Documente Academic

Documente Profesional

Documente Cultură

Ferrite

Încărcat de

Sergy DavinciDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ferrite

Încărcat de

Sergy DavinciDrepturi de autor:

Formate disponibile

Synthesis and Characterization

of Nanostructured Spinel

Ferrites

Muhammad Javed Iqbal

Department of Chemistry

Quaid-i-Azam University

Islamabad

2

NANOSCIENCE

Average human hair 25000 nm wide

Molecules with 30 atoms have 1 nm diameter

Human cells range from 5000 200,000 nm

Proteins ---------- 3-20 nm

Viruses --------- 10-200 nm

Drugs used to fight virus < 5 nm

3

Nanotechnology

Creation of functional (novel) materials, devices and

systems through control of matter on nanometer

length scale ~ 1-100 nm range. 100 nm is not an

arbitrary dividing line

The deviation of properties of nanosized materials

from bulk materials properties are due to surface

effects (S/V ratio, particle size, etc.)

Motivations in nanoscience is to understand how

materials behave when sample sizes are close to

atomic dimensions.

When characteristic length scale of microstructure is

1-100 nm it becomes comparable with the critical

length scales of biological/physical phenomena so

called size and shape effects

4

Nanotubes

Nanostructured Materials

Nanoparticles

Intermediates Nanocomposites

Nanofibres

Nanowires

Ceramics

Drugs Batteryel ectrodes Catalysis

5

Themes of Nanotechnology

the bottom-up approach

the top-down approach

6

Spinel

Great imposter of gemstone history

Famous rubies in

crown jewels (SPINELS)

BLACK PRINCES RUBY

7

Spinel Gallery

8

Spinel Compounds

General formula A[B

2

]O

4

A divalent metal ions Fe

2+

, Mg

2+

, Ni

2+

B Trivalent metal ions Fe

3+

,Cr

3+

,Al

3+,

Mn

3+

Cubic close packing of O

2-

ions

Two types of sites

Octahedral sites (B-sites)

Tetrahedral sites (A-sites)

9

Structure of Spinel

OCTAHEDRAL HOLE

TETRAHEDRAL HOLE

10

Classification of Spinels

NORMAL SPINEL (A)

tet

[B

2

]

oct

O

4

e.g. (Mg)[Al

2

]O

4

, (Zn)[Fe

2

]O

4

INVERSE SPINEL (B)

tet

[A, B]

oct

O

4

e.g. (Fe)[Fe]O

4

, (Fe)[NiFe]O

4

RANDOM SPINEL (B

0.67

A

0.33

)

tet

[A

0.67

B

1.33

]

oct

O

4

11

Types of Magnetic Interactions

Paramagnetism

Ferromagnetism

Anti-ferromagnetism Ferrimagnetisms

12

Why Cobalt Ferrite (CoFe

2

O

4

)?

Perfect chemical stability (metal & alloys unstable

under atmospheric conditions)

Good thermal stability

High electrical resistivity (high frequency devices,

memory cores, recording media)

High saturation magnetization (high density

recording media)

Low coercivity (for recording and reading of data)

Super-exchange interaction

Super-paramagnetism (Biomedical applications)

13

Applications

Medical applications

Magnetic Resonance Imaging

(MRI)

Targeted drug delivery

Hyperthermia for cancer

treatment

High density storage devices

Magnetic fluids

Transformer cores

Microwave devices

Humidity and Gas Sensors

14

Aims & Objectives

To obtain stable, single phase ferrites at different

temperatures.

To synthesize cobalt ferrites with a size ~ 70 nm; more

suitable for use in recording devices.

To enhance the electrical resistivity from >10

7

cm to

consequently decrease eddy current losses & dielectric

constant () for use as transformer cores

To crease the Curie Temperature (Tc)

To increase the coercivity H

c ~

600-1000 Oe for

applications in recording media

15

Experimental

Micro-emulsion method using Poly ethylene glycol

(PEG) as surfactant

Surfactant makes nano-reactors for the formation of

the product

NH

3

(35%) solution is used to maintain pH=9.5

PEG soln

.

