Documente Academic

Documente Profesional

Documente Cultură

Ambar Purohit Capstone

Încărcat de

Ambar PurohitDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ambar Purohit Capstone

Încărcat de

Ambar PurohitDrepturi de autor:

Formate disponibile

Logistics

Logistics is the management of the flow of goods, information and other resources, including

energy and people, between the point of origin and the point of consumption in order to meet

the requirements of consumers. Logistics is a part of supply chain management (SCM).

The word logistics was first claimed to have been associated with the military in 1905 as

a branch of war that pertains to the movement and the supply for armies.

Logistics involves the integration of information, transportation, inventory, warehousing,

material-handling, and packaging, and occasionally security. Logistics is a channel of the

supply chain which adds the value of time and place utility.

Range of Logistics Services

The evolution of logistics and SCM in the 1990s can be traced back to physical distribution

management in the 1970s when there was no coordination among the various functions of an

organization, and each was committed to attain its own goal. This myopic approach then

transformed into integrated logistics management in the 1980s that called for the

integration of various functions to achieve a system-wide objective.

Global logistics industry:

Currently the annual logistics cost of the world is about USD 3.5 trillion. For any country, the

annual logistics cost varies between 9% and 20% of the GDP, the figure for the US being

about 9%

.

The logistics industry is a very competitive one with a large number of international players

having presence in many countries. The service providers have a number of issues to address,

such as pricing pressures, high costs of operations and low returns on investments, hiring and

retaining talent, and pressure from clients to broaden the range of service offerings and

internationalize operations, demand for customized solutions and more value-added services,

besides infrastructure bottlenecks and government regulations.

The service providers have to continuously upgrade their networks and systems and equip

themselves with the latest technologies to carry out their complex operations and provide the

best logistics services to their customers. This involves huge capital expenditure and an

ongoing maintenance costs. Logistics companies the world over are increasingly investing in

technologies like Warehouse Management System (WMS), Enterprise Resources Planning

(ERP), Global Positioning System (GPS) and Radio Frequency Identification (RFID) to

provide the best logistics services increasing transparency and efficiency of supply chains of

their customers.

Globalization, consolidation, technology advancements and outsourcing have led to growth in

the logistics services market. The capabilities of logistics service providers are growing along

with the changing expectations of their clients. As the logistics services industry evolves,

competitors are moving away from asset-based commoditized services to more strategic,

information-based approaches.

Indian Logistics Industry

Background

The logistics sector in India has evolved over the past two decades from being a pure

transportation / warehousing functional service to provision of more value added offerings

like customs clearance, domestic / international freight forwarding, cross-docking, reverse

logistics, freight consolidation, warehousing of modern standards etc. India with a GDP of

about Rs 31,297 billion is estimated to spend 13 per cent of its GDP on logistics creating an

industry size of around Rs. 4,068 billion (approx. Rs 4 lakh crores). The industry generates

employment to 4.5 crore people in the country. The sector has been witnessing double-digit

y-o-y growth rate since 2002 and is expected to be more than USD 120 billion (approx Rs.5.4

lakh crores) by 2015.

India ranked 47

th

in the World Banks 2010 Logistics Performance Index (LPI) out of 115

countries that were assessed for their efficient logistics systems with a score of 3.12 out of a

possible 5.

While there has been a growing recognition in India of logistics as a strategic tool for

enterprise cost reduction and improvement of organizational efficiency on the flip side

however, the logistics sector is characterized by dominance of a disorganized market.

Transporters with fleets smaller than five trucks account for over two-thirds of the total trucks

owned and operated in India and make up 80% of revenues. The freight-forwarding segment

is also represented by thousands of small customs brokers and clearing & forwarding agents,

who cater to local cargo requirements.

In order to reduce logistics costs and focus on core competencies, Indian companies across

verticals are now increasingly seeking and using the services of third-party logistics service

providers. Traditionally LSPs (Logistics Service Providers) concentrated mainly on

transportation and logistics as they form a major share in logistics. However, in order to keep

up with rising demands and customer expectations, companies now also concentrate on value

added services like packaging, custom clearance, inventory management and labeling.

The major elements of logistics costs for Indian Industries include transportation,

warehousing, inventory management and other value added services such as packaging.

