Documente Academic

Documente Profesional

Documente Cultură

TiO2 Nanorod Array For Water Splitting

Încărcat de

Robert RhodesTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

TiO2 Nanorod Array For Water Splitting

Încărcat de

Robert RhodesDrepturi de autor:

Formate disponibile

An Extension of the Method of TiO2 Nanorod

hydrothermal synthesis for use in Gratzal Cell Based

Water Splittin

!o"ert !hodes

Student EE department #CSC

$at %i

Ad&isor and resear'her in %a" of Nanomaterials #CSC

Gonmin Wan

Graduate student (ith %i resear'h roup

$i'huan

Graduate student (ith %i resear'h roup

Su"mitted as partial 'ompletion of the re)uirements for finishin

*

underraduate 'ourse (or+,

Contents

A"stra't------------,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

.art *

/ntrodu'tion------------,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

.art2

Methods------------,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

Method *

Materials and setup------------,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

Experiments------------,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

2

Method 2

Materials and setup------------,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

Experiments------------,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

0ariation of Temperature and data------------,,,,,,,,,,,,,,,,,

0ariation of pre'ursor 'on'entration and data-----------

0ariation of NaCl 'on'entration and data------------,,,,,

.reparation and modifi'ation of 'ondu'ti&e lass su"strate

11 nanorod measurement te'hni)ue11

.art 2

Cir'uit Model3 Assem"ly of 4ye Sensitized Cell3 and Test

results------------,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

,

Con'lusion and 4is'ussion------------,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

Bi"lioraphy------------,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

/ndex------------,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

2

%ist of fiures

5iure 67 setup for method *,-----------,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

5iure *7 setup for method 2,-----------,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

5iure 27 S,E,M imae of Temperature trial------------,,,,

5iure 27 S,E,M imae of NaCl trial------------,,,,,,,,,,,,,,,,

5iure 87 9uantum Effi'ien'y &s, (a&elenth of End .rodu't "efore TiCl8

treatment------------,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

5iure :7 9E &s, (a&elenth after treatment------------,

8

A"stra't

This paper details the de&elopment of a TiO2 nano(ire film suita"le for use in a

photo ele'tro'hemi'al 'ell,

.art *

/ntrodu'tion

The sear'h for alternati&e sour'es of enery to run our modern 'i&ilization has

"een a tryin one, /t has spanned a reat deal of the last 'entury and (ill no dou"t ta+e up

a ood deal3 at least the first half3 of the 'urrent one, With e&er ro(in 'on'erns o&er

the detrimental fis'al and en&ironmental effe'ts of our 'urrent main enery sour'e3 the

(orld has as of no( de'ided to shift the load of its enery demand onto a 'om"ination of

&arious resour'eful and inno&ati&e sour'es (or+in in 'on'ert, E&ery method for

eneration of po(er is "ein tried in this ex'itin resuren'e of zeal to de&elop rid

parity (ith fossil fuels; te'hnoloies rane from "iomass te'hni)ues to tidal po(er and

e&en re&isit lon time 'hampions of the arena su'h as thermo<photo &oltai' 'ells

= in'ludin 'om"inations su'h as thermo photo &oltai' te'hnoloy (hi'h relies on the

eneration of ele'tromaneti' radiation &ia heat from radio isotopes, The enery is then

in'ident upon a photo &oltai' de&i'e of some sort, This te'hnoloy is thouht to "e

parti'ularly useful for extra'tin the surplus enery of radio isotopes or if fusion "e'omes

a 'ommer'ially a&aila"le option3 it miht "e a means of more dire'tly 'ouplin the

:

radiation produ'ed &ia the rea'tion (ithout the need to (astin &alua"le and expensi&e

(ater resour'es &ia 'on&entional thermal 'ouplin,>1'ite /EEE spe'trum issue (here

(ater as resour'e is dis'ussed,

Althouh purely 'ell "ased te'hnoloy persists as a prominent fiure in the realm

of enery te'hnoloies3 it has yet to pro&ide satisfa'tory 'on&ersion effi'ien'y, Other

promisin approa'hes su'h as hydroen 'om"ustion ha&e "e'ome more popular in liht

of the 'urrent short 'omins of 'ell "ased te'hnoloy, /n the past ho(e&er3 hydroen

eneration has posed a serious 'onundrum for proponents of 'leaner enery sour'es, The

relian'e on fossil fuels for its eneration offset its intended purpose of alle&iatin

en&ironmental "urdens, .ure hydroen 3(hile still 'om"usti"le3 pro&ides a less

de&astatin alternati&e to its hydro'ar"on "ased prede'essors and thus 'ontinued interest

in de&elopin ne( eneration s'hemes resulted in (ater splittin as a &ia"le stratey,