Fe(NO

3

)

3

+

Cr(NO

3

)

3

Co(NO

3

)

2

NH

3

pH=9.5

E.Goldman, Modern Ferrite Technology, 2nd ed., Springer, Pittsburgh USA 2006

16

Mechanism of Ferrite Formation

(2-x)Fe(NO

3

)

3

+xMe(NO

3

)

2

+Co(NO

3

)

2

+8NaOH(aq)

(2-x)Fe(OH)

3

.Co(OH)

2

.xMe(OH)

2.

nH

2

O + 8NaNO

3

PEG pH=9.5

CoFe

2-x

Me

x

O

4

(Spinel Ferrite)

Drying at 120 & annealing at 800

o

C

5

o

C/min

(Me = Zr

4+

, Mg

2+

)

17

Characterization Techniques

Thermogravimetric Analysis TG/DTA (Perkin Elmer)

X-ray Diffraction XRD Analysis (PANalytical 3040/60 XPert

PRO )

Energy Dispersive X-ray Fluorescence ED-XRF (Horiba MESA-

500 )

Scanning Electron microscopy SEM (Hitachi VP S3400N )

DC-Electrical Resistivity Measurements by two probe method

(Lab made setup)

Dielectric measurements (Wayne Kerr LCR4275 )

AC-Susceptibility at 273 Hz (Lab made setup)

Magnetic measurements using AC-induction method

18

Parameters Calculated by XRD

Cos

K

D =

cell A

ray x

V N

ZM

d =

[ ]

2 / 1

2 2 2 2

) ( l k h d a + + =

K = shape factor (0.9), = FWHM

= 1.54

Z= no. formula units (8), M=Molar mass

19

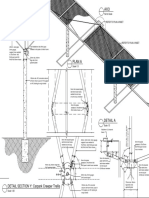

DC Electrical Resistivity Apparatus

DC Electrical Resistivity Apparatus

D = 13mm l = 2.5mm

25-400

0

C

~100-150 V

20

Resistivity Parameters

L

A

R =

y = 4.3696x + 6.4212

R

2

= 0.9956

12

13

14

15

16

17

18

19

20

21

22

1.25 1.75 2.25 2.75 3.25 3.75

1000/T

l

n

=

T k

E

B

a

exp

0

Resistivity is calculated by the formula:

Resistivity shows exponential

dependence on temperature and is

given by Arrhenius-type Equation

where R is the resistance, A = r

2

is area

and L is the width of the pellet, r = 6.5mm

V = IR ;

Activation energy of hopping (Ea) is calculated by plotting resistivity vs 1000/T

21

Dielectric Parameters

Dielectric constant can be calculated by

Tan = 1/2fR

p

C

R

p

= Equivalent parallel resistivity

C

p

= Equivalent parallel capacitance

f = Applied frequency

Dielectric loss is given as

= C d/

o

A

C = Capacitance, d = thickness, A = Cross-sectional area and

o

is the permittivity constant of free space (lit.)

22

H = 0.1 Oe

25-400

0

C

l = 13mm w =

6.5mm

Susceptibility ()

model

AC Magnetic Susceptibility Apparatus

23

Susceptibility vs Temperature

2.02

2.04

2.06

2.08

2.1

2.12

2.14

2.16

2.18

250 300 350 400 450 500 550 600 650 700 750

T/K

1

/

x

(

a

.

u

)

Cr0.1

24

Hysteresis loops for Cr doped cobalt ferrite

-0.15

-0.1

-0.05

0

0.05

0.1

0.15

-0.5 -0.3 -0.1 0.1 0.3 0.5

H/ Tesla

M

/

T

e

s

l

a

Cr=0.1 Cr=0.2

Ms

Mr

Hc

25

Magnetic Parameters

b

s

B

d

M wt Mol

n

585 . 5

. .

=

) 1 ( 5 cos ) 6 ( x x n

K Y B

+ =

Magnetic moment (n

B

) can be calculated by

the formula:

where M

s

is saturation magnetization, d

b

is

the bulk density.