Challenges faced by Indian logistics sector

These are among the supply chain challenges outside companies can expect as they enter the

India market:

Limited physical infrastructure. In India the national highways account for less than

2 percent of the total road network, but carry 40 percent of the traffic. This is one

reason the average speed in India is 20 miles per hour, compared to the Wests 60

miles per hour. The poor condition of roads translates directly to shorter vehicle

lifespan, which increases operating costs and reduces efficiency. Off the highways,

firms can only run trucks smaller than 20 feet. As of now, India invests less than 4

percent of its GDP in infrastructure, compared to Chinas 9 percent.

Over-burdened ports. India has a long coastline, but its port system isnt well

utilized. Seventy percent of the seaborne trade is handled by 2 of its 12 major ports,

while 180 minor ports go virtually unutilized. As a result, turnaround time far lags

other global ports with vessels taking up to 3 days to debark. Many of the secondary

ports have infrastructure problems that arent a quick fix. Even within its large ports,

India cant support 6,000 TEU containerships, which make up 25 percent of todays

shipping volume. In addition to constraining Indias growth in offshore production,

this makes it difficult for manufacturers hoping to import, rather than produce

products for Indian consumers.

Non-existent warehouse standards. There is virtually no complex distribution center

set-up, no standards for suppliers, and little vendor compliance. Beyond that, firms

will find there is little vacant DC space available. Firms entering the country will have

to build this infrastructure, which will include supplying their own electricity, running

water, and road access.

Disorganized trucking operations. Two-thirds of fleets have less than five vehicles,

making it difficult for shippers to manage the plethora of carriers required to handle

shipment volumes. Freight consolidators and brokers take a commission to provide

truck owners with consignments, and corruption is rampant. Also, inadequate

infrastructure causes equipment maintenance costs to be abnormally high. These

increasing costs and dwindling profits leave little opportunity for small fleet owners to

expand.

Multiple tax structures at entry points of different states. Multiple tax rates at

different states, octroi and different documentation requirements at the entry

checkpoints of different states consumes time and increases complexity of trade

between states. This acts a big blockade for movement of goods between states.

FDI regulations for all logistics projects

In general 100% FDI under the automatic route is permitted for all logistic services

FDI up to 100% subject to FIPB approval is permitted for courier services.

FDI up to 49% under the automatic route is permitted for air transport services,

including air cargo services.

100% FDI is permitted in Ports and Harbors under automatic route

100% FDI is permitted under the automatic route for storage and warehousing

including warehousing of agricultural products with cold storage.

100% FDI is permitted in transport and transport support services through automatic

route

3PL

Third-party logistics (3PL) refers to outsourcing transportation, warehousing and other

logistics related activities to a 3PL service provider that were originally performed in-house.

Third-party logistics (3PL) or logistics outsourcing is gaining importance as more and more

corporations across the world, unable to manage their complex supply chains, are outsourcing

logistics activities to the 3PL or logistics service providers. Globalization has led to rapid rise

in the need for outsourcing logistics by companies looking for readymade distribution

channels to an entity with local expertise. Also the process of global sourcing by companies

and supply chains increasingly becoming global and complex has given impetus to the

growth of 3PL services.

By outsourcing logistics activities, corporations are able to not only concentrate on their core

business operations, but also achieve cost-efficiency and improve delivery performance and

customer satisfaction.

Further evolving from outsourcing logistics to 3PL service providers companies are moving

towards 4PL and 5PL service providers to improve their logistics with minimum investments

and in a cost effective manner. This process of evolution helps companies to build efficient

supply chains, reach all the potential customers and achieve customer satisfaction leading to

improved business performance impacting both revenue and profit growth.

Basic principle and functions of 3PL and

Multi-actors logistical co-operation

The concept of 3PL has been developed from the need to extend transportation services by

transportation companies to its customers. Basically, 3PL might be defined as outsourcing of

transport and logistics activities to outside companies that are neither consignors nor

consignees.

3PL came into existence during the deregulation of freight transport industry in the 1980s and

has progressed in the 1990s along with the development of information technologies

The PL Pyramid from 1PL to 5PL might be described as a downstream change of functions in

terms of transport/logistics services.

Most small businesses buying and selling in the same location are 1PL.

As the business expands geographically, the manufacturers logistics border extends, a 2PL

provider is generally a commodity capacity provider, such as a trucking company or a

warehouse operator, a 2PL provides service for a single or a small number of functions in the

supply chain.

With the increasing demand for one-stop solutions, many 2PLs have evolved into 3PLs by

adding new logistics capabilities and integrating their operations. It may or may not involve

asset ownership. 3PL is a broader term that is frequently used to cover businesses in freight

forwarding or contract logistics. It performs all or a large portion of a clients supply chain

logistics activities and its value adding is based on information and knowledge versus a non -

differentiated transportations service at the lowest cost.

