Documente Academic

Documente Profesional

Documente Cultură

Key and Coupling Solutions

Încărcat de

Mark HilarionDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Key and Coupling Solutions

Încărcat de

Mark HilarionDrepturi de autor:

Formate disponibile

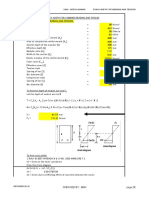

SECTION 8 KEYS AND COUPLINGS

1

FLAT AND SQUARE KEYS

DESIGN PROBLEMS

521. A 2-in. shaft, of cold-drawn AISI 1137, has a pulley keyed to it. (a) Compute the length of square

key and the length of flat key such that a key made of cold-drawn C1020 has the same yield

strength as the shaft does in pure torsion. (b) The same as (a), except that the key material is

AISI 2317, OQT 1000 F. (c) Would you discard either of these keys? Explain.

Solution:

For AISI 1137 shaft, Table AT 8, sy = 93 ksi

Yield Strength of Shaft

s

ys

= 0.6s

y

= 0.6(93) = 55.8 ksi

( )( )( )

kips in

D s

T

ys

= = = 65 87

16

2 8 55

16

3

3

.

.

(a) Key Material, cold-drawn, C1020, Table AT 7

s

y

= 66 ksi

s

ys

= 0.6sy = 0.6(66) = 39.6 ksi

Table AT 19, use b = in , t = 3/8 in.

For square key, b = t = in.

By shear, s

s

= s

ys

( )

( )( )

in

bD s

T

L

s

43 4

2 2 1 6 39

65 87 2 2

.

.

.

= = =

By compression, s

c

= s

y

. Key has lowest yield strength.

( )

( )( )

in

tD s

T

L

c

32 5

2 2 1 66

65 87 4 4

.

.

= = =

Use L = 5.32 in

For Flat key, b = in , t = 3/8 in.

By shear, s

s

= s

ys

( )

( )( )

in

bD s

T

L

s

43 4

2 2 1 6 39

65 87 2 2

.

.

.

= = =

By compression, s

c

= s

y

. Key has lowest yield strength.

( )

( )( )

in

tD s

T

L

c

09 7

2 8 3 66

65 87 4 4

.

.

= = =

Use L = 7.09 in

(b) Key Material, AISI 2317, QOT 1000 F. Table AT 8

s

y

= 71 ksi

s

ys

= 0.6sy = 0.6(71) = 42.6 ksi

Table AT 19, use b = in , t = 3/8 in.

For square key, b = t = in.

By shear, s

s

= s

ys

( )

( )( )

in

bD s

T

L

s

12 4

2 2 1 6 42

65 87 2 2

.

.

.

= = =

By compression, s

c

= s

y

. Key has lowest yield strength.

SECTION 8 KEYS AND COUPLINGS

2

( )

( )( )

in

tD s

T

L

c

94 4

2 2 1 71

65 87 4 4

.

.

= = =

Use L = 4.94 in

For Flat key, b = in , t = 3/8 in.

By shear, s

s

= s

ys

( )

( )( )

in

bD s

T

L

s

12 4

2 2 1 6 42

65 87 2 2

.

.

.

= = =

By compression, s

c

= s

y

. Key has lowest yield strength.

( )

( )( )

in

tD s

T

L

c

59 6

2 8 3 71

65 87 4 4

.

.

= = =

Use L = 6.59 in

(c) Either of the above is not to be discarded since they are designed based on yield strength with

the same factor of safety.

522. A cast-iron pulley transmits 65.5 hp at 1750 rpm. The 1045 as-rolled shaft to which it is to be

keyed is 1 in. in diameter; key material, cold-drawn 1020. Compute the length of flat key and

of square key needed.

Solution:

For shaft: 1045 as-rolled, Table AT 7, s

y

= 59 ksi

For key: Cold-drawn 1020, s

y

= 66 ksi

D = 1 in = 1.75 in

hp = 65.5 hp, n = 1750 rpm

( )

kips in lb in

n

hp

T = = = = 358 2 2358

1750

5 65 000 63 000 63

.

. , ,

Table AT 19, use b = 3/8 in, t = 1/4 in for D = 1 in

Assume smooth load, N = 1.5

For Flat key, b = 3/8 in, t = 1/4 in.

By shear,

s

ys

= 0.6sy = 0.6(66) = 39.6 ksi

ksi

N

s

s

ys

s

4 26

5 1

6 39

.

.

.

= = =

( )

( )( )

in

bD s

T

L

s

272 0

75 1 8 3 4 26

358 2 2 2

.

. .

.

= = =

By compression, use s

y

of shaft the lowest. Pulley has the highest compressive strength (Cast iron).

ksi

N

s

s

y

c

3 39

5 1

59

.

.

= = =

( )

( )( )

in

tD s

T

L

c

549 0

75 1 4 1 3 39

358 2 4 4

.

. .

.

= = =

Use L = 0.549 in - answer

SECTION 8 KEYS AND COUPLINGS

3

For Square key, b = 3/8 in, t = 3/8 in.

By shear, s

s

= s

ys

s

ys

= 0.6s

y

= 0.6(66) = 39.6 ksi

ksi

N

s

s

ys

s

4 26

5 1

6 39

.

.

.

= = =

( )

( )( )

in

bD s

T

L

s

272 0

75 1 8 3 4 26

358 2 2 2

.

. .

.

= = =

By compression, use s

y

of shaft the lowest. Pulley has the highest compressive strength (Cast iron).

ksi

N

s

s

y

c

3 39

5 1

59

.

.

= = =

( )

( )( )

in

tD s

T

L

c

366 0

75 1 8 3 3 39

358 2 4 4

.

. .

.

= = =

Use L = 0.366 in - answer

523. A 3 -in. shaft transmits with medium shock 85 hp at 100 rpm. Power is received through a

sprocket (annealed nodular iron 60-45-10) keyed to the shaft of cold-rolled AISI 1040 (10%

work), with a key of cold-finished B1113. What should be the length of (a) a square key? (b) a

flat key?

Solution:

For sprocket, annealed nodular iron, 60-45-10, Table AT 6, s

y

= 55 ksi

For shaft, cold-rolled AISI 1040 (10% work), Table AT 10, s

y

= 85 ksi

For key, cold-finished B1113, Table AT 7, s

y

= 72 ksi

D = 3 in = 3.25 in

hp = 85 hp

n = 100 rpm

( )

kips in lb in

n

hp

T = = = = 55 53 550 53

100

85 000 63 000 63

. ,

, ,

Table AT 19, use b = in, t = 1/2 in for D = 3 in

For medium shock, N = 2.25

(a) Square key,

b = in, t = in.

By shear,

s

ys

= 0.6s

y

= 0.6(72) = 43.2 ksi

ksi

N

s

s

ys

s

2 19

25 2

2 43

.

.

.

= = =

( )

( )( )

in

bD s

T

L

s

29 2

25 3 4 3 2 19

55 53 2 2

.

. .

.

= = =

By compression, use s

y

of sprocket the lowest.

ksi

N

s

s

y

c

4 24

25 2

55

.

.

