Documente Academic

Documente Profesional

Documente Cultură

Lesson 2 - Common Electric Arc Welding Processes

Încărcat de

Rama Krishna Reddy DonthireddyDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lesson 2 - Common Electric Arc Welding Processes

Încărcat de

Rama Krishna Reddy DonthireddyDrepturi de autor:

Formate disponibile

7/21/2014 Lesson 2 - Common Electric Arc Welding Processes

http://www.esabna.com/euweb/awtc/lesson2_11.htm 1/1

COPYRIGHT 1998 THE ESAB GROUP, INC.

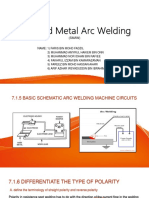

LESSON II

2.3.2.2

Direct current electrode negative (DCEN) is produced when the electrode is

connected to the negative terminal of the power source. Since the electrons f low f rom the

electrode to the plate, approximately 70% of the heat of the arc is concentrated at the work,

and approximately 30% at the electrode end. This allows the use of smaller tungsten elec-

trodes that produce a relatively narrow concentrated arc. The weld shape has deep penetra-

tion and is quite narrow. See Figure 8. Direct current electrode negative is suitable f or weld-

ing most metals. Magnesium and aluminum have a ref ractory oxide coating on the surf ace that

must be physically removed immediately prior to welding if DCSP is to be used.

2.3.2.3

Direct current electrode positive (DCEP) is produced when the electrode is

connected to the positive terminal of the welding power source. In this condition, the electrons

f low f rom the work to the electrode tip, concentrating approximately 70% of the heat of the arc

at the electrode and 30% at the work. This higher heat at the electrode necessitates using

larger diameter tungsten to prevent it f rom melting and contaminating the weld metal. Since

the electrode diameter is larger and the heat is less concentrated at the work, the resultant

weld bead is relatively wide and shallow. See Figure 8.

2.3.2.4 Aluminum and magnesium are two metals that have a heavy oxide coating that acts

as an insulator and must be removed bef ore successf ul welding can take place. Welding with

electrode positive provides a good oxide cleaning action in the arc. If we were to study the

physics of the welding arc, we f ind that the electric current causes the shielding gas atoms to

lose some of their electrons. Since electrons are negatively charged, these gas atoms now

are unbalanced and have an excessive positive charge. As we learned in Lesson I, unlike

charges attract. These positively charged atoms (or positive ions as they are known in

FIGURE 8

Electrode Oxide Heat

Polarity Penetration Cleaning Concentration

Direct Current

Alternating Current

Medium Penetration

Medium Width

Bead

Good

Cleans Oxide

on Each Half

Cy cle

Alternates Between

Electrode and Work

Straight Polarity

Electrode Negativ e

Deep

Penetration

Narrow

Bead

Direct Current

Rev erse Polarity

Electrode Positiv e

Shallow Penetration

Wide Bead

Maximum

None

At

Work

At

Electrode

GAS IONS

+

_

ELECTRON

FLOW

_

_

+

+

EFFECTS OF CURRENT TYPE - GAS TUNGSTEN ARC WELDING

Lesson 1

The Basics of Arc

Welding

Current

Chapter

Table of

Contents

Lesson 2

Common Electric

Arc Welding

Processes

Lesson 3

Covered Electrodes

for Welding

Mild Steels

Lesson 4

Covered Electrodes

for Welding Low Alloy

Steels

Go To Test

Lesson 5

Welding Filler Metals

for Stainless Steels

Print

Lesson 6

Carbon & Low Alloy

Steel Filler Metals -

GMAW,GTAW,SAW

Glossary

Lesson 7

Flux Cored Arc

Electrodes Carbon

Low Alloy Steels

Search

Chapter

(Faster

Download)

Lesson 8

Hardsurfacing

Electrodes

Turn Pages

Lesson 9

Estimating &

Comparing Weld

Metal Costs

Search

Document

(Slower

Download)

Lesson 10

Reliability of Welding

Filler Metals

S-ar putea să vă placă și

- An Essential Guide to Electronic Material Surfaces and InterfacesDe la EverandAn Essential Guide to Electronic Material Surfaces and InterfacesÎncă nu există evaluări

- Physical Properties of High-Temperature SuperconductorsDe la EverandPhysical Properties of High-Temperature SuperconductorsÎncă nu există evaluări