Yafet-Kittle angles (

Y-K

) are determined from

the value of n

B

and dopant content x:

26

XRD patterns of CoCr

x

Fe

2-x

O

4

(x = 0.0 -1.0)

27

SEM of CoCr

0.1

Fe

1.9

O

4

28

Different parameters calculated for Co (Cr

x

Fe

2-x

) O

4

samples

mol (0.01) Cr

content

x

D

(nm)

a

(0.001

)

d

x

(0.01

gcm

-3

)

p

Cr Fe Co

0.0 20

(8.38)

8.385

(5.12)

5.12 0.33 0.00 2.10 1.08

(793)

600 88.62

0.1 73 8.383 5.33 0.48 0.09 1.80 1.11 615 63.50

0.2 62 8.381 5.55 0.44 0.19 1.72 1.09 635 60.95

0.3 65 8.375 5.77 0.44 0.28 1.63 1.09 595 59.41

0.4 49 8.373 5.98 0.48 0.36 1.54 1.09 575 53.49

0.5 66 8.369 6.20 0.51 0.46 1.44 1.09 610 45.91

0.6 53 8.368 6.42 0.54 0.59 1.31 1.10 540 43.85

0.7 40 8.366 6.63 0.57 0.66 1.24 1.10 420 39.85

0.8 70 8.364 6.85 0.60 0.73 1.17 1.09 410 39.49

0.9 49 8.356 7.08 0.62 0.84 1.18 0.98 355 24.93

1.0 49 8.355 7.29 0.65 0.95 1.16 0.90 312

21.32

T

C

(1

K)

29

Plot of resistivity at 393K and activation energy (Ea)

versus chromium content in cobalt ferrites

Ea=0.345-0.520 eV

=5.5910

7

-9.6610

9

cm;

p-type conductivity

0.3

0.35

0.4

0.45

0.5

0.55

0.0 0.2 0.4 0.6 0.8 1.0

Cr content

E

a

/

e

V

0

200

400

600

800

1000

1200

/

c

m

(

1

0

7

)

Ea resistivity

30

Electrical Properties of Spinel Ferrites

Hopping at octahedral (B-sites)

=

T k

E

B

a

exp

0

0

20

40

60

80

100

120

250 300 350 400 450 500 550 600 650 700

Temperature/ K

r

e

s

i

s

t

i

v

i

t

y

/

(

c

m

)

31

Magnetic parameters of chromium substituted cobalt ferrite

determined from hysteresis loops

Cr M

s

(kAm

-1

) M

r

(kAm

-1

) Hc (Oe)

(81.61) (50.96) (879.2)

0.1 119.43 66.08 859.10

814.24

646.19

*

388.74

254.44

57.27

0.2 111.46 63.69

0.4 87.58 50.96

0.6 63.69 34.24

0.8 51.75 19.90

1.0 19.90 4.54

32

Magnetic Properties of Spinel Ferrites

An Anti-parallel arrangement of the ions at tetrahedral

(A-site) and octahedral sites (B-sites)

Fe

3+

(d

5

) Fe

2+

(d

6

)

Fe

3+

Fe

3+

Fe

2+

A site

B site

Superparamagnetic(Hc=0)

t

2

g

eg

33

Plot of saturation magnetization (Ms) and coercivity

(Hc) versus chromium content in cobalt ferrites

Ms= 81-19.90 kAm

-1

(80.8 emu/g)

c= 70-4.56 kAm

-1

0

25

50

75

100

125

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

chromium content 'x'

M

s

/

(

k

A

m

-

1

)

0

10

20

30

40

50

60

70

80

H

c

/

(

k

A

m

-

1

)

Ms

Hc

34

Models for Magnetic Interactions

Neels Model

Yafet-Kittle Model

35

Calculated Y-K angles of chromium substituted

cobalt ferrites

0

10

20

30

40

50

60

70

80

90

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Chromium content

Y

-

K

a

n

g

l

e

s

/

(

d

e

g

r

e

e

)

36

Conclusions for Cr doped series

All the samples synthesized are single phase

Lattice parameter a decreased from 8.385 to 8.355 with increase in

chromium content, x, from 0 -0.1

Resistivity increases with increase (5.5910

7

-9.6610

9

cm) in

chromium content and is more suitable for use in high density recording

devices

The activation energy of hopping increases from 0.345-0.520 eV with

addition of chromium from 0 - 0.1

The Curie temperature has increased for x0.2 (600K to 635K) and

then decreases with increase in chromium concentration

Maximum Ms value (119 kAm

-1

) is observed for Cr = 0.1. Neels model

of sublattices is applicable for pure and Cr = 0.1 doped cobalt ferrite.

For Cr = 0.2 -1.0 Yafet-Kittle model of triangular sublattices is

applicable and the canting angle varies from 24

o

-86

o

.