= = =

( )

( )( )

in

tD s

T

L

c

60 3

25 3 4 3 4 24

55 53 4 4

.

. .

.

= = =

SECTION 8 KEYS AND COUPLINGS

4

Use L = 3.60 in. - answer

(b) Flat key,

b = in, t = in.

By shear, s

s

= s

ys

s

ys

= 0.6s

y

= 0.6(72) = 43.2 ksi

ksi

N

s

s

ys

s

2 19

25 2

2 43

.

.

.

= = =

( )

( )( )

in

bD s

T

L

s

29 2

25 3 4 3 2 19

55 53 2 2

.

. .

.

= = =

By compression, use s

y

of sprocket the lowest.

ksi

N

s

s

y

c

4 24

25 2

55

.

.

= = =

( )

( )( )

in

tD s

T

L

c

40 5

25 3 2 1 4 24

55 53 4 4

.

. .

.

= = =

Use L = 5.40 in. - answer

524. A cast-steel gear (SAE 0030), with a pitch diameter of 36 in., is transmitting 75 hp at 210 rpm to

a rock crusher, and is keyed to a 3-in. shaft (AISI 1045, as rolled); the key is made of AISI C1020,

cold drawn. For a design factor of 4 based on yield strength, what should be the length of (a) a

square key, (b) flat key? (c) Would either of these keys be satisfactory?

Solution:

For cast-steel gear (SAE 0030), Table AT 6, s

y

= 35 ksi

For shaft, AISI 1045, as rolled, Table AT 7, s

y

= 59 ksi

For key, AISI C1020, cold-drawn, Table AT 7, s

y

= 66 ksi

D = 3 in

hp = 75 hp

n = 210 rpm

( )

kips in lb in

n

hp

T = = = = 5 22 500 22

210

75 000 63 000 63

. ,

, ,

Table AT 19, use b = in, t = 1/2 in for D = 3 in

Design factor, N = 4

(a) Square key,

b = in, t = in.

By shear,

s

ys

= 0.6s

y

= 0.6(66) = 39.6 ksi

ksi

N

s

s

ys

s

9 9

4

6 39

.

.

= = =

( )

( )( )

in

bD s

T

L

s

02 2

3 4 3 9 9

5 22 2 2

.

.

.

= = =

By compression, use s

y

of cast-steel gear the lowest.

ksi

N

s

s

y

c

75 8

4

35

. = = =

SECTION 8 KEYS AND COUPLINGS

5

( )

( )( )

in

tD s

T

L

c

57 4

3 4 3 75 8

5 22 4 4

.

.

.

= = =

Use L = 4.57 in. - answer

(b) Flat key,

b = in, t = in.

By shear, s

s

= s

ys

s

ys

= 0.6s

y

= 0.6(66) = 39.6 ksi

ksi

N

s

s

ys

s

9 9

4

6 39

.

.

= = =

( )

( )( )

in

bD s

T

L

s

02 2

3 4 3 9 9

5 22 2 2

.

.

.

= = =

By compression, use s

y

of cast-steel gear the lowest.

ksi

N

s

s

y

c

75 8

4

35

. = = =

( )

( )( )

in

tD s

T

L

c

86 6

3 2 1 75 8

5 22 4 4

.

.

.

= = =

Use L = 6.86 in. - answer

525. An electric motor delivers 50 hp at 1160 rpm to a 1 5/8 in. shaft (AISI 13B45, OQT 1100 F). Keyed

to this shaft is a cast-steel (SAE 080, N & T) pulley whose hub is 2 in. long. The loading may be

classified as mild shock. Decide upon a key for this pulley (material), investigating both flat and

square keys.

Solution:

hp = 50 hp

n = 1160 rpm

D = 1 5/8 in = 1.625 in

Shaft material AISI 13B45, OQT 1100 F, Table AT 10, s

y

= 112 ksi

Pulley material SAE 080, N & T, Table AT 6, s

y

= 40 ksi

L = 2 in

N = 2.0 to 2.25 for mild shock

From Table AT 19 for D = 1 5/8 in

b = 3/8 in, t = in

( )

kips in lb in

n

hp

T = = = = 716 2 716 2

1160

50 000 63 000 63

. ,

, ,

For flat key: b = 3/8 in, t = in

Check for compression:

( )

( )( )( )

ksi

LtD

T

s

c

37 13

625 1 4 1 2

716 2 4 4

.

.

.

= = =

Based on pulley material, 25 2 99 2

37 13

40

. .

.

> = = =

c

y

s

s

N

Therefore safe in compression.

Determine the yield stress on the key

( )

( )( )( )

ksi

LbD

T

s

s

457 4

625 1 8 3 2

716 2 2 2

.

.

.

= = =

SECTION 8 KEYS AND COUPLINGS

6

25 2. = N

s y ys

Ns s s = = 6 0.

( )( ) 457 4 25 2 6 0 . . . =

y

s

ksi s

y

7 16. =

Min. ( )( ) ksi s

y

30 25 2 37 13 = = . . - Minimum yield strength of key material required.

Select SAE 003, Table AT 6, s

y

= 35 ksi Answer.

For square key: b = t = 3/8 in

Check for compression:

( )

( )( )( )

ksi

LtD

T

s

c

914 8

625 1 8 3 2

716 2 4 4

.

.

.

= = =

Based on pulley material, 25 2 49 4

914 8

40

. .

.

> = = =

c

y

s

s

N

Therefore safe in compression.

Determine the yield stress on the key

( )

( )( )( )

ksi

LbD

T

s

s

457 4

625 1 8 3 2

716 2 2 2

.

.

.

= = =

25 2. = N

s y ys

Ns s s = = 6 0.

( )( ) 457 4 25 2 6 0 . . . =

y

s

ksi s

y

7 16. =

Min. ( )( ) ksi s

y

20 25 2 914 8 = = . . - Minimum yield strength of key material required.

Select SAE 003, Table AT 6, s

y

= 35 ksi Answer.

CHECK PROBLEMS

526. A cast-steel (SAE 080, N & T) pulley, attached to a 2-in. shaft, is transmitting 40 hp at 200 rpm,

and is keyed by a standard square key, 3 in. long, made of SAE 1015, cold drawn; shaft material,

C1144, OQT 1000 F. (a) What is the factor of safety of the key? (b) The same as (a) except a flat

key is used.

Solution:

Pulley, Cast steel, SAE 080, N & T, Table AT 6, s

y

= 40 ksi

Key, SAE 1015, cold drawn, Table AT 7, s

y

= 63 ksi

Shaft, C1144, OQT 1000 F, s

y

= 83 ksi

hp = 40 hp

N = 200 rpm

D = 2 in

L = 3 in

( )

kips in lb in

n

hp

T = = = = 6 12 600 12

200

40 000 63 000 63

. ,

, ,

Table AT 19, D = 2 in

b = in, t = 3/8 in

SECTION 8 KEYS AND COUPLINGS

7

a) Square key, b = in, t = in

By shear:

( )

( )( )( )

ksi

LbD

T

s

s

4 8

2 2 1 3

6 12 2 2

.

.

= = =

( )

50 4

4 8

63 6 0

6 0

.

.

.

.