The 4PL provider is essentially a logistics integrator or a one-point contact for the

manufacturers logistics outsourcing requirements. They are responsible for contracting

various 2PL and 3PL providers, and for assembling and managing those end-to-end solutions.

The 5PL solutions focus on providing overall logistics solutions for the entire supply chain.

Supply Chain Management (SCM) is the integration of the activities associated with the flow

and transformation of goods in the respective logistics networks through improved supply

chain relationships based on a common collaborative performance measurement framework

for attaining close, collaborative and well-coordinated network relationships to achieve a

Competitive edge.

Categories of 3PL providers

Some literature sources are describing four categories of 3PL providers:

1) Standard 3PL providers: This is the most basic form of a 3PL provider. They would

perform activities such as, pick and pack, warehousing, and distribution (business) the most

basic functions of logistics. For a majority of these firms, the 3PL function is not their main

activity.

2) Service developers: This type of 3PL provider will offer their customers advanced value-

added services such as: tracking and tracing, cross-docking, specific packaging, or providing

a unique security system. A solid IT foundation and a focus on Economies of scale and scope

will enable this type of 3PL provider to perform these types of tasks.

3) The customer adapters: This type of 3PL provider comes in at the request of the

customer and essentially takes over complete control of the companys logistics activities.

The 3PL provider improves the logistics dramatically, but do not develop a new service. The

customer base for this type of 3PL provider is typically quite small.

4) The customer developers: This is the highest level that a 3PL provider can attain with

respect to its processes and activities. This occurs when the 3PL provider integrates itself

with the customer and takes over their entire logistics function. These providers will have few

customers, but will perform extensive and detailed tasks for them.

CHOOSING A 3PL PROVIDER

3PL relationships are on a contract basis typically involving a long-term commitment. The

key to successful outsourcing relationships is having an organized process for selecting and

communicating with potential 3PL vendors.

Nine steps that should be followed to successfully select a 3PL provider. These are listed and

described as follows:

Form a cross-functional team- Choosing a 3PL provider should be a collaborative effort

between various departments within a company (such as manufacturing, sales, marketing,

finance, quality control, logistics, etc.). Bringing various departments together will allow the

company to choose a 3PL provider that meets the needs of each department within the

company.

Set objectives- Objectives may include reducing costs, reaching new markets, a desire

to concentrate on core competencies, or to be able to compete in a particular industry.

Once a company defines its needs and wants, it can better choose a 3PL provider that

will best suit those needs.

Determine Customer Service Requirements- Since customers are the basic reason for

a companys existence, their needs should be paramount when making a major

decision. Customer service requirements should be delineated so they can be fulfilled

effectively and efficiently. Identifying these needs can also be useful in forecasting

future logistics services.

Develop a List of Candidates- Online research can be used to locate 3PL providers

that can suit ones logistics needs. 3PL providers can also be found in industry

directories and through the International Warehouse Logistics Association (IWLA).

Explore Interest Among 3PL Candidates- Before preparing a formal proposal, it is

wise to check with 3PL providers to see if they would be willing to provide the

services desired. A letter (or e-mail) which summarizes the companys situation and

the logistics needs it seeks may be sent to promising 3PLcandidates. This letter should

also request information from the 3PL providers and the extent of their logistics

capabilities

Solicit Requests for Proposals- After confirming interest from different 3PL

providers, a company may then send requests for proposals (RFPs). The RFPs

should provide a detailed outline of logistic services the company is seeking.

Requirements that should be addressed include distribution, warehousing,

transportation, and the extent of value-added services the company desires. It is

important to go include sufficient detail so the 3PL providers know exactly what kind

of logistic services are being sought.

Visit the Prospective Providers Facilities- Once the list of 3PL providers is narrowed

down to four or five, each of their facilities should be visited by the cross-functional

team. The team can survey each 3PL facility and rate them on various criteria. In

addition to analyzing the 3PLs place of business, the cross-functional team can get a

chance to interact with management and employees and gain a better understanding of

the work ethic and procedures of the 3PLs logistic services.

Review Qualifications- Some of the data to be reviewed includes the RFPs and all

aspects of each 3PL providers business. These include financial information,

strategic fit, general management philosophy, and the providers track record of

customer satisfaction in current and past business relationships.