M. J. Iqbal; M.R. Siddiquah, J. Alloy. Comp. 453 (2008) 513-518

37

Position [2Theta]

20 30 40 50 60 70

Counts

D-1

(220)

(311)

(400)

(511)

(440)

x=0.1

x=0.2

x=0.3

x=0.4

x=0.5

x=0.0

Zr-Mg Doped Cobalt Ferrite

XRD patterns of CoZr

x

Mg

x

Fe

2-2x

O

4

38

mol

x D

(nm)

a

(0.001

gcm

-3

)

d

x

(0.01

gcm

-3

)

p

Zr Fe Mg

0.0 20 8.385 5.12 0.33 0.00 2.10 0.00 600 88.62 50.96

0.1 52 8.387 5.12 0.46 0.09 1.80 0.04 625 94.62 31.85

0.2 53 8.364 5.17 0.41 0.20 1.72 0.11 620 76.52 22.29

15.92

14.33

13.93

0.3 47 8.350 5.21 0.46 0.26 1.63 0.21 555 84.27

0.4 47 8.343 5.23 0.46 0.37 1.54 0.32 525 116.46

0.5 35 8.339 5.24 0.39 0.46 1.44 0.39 520 109.99

T

C

(1

K)

Mr

(kAm

-1

)

Calculated values of lattice parameter (a), crystallite size (D), X-ray density (dx),

porosity (p), dielectric constant () and remanence (Mr) of CoMg

x

Zr

x

Fe

2-2x

O

4

(x =

0.0-0.5)

39

SEM images of Zr-Mg substituted cobalt ferrites

Zr/Mg=0.1 Zr/Mg=0.5

40

Plot of resistivity at 293K and activation energy (Ea)

versus Zr/Mg content in cobalt ferrites

Ea = 0.34-0.48 eV

p= 5.5910

7

-2.7510

9

cm

0

50

100

150

200

250

300

0.0 0.1 0.2 0.3 0.4 0.5

content 'x'

/

(

c

m

)

1

0

7

0.34

0.39

0.44

E

a

/

e

V

(293 )

Ea

41

Plot of saturation magnetization (Ms) and coercivity

versus Zr/Mg content in cobalt ferrites

10

20

30

40

50

60

70

80

90

0.0 0.1 0.2 0.3 0.4 0.5

content 'x'

M

s

/

k

A

m

-

1

Ms Hc

M

s

= 81-23.89 kAm

-1

(80.8 emu/g)

c

= 70-46.18 kAm

-1

42

Calculated Y-K angles of Zr/Mg substituted cobalt

ferrites

0

10

20

30

40

50

60

70

0.0 0.1 0.2 0.3 0.4 0.5

content 'x'

Y

-

K

a

n

g

l

e

s

/

(

d

e

g

r

e

e

)

43

Conclusions for Zr-Mg doped cobalt

ferrite

All the samples synthesized are single spinel phase

Resistivity increases (5.5910

7

to 2.7510

9

cm) with increase

in Zr-Mg content as expected

Dielectric constant of the materials has shown irregular trend but

overall show an increasing trend.

The Curie temperature shows first increase (625K for x=0.1) and

then decreasing trend with increase in Zr-Mg concentration

(520K for x=0.5) (635 K for Cr doped sample)

Zr-Mg addition was expected to increase the saturation

magnetization but it has decreased the Ms value from 81 to

23.89 kAm

-1

, suggesting that Neels two sub-lattice model is not

applicable. Yafet-Kittle model was applied to explain the

decrease in Ms values.

Yafet-Kittle angles varies from 23

o

-64

o

.

M.J. Iqbal; M.R. Siddiquah, J. Magn. Magn. Mater. 320 (2008)

845-850

44

Lithium Manganate Nanomaterials

Doped with Rare-earth Elements

45

Properties of Lithium Manganate Spinel

Most promising cathode materials for

rechargeable Li-batteries

due to their elevated power density

low cost & environmental friendliness

Small polaron semiconductor

Low electrical resistivity (10

5

cm)

High dielectric constant (~ 250)

Low dielectric losses

46

Applications of Lithium Manganate Spinel

Energy source for portable consumer devices

(laptops, cameras, cellular phones, etc.)