= = = =

s

y

s

ys

s

s

s

s

N < 6.21

By compression:

( )

( )( )( )

ksi

LtD

T

s

c

8 16

2 2 1 3

6 12 4 4

.

.

= = =

( )

38 2

8 16

40

.

.

= = =

c

y

s

pulley s

N < 6.21

Answer N = 2.38

b) Flat key, b = in, t = 3/8 in

By shear:

( )

( )( )( )

ksi

LbD

T

s

s

4 8

2 2 1 3

6 12 2 2

.

.

= = =

( )

50 4

4 8

63 6 0

6 0

.

.

.

.

= = = =

s

y

s

ys

s

s

s

s

N < 6.21

By compression:

( )

( )( )( )

ksi

LtD

T

s

c

4 22

2 8 3 3

6 12 4 4

.

.

= = =

( )

78 1

4 22

40

.

.

= = =

c

y

s

pulley s

N < 6.21

Answer N = 1.78

527. A cast-steel (SAE 080, N & T) pulley is keyed to a 2 1/2-in. shaft by means of a standard square

key, 3 -in. long, made of cold-drawn SAE 1015. The shaft is made of cold-drawn AISI 1045. If

the shaft is in virtually pure torsion, and turns at 420 rpm, what horsepower could the assembly

safely transmit (steady loading)?

Solution:

Pulley, Cast steel, SAE 080, N & T, Table AT 6, s

y

= 40 ksi

Key, SAE 1015, cold drawn, Table AT 7, s

y

= 63 ksi

Shaft, AISI 1045, cold drawn, Table AT 7, s

y

= 85 ksi

N = 420 rpm

L = 3 in = 3.5 in

D = 2 in

Table AT 19, D = 2 in

b = 5/8 in, t = 7/16 in

Square Key, b = t = 5/8 in

N = 1.5 for steady loading (smooth)

For shaft:

SECTION 8 KEYS AND COUPLINGS

8

( )

( )( )( )

( )

kips in

N

D s

D s

T

y

s

= = = = 31 104

16 5 1

5 2 85 6 0

16

6 0

16

3 3

3

.

.

. .

.

Key:

By shear:

2

LbD s

T

s

=

( )

ksi

N

s

N

s

s

y ys

s

2 25

5 1

63 6 0

6 0

.

.

.

.

= = = =

( )( )( )( )

kips in T = = 9 68

2

5 2 8 5 5 3 2 25

.

. . .

< 104.31 in-kips

By compression:

4

LtD s

T

c

=

( )

ksi

N

pulley s

s

y

c

67 26

5 1

40

.

.

= = =

( )( )( )( )

kips in T = = 46 36

4

5 2 8 5 5 3 67 26

.

. . .

< 104.31 in-kips

Use kips in kips in T = = 460 36 46 36 , .

( )

hp

Tn

hp 243

000 63

420 460 36

000 63

= = =

,

,

,

528. The same as 527, except that the diameter is 3 in. and the length of the key is 5 in.

Solution:

Pulley, Cast steel, SAE 080, N & T, Table AT 6, s

y

= 40 ksi

Key, SAE 1015, cold drawn, Table AT 7, s

y

= 63 ksi

Shaft, AISI 1045, cold drawn, Table AT 7, s

y

= 85 ksi

N = 420 rpm

L = 5 in

D = 3 in

Table AT 19, D = 3 in

b = 3/4 in, t = 1/2 in

Square Key, b = t = 3/4 in

N = 1.5 for steady loading (smooth)

For shaft:

( )

( )( )( )

( )

kips in

N

D s

D s

T

y

s

= = = = 25 180

16 5 1

3 85 6 0

16

6 0

16

3 3

3

.

.

.

.

Key:

By shear:

2

LbD s

T

s

=

SECTION 8 KEYS AND COUPLINGS

9

( )

ksi

N

s

N

s

s

y ys

s

2 25

5 1

63 6 0

6 0

.

.

.

.

= = = =

( )( )( )( )

kips in T = = 75 141

2

3 4 3 5 2 25

.

.

< 180.25 in-kips

By compression:

4

LtD s

T

c

=

( )

ksi

N

pulley s

s

y

c

67 26

5 1

40

.

.

= = =

( )( )( )( )

kips in T = = 75

4

3 4 3 5 67 26.

< 180.25 in-kips

Use kips in kips in T = = 000 75 75 ,

( )

hp

Tn

hp 500

000 63

420 000 75

000 63

= = =

,

,

,

MISCELLANEOUS KEYS

529. Two assemblies, one with one feather keys, are shown, with the assumed positions of the

normal forces N. Each assembly is transmitting a torque T. Derive an equation for each case

giving the axial force needed to slide the hub along the shaft (f = coefficient of friction). Does

either have an advantage in this respect?

Solution:

a)

2

ND

T =

D

T

N

2

=

Axial force =

D

fT

fN F

2

= =

b) ND

ND

T = =

2

2

D

T

N =

Axial force =

D

fT

fN F = =

Assembly (b) is stronger than assembly (a) which has an axial force half that of assembly (b).

SECTION 8 KEYS AND COUPLINGS

10

530. A 1 11/16-in. shaft rotating at 200 rpm, carries a cast-iron gear keyed to it by a x 1 -in.

Woodruff key; shaft material is cold-finished SAE 1045. The power is transmitted with mild

shock. What horsepower may be safely transmitted by the key, (a) if it is made of cold-drawn

SAE 1118? (b) if it is made of SAE 2317, OQT 1000 F? (c) How many keys of each material are

needed to give a capacity of 25 hp? Specify a choice.

Solution:

Only shear is used.

D = 1 11/16 in

n = 200 rpm

Woodruff key = x 1 in

N = 2 for mild shock

Shear force for key

s s

A s

D

T

F = =

2

2

D A s

T

s s

=

Table 10.1, x 1 in Woodruff Key is Key No. 810

Shear area, A

s

= 0.296 sq. in.

(a) Key, cold-drawn 1118, Table AT 7, s

y

= 75 ksi

( )

ksi

N

s

N

s

s

y ys

s

5 22

2

75 6 0

6 0

.

.

.

= = = = < 24.06 ksi

( )( )

lb in kips in T = =

|

\

|

= 5620 62 5

2

16

11

1 296 0 5 22

.

. .

( )( )

hp

Tn

hp 84 17

000 63

200 5620

000 63

.

, ,

= = =

(b) Key, SAE 2317, OQT 1000F, Table AT 7, s

y

= 79 ksi

( )

ksi

N

s

N

s

s

y ys

s

7 23

2

79 6 0

6 0

.

.

.

= = = = < 24.06 ksi

( )( )

lb in kips in T = =

|

\

|

= 5920 92 5

2

16

11

1 296 0 7 23

.

. .

( )( )

hp

Tn

hp 79 18

000 63

200 5920

000 63

.

, ,

= = =

(c) Number of keys for (a) = 25 / 17.84 = 1.4 or 2 keys

Number of keys for (b) = 25 / 18.79 = 1.33 or 2 keys

Select (b) which is stronger.

