Documente Academic

Documente Profesional

Documente Cultură

Casting Terms

Încărcat de

deepzsohlDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Casting Terms

Încărcat de

deepzsohlDrepturi de autor:

Formate disponibile

9/11/12 Lecture 2

1/2 nptel.iitm.ac.in/courses/Webcourse-contents/IIT-ROORKEE//lecture2.htm

Lecture 2

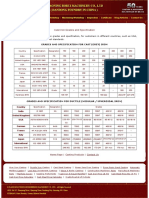

Casting Terms (Click on the figure 1 to view)

1. Flask: A metal or wood frame, without fixed top or bottom, in which the mold is formed. Depending upon the position

of the flask in the molding structure, it is referred to by various names such as drag lower molding flask, cope

upper molding flask, cheek intermediate molding flask used in three piece molding.

2. Pattern: It is the replica of the final object to be made. The mold cavity is made with the help of pattern.

3. Parting line: This is the dividing line between the two molding flasks that makes up the mold.

4. Molding sand: Sand, which binds strongly without losing its permeability to air or gases. It is a mixture of silica sand,

clay, and moisture in appropriate proportions.

5. Facing sand: The small amount of carbonaceous material sprinkled on the inner surface of the mold cavity to give a

better surface finish to the castings.

6. Core: A separate part of the mold, made of sand and generally baked, which is used to create openings and various

shaped cavities in the castings.

7. Pouring basin: A small funnel shaped cavity at the top of the mold into which the molten metal is poured.

8. Sprue: The passage through which the molten metal, from the pouring basin, reaches the mold cavity. In many

cases it controls the flow of metal into the mold.

9. Runner: The channel through which the molten metal is carried from the sprue to the gate.

10. Gate: A channel through which the molten metal enters the mold cavity.

11. Chaplets: Chaplets are used to support the cores inside the mold cavity to take care of its own weight and overcome

the metallostatic force.

12. Riser: A column of molten metal placed in the mold to feed the castings as it shrinks and solidifies. Also known as

feed head.

13. Vent: Small opening in the mold to facilitate escape of air and gases.

Figure 1 : Mold Section showing some casting terms

Steps in Making Sand Castings

9/11/12 Lecture 2

2/2 nptel.iitm.ac.in/courses/Webcourse-contents/IIT-ROORKEE//lecture2.htm

There are six basic steps in making sand castings:

1. Patternmaking

2. Core making

3. Molding

4. Melting and pouring

5. Cleaning

Pattern making

The pattern is a physical model of the casting used to make the mold. The mold is made by packing some readily formed

aggregate material, such as molding sand, around the pattern. When the pattern is withdrawn, its imprint provides the mold

cavity, which is ultimately filled with metal to become the casting. If the casting is to be hollow, as in the case of pipe fittings,

additional patterns, referred to as cores, are used to form these cavities.

Core making

Cores are forms, usually made of sand, which are placed into a mold cavity to form the interior surfaces of castings. Thus

the void space between the core and mold-cavity surface is what eventually becomes the casting.

Molding

Molding consists of all operations necessary to prepare a mold for receiving molten metal. Molding usually involves placing

a molding aggregate around a pattern held with a supporting frame, withdrawing the pattern to leave the mold cavity, setting

the cores in the mold cavity and finishing and closing the mold.

Melting and Pouring

The preparation of molten metal for casting is referred to simply as melting. Melting is usually done in a specifically

designated area of the foundry, and the molten metal is transferred to the pouring area where the molds are filled.

Cleaning

Cleaning refers to all operations necessary to the removal of sand, scale, and excess metal from the casting. Burned-on

sand and scale are removed to improved the surface appearance of the casting. Excess metal, in the form of fins, wires,

parting line fins, and gates, is removed. Inspection of the casting for defects and general quality is performed.

Goto Home

S-ar putea să vă placă și

- User Manual PDFDocument8 paginiUser Manual PDFcooljay2708Încă nu există evaluări

- Lathe: Common Types of Lathes: Engine LatheDocument9 paginiLathe: Common Types of Lathes: Engine LatheRavi_Kiran_5665Încă nu există evaluări

- ThermalDocument77 paginiThermaldeepzsohlÎncă nu există evaluări

- Guru Nanak Dev Thermal Plant: BathindaDocument28 paginiGuru Nanak Dev Thermal Plant: BathindadeepzsohlÎncă nu există evaluări

- Guru Nanak Dev Thermal Plant: BathindaDocument28 paginiGuru Nanak Dev Thermal Plant: BathindadeepzsohlÎncă nu există evaluări