Automobile starters, hybrid electric vehicles (HEV),

Uninterruptible power supplies (UPS)

Discrete and multilayer chip (MLC) capacitor (cellular

phones, military radio, etc.)

Low loss substrate for microwave integrated circuits

Microwave telecommunication applications (e.g.

microwave antenna, receivers, etc.)

Advanced microelectronics technologies such as

dynamic random access memories (DRAM)

47

Objectives

To synthesize stoichiometric, single-phase

spinel nano-sized particles of lithium manganate

and its doped derivatives

To investigate the effect of rare-earth element

(La, Ce, and Pr) as dopant on d.c. resistivity

To enhance stability of spinel lattice in order to

improve power capacity of batteries

Investigation of dielectric properties

48

Work Plan

LiMn

2

O

4

Mn

3+

Mn

4+ (High spin, d

4

,

(low spin, d

3

,

t

2g

3

e

g

1

)

t

2g

3

e

g

0

)

Jahn-Teller active

Jahn-Teller inactive

More important for odd number

occupancy of the e

g

level

More pronounced for complexes

with 3 electrons in e

g

level

La

3+=

(Xe)f, Ce

3+

=(Xe)f

1

, Pr

3+

=(Xe)f

2

Reduce the Jahn-Teller active Mn

3+

ion

Decrease the possibility of Jahn-Teller distortion

but results in an increase in resistivity

Increase the average ionic valance of Mn

Stabilize the cubic structure

Jahn-Teller

inactive

Larger binding

energy in MO

6

octahedral site

49

Experimental

LiNO

3

(aq)+Mn(CH

3

COO)

2

(aq) +H

3

C

6

H

5

O

7

NH

3

pH = 7

Li(cit) + Mn(cit) + NH

4

NO

3

(aq)

LiO.Mn

2

O

3

+ H

2

O

LiMn

2

O

4

120

0

C

800

o

C 8 h

Cit = [C

6

H

5

O

7

]

3-

(1:2:3)

8-10h

Citrate sol-gel method

50

XRD patterns of LiLa

x

Mn

2x

O

4

samples where

(a) x = 0.00, (b) x = 0.04, (c) x = 0.08, (d) x = 0.12,

(e) x = 0.16 and (f) x = 0.20.

(111)

(311)

(400)

(331) (511) (531)

(440)

Intensity (a.u)

2 (degree)

51

Parameters Calculated from XRD Data

Samples

Molar Mass

(g/mol)

a/

0.01

V/

3

0.01

D/nm

0.02

dx(g.cm

-3

)

0.02

LiMn

2

O

4

180.82 8.24 559.47 37 4.32

LiLa

0.04

Mn

1.96

O

4

184.18

8.22

555.41

27 4.41

LiLa

0.12

Mn

1.88

O

4

190.89

8.21

553.38

21 4.58

LiLa

0.20

Mn

1.80

O

4

197.61

8.19

549.35

27 4.75

LiCe

0.04

Mn

1.96

O

4

184.23

8.25

561.51

38 4.36

LiCe

0.12

Mn

1.88

O

4

191.04

8.23

557.44

25 4.54

LiCe

0.20

Mn

1.80

O

4

197.85

8.21

553.38

26 4.71

LiPr

0.04

Mn

1.96

O

4

184.27 8.24 559.47 26 4.40

LiPr

0.12

Mn

1.88

O

4

191.13 8.22 555.41 24 4.59

LiPr

0.20

Mn

1.80

O

4

198.01 8.20 551.36 25 4.77

52

Homogenous phase

Uniformly distributed particles

Highly porous morphology

Scanning electron micrographs of (a) LiMn

2

O

4

;

(b) LiLa

0.04

Mn

1.96

O

4

; (c) LiCe

0.04

Mn

1.96

O

4

;

(d) LiPr

0.04

Mn

1.96

O

4

a b

c d

53

in the range of 10

5

cm

increases up to x = 0.12

: Pr<La<Ce at x = 0.04

Plot of dc resistivity (a) and activation energy (b) Vs.

dopant content, x

a b

Ea increases with dopant conc.