531. A 3/16 x 1-in. Woodruff key is used in a 1 3/16-in. shaft (cold-drawn SAE 1045). (a) If the key is

made of the same material, will it be weaker or stronger than the shaft in pure torsion? (b) If the

key is made of SAE 4130, WQT 1100 F, will it be weaker or stronger? For the purposes here, the

weakening of the shaft by the keyway is ignored.

SECTION 8 KEYS AND COUPLINGS

11

Solution:

Woodruff key, 3/16 x 1 in.

D = 1 3/16 in

Shaft: Cold drawn, SAE 1045 (Table AT 8) s

y

= 85 ksi

2

D A s

T

s s

=

Table 10.1, 3/16 x 1 in., Woodruff key is Key no. 608.

Shear area = A

s

= 0.178 sq. in.

(a) Key material = Shaft Material

In yield: For key

( )( )

kips in

D A s

D A s

T

s y

s s

=

|

\

|

= = = 39 5

2

16

3

1 178 0 85 6 0

2

6 0

2

.

. .

.

For shaft:

( )( )

kips in

D s

D s

T

y

s

=

|

\

|

= = = 77 16

16

16

3

1 85 6 0

16

6 0

16

3

3

3

.

.

.

Therefore the key is weaker.

(b) Key material = SAE 4130, WQT 1100, Table AT 7, s

y

= 114 ksi

In yield: For key

( )( )

kips in

D A s

D A s

T

s y

s s

=

|

\

|

= = = 23 7

2

16

3

1 178 0 114 6 0

2

6 0

2

.

. .

.

For shaft:

( )( )

kips in

D s

D s

T

y

s

=

|

\

|

= = = 77 16

16

16

3

1 85 6 0

16

6 0

16

3

3

3

.

.

.

Therefore the key is weaker.

532. A 2-in. shaft (cold-finished SAE 1137) is connected to a hub by a 3/8-in. radial taper pin made of

4150, OQT 1000 F. (a) What horsepower at 1800 rpm would be transmitted when the pin is

about to be sheared off? (b) For this horsepower, what peak torsional stress may be repeated in

the shaft? Is the shaft safe from fatigue at this stress?

Solution:

D = 2 in

d = 3/8 in

n = 1800 rpm

(a) For pin material , 4150, OQT 1000 F, Table AT9, su = 193.5 ksi

( ) ( )

|

|

\

|

=

|

|

\

|

= =

2 4

2 2

2 2

d

s

d

s A s F

s s s s

D d s

D d

s

FD

T

s s

2

2

4

1

2 2 2

= |

\

|

|

|

\

|

= =

( ) ksi s s s

u us s

1 145 5 193 75 0 75 0 . . . . = = = =

SECTION 8 KEYS AND COUPLINGS

12

( )( ) ( ) lb in kips in T = =

|

\

|

= 050 32 05 32 2

8

3

1 145

4

1

2

, . .

( )( )

hp

Tn

hp 7 915

000 63

1800 050 32

000 63

.

,

,

,

= = =

(b) For shaft, cold-finished, SAE 1137, Table AT 8, s

u

= 103 ksi

ksi

s

s s

u

n ns

96 30

2

103

6 0

2

6 0 6 0 . . . . = |

\

|

= |

\

|

= =

But,

( )

( )

ksi ksi psi

D

T

s

s

96 30 4 20 404 20

2

050 32 16 16

3 3

. . ,

,

< = = = =

52 1

4 20

96 30

.

.

.

= = =

s

ns

s

s

N > 1.5, therefore safe from fatigue at this stress.

533. A 20-in. lever is keyed to a 1 7/8-in. shaft (cold-finished SAE 1141) by a radial taper pin whose

mean diameter is 0.5 in.; pin material, C1095, OQT 800 F. The load on the lever is repeatedly

reversed; N = 2 on endurance strength. What is the safe lever load (a) for the shaft, (b) for the

pin key (shear only), (c) for the combination?

Solution:

T = FL where F = safe lever load.

L = 20 in

D = 1 7/8 in = 1.875 in

Shaft Material, cold finished, SAE 1141, Table AT 10.

ksi s

y

90 =

8 1. =

n

y

s

s

ksi s

n

50

8 1

90

= =

.

Pin Material, C1095, OQT 800 F, Table AT 9.

ksi s

u

176 =

( ) ksi s s

u n

88 176 5 0 5 0 = = = . .

(a) For the shaft.

( )

ksi

N

s

s

y

s

15

2

50 6 0

6 0

= = =

.

.

( )( )

lbs in kips in

D s

T

s

= = = = 414 19 414 19

16

875 1 15

16

3 3

, .

.

FL T =

( ) 20 414 19 F = ,

lb F 7 970. =

(b) For the pin.

( )

ksi

N

s

s

y

s

4 26

2

88 6 0

6 0

.

.

.

= = =

SECTION 8 KEYS AND COUPLINGS

13

( )

3

2

4

4

2

2

d

T

d d

T

A

d T

s

s

s

= = =

( )( )

lbs in kips in

d s

T

s

= = = = 2592 592 2

4

5 0 4 26

4

3 3

.

. .

FL T =

( ) 20 2592 F =

lb F 6 129. =

(c) For the combination.

Use lb F 6 129. =

534. A lever is keyed to a 2 -in. shaft made of SAE 1035, as rolled, by a radial taper pin, made of SAE

1020, as rolled. A load of 200 lb. is applied to the lever 22 in. from the center of the shaft. (a)

What size pin should be used for N = 3 based on the yield strength in shear? (b) Let the hub

diameter be 5 in. and assume that the part of the pin in the hub is uniformly loaded cantilever

beam. Compute the bending stress and comment on the bending strength (especially if the

loading varies).

Solution:

Shaft material, SAE 1035, as rolled, Table AT 7, s

y

= 55 ksi

Pin material, SAE 1020, as rolled, Table AT 7, s

y

= 48 ksi

F = 200 lb, L = 22 in, N = 3

D = 2 in, D

h

= 5 in

T = FL = (200)(22) = 4400 in-lb = 4.4 in-kips

(a) For the pin:

( )

ksi

N

s

s

y

s

6 9

3

48 6 0

6 0

.

.

.

= = =

( )

3

2

4

4

2

2

d

T

d d

T

A

d T

s

s

s

= = =

( )

3

4 4 4

6 9

d

.

. =

in d 836 0. =

Use in in d 875 0

8

7

. = =

(b) For the bending stress.

As cantilever beam let

( ) D D L

h

=

2

1

( ) in L 25 1 5 2 5

2

1

. . = =

From Table AT 2.

2 2

2

FL wL

M = =

Where F is the uniform load.

SECTION 8 KEYS AND COUPLINGS

14

( )

lb

D D

T

D

T

F

h m

2347

5 2 5

4400 4 4 2

2 =

+

=

+

= =

.

lb F 1174 =

( )( )

lb

FL

M 734

2

25 1 1174

2

= = =

.

Bending stress

( )

( )

ksi psi

d

M

s

b

16 11 160 11

875 0

734 32 32

3 3

. ,

.

= = = =

If the loading varies and factor of safety of 3.

( ) ksi Ns s

b n

48 33 16 11 3 . . = = =

Pin material, SAE 1020, as rolled, Table AT 7, s

y

= 48 ksi, s

u

= 65 ksu.

