the conveyor. Normally the scale is centered between the rails.

For wider conveyors, it is acceptable to position the scale off center, closer to the operator

(indicated by the arrow in the photograph below). Push the scale toward the out-feed conveyor until

the feet rest against the side of the hanger.

Scale Resting on Hangers, Direction of Lateral Adjustment Indicated

4. Place the platter on the scale and press down firmly on all four corners.

METTLER TOLEDO

Installation Instructions

PS90 Scale

Conveyor Scale Drop-In Kit

Kit number 64058112 Document: 64058111 - CHG:02 - 04/08 Page 5 of 5

5. For the ball top platter, it will be necessary to place a piece of flat material on top of the scale to

make the leveling adjustments. First, adjust the feet on the lead-in side of the scale so that the top

is at least inch above the lead-in rollers the dimension indicated in the figures below.

Direction of package movement

Lead-In Side Height Relative to Conveyor

inch minimum

Lead-In Side Height Relative to Conveyor, Side View

6. With the bubble level on top of the platter, adjust the feet on the downstream side of the scale until

the scale is level.

7. Place the longest package to be measured on the scale and verify the package does not touch the

conveyor. It may be necessary to adjust the scale height or reduce the slope of the conveyor. A

typical lead-in slope would be 1 inch per 10 feet of conveyor.

8. When the adjustments are complete, verify the scale is stable by pressing down on all four corners,

then lock the jam nuts on the feet.

S-ar putea să vă placă și

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Beltway Scale Manual 2009Document56 paginiBeltway Scale Manual 2009morris_timÎncă nu există evaluări

- Heidts Superide IRSDocument8 paginiHeidts Superide IRSNovita EmRoseÎncă nu există evaluări

- SPANCO FR WSB Instmaint Manual 103 0011 Rev06 11Document24 paginiSPANCO FR WSB Instmaint Manual 103 0011 Rev06 11Eduardo OchaitaÎncă nu există evaluări

- Rolling InstallnstructionsDocument8 paginiRolling InstallnstructionsANDIÎncă nu există evaluări

- Turbine Flow Meter: Installation/Operation ManualDocument20 paginiTurbine Flow Meter: Installation/Operation ManualHany RifaatÎncă nu există evaluări

- FAST M10 Universal Mount Kit Instructions 07092008Document6 paginiFAST M10 Universal Mount Kit Instructions 07092008BrianCookÎncă nu există evaluări

- Build Your Own Axle: Read All Instructions Before StartingDocument2 paginiBuild Your Own Axle: Read All Instructions Before Startinggamini ranaweeraÎncă nu există evaluări

- Reese SC Weight Distributing Hitch n66155Document7 paginiReese SC Weight Distributing Hitch n66155Bud HeberlingÎncă nu există evaluări

- 601 Car Frame Installations R1Document16 pagini601 Car Frame Installations R1bhupiisterÎncă nu există evaluări

- Mnit001 Meter ManualDocument20 paginiMnit001 Meter Manualsiddiquiee74Încă nu există evaluări

- VDO Gauge InstallationDocument4 paginiVDO Gauge Installationurule2kÎncă nu există evaluări

- Thomas Thomas Thomas Thomas: Type Cmr/AmrDocument4 paginiThomas Thomas Thomas Thomas: Type Cmr/AmrGustavo Espinosa MartinezÎncă nu există evaluări

- Manual Mantenimiento Mission 40Document8 paginiManual Mantenimiento Mission 40Daygor Martinez SabucoÎncă nu există evaluări

- Vernier Dynamics SystemDocument6 paginiVernier Dynamics SystemScience HouseÎncă nu există evaluări

- Drive Unit Removal and Re-InstallationDocument10 paginiDrive Unit Removal and Re-InstallationSuhas JadhavÎncă nu există evaluări

- Shuttlepod MiniDocument1 paginăShuttlepod MiniKalygulyÎncă nu există evaluări

- Honda Pilot Roof Rack CrossbarsDocument2 paginiHonda Pilot Roof Rack Crossbarsgohchuansin100% (1)