- 4-GAS TUNGSTEN ARC WELDING (GTAW) and PLASMA arc weldingDocument19 pagini4-GAS TUNGSTEN ARC WELDING (GTAW) and PLASMA arc weldingabastosuaptÎncă nu există evaluări

- Particle Strengthening of The Surface of Copper Electrode For Electrical Discharge MachiningDocument7 paginiParticle Strengthening of The Surface of Copper Electrode For Electrical Discharge MachiningMariana Hernández PérezÎncă nu există evaluări

- Smaw and Tig WeldingDocument46 paginiSmaw and Tig WeldingRajesh Kumar Ravi100% (1)

- Specific Welding DetalsDocument17 paginiSpecific Welding DetalsradiantsteelÎncă nu există evaluări

- Electron Beam WeldingDocument11 paginiElectron Beam WeldingSelva KumarÎncă nu există evaluări

- 1.6 - Introduction To Gas-Shielded Arc WeldingDocument36 pagini1.6 - Introduction To Gas-Shielded Arc WeldingReza DhonyÎncă nu există evaluări

- Arc and Special Welding TechniquesDocument10 paginiArc and Special Welding TechniquesAvinash ChandraÎncă nu există evaluări

- 2011 16 6 STWJ Patil Srivastava Anurag deDocument5 pagini2011 16 6 STWJ Patil Srivastava Anurag desongyang hanÎncă nu există evaluări

- Performance Capabilities of EDM Machining Using Aluminum, Brass and Copper For AISI 304L MaterialDocument6 paginiPerformance Capabilities of EDM Machining Using Aluminum, Brass and Copper For AISI 304L MaterialInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- ElectronbeamweldingDocument45 paginiElectronbeamweldingzerogravityÎncă nu există evaluări

- Electron Beam WeldingDocument19 paginiElectron Beam WeldingRajan BhadoriyaÎncă nu există evaluări

- 1.7-Tungsten-Inert Gas WeldingDocument45 pagini1.7-Tungsten-Inert Gas WeldingReza DhonyÎncă nu există evaluări

- Arc WeldingDocument16 paginiArc WeldingManohara BabuÎncă nu există evaluări

- Arc Welding-1Document14 paginiArc Welding-1m9966822Încă nu există evaluări

- Electro Discharge MachiningDocument54 paginiElectro Discharge MachiningLihas AirohalÎncă nu există evaluări

- Welding: Training Partner-Chameli Devi Group of Institutions, Indore QP Name-Welding Technician Lavel-4Document14 paginiWelding: Training Partner-Chameli Devi Group of Institutions, Indore QP Name-Welding Technician Lavel-4Bouzaida MaherÎncă nu există evaluări

- Electrical Discharge MachiningDocument30 paginiElectrical Discharge MachiningParas MalhotraÎncă nu există evaluări

- Unit 7 Shielded Gas Arc Welding: ObjectivesDocument29 paginiUnit 7 Shielded Gas Arc Welding: ObjectivesvipulÎncă nu există evaluări

- Electric Discharge Machining (EDM)Document34 paginiElectric Discharge Machining (EDM)Paras Malhotra0% (2)

- Electrochemical Machining (Ecm)Document17 paginiElectrochemical Machining (Ecm)Rajeev DangÎncă nu există evaluări

- UeetDocument21 paginiUeetIts FickÎncă nu există evaluări

- Keje Welding DaamDocument12 paginiKeje Welding Daamdzuko shamÎncă nu există evaluări

- Welding NotesDocument5 paginiWelding NotesRakesh RanjanÎncă nu există evaluări

- Assignment 4 EDMDocument2 paginiAssignment 4 EDMGowrisanthosh Palika100% (2)

- WELD-Arc Welding - Maine Welding CompanyDocument7 paginiWELD-Arc Welding - Maine Welding CompanypeterÎncă nu există evaluări

- 2.2 Shielded Metal Arc WeldingDocument4 pagini2.2 Shielded Metal Arc WeldingMat SerabaiÎncă nu există evaluări

- TIG2Document6 paginiTIG2Shubham100% (1)

- EDM Introduction Explains History and Working PrinciplesDocument49 paginiEDM Introduction Explains History and Working PrinciplesChalla varun KumarÎncă nu există evaluări

- EDM Process Guide: Electrical Discharge MachiningDocument28 paginiEDM Process Guide: Electrical Discharge MachiningJayant SisodiaÎncă nu există evaluări

- Welding NOTESDocument5 paginiWelding NOTESAnonymous utfuIcnÎncă nu există evaluări