( ) ksi s s

u n

5 32 65 5 0 5 0 . . . = = =

The bending stress is nearly safe as the load varies.

535. A sprocket, transmitting 10 hp at 100 rpm, is attached to a 1 7/16 in. shaft as shown in Fig.

10.15, p. 290., Text; E = 3-1/2 in. What should be the minimum shear pin diameter if the

computed stress is 85% of the breaking stress mentioned in the Text?

Solution:

hp = 10 hp, n = 100 rpm, D = 1 7/16 in = 1.4375 in, E = 3 in = 3.5 in

( )

lb in

n

hp

T = = = 6300

100

10 000 63 000 63 , ,

lb

E

T

F 1800

5 3

6300

= = =

.

From text, Page 290. Breaking stress = 50,000 psi

( ) psi s

s

500 42 000 50 85 0 , , . = =

2

4

d

F

s

s

=

( )

2

1800 4

500 42

d

= ,

in d 2322 0. = use in.

536. A gear is attached to a 2-in. shaft somewhat as shown in Fig. 10-15, p. 290, Text; E = 3 5/16 in.;

minimum shear-pin diameter = 3/8 in. with a rated torque of 22 in-kips. (a) For this torque,

compute the stress in the shear pin. (b) From the ferrous metals given in the Appendix, select

those that would give a resisting torque of about 110% of the rated value. Choose one,

specifying its heat treatments or other conditions.

Solution:

D = 2 in

E = 3 5/16 in = 3.3125 in

d = 3/8 in

T = 22 in-kips

(a) Stress in shear-pin

lb

E

T

F 64 6

3125 3

22

.

.

= = =

SECTION 8 KEYS AND COUPLINGS

15

( )

( )

ksi s

s

12 60

8 3

64 6 4

2

.

.

= =

(b) Select material. ( ) ksi s

us

13 66 12 60 1 1 . . . = =

From appendix, Table AT 7, select Cold drawn, C1020 with s

us

= 66 ksi

SPLINES

537. A shaft for an automobile transmission has 10 splines with the following dimensions: D = 1.25

in., d = 1.087 in., and L = 1.000 in. (see Table 10.2, p. 287, Text). Determine the safe torque

capacity and horsepower at 3600 rpm of this sliding connection.

Solution:

D = 1.25 in, d = 1.087 in, L = 1.000 in, N

t

= 10, n = 3600 rpm

( )( )( )( ) lb in N r hL T

t m

= 1000

4

d D

r

m

+

=

Table 10.2 for 10 splines, sliding connection

D h 095 0. =

Then

( ) in h 11875 0 25 1 095 0 . . . = =

But

in

d D

h 0815 0

2

087 1 25 1

2

.

. .

=

= actual

in r

m

58425 0

4

087 1 25 1

.

. .

=

+

=

( )( )( )( )( ) lb in T = = 2 476 10 58425 0 000 1 0815 0 1000 . . . . - ans

( )( )

hp

Tn

hp 2 27

63000

3600 2 476

63000

.

.

= = = - ans

538. The rear axle of an automobile has one end splined. For this fitting there are ten splines, and D =

1.31 in., d = 1.122 in., and L = 1 15/16 in. The minimum shaft diameter is 1 3/16 in. (a)

Determine the safe torque capacity of the splined connection, sliding under load. (b) Determine

the torque that would have the splines on the point of yielding if the shaft is AISI 8640, OQT

1000 F, if one fourth of the splines are in contact. (c) Determine the torsional stress in the shaft

corresponding to each of these torques.

Solution:

D = 1.31 in, d = 1.122 in, L = 1 15/16 = 1.9375 in, N

t

= 10

D

r

= 1 3/16 in = 1.1875 in

( )( )( )( ) lb in N r hL T

t m

= 1000

4

d D

r

m

+

=

Table 10.2 for 10 splines, sliding connection

D h 095 0. =

Then

( ) in h 12445 0 31 1 095 0 . . . = =

SECTION 8 KEYS AND COUPLINGS

16

But

in

d D

h 094 0

2

122 1 31 1

2

.

. .

=

= (actual)

in r

m

608 0

4

122 1 31 1

.

. .

=

+

=

(a) Safe Torque

( )( )( )( )( ) lb in T = = 32 1107 10 608 0 9375 1 094 0 1000 . . . . - ans

(b) Torque by splines required on the point of yielding with one fourth of splines in contact (Page

288).

From Table AT-7, AISI 8640, OQT 1000 F. s

y

= 150 ksi, s

s

= s

ys

= 0.6s

y

= 0.6(150) = 90 ksi

( )( )( )( )

kips in

D DL s

T

s

= |

\

|

(

= |

\

|

|

\

|

= 76 58

2

31 1

8

9375 1 31 1 90

2 8

.

. . .

lbs in T = 760 58,

(c) Torsional stress in the shaft

From safe torque of 1107.32 in-lb

( )

( )

psi

D

T

s

r

s

3368

1875 1

32 1107 16 16

3 3

= = =

.

.

- ans

From torque at the point of yield

( )

( )

psi

D

T

s

r

s

711 178

1875 1

760 58 16 16

3 3

,

.

,

= = =

- ans (too high)

539. An involute splined connection has 10 splines with a pitch P

d

of 12/24 (a) Determine the

dimension of this connection. (b) Compute the length of spline to have the same torsional

strength as the shaft when one fourth the splines carry the load; minimum shaft diameter is

9/16 in. (no sliding). Check for compression.

Solution:

N

t

= 10, P

d

= 12, D

r

= 9/16 in = 0.5625 in

(a) Dimension D

in

P

N

D

d

t

8333 0

12

10

. = = =

(b) Length of spline (same torsional strength as the shaft when one fourth the splines carry the load

(Page 288).

( )

in

D

D

L

r

2136 0

8333 0

5625 0

3 3

.

.

.

= = =

Check for compression.

Failure in compression is not likely (Page 289) and can be checked by using the projected

contact area.

Projected contact area:

( )( )

2

0356 0 8333 0 2136 0 2 0 2 0 in LD A

c

. . . . . = = = based on one-fourth of the teeth being under load.

COUPLINGS

540. A flange coupling has the following dimensions (Fig. 10.19, p. 291, Text): d = 5, D = 8 5/8, H = 12

, g = 1 , h = 1, L = 7 in.; number of bolts = 6; 1 x 1 -in. square key. Materials: key, cold-

drawn AISI 1113; shaft, cold-rolled, AISI 1045; bolts, SAE grade 5 (5.8). Using the static

SECTION 8 KEYS AND COUPLINGS

17

approach with N = 3.3 on yield strengths, determine the safe horsepower that this connection

may transmit at 630 rpm.

Solution:

d = 5 in

D = 8 5/8 in = 8.625 in

H = 12 in = 12.25 in

g = 1 in = 1.5 in

h = 1 in

L = 7 in = 7.25 in

N = 3.3

n

b

= 630 rpm

Square key = 1 in x 1 in

Materials:

Key: cold-drawn AISI 1113, Table AT 7, s

y

= 72 ksi, s

ys

= 0.6s

y

= 0.6(72) = 43.2 ksi

Shaft: cold-rolled, AISI 1045, Table AT 8, s

y

= 85 ksi, s

ys

= 0.6s

y

= 0.6(85) = 51 ksi

Bolt: SAE Grade 5, h = 1 in. s

y

= 81 ksi, s

ys

= 0.6s

y

= 0.6(81) = 48.6 ksi

No given material for the flange.