- Lecture 3Document3 paginiLecture 3DeepSharanÎncă nu există evaluări

- Thermal Power Plant BathindaDocument58 paginiThermal Power Plant Bathindadeepzsohl100% (1)

- Lecture 1Document2 paginiLecture 1deepzsohlÎncă nu există evaluări

- Lecture 1Document2 paginiLecture 1deepzsohlÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hand Molding Demonstration ProcessDocument45 paginiHand Molding Demonstration ProcessqueenofthegypsiesÎncă nu există evaluări

- Project Report FOR Casting Iron & Copper: PromoterDocument11 paginiProject Report FOR Casting Iron & Copper: PromoterdjchiragÎncă nu există evaluări

- Common Casting Defects - Sand Mold, Metal CastingDocument10 paginiCommon Casting Defects - Sand Mold, Metal CastingAbhinav Pratap MauryaÎncă nu există evaluări

- Casting: ©2010 John Wiley & Sons, Inc. M P Groover, Principals of Modern Manufacturing 4/e SI VersionDocument74 paginiCasting: ©2010 John Wiley & Sons, Inc. M P Groover, Principals of Modern Manufacturing 4/e SI VersionNjabulo MdlaloseÎncă nu există evaluări

- Continuous Casting Process ExplainedDocument11 paginiContinuous Casting Process ExplainedakritiÎncă nu există evaluări

- Unit 3 Casting DefectsDocument70 paginiUnit 3 Casting Defectsraymon sharmaÎncă nu există evaluări

- Me 132 Report: Casting Processes Modern/ COntemporaryDocument23 paginiMe 132 Report: Casting Processes Modern/ COntemporaryElvin Jay TesoroÎncă nu există evaluări

- Casting N Moulding Lab ReportDocument3 paginiCasting N Moulding Lab ReportGalibÎncă nu există evaluări

- Die CastingDocument6 paginiDie Castingkutik3bugerÎncă nu există evaluări

- Metal-Casting Processes and EquipmentDocument48 paginiMetal-Casting Processes and EquipmenttemesgenÎncă nu există evaluări

- Cast Iron Grades and SpecificationDocument1 paginăCast Iron Grades and SpecificationRajagopal100% (1)

- ME - 32021 Chapter (2) FOUNDRY PROCESSESDocument47 paginiME - 32021 Chapter (2) FOUNDRY PROCESSESWILYÎncă nu există evaluări

- 3 - Metal Casting Processes (Chapter 8)Document103 pagini3 - Metal Casting Processes (Chapter 8)faisalÎncă nu există evaluări

- Me310 HW 3Document3 paginiMe310 HW 3HafizSikandarÎncă nu există evaluări

- Casting DefectsDocument10 paginiCasting DefectsshahazadÎncă nu există evaluări

- PDC Industries ListDocument16 paginiPDC Industries Listetamil87Încă nu există evaluări

- Differences Between Metal Forming Process and Casting ProcessDocument21 paginiDifferences Between Metal Forming Process and Casting ProcessFarhana Eyla75% (4)

- Green Sand CastingDocument14 paginiGreen Sand Castingkarthick rajaÎncă nu există evaluări

- CH 12Document11 paginiCH 12chaitanyacheggÎncă nu există evaluări

- Metal Casting: Design, Materials, and EconomicsDocument15 paginiMetal Casting: Design, Materials, and EconomicsIndunil Prasanna Bandara WarnasooriyaÎncă nu există evaluări

- Quality Casting ManualDocument27 paginiQuality Casting ManualvisitabhinavÎncă nu există evaluări

- Defects in CastingDocument4 paginiDefects in CastingArjun Singh MarjaraÎncă nu există evaluări

- Tutorial MSDocument4 paginiTutorial MSVidhya NairÎncă nu există evaluări

- Casting Defects - Dr. Manjula NanayakkaraDocument22 paginiCasting Defects - Dr. Manjula NanayakkaraDilupa HerathÎncă nu există evaluări

- Identifying Casting Defects - AFSDocument3 paginiIdentifying Casting Defects - AFSnddkÎncă nu există evaluări

- Core Making Techniques and TypesDocument14 paginiCore Making Techniques and TypesZaky MuzaffarÎncă nu există evaluări

- Casting, Welding, Machine Tools, Material SC PDFDocument240 paginiCasting, Welding, Machine Tools, Material SC PDFSanjay Kajal0% (1)

- Metal CastingDocument93 paginiMetal CastinghashimtkmceÎncă nu există evaluări

- Common Casting Defects and Their CausesDocument5 paginiCommon Casting Defects and Their CausesAgung Ngurah RendraÎncă nu există evaluări

- Riser DesignDocument4 paginiRiser DesignJiggy Jick100% (1)