The (ater splittin pro'ess des'ri"ed "y the o&erall rea'tion7

> * , = 2 8 2

2 2 2

Eq O H O H + +

/n e)uation *3 in'ident photons lead to the eneration of hydroen at one ele'trode= often

made of platinum> and oxyen at another= for the purposes of this paper this ele'trode is

of TiO2 > in an ele'tro'hemi'al rea'tion, Of the different oxide semi'ondu'tors elii"le

for said rea'tion3 TiO2 pro&ides for one of the more effi'ient<simpler photo 'atalysts, A

dyed TiO2 a'hie&es the result of e)uation * &ia the follo(in series of rea'tions7

2

2 2

2

2 2

8 8 2

H e H

H O h O H

h e TiO

+

+ +

+ +

+

+ +

+

To "e more a''urate3 the photons intera't (ith the dye 'oatin the (ires and the

enerated ele'trons are e?e'ted into the (ires after (hi'h the rea'tion pro'eeds as

des'ri"ed a"o&e so that the (ires seem to "e a sour'e of photo enerated ele'trons, The

first rea'tion o''urs at the TiO2 ele'trode (hile the se'ond ta+es pla'e at the se'ond

ele'trode =made of platinum or in some 'ases 'ar"on>, The desired effe't is to ensure that

the @ ions at the .t ele'trode are redu'ed to hydroen as (ithout the need of an

external potential, /n order to indu'e the redu'tion rea'tion at the pt ele'trode thusly3 the

A

enery of 'ondu'tion "and ele'trons in the oxide semi'ondu'tor ele'trode =TiO2 > must

meet or ex'eed the potential for @2 formation =refer to fiure *,>, This situation sets

'onditions on the "and ap of the desired material =*,22B*,2: e0> as the (a&elenth of

operation for the photoBeneratin ele'trode (ill fall (ithin the spe'trum of #0

radiation, Smaller "and aps lead to more enery a&aila"le for eneratin hiher enery

'ondu'tion ele'trons ho(e&er smaller "and ap materials that ha&e thus far "een

in&estiated ha&e suffered from 'orrosion (hen pla'ed into the a)ueous solution setup

that ma+es TiO2 photo 'atalysts useful,

*

4ye sensitization to pull the operatin spe'trum

to &isi"le liht = (a&elenths not so reatly attenuated near Earth surfa'e> as in the

Gratzel Cell3 'urrently represents the most pra'ti'al step in the riht dire'tion, The

Gratzel "ased photo 'atalyti' enery 'ell relies on a photo ele'trode "ased on a TiO2

4SSC = dye sensitized solar 'ell7 the Gratzel 'ell is a type of dss'>, The 5TO =flourine

doped tin oxide> su"strate upon (hi'h the nanorods of the Gratzel 'ell are ro(n also

ser&es as a transparent prote'tion for the relati&ely fraile rods (hi'h fa'e the interior of

the 'ell and (hi'h lie inside of the ele'trolyte as pi'tured in the fiure "elo(,

On the left side3 hydroen is enerated "y redu'tion at the anode end (hile on the riht

oxyen is redu'ed as the ele'tron 'urrent flo(s throuh the resister under &oltmeter C0D,

To dri&e the rea'tion des'ri"ed a"o&e the fiure3 a photon of enery h& is transmitted

throuh the plate on the riht side of the 'ell and stri+es the nano(ires = (hi'h a't as

"oth as ele'tro 'atalyst and anode, @oles are 'reated in the anode and these are for'ed

to(ards the exterior of this ele'trode =to(ards the "order "et(een the ele'trode and the

E

surroundin li)uid "ein split> Essentially3 holes flo( into the riht side (here oxyen

results from oxidation =&ia hole ele'tron re'om"ination>at the nBtype TiO2 (hereas the

ex'ess ele'trons inside the nBtype material flo( throuh the external resistor as ele'tron