- Arc Welding AbstractDocument5 paginiArc Welding AbstractotuozegarbaÎncă nu există evaluări

- 5.arc WeldDocument40 pagini5.arc Weldalinader20022Încă nu există evaluări

- Chapter-1 Introduction:-1.1: GeneralDocument22 paginiChapter-1 Introduction:-1.1: Generalk.vikasÎncă nu există evaluări

- Atomic Hydrogen Welding Process ExplainedDocument1 paginăAtomic Hydrogen Welding Process ExplainedShiva YvmÎncă nu există evaluări

- Types of Welding ArcsDocument14 paginiTypes of Welding ArcsArnab GoswamiÎncă nu există evaluări

- Information Sheet 8.2.1 Striking An ArcDocument4 paginiInformation Sheet 8.2.1 Striking An ArcJerryson CabriasÎncă nu există evaluări

- PART 171 When Manual Metal Arc Welding, Which Electrode Polarity Should I UseDocument2 paginiPART 171 When Manual Metal Arc Welding, Which Electrode Polarity Should I Useravindra_jivaniÎncă nu există evaluări

- National Institute of Textile Engineering and Research (NITER)Document6 paginiNational Institute of Textile Engineering and Research (NITER)shahadat hossainÎncă nu există evaluări

- I. Welding: (What About Flux Cored Arc Welding??)Document4 paginiI. Welding: (What About Flux Cored Arc Welding??)Ravi PoudelÎncă nu există evaluări

- CHAPTER 7 - WeldingDocument34 paginiCHAPTER 7 - WeldingMuhamad Haikal OthmanÎncă nu există evaluări

- Welding Shop Lab ManualDocument13 paginiWelding Shop Lab Manualcijiv82077Încă nu există evaluări

- edm-170421105019Document28 paginiedm-17042110501922210021 TANWADE RUTURAJ RAVINDRAÎncă nu există evaluări

- EDM Electrode Material Properties and SelectionDocument6 paginiEDM Electrode Material Properties and Selectionomer21Încă nu există evaluări

- Electro Discharge Machining (Edm)Document35 paginiElectro Discharge Machining (Edm)Pinakin KatariaÎncă nu există evaluări

- Arc Welding Equipment and ProcessesDocument40 paginiArc Welding Equipment and Processesali100% (1)

- GTAW Tig WeldingDocument10 paginiGTAW Tig WeldingSteve M D'souzaÎncă nu există evaluări

- Physics of Welding Better VersionDocument3 paginiPhysics of Welding Better VersionKhurram RehmanÎncă nu există evaluări

- Electron Beam WeldingDocument20 paginiElectron Beam WeldingkumarÎncă nu există evaluări

- Welding Engineering - FALL2021-22 - Module 1Document44 paginiWelding Engineering - FALL2021-22 - Module 1dhaya nidhiÎncă nu există evaluări

- Electrode Converted Into TextDocument14 paginiElectrode Converted Into TextNeha NimbarkÎncă nu există evaluări

- Dry Type Arc Welding MachineDocument11 paginiDry Type Arc Welding MachineIsaac Honny Jnr100% (1)

- S3 ME FEE Notes Mod 4 FINALDocument25 paginiS3 ME FEE Notes Mod 4 FINALAmal MonichanÎncă nu există evaluări

- Smaw PDFDocument10 paginiSmaw PDFArizapatazoÎncă nu există evaluări

- 121Document39 pagini121veerusiteÎncă nu există evaluări

- Vinay Kumar Bharti-EbwDocument14 paginiVinay Kumar Bharti-Ebwvinay BhartiÎncă nu există evaluări

- Resistance and Special WeldingDocument24 paginiResistance and Special WeldingKBSMANITÎncă nu există evaluări

- How to select the right welding electrodeDocument6 paginiHow to select the right welding electrodeRobert DelafosseÎncă nu există evaluări

- Excel 2007 FunctionsDocument24 paginiExcel 2007 FunctionsPopescu AndreiÎncă nu există evaluări

- SSDocument4 paginiSSSaran KumarÎncă nu există evaluări

- Keyboard SettingDocument10 paginiKeyboard SettingDiayana Amirah Mohd RadinÎncă nu există evaluări

- A Guide To Aluminum WeldingDocument2 paginiA Guide To Aluminum WeldingRama Krishna Reddy DonthireddyÎncă nu există evaluări