- Conveyor Assembly Manual PDFDocument68 paginiConveyor Assembly Manual PDFzaiayra71Încă nu există evaluări

- Procedure For CASED HOLE Sidetrack WhipstockingDocument12 paginiProcedure For CASED HOLE Sidetrack WhipstockingMohamed MahmoudÎncă nu există evaluări

- Para-Flex Couplings Dodge: Installation Instructions Manual ForDocument4 paginiPara-Flex Couplings Dodge: Installation Instructions Manual ForAdrian CantaragiuÎncă nu există evaluări

- Taig Lathe ManualDocument12 paginiTaig Lathe Manualspayt100% (1)

- R-83 EC-LC ManualDocument11 paginiR-83 EC-LC ManualpaulmmccoyÎncă nu există evaluări

- smhs 7727 Special Instruction-проверка установки гильз 3400Document5 paginismhs 7727 Special Instruction-проверка установки гильз 3400AminadavÎncă nu există evaluări

- MM01001 enDocument32 paginiMM01001 enmahmoud yarahmadiÎncă nu există evaluări

- Hug 8220Document5 paginiHug 8220Gabriel ChiavettoÎncă nu există evaluări

- smhs 7727 Special Instruction-проверка установки гильз 3400Document5 paginismhs 7727 Special Instruction-проверка установки гильз 3400Евгений АбрамовÎncă nu există evaluări

- 52 - On Site Column Erection ProcedureDocument5 pagini52 - On Site Column Erection ProcedureRuslan GaponÎncă nu există evaluări

- Work Instruction Title: Set Up Procedure For Fin Press: Revision RecordDocument4 paginiWork Instruction Title: Set Up Procedure For Fin Press: Revision RecordBalachandar SathananthanÎncă nu există evaluări

- Erection Procedure SCRDocument23 paginiErection Procedure SCRvskreddy90% (10)

- Style EJ403: Installation InstructionsDocument1 paginăStyle EJ403: Installation InstructionsTanmoy DuttaÎncă nu există evaluări

- Whip StockDocument4 paginiWhip StockSasan AbbasiÎncă nu există evaluări

- ManifoldaaraDocument10 paginiManifoldaarapa1busynessÎncă nu există evaluări

- Adjustable Pitch Propeller Taper-Lock HubDocument2 paginiAdjustable Pitch Propeller Taper-Lock HubhaosfÎncă nu există evaluări

- 80-96 F150 2 1/2" Lift Kit InstructionsDocument4 pagini80-96 F150 2 1/2" Lift Kit Instructionsisaacllugo1Încă nu există evaluări

- Grid Coupling Installation InstructionsDocument2 paginiGrid Coupling Installation Instructionsakashwsl92Încă nu există evaluări

- Weld Test Stand Assembly ManualDocument9 paginiWeld Test Stand Assembly ManualLUIS CORDOVA ZANCHESÎncă nu există evaluări

- Method Statement - Stub SettingDocument6 paginiMethod Statement - Stub SettingShubham PatelÎncă nu există evaluări

- Instruction Manual: Bharat Heavy Electricals Limited TiruchirapalliDocument7 paginiInstruction Manual: Bharat Heavy Electricals Limited TiruchirapalliUJJAL KUMAR BHATTACHARYAYÎncă nu există evaluări

- Slr250 RidgidDocument80 paginiSlr250 RidgidAlex HammilionÎncă nu există evaluări

- Installing T400 Load Sensors: Doc #: 11080 Rev:A T400 InstallationDocument7 paginiInstalling T400 Load Sensors: Doc #: 11080 Rev:A T400 InstallationHusnulKhotimahÎncă nu există evaluări

- MP30 User GuideDocument5 paginiMP30 User GuideSundar KandasamyÎncă nu există evaluări

- Final Drive AssemblyDocument118 paginiFinal Drive AssemblyKARTHICKRAJ KANDASAMYÎncă nu există evaluări

- D90KS Commissioning PDFDocument20 paginiD90KS Commissioning PDFMax Rojas100% (1)