Ea value ranges up to 0.3-0.4 eV

2

3

4

5

6

7

8

9

10

0.03 0.08 0.13 0.18

Dopant content, x

c

m

)

1

0

5

La

Ce

Pr

0.25

0.27

0.29

0.31

0.33

0.35

0.37

0.39

0.41

0.43

0.03 0.08 0.13 0.18

Dopant content, x

E

a

(

e

V

)

La

Ce

Pr

Initially the tetrahedral Mn

3+

ions may have to shift to the octahedral site due to addition

of dopant before the critical content and x >0.16 the dopants may not be able to occupy

the octahedral site

54

LiMn

2

O

4

% of Mn

3+

decreases with the increase in

dopant contents

Electrical conduction is due to hopping

mechanism in Mn

3+

/Mn

4+

o The tetrahedral Mn

3+

ions may have to shift to the octahedral site

o Dopant may not be able to occupy the octahedral site >0.16

Mn

3+

Mn

4+

La

3+

, Ce

3+

, Pr

3+

Resistivity increases

Resistivity decreases

La

3+

, Ce

3+

, Pr

3+

(x0.16-0.20)

(x0.04-0.16)

55

Dielectric

parameters

f(MHz) LiMn

2

O

4

LiLa

0.04

Mn

1.96

O

4

LiCe

0.04

Mn

1.96

O

4

LiPr

0.04

Mn

1.96

O

4

0.001 3.810

6

7.010

6

9.710

3

21.810

6

0.1 830.41 903.53 478.50 1191.17

1 124 127 62 240

0.001 138 150 9.04 256

0.1 2.27 3.19 0.94 4.26

1 0.89 1.14 0.64 1.56

tan

Parameters Calculated from Dielectric Measurements

56

Conclusions

All the samples are stoichiometric, single-phase spinel compounds

with the crystallite size ranges 21-36nm

Resistivity increases from (5.010

5

to 8.510

5

cm) for x 0.12

The activation energy of hopping increases (0.39-0.42 eV) for x 0.12

Dielectric constant of the materials decreases with increasing applied

frequency

Pr-substituted spinel material is found to have maximum value of

dielectric constant of 240, with dielectric loss of 1.56

M.J. Iqbal, Z Ahmad., J. Power Sources, 179 (2008) 763-769

57

Spinel Magnesium Aluminate

Nanomaterials

(By Sol Gel Method)

58

Refractory material and is used in cement rotary kilns,

vacuum induction furnaces and glass industries

Catalyst support in the field of environmental catalysis,

petroleum processing and fine chemical production

Humidity and gas sensing material

Magnesium Aluminate; MgAl

2

O

4

Applications

59

XRD patterns of MgFe

x

Al

2-x

O

4

samples where (a) x = 0.00, (b) x = 0.1,

(c) x = 0.2, (d) x = 0.3, (e) x = 0.4, (f) x = 0.5, (g) x=0.6

60

Scanning electron micrographs of MgAl

2

O

4

61

Parameters Calculated from XRD Data

Sample

codes

Molar mass

Values

a

()0.043

V

()

D

(nm)

d

x

(gcm

-3

)

0.064

MgAl

2

O

4

142.0

144.8

144.9

8.056 522.8 12-18

MgAl

1.9

Mn

0.1

O

4

8.087 528.7 17-21 3.639

MgAl

1.9

Fe

0.1

O

4

3.621

8.083 528.5 15-19 3.643

62

13

15

17

19

21

23

25

1.5 1.7 1.9 2.1 2.3 2.5

1000/T (K

-1

)

l

n

0

0.1

0.2

0.3

0.4

0.5

0.6

Ca

2+

content, x =

0

1

2

3

4

5

6

7

400 450 500 550 600 650

T/K

(

.

c

m

)

1

0

8

0.1

0.2

0.3

0.4

0.5

0.6

decreases on increasing temp.