Bolts in shear:

ksi

N

s

s

ys

s

73 14

3 3

6 48

.

.

.

= = =

s b

s N

h

F

4

2

=

8 2

2

H s N h FH

T

s b

= =

( ) ( )( )( )

kips in T = = 158 425

8

25 12 73 14 6 1

2

.

. .

lbs in T = 158 425,

( )( )

hp

Tn

hp 4252

000 63

630 158 425

000 63

= = =

,

,

,

Bolts in compression:

ksi

N

s

s

y

c

55 24

3 3

81

.

.

= = =

c b

hgs N F =

SECTION 8 KEYS AND COUPLINGS

18

2 2

H hgs N FH

T

c b

= =

( )( )( )( )( )

kips in T = = 319 1353

2

25 12 55 24 5 1 1 6

.

. . .

lbs in T = 319 353 1 , ,

( )( )

hp

Tn

hp 533 13

000 63

630 319 353 1

000 63

,

,

, ,

,

= = =

Key in shear:

ksi

N

s

s

ys

s

09 13

3 3

2 43

.

.

.

= = =

( )( )( )( )

kips in

bdL s

T

s

= = = 570 296

2

25 7 5 25 1 09 13

2

.

. . .

lbs in T = 570 296,

( )( )

hp

Tn

hp 2966

000 63

630 570 296

000 63

= = =

,

,

,

Key in compression:

ksi

N

s

s

y

c

82 21

3 3

72

.

.

= = =

( )( )( )( )

kips in

tdL s

T

c

= = = 180 247

4

25 7 5 25 1 82 21

4

.

. . .

lbs in T = 180 247,

( )( )

hp

Tn

hp 2472

000 63

630 180 247

000 63

= = =

,

,

,

Shaft in shear:

ksi

N

s

s

ys

s

45 15

3 3

51

.

.

= = =

( ) ( )

kips in

s d

T

s

= = = 200 379

16

45 15 5

16

3 3

.

.

lbs in T = 200 379,

( )( )

hp

Tn

hp 3792

000 63

630 200 379

000 63

= = =

,

,

,

The safest horsepower is the lowest which is 2472 hp.

541. A cast-iron (ASTM 25) jaw clutch with 4 jaws transmits 50 hp at 60 rpm. The inside diameter of

the jaws is 3 in. Considering rough handling, choose N = 8 on ultimate strengths. Make

reasonable and conservative assumptions and compute (a) the outside diameter of the jaws, (b)

the length of jaws h.

SECTION 8 KEYS AND COUPLINGS

19

Solution:

For ASTM 25, s

uc

= 97 ksi, in shear s

us

= 35 ksi (Table AT 6)

( )

lbs in

n

hp

T = = = 500 52

60

50 000 63 000 63

,

, ,

kips in T = 5 52.

(a) The outside diameter of the jaws

ksi

N

s

s

us

s

375 4

8

35

. = = =

Assume D

m

as the average diameter, t = thickness = D

o

D

i

, N

j

= number of jaws

Shear area,

( )

|

\

|

|

\

| +

|

|

\

|

=

|

|

\

|

=

2 2 2

1

2

1

i o i o

j j

m

s

D D D D

N

t

N

D

A

( )

2 2

2 2

32 4 4 2

1

i o

i o

s

D D

D D

A =

|

|

\

|

|

\

|

=

i o m

D D

T

D

T

F

+

= =

4 2

( ) ( )( )

2 2 2 2

128 32 4

i o i o i o i o s

s

D D D D

T

D D D D

T

A

F

s

+

=

+

= =

( )

( )( ) 9 3

5 52 128

375 4

2

+

=

o o

D D

.

.

By trial and error.

in D

o

466 7. = or in D

o

5 7. =

(b) The length of jaws h.

ksi

N

s

s

uc

c

125 12

8

97

. = = =

( )

2

i o j

c

D D h N

A

=

( ) ( ) ( )

i o i o i o j c

c

D D h

F

D D h

F

D D h N

F

A

F

s

= =

2 4

2 2

( )

( ) ( )

2 2

2

2

4

i o i o

i o

c

D D h

T

D D h

D D T

s

+

=

SECTION 8 KEYS AND COUPLINGS

20

( )

( ) ( ) [ ]

2 2

3 5 7

5 52 2

125 12

=

.

.

.

h

in h 1833 0. = or in h

16

3

=

542. The universal joint shown is made of AISI 3150, OQT 1000 F; a = 2 7/16 in., D = 9/16; n = 400

rpm. (a) What torque may be transmitted for shear of the pin (N = 5 on ultimate)? (b)

Considering the pin as a simply supported beam of length a with the load distributed from a

maximum at the outer (triangular), compute the safe transmitted torque (Same N). (c) In order

not to have excessive wear on the pin, the average bearing pressure should not excced 3 ksi.

Compute this transmitted torque. (d) What is the safe power?

Solution:

For AISI 3150, OQT 1000 F, Table AT 7, s

u

= 151 ksi, s

us

= 113 ksi

N = 5

p

b

= 3 ksi

a = 2 7/16 in = 2.4375 in

D = 9/16 in = 0.5625 in

n = 400 rpm

(a) Torque transmitted for shear of the pin.

ksi

N

s

s

us

s

6 22

5

113

. = = =

Each shear area

( )( )( )

kips

D

s F

s

616 5

4

5625 0 6 22

4

2 2

.

. .

= =

|

|

\

|

=

( )( ) kips in Fa

Fa

T = = = = 687 13 4375 2 616 5

2

2 . . .

lbs in T = 687 13,

(b) Torque transmitted for shear of the pin (simply supported beam)

3

Fa

M T = =

( )( )

kips in T = = 563 4

3

4375 2 616 5

.

. .

lbs in T = 563 4,

SECTION 8 KEYS AND COUPLINGS

21

(c) Torque transmitted for shear of the pin (p

b

= 3 ksi)

( ) Da

F

a D

F

A

F

p

b

b

2 2

= = =

( )( ) 4375 2 5625 0 2

3

. .

F

=

ksi F 23 8. =

3

Fa

M T = =

( )( )

kips in T = = 687 6

3

4375 2 23 8

.

. .

lbs in T = 687 6,

(d) Safe power

( )( )

hp

Tn

hp 97 28

000 63

400 563 4

000 63

.

,

,

,

= = =

544. A diagrammatic representation of a universal joint is shown, two yoke parts, the type being

similar to Figs. 10.28 and 12.10, Text. The pin extensions have a diameter D = in.; a = 11/16 in.,

material of all parts is 4340, OQT 800. Let N = 4 on ultimate stresses; n = 2400 rpm. Compute the

safe torque for (a) shear of pins, (b) the pin extensions in bending, assuming that the load

distribution is from zero at the outside pin ends to a maximum at the inside yoke surfaces, (c) an

average bearing pressure on pins of 4 ksi. (d) What is the corresponding horsepower capacity?