'urrent and redu'e positi&e hydroen 'ores to produ'e hydroen at the other ele'trode

Water splittin &ia 'on&ertin of solar enery into the redox potential ne'essary

for splittin mole'ules has indeed pro&en to "e a dauntin tas+, /n'reased re)uirements

on po(er and spatial 'onstraints of enery systems desin 'all for relia"le3 lo( 'ost3

'ompa't methods of eneratin the re)uired potential to dri&e rea'tions ne'essary for the

eneration of hydroen &ia solar methods; thus another road "lo'+ lay ahead of

resear'hers, With the need to redu'e size3 fine tune material properties3 and refine

performan'e in mind3 many resear'hers and de&elopers ha&e turned to nano stru'tured

materials as a solution, 5or the purposes of hydroen eneration3 this has led to the use of

nano rod films as the 'atalyst for the rea'tion 'on&ertin (ater to hydroen and

a''ompanyin extraneous produ'ts, One of the suita"le materials for this purpose3 as

pre&iously mentioned3 is titanium dioxide usually o"tained &ia a rea'tion in&ol&in some

other titanium pre'ursor su'h as the one used for the experiments des'ri"ed in this paper

(here titanium "ut oxide solution is hydrolyzed in an @C%<@2O solution, The pro'ess

must "e run multiple times to a'hie&e optimal results (hen retainin the default

parameters,

This paper deals (ith impro&in = in this 'ase further in'reasin lenth F sin'e it

is dire'tly proportional to )uantum effi'ien'yG and minimizin ne'essary ro(th time> a

nano rod film to "e used in a dye sensitized 'ell, The method 'onsists of examinin some

of the ro(th parameters and determinin (hi'h of them are most sinifi'ant in

aumentin the existin method there"y in'reasin the effe'ti&e surfa'e area of the photo

ele'trode, /n addition to this3 / experimented (ith an aspe't of the nanorod ro(th left

larely nele'ted "y Adyl and %iu; / modified the texture of the 'oatin on the

'ondu'ti&e lass so that the (ires (ould ha&e a more le&el surfa'e upon (hi'h to

nu'leate and ro( thus de'reasin the 'han'es of (ires ro(in at anles to the

su"strate3 'ollidin3 and "rea+in "efore rea'hin a sinifi'ant heiht, / also ma+e use of

a ne( and far less expensi&e more &olatile pre'ursor to ser&e as the 'rystal ro(th

H

material, #ltimately / produ'ed a 'ell ro(n in 26I less time (ith HI hiher pea+

effi'ien'y than that des'ri"ed "y %iu et al,

.art 2

Methods

The first synthesis te'hni)ue employed for rod eneration (as a 'hemi'al &apor

deposition method = C04>, A '&d rea'tor (as fashioned from a lass tu"e atta'hed to a

as line on one end and a &a'uum pump system on the other, A old doped sili'on (afer

ser&ed as the ro(th area, The use of old parti'les on the surfa'e 'atalyzed 'rystal

nu'leation on the su"strate, The as flo( ser&ed as the transport me'hanism from the

small 'erami' &essel (here the pre'ursor (as held inside of the tu"e to the taret point on

the (afer further do(n in the tu"e, Sin'e no other asses (ere a&aila"le3 hydroen as

had to "e used at near &a'uum pressure =and the a"sen'e of oxyen (hi'h (as espe'ially

important sin'e the method 'alled for temperatures of :66J> @eatin allo(ed the

pre'ursor to su"limate and tra&el to the taret point (ith the rest of the stream, The main

'onditions to "e ad?usted (here the distan'e "et(een the pre'ursor and taret = due to an

existin temperature radient a'ross the lenth of the tu"e sin'e the heater had the heat

sour'e set dead 'enter>, Althouh this te'hni)ue pro&ed unsu''essful3 a "rief dis'ussion is

still merited,

2,*,* Material properties and setup

K

5iure6 illustrates the experimental setup for the first method used

The pre'ursorLs thermal and me'hani'al =&is'osity3 effusion relati&e to transport

as3 i,e properties as a fluid> (ere 'ru'ial to o"tainin any ood results, So findin the

su"limation 'onditions and resultin &apor pressure for the pre'ursor (as the first step in

the pro'edure, Continuin (ith the pro'ess of findin a "en'h mar+ set of 'onditions3 /

ran a trial heatin of the tu"e to esta"lish a 'rude temperature profile of the radient alon

the tu"e, After ta+in the temperature at &arious points from the 'enter of the tu"e to the

far end usin an /,!, thermometer3 / 'hose positions for the pre'ursor and (afer "oth of