Choose the Best Candidate- Once all data are reviewed by the cross-functional team,

its time to choose the 3PL provider that will best meet the companys logistics

needs. This begins a long term relationship calling for the cross-functional team to

continually rate the effectiveness of the chosen 3PL provider to ensure future success

and strategic fit with the company.

Selecting a 3PL Provider

Selection process

To manage the RFQ (Request for Quotation) process for selecting your 3PL provider, it is

best to appoint a multi-disciplined project team typically between six and ten participants

and adopt a structured model for engaging and leading the project team through the selection

process.

1. Define RFQ Requirements

a. Detailed scoping of logistics model within your supply chain

b. Compile detailed requirements specifications, metrics & templates

2. Issue RFQ to Invited 3PL Vendors

a. Pre-qualify vendors, execute confidentiality agreements

b. Manage bid process with 3PLs, including dealing with queries

c. Compile queries and responses, collate and issue updates

3. Receive Proposals from 3PL Vendors

a. Review proposals, map to requirements and criteria

b. Collate team views and feedback, compile comments and questions

4. Vendor Presentations

a. 3PL to present their company, solution and benefits

b. Management discussions process, people, pricing

5. Site Visits

a. Visit 3PLs logistics facility view operations, processes, people

b. Review capabilities, capacity, competencies

6. Short List (as required)

a. Continue with further exploration and evaluation

b. Probe deeper into capabilities, pricing models & assumptions

7. References

a. Consultations with client references provided by 3PL

b. Obtain independent perspective market reputation, ex-clients

8. Executive Engagement

a. 3PL present to senior management

b. Explore and assess organisational fit

9. Evaluation & Selection

a. Compare and contrast company, solution, economics

b. Map shortlisted venders to evaluation criteria

Evaluation criteria

It is important to compile your criteria for evaluating the potential 3PL providers and for the

project team members to independently rate and score the participants. Rather than compiling

the actual total scores, compare each team members resulting ranking of the bidders (first,

second, third place) this will neutralise the impact of some team members being more

generous with their scores than others. Having collated the rankings, explore any significant

areas of difference through discussion and review of specific line item details.

In compiling your evaluation criteria, include both quantitative and qualitative factors,

together with consideration of future potential requirements. Consider the following seven

main categories for your evaluation criteria to support your selection process. Within each

category, expand the detailed expectations and requirements to match your business needs

and specific circumstances.

1. 3PL Provider Size and scale of their operations; their standing in the industry; market

reputation; financial viability; senior managements active involvement in the bidding

process; their commitment levels; their corporate DNA vision, values, and their approach to

corporate responsibility; their relevance/appropriateness to your company needs.

2. Logistics Solution 3PLs operational capabilities in terms of warehouse, equipment,

space; capability of the proposed solution to meet your business needs; their expertise;

adequate logistic network to meet supply chain requirements.

3. Economics -competitive price; opportunities for economies of scale; flexibility in their

pricing to meet the emerging requirements.

4. Technology robustness of their information technology platform and systems, and their

ability to integrate with your IT systems; their IT capability and competence; prior experience

in similar system integrations.

5. Future Proof capability to grow with you as your business grows; scalability and

flexibility; ability to meet your future potential needs; speed with which they can ramp up

operations; capability and financial means to expand their skills base and operations.

6. Value Add their ability, in terms of experience, knowledge and expertise, to help you

improve your companys logistics activities; industry leadership; their ability to take a

proactive approach to explore and propose mutually beneficial solutions.

7. Services Delivery your confidence levels in their ability to deliver on the promise

execute on their proposed solution to deliver the operational requirements and business

benefits consistently, reliably and cost-effectively; capacity to deliver on your requirements

through the three additional marketing Ps that are critically important in Services businesses

the Physical results, the Processes and the People; experiences of other customers through

anecdotal evidence and client references.

When selecting a 3PL provider it is very tempting to focus on evaluating items 2 and 3

these hard dimensions are tangible and relatively straightforward to compare across

multiple vendors. However, the soft factors the intangibles in items 5, 6 and 7 are of equal

if not more, importance. These soft factors are what will determine the long-term

sustainability and success of your chosen service provider and their logistics solution. Careful

consideration of all of the evaluation criteria is essential to ensure a successful outcome.

Deciding to a use a third party logistics company is a decision that depends on a variety of

factors that differ from business to business. The decision to outsource certain business

functions will depend on the companys plans; future objectives, product lines, expansion,

acquisitions, etc.