- Disclosure To Promote The Right To InformationDocument99 paginiDisclosure To Promote The Right To InformationgovimanoÎncă nu există evaluări

- C StructDesign Bendapudi Feb10Document3 paginiC StructDesign Bendapudi Feb10samvendanÎncă nu există evaluări

- The Iron-Carbon Equilibrium Diagram: AbstractDocument4 paginiThe Iron-Carbon Equilibrium Diagram: AbstractRama Krishna Reddy DonthireddyÎncă nu există evaluări

- Fe-C Phase DiagramDocument34 paginiFe-C Phase DiagramYoung-long Choi100% (1)

- Meng 6BDocument67 paginiMeng 6BRama Krishna Reddy DonthireddyÎncă nu există evaluări

- 201397113331M293MP142P 0 Tech Spec BPI R00Document27 pagini201397113331M293MP142P 0 Tech Spec BPI R00Rama Krishna Reddy DonthireddyÎncă nu există evaluări

- AutoCAD One Key Shortcut Guide - AutoCAD Commands - Autodesk StoreDocument8 paginiAutoCAD One Key Shortcut Guide - AutoCAD Commands - Autodesk StoreRama Krishna Reddy DonthireddyÎncă nu există evaluări

- Chandra Sekhar Naik - LinkedInDocument4 paginiChandra Sekhar Naik - LinkedInRama Krishna Reddy DonthireddyÎncă nu există evaluări

- Fe-Fe3c Diagram VerygoodDocument3 paginiFe-Fe3c Diagram VerygoodRama Krishna Reddy DonthireddyÎncă nu există evaluări

- Engineering CPWD Analysis of Rates - 1Document571 paginiEngineering CPWD Analysis of Rates - 1javedk_33Încă nu există evaluări

- 415V AC Distribution Board ChecklistDocument136 pagini415V AC Distribution Board ChecklistRama Krishna Reddy Donthireddy100% (2)

- Pipe Inspection SpecificationDocument10 paginiPipe Inspection SpecificationRama Krishna Reddy DonthireddyÎncă nu există evaluări

- ABB Lummus Global B.V. Piling SpecificationDocument25 paginiABB Lummus Global B.V. Piling SpecificationRama Krishna Reddy DonthireddyÎncă nu există evaluări

- Pipe Inspection SpecificationDocument49 paginiPipe Inspection SpecificationRama Krishna Reddy DonthireddyÎncă nu există evaluări

- Iocl Tank Spec F-601 Rev 0Document18 paginiIocl Tank Spec F-601 Rev 0Rama Krishna Reddy Donthireddy100% (1)

- 000007Document34 pagini000007Rama Krishna Reddy DonthireddyÎncă nu există evaluări

- WeldingDocument3 paginiWeldingveera_saikumarÎncă nu există evaluări

- QC EnggDocument4 paginiQC EnggRama Krishna Reddy DonthireddyÎncă nu există evaluări

- Piping BrochureDocument2 paginiPiping Brochureramesh00Încă nu există evaluări

- Iocl Shell & Tube He's Spec Ea-601 Rev 0Document5 paginiIocl Shell & Tube He's Spec Ea-601 Rev 0Rama Krishna Reddy DonthireddyÎncă nu există evaluări

- Ga 603Document9 paginiGa 603Rama Krishna Reddy DonthireddyÎncă nu există evaluări

- Iocl Heavy Wall Vessels Spec D-612 Rev 0Document8 paginiIocl Heavy Wall Vessels Spec D-612 Rev 0Rama Krishna Reddy DonthireddyÎncă nu există evaluări

- Weldingappsmaw Fcaw Gmaw Gtaw SawDocument20 paginiWeldingappsmaw Fcaw Gmaw Gtaw SawNguyen Huu TriÎncă nu există evaluări

- Nominal Pipe Size NPS, Nominal Bore NB, Outside Diameter ODDocument5 paginiNominal Pipe Size NPS, Nominal Bore NB, Outside Diameter ODRama Krishna Reddy DonthireddyÎncă nu există evaluări

- The ABC's of Arc Welding and InspectionDocument93 paginiThe ABC's of Arc Welding and Inspectionmichaeldtalbott100% (1)

- Standard Pipe SizesDocument5 paginiStandard Pipe Sizessivak78mduguhaÎncă nu există evaluări

- QUIZ 2 BUMA 20013 - Operations Management TQMDocument5 paginiQUIZ 2 BUMA 20013 - Operations Management TQMSlap ShareÎncă nu există evaluări