(hi'h seemed suita"le i&en the hih temperature re)uirements for

su"limation<deposition; The pre 'onditions for lo( pressure (ere met (ith the &a'uum

system, / hypothesized that the denser pre'ursor as "ein mu'h slo(er than the

*6

transport as (ould ha&e plenty of time to 'ool do(n 'omplete the deposition pro'ess

upon rea'hin the taret thus in the interest of time the flo( and pressure settins on the

mass flo( 'ontroller (ere ad?usted to speed deposition (ith little or no loss of &aporized

pre'ursor out of the rea'tor, With the initial 'onditions 'hosen3 the experiments pro'eeded

as follo(s,

2,*,2 Experiments

#pon examinin the (afer from the first run under S,E,M3 it appeared to me that

most of the pre'ursor had "een s(ept into the &a'uum system and exhausted to the

outside= &ia fume hood,>, Examination of the 'erami' "oat 'onfirmed that redu'in the

flo(, #sin some )ui'+ estimation and GrahamLs la(3 / de'ided that the first parameter to

&ary should "e amount of pre'ursor, @al&in the amount of pre'ursor pro&ed to "e

helpful,

4oin this produ'ed a mu'h reater 'on'entration of rods on the surfa'e al"eit not

enouh to ?ustify the oals of redu'ed lateral dimensions follo(ed "y in'reased density,

We had hoped to "e a"le to in'rease the density of rods on the su"strate (hile pre&entin

the rods from 'ro(din toether to form a 'ontinuous film thus off settin the ained

surfa'e area of the prisms<rods, No su'h in'reased density (as realized, The pre'ursor

did ha&e more time to deposit no( "ut the 'on'entration on the su"strate and thus the

nano rod 'on'entration still suffered the effe'ts of pre'ursor loss to the outside,

So next the taret (afer lo'ation (as &aried to find optimal temperature &s, distan'e

'onditions for deposition, / ad?usted the tu"eLs position (ithin the heater to pro&ide as

mu'h room as possi"le for a sort of temperature Dlandin stripM (ithout usin the spa'e

too 'lose to the &a'uum pump openin, /nstead of &aryin the flo( parameters too mu'h3

/ de'ided it (ould "e "etter to ad?ust the distan'e "et(een destination and sour'e as (ell

as destination and sin+ instead,

2,2,6 Se'ond method

**

5iure * illustratin experimental setup

The se'ond te'hni)ue (as a hydrothermal synthesis method similar to the method

employed "y %iu and Aydil

2

, Titanium "ut oxide pre'ursor (as hydrolyzed in an h'l<h2o

solution (hi'h (as then pla'ed in an small Teflon lined stainless steel auto'la&e, A

sample of fluorine doped tin oxide ='ondu'ti&e on a sinle side of the pie'e of lass> (as

pla'ed inside the auto'la&e and the (hole assem"ly (as thorouhly se'ured3 sealed and

pla'ed inside of the la"oratory o&en, The ro(th 'onditions =spe'ifi'ally temperature3

ro(th time3 pre'ursor 'on'entration3 and NaCl7@C%7 @2O ratio,> /n the a"sen'e of

&ariation of parameters pro'ess (as simply run until ?ust "efore the rea'tion rea'hed

e)uili"rium then the fto su"strate (as pla'ed into a freshly mixed solution so that another

iteration of the pro'ess miht o''ur until a limitin lenth (as a'hie&ed = H mi'rometers

if fto (as repla'ed e&ery 8 hours for 26 hours>, The purpose of the experiments in this

paper (as to find those &ariations of parameters (hi'h further aumented the results of

this iterati&e pro'ess,

The default ro(th 'onditions7

*2

Temp,B*:6 derees Celsius

.re'ursorB,: ml

TimeB: hours

NaCl7@C%7 @2O ratioB*7*76

26 ml total @C%<@2O=*: ml @C%=a)>3*: ml @2O>

2,2,* 0ariation of temperature

2,2,2 @ypothesis7

The intended result (as the rapid ro(th in the dire'tion perpendi'ular to the

su"strate, The most desira"le effe't (ould ha&e "een for the &erti'al ro(th to ha&e

drasti'ally surpassed the ro(th rate of the 'ross se'tion at suffi'iently hih temperature