- Service Information Letter: Trunnion Adjustment - Double Barrels OnlyDocument7 paginiService Information Letter: Trunnion Adjustment - Double Barrels OnlyjustincliftonÎncă nu există evaluări

- Operation and Maintenance Instructions: 334 SERIES THREE-PIECE BALL VALVES - 1/4" To 2-1/2"Document5 paginiOperation and Maintenance Instructions: 334 SERIES THREE-PIECE BALL VALVES - 1/4" To 2-1/2"MASOUDÎncă nu există evaluări

- SkidSteer Track Installation InstructionsDocument16 paginiSkidSteer Track Installation InstructionsMichael KhushfÎncă nu există evaluări

- Serie 60 Informacion AdicionalDocument51 paginiSerie 60 Informacion AdicionalMauricio Campos QuirosÎncă nu există evaluări

- Balança 4182-A (Mecanica) - Revisão 02.08.2007 PDFDocument12 paginiBalança 4182-A (Mecanica) - Revisão 02.08.2007 PDFKadson AmaralÎncă nu există evaluări

- 67-68 Cougar Rear TorqueArmDocument18 pagini67-68 Cougar Rear TorqueArmChristian VillaÎncă nu există evaluări

- Adjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersDocument13 paginiAdjustment of The HD-8 Carburetors For The BJ8 Courtesy of Steve ByersJ.d. LangleyÎncă nu există evaluări

- Kearney and Trecker Installation ManualDocument12 paginiKearney and Trecker Installation Manualaa987100% (1)

- TH 3 MKDocument20 paginiTH 3 MKAdrianoAmadorÎncă nu există evaluări

- Installation ManualDocument12 paginiInstallation ManualalrounderÎncă nu există evaluări

- Maintenance Instruction Manual: Severe Service Control ValvesDocument9 paginiMaintenance Instruction Manual: Severe Service Control Valvesابزار دقیقÎncă nu există evaluări

- Apluslift HW 10kbpDocument17 paginiApluslift HW 10kbpGBÎncă nu există evaluări

- Adjustable Tow Bar Instructions: Read, Understand, Follow and Save These InstructionsDocument22 paginiAdjustable Tow Bar Instructions: Read, Understand, Follow and Save These InstructionsWilliam BarriosÎncă nu există evaluări

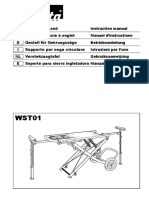

- Deawst01 StandDocument16 paginiDeawst01 StandA D PierceÎncă nu există evaluări

- Steering Column TiltDocument10 paginiSteering Column TiltToua YajÎncă nu există evaluări

- Compact Metal Bender Manual PDFDocument64 paginiCompact Metal Bender Manual PDFarnoldodiel55% (11)

- Alfa Laval Partes BWPX 307 PDFDocument72 paginiAlfa Laval Partes BWPX 307 PDFMARCO VERAMENDIÎncă nu există evaluări

- Parts Information: Contact-Cooled Rotary Screw Air CompressorDocument124 paginiParts Information: Contact-Cooled Rotary Screw Air CompressorDouglas AlexandreÎncă nu există evaluări

- 330CL UhdDocument40 pagini330CL UhdFgaier AhmedÎncă nu există evaluări

- Manual en Ventiloconvector HEIZTECH 2022Document36 paginiManual en Ventiloconvector HEIZTECH 2022saint77gÎncă nu există evaluări

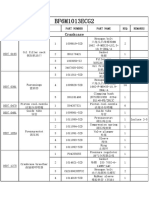

- BF6M1013ECG2 Parts CatalogDocument137 paginiBF6M1013ECG2 Parts CatalogAndreyIvanovÎncă nu există evaluări

- Pages From Certificate of Conformance For Lot-2 ASTM A490M Bolts, Nuts &washers (Key's and Clamp)Document1 paginăPages From Certificate of Conformance For Lot-2 ASTM A490M Bolts, Nuts &washers (Key's and Clamp)Krishna VachaÎncă nu există evaluări