Once a decision has been made to outsource certain processes then a company will begin a

search for the right 3PL that fits all their requirements at the best possible price. There are

three types of Third Party Logistics Company that operate today.

Asset Based

Management Based

Integrated Providers

Asset based third party logistics companies use their own trucks, warehouses and personnel

to operate their business. Management based companies provide the technological and

managerial functions to operate the logistics functions of their clients, but do so using the

assets of other companies and do not necessarily own any assets. The third category,

Integrated Providers, can either be asset based or management based companies that

supplement their services with whatever services are needed by their clients.

When selecting a 3PL, the request for information (RFI) or quotation (RFQ) should be as

detailed as possible. The company that is selected should be able to fulfill all the logistics

requirements and that can only be assured if every requirement is communicated to potential

companies. The RFI should include a detailed description of the areas to be outsourced. This

will usually include:

The scope of the contract, including locations, facilities, departments.

Information on volumes involved; number of deliveries, warehouse sizes, number of

items, etc.

The logistics tasks are to be performed, e.g. warehousing, transportation, etc.

The level of performance required.

Gati Ltd

Company Background

Gati is a pioneer in Express Distribution and supply chain solutions in India. Gati started

operations in 1989 as a door-to-door cargo company. A division of Transport Corporation of

India (TCI), it was the result of Mr. Mahendra K Agarwals conscious decision after he

returned from the United States with a degree in management. When he joined TCI in 1980,

it was one of the top three transport companies in India. His aim was to rebuild an otherwise

successful TCI based on systems and processes and manage it professionally to meet implicit

and explicit consumer needs.

Based on customers feedback and interaction, Agarwal felt that, apart from moving cargo,

TCI could do something different which customers would value and appreciate. Thus Gati

was introduced in the market as a door-to-door cargo company with commitment on delivery

and money back guarantee. The name Gati was selected to reflect and represent speed with

direction.

Agarwal was aware that Gati was a late entrant to the generic cargo business. To make

progress, the business needed to be conducted with a different perspective. Gati was willing

to wait to generate surplus from the business. Agarwal chose time bound, point to point

delivery, premium priced cargo management service. With this offering, Gati introduced the

concept of express cargo in the Indian context.

VISION and MISSON statement

Be a globally preferred provider of India-centric supply chain services and solutions, and a

leader in the Asia Pacific region.

Delight customers with quality service by setting new trends through innovation and

technology.

Be the most preferred organization for all stakeholders.

Be a responsible corporate citizen with the unwavering commitment to environmental

protection and conservation.

Business:

Gatis core business is Express Distribution and Supply Chain Solutions. It offers total end-

to-end logistics solutions to its customers.

Its two lines of business are

Capabilities

Gati is Indias only multimodal logistics company, offering seamless connectivity

across air, road, ocean and rail.

It is the Indias first logistics company to receive ISO 9001 certification

Gati covers 603 of Indias 611 districts, a reach unmatched by any other player.

It has a fleet of 4000 vehicles, 94 refrigerated trucks and 6 marine vessels to ensure

faster time to markets through well streamlined operations.

Leverages an extensive technology backbone that allows tracking of shipments online

Provides real-time delivery information on shipments

Has over 2 million sq.ft. of best-in-class mechantronic warehousing space, spanning

the length and breadth of India

Delivers a record 3 million packages weighing over 46,000 tons every month

Has a dedicated workforce of 2,850 well trained Gatiites

Products/Services of Gati

Gati offers a host of products and services customised to meet the logistics requirements of

its customers. They are

Gati Surface Express

Gati Air Express

AI Gati Courier

Gati Art Express

Gati Supply ChainIntegrated Logistics

Gati Kausar Cold chain logistics

Gati Transport Solutions Full Truck Load

Gati Europe Express

Gati Global Express

Gati Internationalthe global arm

Gati Coast to Coastthe shipping division

Gati Happiness Gift services

Gati Student Express

With its superior coverage, reach, facilities and capabilities Gati is all geared to provide the

best end-to-end logistics services to companies in different industry verticals. The company

has over the years has evolved from a desk-to-desk cargo company to a preferred 3PL.

Performance of the company

The companys revenue has consistently grown at a CAGR of 12% from 2001-2009

increasing its share of logistics services in the country

Evolution of business mix

Business by divisions:

As can be seen from the below chart there has been shift in the companys business mix over

the years from low margin express segment to high margin logistics and freight segment.

The trend to outsource logistics to 3PL will further improve the earnings of the company.