= thus pre&entin 'lumpin toether

*

,> Maintainin the strenth of the rods = aainst the

shear and 'ompressi&e stress as the rod heiht in'reased> re)uired a reater amount of

pre'ursor ho(e&er in order to find the proper amount3 the heiht limit under default

'onditions for pre'ursor 'om"ined (ith the 'onditions for a sta"le rod (ould determine

the ne'essary deree of re enfor'ement and thus amount of TiO2, , The temperature had to

remain "elo( 266 C to pre&ent destru'tion of the Teflon linin of the auto'la&e, Also3

too hih a temperature leads to premature peelin of the film off of the 5TO su"strate,

2,2,2 O"ser&ation and results7

The film re( to ?ust under * um (ithin : hours at *H6 C "ut the film peeled off

due to the fa't that the rea'tion rea'hed e)uili"rium (ithin the ro(th time at that

temperature, After experimentin (ith the temperature / found that *A6B*A:C made for

ro(th at a more tra'ta"le rate, Also3 'lumpin of (ires (as sinifi'ant as seen in fiure

*,

*2

5i 2 nanorods at *A6 C

2,2,* 0ariation of 'on'entration

/ +ept the default 'onditions "ut &aried the pre'ursor 'on'entration "et(een ,: ml and

* ml (ith the hopes of extrapolatin a more exa't relationship "et(een the titanium "ut

oxide pre'ursor 'on'entration and the aspe't ratio

2,2,2 O"ser&ation and results7

2,8,* 0ariation of NaCl 'on'entration

2,8,2 @ypothesis7

The (ires are "uilt from Ti /0 units in any &ia"le pre'ursor ?oinin toether and

in'reasin the diameter and heiht of the stru'ture as more units ?oin, At appropriate

'on'entrations3 Cl ions (ould inhi"it the in'lusion of Ti /0 units into the stru'ture of the

(ire alon the radial dire'tion (hile allo(in further ro(th alon the heiht (ith Cl

ions en'apsulatin ea'h thin sement of rod alon the z dire'tion

*8

2,8,2 a O"ser&ation and results7

The first run (ith ,62 <ml led to the entire su"strate and TiO2 film "ein o&er'ome

"y a film of salt, After rinsin a(ay the salt layer a layer of TiO2 (as &isi"le "ut (as

mu'h less thi'+ than in pre&ious experiments implyin reatly foreshortened (ires, Most

li+ely the salt layer isolated the underlyin film from 'onta'tin the @C%7@2O7 pre'ursor

solution thus haltin the rea'tion,, !edu'tion to half that 'on'entration led to only

marinally fa&ora"le results as the film resem"led that (hi'h (as produ'ed at *A6 C in

the first experiment "ut (ith areas of redu'ed 'lumpin sporadi'ally distri"uted a'ross

the su"strate,

5i 2 after addin ,62 <ml of NaCl

2,:,* MO4/5/CAT/ON O5 CON4#CT/0E S#BST!ATE

Seein as thouh &ariation of the pre&ious parameters led to modest in'rease in rod

lenth3 / de'ided to in&estiate a sixth Dro(th 'onditionM mentioned "y %iu "ut not

a'tually modified "y that roup, / 'reated a ne( 'ondu'ti&e su"trate ta+in 'are to add as

many layers as slo(ly as tolera"le so as to reap a layer of 5TO seed 'rystals nearly

alined (ith the su"strate axis, This (ould mitiate the effe'ts of the non 'rystalline

nature of the lass sin'e the "ottom layers of 5TO suffer more from the amorphous

*:

stru'ture of the lass (hile ea'h su''essi&e layer (ould suffer less from this pro"lem,