- Dxi 450 Engine Torque Settins PDFDocument63 paginiDxi 450 Engine Torque Settins PDFvaleriy100% (2)

- Innocentis Parts ListDocument35 paginiInnocentis Parts ListHandrito YudoÎncă nu există evaluări

- Ensayo CBR (D4429-09a)Document7 paginiEnsayo CBR (D4429-09a)joake spasÎncă nu există evaluări

- Diploma 6 Sem (Mechanical Engineering) Course Code: 601 Subject Name: Design of Machine Elements Important Questions Chapter-1Document4 paginiDiploma 6 Sem (Mechanical Engineering) Course Code: 601 Subject Name: Design of Machine Elements Important Questions Chapter-1suneel kumar rathoreÎncă nu există evaluări

- Bolt Loading NotesDocument5 paginiBolt Loading NotesTarek AbulailÎncă nu există evaluări

- Consolidated Safety Valve Type 1510,1511 and 1811Document40 paginiConsolidated Safety Valve Type 1510,1511 and 1811Marcio Silva100% (1)

- 17-1cs-Normal Tightening and Loosening of Flange BoltsDocument3 pagini17-1cs-Normal Tightening and Loosening of Flange Boltsyulianus_sr100% (1)

- Maintenance ManualDocument10 paginiMaintenance ManualAbo MohammedÎncă nu există evaluări

- Chainsaw Milling Summary ReportDocument72 paginiChainsaw Milling Summary ReportJohn JohnsÎncă nu există evaluări

- Base Plate Uc152x152x23Document2 paginiBase Plate Uc152x152x23sonofalexanderÎncă nu există evaluări

- Shutdown SIS: Truck 777D Truck FKR 777D Off-Highway Truck FKR00001-UP (MACHINE) POWERED BY 3508B EngineDocument3 paginiShutdown SIS: Truck 777D Truck FKR 777D Off-Highway Truck FKR00001-UP (MACHINE) POWERED BY 3508B EngineGerald BoyÎncă nu există evaluări

- McDes1 Review Sample Problems Shaft Keys CouplingsDocument20 paginiMcDes1 Review Sample Problems Shaft Keys CouplingsAngeloTomalonÎncă nu există evaluări

- Press Tool Technical RequirementsDocument6 paginiPress Tool Technical RequirementsVenkateswaran venkateswaranÎncă nu există evaluări

- RATES For 2073-74: A. Approved Labour RateDocument40 paginiRATES For 2073-74: A. Approved Labour Rateक्षितिज चौलागाईंÎncă nu există evaluări

- Parker Lucifer Valves 321h35 ManualDocument4 paginiParker Lucifer Valves 321h35 ManualFerney Martinez Romero Martinez RomeroÎncă nu există evaluări

- Pas 00024-2012Document92 paginiPas 00024-2012Emre ÖzaydınÎncă nu există evaluări

- Airflow Sensor PotentiometerDocument2 paginiAirflow Sensor Potentiometerazizja1100% (2)

- Design of Moment ConnectionDocument2 paginiDesign of Moment ConnectionCarlos Eduardo González RamírezÎncă nu există evaluări

- 90-126-02 Angulus 2 Angled Screwdriver PDFDocument24 pagini90-126-02 Angulus 2 Angled Screwdriver PDFDrGurkirpal Singh MarwahÎncă nu există evaluări

- For Construction: MAX. DIST. 0.5EDocument1 paginăFor Construction: MAX. DIST. 0.5EHimal Nilanka RathnayakaÎncă nu există evaluări

- ARB 3438100 FittingDocument7 paginiARB 3438100 FittingthailanÎncă nu există evaluări

- Me 708Document17 paginiMe 708Ana Victoria LeonÎncă nu există evaluări

- Catalog: Shop ToolsDocument140 paginiCatalog: Shop Toolsagniva dattaÎncă nu există evaluări

- Smartax Ma5671Document12 paginiSmartax Ma5671Farooq Omer KhanÎncă nu există evaluări