Increase in assets and a rise in capabilities

The company has continuously invested in assets to increase its capabilities to deliver the best

logistics solutions. The company is transforming its network into a hub and spoke model to

increase the reach and operational efficiency.

Major competitors

The company over the years has built an extensive capability over the years to take on

competition, both from domestic and international competitors operating in the country. But

the competitors are catching up. Since the market for reliable logistics services is increasing

new players are entering the market and the established players are consolidating.

Many large manufacturing and service units like Reliance, Mahindra & Mahindra, Future

Group have established their own in-house logistics divisions. Now these companies plan to

provide logistics services to other companies also.

The major competitors of Gati in Express Division are

TNT

Safexpress

TCI XPS

AFL

Blue Dart

Distribution channels of Gati in Retail segment

In a country like India with so many diversities no single distribution channels is perfect.

Companies have to adopt a multi modal distribution network keeping in view of the factors

like market potential, nature of the product, customer expectations, company strategy,

industry trends, etc to reach a maximum number of potential customers.

Gati has two types of customers one who has a long term relationship and regular

transactions with Gati. These customers are contractual customers who are extended a period

of credit as per the agreement. Then there are customers who do a single transaction or

irregular transactions with Gati, these customers deal with Gati on cash basis and the segment

is called Retail Segment. They can be either individuals or businesses.

Gati is in service industry providing complex logistics solutions to customers. Gati follows a

multi modal distribution network to reach both business and individual customers. Here time

and material safety are critical factors affecting the customer satisfaction. So the company has

to keep in mind these aspects while designing a distribution channel.

Elements of the distribution network

The several elements of Distribution network are as described below:

OU Operating Unit (OU) is the company office/hub which administers all the operations in

the regions under it. It may also act a transit hub.

Franchise - A franchise is a channel partner appointed by the company to carryout the

operations of an OU where the company doesnt have its own infrastructure or chooses to do

so depending on market conditions.

Kiosk A kiosk is a channel partner whose main job is to operate an outlet where customers

can book their shipments to be carried by the company.

Caf A caf is a company owned outlet where apart from booking services, other services

like Internet browsing, Printouts and Photocopying services are also offered.

GA Gati Associate (GA) is a channel partner who owns a vehicle and maintains it as

prescribed by the company whose primary job is to liaise with the areas sales force, take

shipment orders from customers, do booking, pickup the material from customers door and

deliver it at the regional OU.

Sales Force Sales Force consists of the personnel of the company whose key

responsibilities are Retention business development (RBD), New business development

(NBD), Channel partner development (CPD), Collections and Promotional activities in the

area under him.

Channel Design

Earnings are shared with members of the distribution channels depending upon the function

performed by them in the channel, product, individual docket charges and rates applicable

after a ceiling on earnings of the member in a month.

Kiosk:

The main function of a kiosk is booking a shipment. A kiosk is paid depending on whether it

has its own connectivity with Gati, the kind of product offered and an upper and lower limit

on margins per docket.

GA:

The main function of a GA is providing connectivity i.e. carrying a shipment. A GA is paid

depending on whether it is booking/delivery, the kind of product offered, and ceiling on the

earnings in a month and an upper limit and lower limit on margins per docket.

Franchise:

The main function of a Franchise is operating an OU. A franchise is paid depending on

whether it is booking/delivery, the kind of product offered, and ceiling on the earnings in a

month and an upper limit and lower limit on margins per docket.

Analysis of survey of Gati kiosks and competitor outlets

A survey of all the24 kiosks of Gati in Kolkata over a period of 20 days to find out the nature

of transactions done at these outlets, average sales per month, promotional activities carried

out at these outlet locations and their experience with company and its sales personnel.

Kiosk sales per month (in Rs)

39%

26%

17%

9%

9%

<50000

50000-100000

100000-200000

300000-400000

400000-500000

Average Courier and Cargo booking ratio at Kiosks

15%

85%

Courier

Cargo

From the above graph it is clear that kiosks are doing very low business in courier bookings.\

Competitors in courier services

24%

20%

23%

20%

13%

DTDC

Blue Dart

First Flight

Overnite

Others

From the above graph it can be concluded that courier industry is a very competitive one with

a large number of competitors vying aggressively with their distribution network and price

for the small pie.

Competitors in Cargo services

10%

37%

21%

7%

11%

14%

Blue Dart

Gati

Safexpress

TNT

XPS

Others

From the above graph it is clear that Gati has very little competition in cargo and express

distribution services and the company should focus on this segment.