Semi-conducting behavior

ranges up to 10

8

ohm.cm

Activation energy is directly related to dc resistivity

a

b

Fig. (a, b) Plots of dc electrical resistivity for MgAl

2

O

4

samples

vs Temperature

63

MgAl

2

O

4

Mg

2+

Al

3+

Electrical conduction is increased due to

replacement of Al ions with Mn

3+

and Fe

3+

at

the octahedral site

Cr

3+

, Mn

3+

, Fe

3+

Have Octahedral

site preference

Resistivity decreases

64

Parameters calculated by Resistivity Measurements

Samples E

a

/eV

Resistivity at 150

o

C

( 10

8

cm) 1.924

MgAl

2

O

4

0.924 6.989

MgAl

1.9

Mn

0.1

O

4

0.692 1.414

MgAl

1.9

Fe

0.1

O

4

0.682 1.919

65

Conclusions

All the synthesized samples are single-phase spinels

with cubic symmetry

Crystallite size ranges from 12-31 nm

Particle size ranges from 40-55 nm by SEM

X-ray density increases 3.505 to 3.692 gcm

-3

Resistivity decreases 6.9-1.9x10

8

cm with increase in

dopant content

M.J. Iqbal; S. Farooq, S., Mater. Sci. Engg. B, 136 (2007) 140-147

66

Effect of solution pH on the

properties of MgAl

2

O

4

and its

derivative

67

Objectives

To study the effect of pH on the formation and

properties of nano sized spinel magnesium

aluminates

To determine the minimum pH required for

the formation of the spinel single phase

To study the electrical properties of the

magnesium aluminates synthesized at

different pH values (5-10)

68

Coprecipitation Method

Mg(NO

3

)

2

.6H

2

O + 2Al(NO

3

)

3

.9H

2

O + NH

4

OH MgAl

2

O

4

(1:2 M)

NH

4

OH

Drying at 120

o

C/ 12hrs

Annealing 950

o

C/ 8hrs

pH (5-10)

1 hr stirring, aged overnight

Mg(NO

3

)

2

.6H

2

O + 2Al(NO

3

)

3

. 9H

2

O

Mg(OH)

2

Al

2

(OH)

6

H

2

O

.

+ NH

4

NO

3

(aq)

MgO.Al

2

O

3

+ H

2

O

MgAl

2

O

4

Powdered (pelletized)

69

Position [2Theta]

20 30 40 50 60 70

I

n

t

e

n

s

i

t

y

[

a

.

u

]

(111)

(220)

(311) (400)

(511)

(440)

pH 5

pH 6

pH 7

pH 8

pH 9

pH 10

(a)

111

220

311

400

511

440

X-Ray Diffraction Patterns of Magnesium aluminate at pH 5 - 10

70

Thermal Analysis of Magnesium Aluminates at different pH

71

-10

10

30

50

70

90

110

130

9 9.5 10 10.5 11 11.5 12 12.5 13 13.5 14

ln (f / Hz)

pH 5

pH 6

pH 7

pH 8

pH 9

pH 10

(a)

Electrical Properties

0

5

10

15

20

25

250 300 350 400 450 500 550 600 650 700

T (K)

c

m

)

x

1

0

9

pH 5

pH 6

pH 7

pH 8

pH 9

pH 10

(a)

T

MS

M

e

t

a

l

l

i

c

b

e

h

a

v

i

o

r

S

e

m

i

-

c

o

n

d

u

c

t

o

r

b

e

h

a

v

i

o

r

72

Resistivity and Dielectric constant values

pH 5 6 7 8 9 10

D (nm)

(2)

9-15 6-10 6-9 10-14 11-17 7-16

( cm)x10

9

(1.26) at

350K

2.23 3.75 10.13 3.42 1.59* 2.9

(0.15)

1MHz

8.26 9.88 9.51 10.21 8.09* 9.14

73

Conclusions

Single phase spinel magnesium aluminate was

successfully synthesized at the studied pH range of 5-

10 by the coprecipitation method.

Crystallite sizes obtained between 6 17 nm

Resistivity values range between 1.59 10.13 x 10

9

Ohm.cm with the minimum value at pH 9.

Dielectric constant values range between 8.26- 10.21

with a lowest value obtained at pH 9.

M.J. Iqbal; B. Ismail, J. Alloy. Comp. (Submitted)

74

THANKS

X-ray diffraction pattern of CoFe

2

O

4

nanoparticles,

average crystallite size, 21 nm.