/ used a spray pyro lysis method to apply a 'ondu'ti&e layer to 'ommon lass, /

dissol&ed SnCl8 in ethanol (hile heatin a fe( lass slides to a"out 2:6 C, /mmediately

after remo&in the slides from the o&en3 / sprayed them (ith a mist of the solution and

then returned them to the o&en, /n the interest of hastenin time to testin of the effe'ts

of impro&ed texture of the su"strate on )uantum effi'ien'y3 / stopped (hen the resistan'e

of the slides (as a mea ohm, This is (hat lead to the de'reased o&erall effi'ien'y

relati&e to %iu "ut (ith more time and sprayin the pro'ess (ould yield lo(er 'onta't

resistan'e and in'reased o&erall effi'ien'y, My ma?or 'on'ern (as the effe't on E9E and

any remainin time (ould "e used to 'reate slides of hiher 'ondu'ti&ity,

.art 2

Assem"ly and Testin of Cell

After 'ompletin the nano(ire<rod array / assem"led the 'ell "y su"merin the

array in a &ial of an antho'yanin "ased orani' dye for H hours, After(ards3 the array (as

remo&ed and pressed array side up to 'ondu'ti&e side of another 'ondu'ti&e slide (hi'h

had "een 'oated (ith 'ar"on on that side, After me'hani'ally se'urin the assem"ly3 /

applied a fe( drops of an iodide solution to one side of the 'ell and let 'apillary for'es

dra( it into the spa'e "et(een the t(o ele'trodes, / me'hani'ally se'ured the assem"ly

and added some ma+eshift ele'tri'al 'onta'ts to the exposed 'ondu'ti&e lass, 4urin the

ro(th pro'ess3 part of the (ire 'o&ered lass (as prote'ted "y an adhesi&e (hi'h

inhi"ited (ire ro(th on that part of the surfa'e,

#sin (eather ser&i'e data3 a photo sensor of +no(n spe'tral response3 a

flashtu"e3 and a multimeter3 / exposed the 'ell to sunliht = 'hara'terized "y (eather

ser&i'e and 'orro"orated "y photo sensor > and the flashtu"e = used in solar simulators>

and too+ measurements ne'essary to 'al'ulate 9E7

> =

> =

P

I I

q

hc

QE

dark

=

E) 2

Where hN plan+ 'onstant

'N speed of liht

*A

)N 'hare of an ele'tron

/ is the 'urrent at the (a&elenth of interest

/ dar+ is the 'urrent under no illumination and

. is the in'ident po(er at the (a&elenth of interest

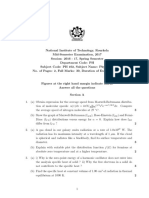

quantum efficiency vs wavelength

0

5

10

15

20

25

30

450 500 550 600 650 700 750 800 850 900

q

u

a

n

t

u

m

e

f

f

i

c

i

e

n

c

y

(

%

)

absorbed wae!en"t# in nanometers

The a"o&e 'hart refle'ts the "eha&ior of the 'ell "efore treatment (ith TiCl8

(hose effe't is found to nearly dou"le the )uantum effi'ien'y resultin in7

*E

The treatment 'onsists of su"merin the nanorod array =prior to dyin it > and

then remo&in the array from the solution and heatin the array for at least *: min at 866

C, After treatment3 the pea+ effi'ien'y is a"out HI hiher in the 8:6nm reion than the

:6I o"tained "y %iu et al,

Con'lusion7

/ impro&ed the effi'ien'y of the 'ell in ma?or part "y modifyin the su"strate

upon (hi'h it (as ro(n, 5uture plans in'lude in'reasin the size s'ale of the array so as

to use it to enerate the 'hemi'al enery storae medium for po(erin other pro?e'ts,

A'+no(ledements7 On'e aain / than+ .rof, $at %i for super&isin this pro?e't

(hi'h allo(ed me to "oth impro&e my +no(lede of 'hemistry (hile applyin my

enineerin s+ills to de&elopin a handy produ't, / also than+ his raduate students Gon

Min and $i'huan for trainin me in the use of e)uipment, 5inally3 "ut not least3 / than+

.rof, Oo"ayashi for pro&idin my an opportunity to ain some "a'+round in

nanos'ien'e prior to my transfer to the %i la" and for his referrin me to .rof, %i,

*H

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Powerwall 2 AC Owners ManualDocument60 paginiPowerwall 2 AC Owners ManualteslavanaÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Suzuki GSXS 1000 Manual Servicio Tecnico PDFDocument86 paginiSuzuki GSXS 1000 Manual Servicio Tecnico PDFRoberto Nicolás Mera Velásquez75% (8)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Introduction To Heat Transfer and Heat ExchangersDocument335 paginiIntroduction To Heat Transfer and Heat Exchangersmohamed abd eldayem100% (2)