Solution:

For AISI 4340, OQT 800 F, Table AT 7, s

u

= 221 ksi, s

us

= 0.75s

u

= 0.75(221) = 166 ksi

N = 4

p

b

= 4 ksi

a = 11/16 in = 0.6875 in

D = 3/4 in = 0.75 in

n = 2400 rpm

(a) Torque transmitted for shear of the pin.

ksi

N

s

s

us

s

5 41

4

166

. = = =

Each shear area

( )( )( )

kips

D

s F

s

33 18

4

75 0 5 41

4

2 2

.

. .

= =

|

|

\

|

=

( )( ) kips in Fa M T = = = = 602 12 6875 0 33 18 . . .

lbs in T = 602 12,

SECTION 8 KEYS AND COUPLINGS

22

(b) Torque transmitted for shear of the pin (simply supported beam)

3

2Fa

M T = =

( )( )

kips in T = = 401 8

3

6875 0 33 18 2

.

. .

lbs in T = 401 8,

(c) Torque transmitted for shear of the pin (p

b

= 4 ksi)

Da

F

A

F

p

b

b

= =

( )( ) 6875 0 75 0

4

. .

F

=

ksi F 063 2. =

3

2Fa

M T = =

( )( )

kips in T = = 9455 0

3

6875 0 063 2 2

.

. .

lbs in T = 5 945.

(d) Safe power

( )( )

hp

Tn

hp 02 36

000 63

2400 5 945

000 63

.

,

.

,

= = =

- End -

S-ar putea să vă placă și

- Fans and BlowersDocument16 paginiFans and BlowersKristian Taruc75% (8)

- ScrewsDocument35 paginiScrewsRodel Marata100% (2)

- Brakes & ClutchesDocument52 paginiBrakes & ClutchesponcatoeraÎncă nu există evaluări

- Machine Design & Shop Practice Refresh Trivia #1Document122 paginiMachine Design & Shop Practice Refresh Trivia #1joe125683% (6)

- Clutch PDFDocument6 paginiClutch PDFKenji LacambraÎncă nu există evaluări

- Problem 11.1: Solutions To Chapter 11 Exercise ProblemsDocument28 paginiProblem 11.1: Solutions To Chapter 11 Exercise ProblemsARSENE BRICE NDEMA BOMEÎncă nu există evaluări

- Welded ConnectionDocument11 paginiWelded Connectionmechanicz0% (1)

- Material Schedule FormatDocument104 paginiMaterial Schedule FormatJibril Tauheed83% (6)

- Psme QuizDocument9 paginiPsme QuizJerico LlovidoÎncă nu există evaluări

- Delorean Headliner Installation GuideDocument4 paginiDelorean Headliner Installation GuideJames Pilcher0% (1)

- Machine Design Solved ProblemsDocument19 paginiMachine Design Solved Problemsashier dave calulot86% (7)

- Flat Belt Formulas Belt Tension RatioDocument3 paginiFlat Belt Formulas Belt Tension RatioCHRISTIAN JAYSON PEDROCHEÎncă nu există evaluări

- Me 145 - Machine Design 2: Engr - Harrison R. Flores PME 5072Document56 paginiMe 145 - Machine Design 2: Engr - Harrison R. Flores PME 5072allen eugene vizmanos100% (1)

- Machine DesignDocument76 paginiMachine DesignTerenz Calangi67% (3)

- Inconel 718Document28 paginiInconel 718aavadepa100% (1)

- Machine Design 2Document43 paginiMachine Design 2kenneth roblesÎncă nu există evaluări

- Thermodynamics Module 4Document13 paginiThermodynamics Module 4Albert Julian M. BarjoseÎncă nu există evaluări

- Spur GearDocument33 paginiSpur GearMauÎncă nu există evaluări

- MD Stress Shafts Keys Couplingsppt For ReviewDocument103 paginiMD Stress Shafts Keys Couplingsppt For ReviewKent Tunacao100% (1)

- Deophantine 6 ProblemsDocument231 paginiDeophantine 6 ProblemsCaro Kan LopezÎncă nu există evaluări

- Power Screw Example ProblemsDocument2 paginiPower Screw Example ProblemsJosafatÎncă nu există evaluări

- Calculating Indicated Mean Effective Pressure and Engine Cooling CapacityDocument2 paginiCalculating Indicated Mean Effective Pressure and Engine Cooling CapacitytiburciomadlangtutaÎncă nu există evaluări

- Crackwidth For Wall (Combined Bending and Tension)Document3 paginiCrackwidth For Wall (Combined Bending and Tension)mukhleshÎncă nu există evaluări

- Compressiong SpringsDocument68 paginiCompressiong SpringsponcatoeraÎncă nu există evaluări

- Mechanical ShaftsDocument52 paginiMechanical ShaftsErnesto Elljr Landisan Locaben Jr.75% (16)

- BeringDocument14 paginiBeringRams0% (1)

- Machine Design ProblemsDocument32 paginiMachine Design ProblemsMark Lucriana Mariscotes76% (17)

- Enhancing and Decorating The Finished ProductsDocument13 paginiEnhancing and Decorating The Finished ProductsRosemarie LabastidaÎncă nu există evaluări

- KeysDocument6 paginiKeysÐÅzurin67% (3)

- Brakes: Presented By: Cerda, JoshuaDocument22 paginiBrakes: Presented By: Cerda, JoshuaJoshua100% (2)

- Design of Couplings Tutorial: Bolt Sizing, Friction Power & Torque CapacityDocument5 paginiDesign of Couplings Tutorial: Bolt Sizing, Friction Power & Torque Capacityallahm123100% (1)

- Bolts, screws, threads and their designDocument8 paginiBolts, screws, threads and their designKen YuÎncă nu există evaluări

- JIS G3101 SS 400 Steel Plate StandardDocument6 paginiJIS G3101 SS 400 Steel Plate StandardArun kumarÎncă nu există evaluări

- Melect 2: Strength of Materials, Shafting, Keys & Coupling, Belts, Chains & Sprockets, Bolts & ScrewsDocument88 paginiMelect 2: Strength of Materials, Shafting, Keys & Coupling, Belts, Chains & Sprockets, Bolts & ScrewsLordesÎncă nu există evaluări

- Section 15Document58 paginiSection 15Ya Hoo100% (1)

- MODULE 2.1 - Specific Speed of PumpsDocument4 paginiMODULE 2.1 - Specific Speed of PumpsBench Frio Avelino100% (1)

- Rollerchains With SampleDocument7 paginiRollerchains With Samplewaar lockÎncă nu există evaluări

- Piping Dead Legs: Plastic Pipe Is Particularly Susceptible To Freeze CrackingDocument3 paginiPiping Dead Legs: Plastic Pipe Is Particularly Susceptible To Freeze CrackingJithin FrancizÎncă nu există evaluări

- Clutches (Lec7)Document50 paginiClutches (Lec7)Niño Jhim Andrew80% (5)

- Machine DesignDocument6 paginiMachine DesignBjorn Martinez50% (4)