K. Maaz et al. J. Magn. Magn. Mater. 308(2007)289-295

XRD patterns of ZnFe

2

O

4

nanoparticles, average particle

size, 18 52 nm

M. Atif et al. Solid State Comm. 138(2006)416-421.

77

XRD patterns of NiAl

2

O

4

nanoparticles, average particle

size,

8 30 nm

S. Kurien et al. Mater. Chem. Phys. 98(2006)470-476.

8 nm

10 nm

14 nm

30 nm

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Why File A Ucc1Document10 paginiWhy File A Ucc1kbarn389100% (4)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Calculus HandbookDocument198 paginiCalculus HandbookMuneeb Sami100% (1)

- Sample Cross-Complaint For Indemnity For CaliforniaDocument4 paginiSample Cross-Complaint For Indemnity For CaliforniaStan Burman75% (8)

- Ed Post Lab Heat of Formation of NaClDocument4 paginiEd Post Lab Heat of Formation of NaClEdimar ManlangitÎncă nu există evaluări

- Better Photography - April 2018 PDFDocument100 paginiBetter Photography - April 2018 PDFPeter100% (1)

- Biblical Foundations For Baptist Churches A Contemporary Ecclesiology by John S. Hammett PDFDocument400 paginiBiblical Foundations For Baptist Churches A Contemporary Ecclesiology by John S. Hammett PDFSourav SircarÎncă nu există evaluări

- Benko Gambit-Jacobs and Kinsman, 1999Document163 paginiBenko Gambit-Jacobs and Kinsman, 1999johnson Greker100% (3)

- Process Strategy: Powerpoint Slides by Jeff HeylDocument13 paginiProcess Strategy: Powerpoint Slides by Jeff HeylMuizzÎncă nu există evaluări

- Acampamento 2010Document47 paginiAcampamento 2010Salete MendezÎncă nu există evaluări

- SEC CS Spice Money LTDDocument2 paginiSEC CS Spice Money LTDJulian SofiaÎncă nu există evaluări

- Advent Wreath Lesson PlanDocument2 paginiAdvent Wreath Lesson Planapi-359764398100% (1)

- Unit 4Document15 paginiUnit 4David Lopez LaraÎncă nu există evaluări

- Rare Malignant Glomus Tumor of The Esophagus With PulmonaryDocument6 paginiRare Malignant Glomus Tumor of The Esophagus With PulmonaryRobrigo RexÎncă nu există evaluări

- Model TB-16Document20 paginiModel TB-16xuanphuong2710Încă nu există evaluări

- Asan Visa Ae102901499Document2 paginiAsan Visa Ae102901499hardeep ranaÎncă nu există evaluări

- BioremediationDocument21 paginiBioremediationagung24864Încă nu există evaluări

- Pest of Field Crops and Management PracticalDocument44 paginiPest of Field Crops and Management PracticalNirmala RameshÎncă nu există evaluări

- Use of Travelling Waves Principle in Protection Systems and Related AutomationsDocument52 paginiUse of Travelling Waves Principle in Protection Systems and Related AutomationsUtopia BogdanÎncă nu există evaluări

- 2013 Cases Penned by Justice BernabeDocument11 pagini2013 Cases Penned by Justice BernabeJoan PabloÎncă nu există evaluări

- Teks Drama Malin KundangDocument8 paginiTeks Drama Malin KundangUhuy ManiaÎncă nu există evaluări

- Bigbazaar PDFDocument14 paginiBigbazaar PDFazhagu sundaramÎncă nu există evaluări

- Kidney Stone Diet 508Document8 paginiKidney Stone Diet 508aprilÎncă nu există evaluări

- s15 Miller Chap 8b LectureDocument19 paginis15 Miller Chap 8b LectureKartika FitriÎncă nu există evaluări

- Fire Technical Examples DIFT No 30Document27 paginiFire Technical Examples DIFT No 30Daniela HanekováÎncă nu există evaluări

- Japanese GardensDocument22 paginiJapanese GardensAnmol ChughÎncă nu există evaluări

- Clash of Clans Hack Activation CodeDocument2 paginiClash of Clans Hack Activation Codegrumpysadness7626Încă nu există evaluări

- TrellisDocument1 paginăTrellisCayenne LightenÎncă nu există evaluări

- Adverbs of Manner and DegreeDocument1 paginăAdverbs of Manner and Degreeslavica_volkan100% (1)

- Building For The Environment 1Document3 paginiBuilding For The Environment 1api-133774200Încă nu există evaluări

- TW BT 01 - Barstock Threaded Type Thermowell (Straight) : TWBT - 01Document3 paginiTW BT 01 - Barstock Threaded Type Thermowell (Straight) : TWBT - 01Anonymous edvYngÎncă nu există evaluări