Experience with company and its workforce

0% 0%

46%

37%

17%

Very bad

Bad

OK

Good

Very Good

What should be done by the company to increase sales at kiosks?

47%

21%

32%

Promotion

Improve services

Better support

Distribution infrastructure of logistics companies in Kolkata

Courier companies

0

20

40

60

80

100

120

140

DTDC First Filight Overnite Gati Blue Dart

Cargo Companies

0

5

10

15

20

25

30

Blue Dart Gati Safexpress XPS AFL TNT

From the above two graphs it is amply clear that Gati has adequate market penetration as

compared to other companies in cargo business. So the company should focus on its cargo

business and expand its share of the pie.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Dynamic Law of ProsperityDocument1 paginăThe Dynamic Law of Prosperitypapayasmin75% (4)

- Einstein Quotes On SpiritualityDocument2 paginiEinstein Quotes On Spiritualitybob jamesÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- ThiruppavaiDocument157 paginiThiruppavaiajiva_rts100% (49)

- The Art of Communication PDFDocument3 paginiThe Art of Communication PDFHung Tran JamesÎncă nu există evaluări

- A To Z of Architecture PDFDocument403 paginiA To Z of Architecture PDFfaizan100% (1)

- Schneider Electric Strategy PresentationDocument10 paginiSchneider Electric Strategy PresentationDeepie KaurÎncă nu există evaluări

- Non-Verbal, Verbal Aptitude Test ExamplesDocument3 paginiNon-Verbal, Verbal Aptitude Test ExamplesAmbar Purohit100% (1)

- Past Tense Irregular Verbs Lesson Plan 02Document7 paginiPast Tense Irregular Verbs Lesson Plan 02drdineshbhmsÎncă nu există evaluări

- Global CompetitivenessDocument30 paginiGlobal CompetitivenessAmbar Purohit50% (2)

- Republic of Indonesia's Sovereign Immunity Upheld in Contract DisputeDocument2 paginiRepublic of Indonesia's Sovereign Immunity Upheld in Contract DisputeEllis Lagasca100% (2)

- Tthe Sacrament of Reconciliation1Document47 paginiTthe Sacrament of Reconciliation1Rev. Fr. Jessie Somosierra, Jr.Încă nu există evaluări

- MCQ OSCM Unit 1Document22 paginiMCQ OSCM Unit 1ShammimBegum67% (6)

- Folk Art Practical L-9Document15 paginiFolk Art Practical L-9Ambar PurohitÎncă nu există evaluări

- Basic Arithmetic Operations Short CutsDocument6 paginiBasic Arithmetic Operations Short Cutskarupu31081991Încă nu există evaluări

- Memorandum: Memorandum of Instructions On Project & Service ExportsDocument97 paginiMemorandum: Memorandum of Instructions On Project & Service ExportsAmbar PurohitÎncă nu există evaluări

- MCQ On IR 1Document13 paginiMCQ On IR 1Ambar Purohit50% (2)

- Trigonometric FunctionsDocument21 paginiTrigonometric FunctionsPolisettyGupthaÎncă nu există evaluări

- GK QuestionsDocument3 paginiGK QuestionsAmbar PurohitÎncă nu există evaluări

- Value Creation in MarketingDocument3 paginiValue Creation in MarketingAmbar PurohitÎncă nu există evaluări

- Export Procedures GuideDocument39 paginiExport Procedures GuideVamsi Krishna SivadiÎncă nu există evaluări

- Financial Planning For A FamilyDocument4 paginiFinancial Planning For A FamilyAmbar PurohitÎncă nu există evaluări

- JIT II: Reducing Inventory and Costs by Shifting Responsibility to SuppliersDocument4 paginiJIT II: Reducing Inventory and Costs by Shifting Responsibility to SuppliersAmbar PurohitÎncă nu există evaluări

- Session 1 - Introduction To Operations ManagementDocument17 paginiSession 1 - Introduction To Operations ManagementAmbar PurohitÎncă nu există evaluări

- Foreign Trade ResultsDocument2 paginiForeign Trade ResultsAmbar PurohitÎncă nu există evaluări

- 10 Golden Rules of Investing: How To Secure Your Financial FutureDocument21 pagini10 Golden Rules of Investing: How To Secure Your Financial FutureAmbar PurohitÎncă nu există evaluări