- Key and Coupling Solutions PDFDocument22 paginiKey and Coupling Solutions PDFAlexander Pernia Diaz100% (1)

- Machine Design - 1508581959091 PDFDocument67 paginiMachine Design - 1508581959091 PDFEjay Balaba0% (1)

- Module 4 Flexible Connectors - ChainsDocument14 paginiModule 4 Flexible Connectors - ChainsBilly Jhun100% (1)

- Edited11 Belts ProblemsDocument17 paginiEdited11 Belts ProblemsDeo Warren63% (8)

- Clutch and BrakesDocument2 paginiClutch and Brakesrenz magat100% (1)

- SFSP Catalogue Guide for Pipe Supports and AccessoriesDocument50 paginiSFSP Catalogue Guide for Pipe Supports and AccessoriesAnees OlasserilÎncă nu există evaluări

- Section 4 PDFDocument70 paginiSection 4 PDFherrerafaridÎncă nu există evaluări

- MD - Chapter 1Document5 paginiMD - Chapter 1Delia GantiaÎncă nu există evaluări

- Flexible Power-Transmitting Elements: JCSF Mechanical Engineering Reviewer Machine Design: FlexibleDocument25 paginiFlexible Power-Transmitting Elements: JCSF Mechanical Engineering Reviewer Machine Design: FlexibleRobert Michael CorpusÎncă nu există evaluări

- J4011 - PNEUMATIC & HYDRAULIC (Hydraulic Basic)Document43 paginiJ4011 - PNEUMATIC & HYDRAULIC (Hydraulic Basic)Boy LiverpoolÎncă nu există evaluări

- 25.1 Shaftings Keys Couplings and ColumnsDocument11 pagini25.1 Shaftings Keys Couplings and ColumnsNob GanzÎncă nu există evaluări

- Eccentric loading design problemDocument133 paginiEccentric loading design problemILAYAPERUMAL K100% (2)

- Problems in Mechanical DesignDocument62 paginiProblems in Mechanical DesignimrancenakkÎncă nu există evaluări

- Analysis of Project Success Factors in Construction IndustryDocument14 paginiAnalysis of Project Success Factors in Construction IndustryJuan AlayoÎncă nu există evaluări

- Chapter 11Document1 paginăChapter 11Dante C. Castro100% (1)

- Completion Exam for Air Conditioning SystemsDocument1 paginăCompletion Exam for Air Conditioning SystemsEngineer ZephyrusÎncă nu există evaluări

- Keys and couplings design problemsDocument1 paginăKeys and couplings design problemsVon A. Damirez50% (2)

- Membrane StructuresDocument6 paginiMembrane StructuresMonica MarcabaÎncă nu există evaluări

- Wire Ropes GuideDocument19 paginiWire Ropes GuideNeil RubsÎncă nu există evaluări

- 1BELTSDocument19 pagini1BELTSNeil RubsÎncă nu există evaluări

- Me132p b39 Gonzales Quiz 1Document6 paginiMe132p b39 Gonzales Quiz 1WUSHÎncă nu există evaluări

- MD Module 2 Shaft DesignDocument6 paginiMD Module 2 Shaft DesignCllyan ReyesÎncă nu există evaluări

- Problem Set 2 in Machine Design 1Document1 paginăProblem Set 2 in Machine Design 1Mohamed Abdirahman0% (1)

- Engineering Materials Practice Problems in Simple StressesDocument4 paginiEngineering Materials Practice Problems in Simple StressesEu Aumentado100% (1)

- Additional Example For Lecture 1Document1 paginăAdditional Example For Lecture 1nadia_shuhada_2Încă nu există evaluări

- Chapter 11Document6 paginiChapter 11Paulo AzañeroÎncă nu există evaluări

- ColumnsDocument17 paginiColumnsponcatoeraÎncă nu există evaluări

- Home Work No.5: BY: Jhun Michael D. Locus ME-5301Document6 paginiHome Work No.5: BY: Jhun Michael D. Locus ME-5301Jhun Michael LocusÎncă nu există evaluări

- Key and Coupling SolutionsDocument28 paginiKey and Coupling SolutionsJohn Renz RetiroÎncă nu există evaluări

- IicDocument58 paginiIicAUNGPSÎncă nu există evaluări

- S He E G B: 4.5 Water Hammer Phenomenon in PipelinesDocument9 paginiS He E G B: 4.5 Water Hammer Phenomenon in PipelinesWalter Velásquez100% (1)

- Steel Pile Application For MaritimeDocument57 paginiSteel Pile Application For MaritimenguyenvanduyetÎncă nu există evaluări

- AlamilloDocument21 paginiAlamilloAbishaTeslinÎncă nu există evaluări

- Monthly Management Meeting #12: Dhaka Water Supply Sector Development ProjectDocument25 paginiMonthly Management Meeting #12: Dhaka Water Supply Sector Development ProjectAl JawadÎncă nu există evaluări

- Ficha Tecnica CableDocument2 paginiFicha Tecnica CableAriel HerreraÎncă nu există evaluări

- Cooling Tower TNCDocument6 paginiCooling Tower TNCAarol Hatta100% (1)

- C101 Electrolytic Tough Pitch CopperDocument2 paginiC101 Electrolytic Tough Pitch CopperMADDI MADHAV.Încă nu există evaluări

- Civil Engineer Seeks MS to Further Career GoalsDocument3 paginiCivil Engineer Seeks MS to Further Career GoalsDivya vijayakumar100% (1)

- ContinueDocument2 paginiContinueArdianÎncă nu există evaluări

- Engineering Instructions - FTTH House WiringDocument18 paginiEngineering Instructions - FTTH House WiringReena SharmaÎncă nu există evaluări

- Data Aire MINICeiling 2003Document44 paginiData Aire MINICeiling 2003dataaireÎncă nu există evaluări

- Environment, Health & Safety Murra Warra Stage 2 Wind Farm: WTG SWMS RegisterDocument1 paginăEnvironment, Health & Safety Murra Warra Stage 2 Wind Farm: WTG SWMS RegisterAndrew RobertsÎncă nu există evaluări

- Saep 1024Document5 paginiSaep 1024balajiÎncă nu există evaluări

- Hydraulic Calculation For Fire PumpDocument9 paginiHydraulic Calculation For Fire PumpShaifful NizamÎncă nu există evaluări

- Swivel Joint SRL825: Ptfe-LinedDocument1 paginăSwivel Joint SRL825: Ptfe-Linedady vÎncă nu există evaluări

- SOPs To Work Maunal 2019 20 March 2019 PDFDocument274 paginiSOPs To Work Maunal 2019 20 March 2019 PDFAbhishek Choudhary100% (5)

- Proper Handling and Installation of Diaphragm Seal SystemsDocument0 paginiProper Handling and Installation of Diaphragm Seal Systemsyousaf_zai_khan81995Încă nu există evaluări

- Áfico de Correlación Del Martillo Schmidt Miller 1965 PDFDocument1 paginăÁfico de Correlación Del Martillo Schmidt Miller 1965 PDFalexanderÎncă nu există evaluări

- Valvulas Solenoide para DieselDocument4 paginiValvulas Solenoide para DieselCarlos Ramos MorenoÎncă nu există evaluări