- DRM 25Document14 paginiDRM 25Anantha RajanÎncă nu există evaluări

- 2002 AriDocument53 pagini2002 AriMbarouk Shaame MbaroukÎncă nu există evaluări

- University Reserch Worksheet PDFDocument7 paginiUniversity Reserch Worksheet PDFapi-410567922Încă nu există evaluări

- Managerial Performance Evaluation ProceduresDocument3 paginiManagerial Performance Evaluation Procedures1robcortesÎncă nu există evaluări

- ResumeDocument5 paginiResumeSaeed SiriÎncă nu există evaluări

- Final System DocumentationDocument31 paginiFinal System DocumentationEunice AquinoÎncă nu există evaluări

- Events of National Importance 2016Document345 paginiEvents of National Importance 2016TapasKumarDashÎncă nu există evaluări

- SO CF, Internal Fault Map Class 1A SO CF, Internal Fault Map Class 2A SO CF, External Condition Map Class 1BDocument15 paginiSO CF, Internal Fault Map Class 1A SO CF, Internal Fault Map Class 2A SO CF, External Condition Map Class 1BATMMOBILISÎncă nu există evaluări

- Stage TwoDocument34 paginiStage TwoThar LattÎncă nu există evaluări

- Teodorico M. Collano, JR.: ENRM 223 StudentDocument5 paginiTeodorico M. Collano, JR.: ENRM 223 StudentJepoyCollanoÎncă nu există evaluări

- Mindfulness With Collegiate Gymnasts - Effects On Flow, Stress and Overall Mindfulness LevelsNicholas P. Cherupa,, Zeljka VidicDocument13 paginiMindfulness With Collegiate Gymnasts - Effects On Flow, Stress and Overall Mindfulness LevelsNicholas P. Cherupa,, Zeljka VidicGABRIELÎncă nu există evaluări

- Develop Network Monitoring System IP Subnet CalculatorDocument23 paginiDevelop Network Monitoring System IP Subnet CalculatorabiramanÎncă nu există evaluări

- MAPEH 6- WEEK 1 ActivitiesDocument4 paginiMAPEH 6- WEEK 1 ActivitiesCatherine Renante100% (2)

- Scedule Maintenance KBN Mill 2020Document9 paginiScedule Maintenance KBN Mill 2020slamet supriyadiÎncă nu există evaluări

- Movement Joints (NHBC)Document5 paginiMovement Joints (NHBC)hemendraengÎncă nu există evaluări

- Superficial ConclusionDocument49 paginiSuperficial ConclusionIngrid ParissÎncă nu există evaluări

- Plenaristas León 2022xDocument6 paginiPlenaristas León 2022xGloria MontielÎncă nu există evaluări

- Volvo S6 66 Manual TransmissionDocument2 paginiVolvo S6 66 Manual TransmissionCarlosÎncă nu există evaluări

- Guimaras State CollegeDocument5 paginiGuimaras State CollegeBabarianCocBermejoÎncă nu există evaluări

- Quiz 1Document3 paginiQuiz 1JULIANNE BAYHONÎncă nu există evaluări

- Information HandoutsDocument6 paginiInformation HandoutsPooja Marwadkar TupcheÎncă nu există evaluări

- Alaris 8210 and 8220 SpO2 Module Service ManualDocument63 paginiAlaris 8210 and 8220 SpO2 Module Service ManualNaveen Kumar TiwaryÎncă nu există evaluări

- CEILING BOARDING GUIDEDocument5 paginiCEILING BOARDING GUIDEahahÎncă nu există evaluări

- Effect of Social Media On The Academic PerformanceDocument55 paginiEffect of Social Media On The Academic PerformanceFJ Asufra100% (2)

- 199-Article Text-434-1-10-20200626Document11 pagini199-Article Text-434-1-10-20200626ryan renaldiÎncă nu există evaluări

- Maytag MDG78PN SpecificationsDocument2 paginiMaytag MDG78PN Specificationsmairimsp2003Încă nu există evaluări

- Critical Thinking Essay-Animal Testing: Rough DraftDocument10 paginiCritical Thinking Essay-Animal Testing: Rough Draftjeremygcap2017Încă nu există evaluări

- 5 Tests of Significance SeemaDocument8 pagini5 Tests of Significance SeemaFinance dmsrdeÎncă nu există evaluări

- DLP Din8Document2 paginiDLP Din8KOUDJIL MohamedÎncă nu există evaluări