- IBDocument2 paginiIBAmbar PurohitÎncă nu există evaluări

- IBDocument2 paginiIBAmbar PurohitÎncă nu există evaluări

- 3CET REPORT ANALYSISDocument27 pagini3CET REPORT ANALYSISsaxenasai0% (1)

- IBDocument11 paginiIBAmbar PurohitÎncă nu există evaluări

- Tax Investments Should Be Part of Asset Allocation Policy: B. VenkateshDocument2 paginiTax Investments Should Be Part of Asset Allocation Policy: B. VenkateshAmbar PurohitÎncă nu există evaluări

- YogaDocument4 paginiYogaAmbar PurohitÎncă nu există evaluări

- CARAGA REGIONAL SCIENCE HIGH SCHOOL ASSESSMENT #1Document3 paginiCARAGA REGIONAL SCIENCE HIGH SCHOOL ASSESSMENT #1Joana Jean SuymanÎncă nu există evaluări

- Free ArtistDocument1 paginăFree Artistnunomgalmeida-1Încă nu există evaluări

- Activity 1: 2. Does His Homework - He S 3 Late ForDocument10 paginiActivity 1: 2. Does His Homework - He S 3 Late ForINTELIGENCIA EDUCATIVAÎncă nu există evaluări

- List of MeriendasDocument17 paginiList of MeriendasKristoffer OgalinoÎncă nu există evaluări

- Fish Feed Composition and ProductionDocument54 paginiFish Feed Composition and ProductionhaniffÎncă nu există evaluări

- Multiple Choice Questions Class Viii: GeometryDocument29 paginiMultiple Choice Questions Class Viii: GeometrySoumitraBagÎncă nu există evaluări

- The Names & Atributes of Allah - Abdulillah LahmamiDocument65 paginiThe Names & Atributes of Allah - Abdulillah LahmamiPanthera_Încă nu există evaluări

- Towards A Socially Responsible Management Control SystemDocument24 paginiTowards A Socially Responsible Management Control Systemsavpap78Încă nu există evaluări

- An Equivalent SDOF System Model For Estimating The Earthquake Response of R/C Buildings With Hysteretic DampersDocument8 paginiAn Equivalent SDOF System Model For Estimating The Earthquake Response of R/C Buildings With Hysteretic DampersAlex MolinaÎncă nu există evaluări

- Khilafat Movement Pakistan Studies (2059)Document5 paginiKhilafat Movement Pakistan Studies (2059)emaz kareem Student0% (1)

- David Emmett & Graeme Nice - What You Need To Know About Cannabis - Understanding The FactsDocument120 paginiDavid Emmett & Graeme Nice - What You Need To Know About Cannabis - Understanding The FactsJovana StojkovićÎncă nu există evaluări

- 6 Economics of International TradeDocument29 pagini6 Economics of International TradeSenthil Kumar KÎncă nu există evaluări

- Solving Problems Involving Simple Interest: Lesson 2Document27 paginiSolving Problems Involving Simple Interest: Lesson 2Paolo MaquidatoÎncă nu există evaluări

- Year 7 Depth Study 2a 2020 5Document6 paginiYear 7 Depth Study 2a 2020 5api-508928238Încă nu există evaluări

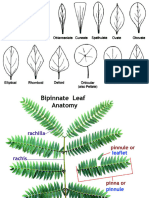

- Types, Shapes and MarginsDocument10 paginiTypes, Shapes and MarginsAkhil KanukulaÎncă nu există evaluări

- Choosing the Right Organizational Pattern for Your SpeechDocument19 paginiChoosing the Right Organizational Pattern for Your SpeechKyle RicardoÎncă nu există evaluări

- The Son of Man Rides The Clouds Pt. 2b - Answering Islam BlogDocument5 paginiThe Son of Man Rides The Clouds Pt. 2b - Answering Islam BlogbenciusilviuÎncă nu există evaluări

- Economy 1 PDFDocument163 paginiEconomy 1 PDFAnil Kumar SudarsiÎncă nu există evaluări

- MICROHARDNESS TESTER HMV-2 - SeriesDocument9 paginiMICROHARDNESS TESTER HMV-2 - SeriesRicoÎncă nu există evaluări

- Nursing ManagementDocument14 paginiNursing ManagementNolan Ivan EudinÎncă nu există evaluări

- Specification For Corrugated Bitumen Roofing Sheets: Indian StandardDocument10 paginiSpecification For Corrugated Bitumen Roofing Sheets: Indian StandardAmanulla KhanÎncă nu există evaluări