- Casing ScrapersDocument2 paginiCasing ScrapersthetrevanianÎncă nu există evaluări

- 80ZV 2Document12 pagini80ZV 2mhmd_saad100% (2)

- Commander's Smartbook Equipment CatalogDocument59 paginiCommander's Smartbook Equipment CatalogWilliam 'Junior' Hof100% (1)

- E20 Heat Load Calculation SheetDocument1 paginăE20 Heat Load Calculation SheetȘtefan C. Petre50% (2)

- TM-5-3810-307-24P Groove PDFDocument1.017 paginiTM-5-3810-307-24P Groove PDFGustavoÎncă nu există evaluări

- From Newton To Mandelbrot-A Primer in Theoretical PhysicsDocument277 paginiFrom Newton To Mandelbrot-A Primer in Theoretical PhysicsΠΑΝΑΓΙΩΤΗΣ ΨΥΧΑΣ100% (1)

- Abstract-Piezoelectric Energy HarvestingDocument2 paginiAbstract-Piezoelectric Energy HarvestingGanesh Venugopal100% (5)

- Crude TBP Country Nigeria Distillation: Akpo BlendDocument2 paginiCrude TBP Country Nigeria Distillation: Akpo Blendeke23Încă nu există evaluări

- S13 - TR01 - Serial 50263Document21 paginiS13 - TR01 - Serial 50263AhmedRaafatÎncă nu există evaluări

- CoatingDocument16 paginiCoatingPubg fansÎncă nu există evaluări

- Mini Project - MECHDocument19 paginiMini Project - MECHmahendiran123Încă nu există evaluări

- Drive Fundamentals and DC Motor CharacteristicsDocument3 paginiDrive Fundamentals and DC Motor CharacteristicsJoeÎncă nu există evaluări

- Cam Price List (Philips)Document36 paginiCam Price List (Philips)dave6522Încă nu există evaluări

- ME454Document3 paginiME454jondhaleprashantmansubraoÎncă nu există evaluări

- Department of Chemical Engineering: National Institute of Technology RourkelaDocument53 paginiDepartment of Chemical Engineering: National Institute of Technology RourkelaDeep KaneriyaÎncă nu există evaluări

- Control SystemDocument12 paginiControl SystemAnish NairÎncă nu există evaluări

- Spectrasyn Plus™ 5: Advanced Polyalphaolefin (Pao) FluidDocument2 paginiSpectrasyn Plus™ 5: Advanced Polyalphaolefin (Pao) FluidMaram YasserÎncă nu există evaluări

- 1. المضخهDocument20 pagini1. المضخهالمهندسوليدالطويلÎncă nu există evaluări

- Energy, Work & Power QPDocument8 paginiEnergy, Work & Power QPSalman Farsi TaharatÎncă nu există evaluări

- Chapter 2Document16 paginiChapter 2Aly AshrafÎncă nu există evaluări

- Honeywell AQ2000Document8 paginiHoneywell AQ2000vsilickasÎncă nu există evaluări

- 06 Ba Exakt 80eplus EnglischDocument154 pagini06 Ba Exakt 80eplus EnglischAya adelÎncă nu există evaluări

- PH102Document2 paginiPH102Shobhit ParkiÎncă nu există evaluări

- Dokumen - Tips - Astm A159 Standard Specification For Automotive Gray Iron CastingsDocument2 paginiDokumen - Tips - Astm A159 Standard Specification For Automotive Gray Iron CastingsJeovanne CabralÎncă nu există evaluări

- Processes Affecting Changes in PropertiesDocument13 paginiProcesses Affecting Changes in PropertiesMark julius garciaÎncă nu există evaluări

- Transformer Interview Questions & Answers: Search For Jobs..Document29 paginiTransformer Interview Questions & Answers: Search For Jobs..shamshadÎncă nu există evaluări

- MOI - Riyadh-UL Control Panel With VFD (2 Duty + 1 Standby)Document17 paginiMOI - Riyadh-UL Control Panel With VFD (2 Duty + 1 Standby)Emad AbushrarÎncă nu există evaluări