Documente Academic

Documente Profesional

Documente Cultură

Torrefaction Technology For Biomass Pretreatment Process

Încărcat de

Surasan Thepsiri0 evaluări0% au considerat acest document util (0 voturi)

39 vizualizări8 paginisu

Titlu original

2_TorrefactionTechnologyBiomassPre-TreatmentProcess_2.pdf

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentsu

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

39 vizualizări8 paginiTorrefaction Technology For Biomass Pretreatment Process

Încărcat de

Surasan Thepsirisu

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 8

Torrefaction Technology

for Biomass Pretreatment Process

a+aa e a a u aa a..ea a

a u.a+a.+aIo..a+.

2

Overview

- Global Warming

- Decrease Power Generation

of Nuclear Power Plant

- 2020 Policy of EU

- Logistic cost depends on diesel price.

Wood Pellet Cost Distribution

32%

35%

33%

Raw Mat.

Process

Logistic

Renewables 2013 Global Status Report

Wood Pellet Association of Canada

3

Overview

an interesting option to improve biomass properties to get

more uniformity. Densication by means of pelletization is

considered to be a proven technology to improve biomass

properties for its conversion into heat and power. Pellets

from torreed biomass are attractive with respect to heating

value, grindability, combustion nature, storage, transport

and handling which make them attractive as replacement

for coal in existing power stations. Energy research Centre

Netherlands (ECN) [20,26,27] developed the so-called BO

2

process (in initial literature also referred to as the TOP

process) in which pellets are processed with torreed

biomass. Compared to non-torreed pellets BO

2

pellets show

better hydrophobic behavior, strength and higher density.

The main characteristics of different pellets are shown in

Table 3 [27].

The BO

2

process combines torrefaction and pelletization

and according to Fig. 14 torrefaction is introduced into the

system as a unit after drying and before size reduction in

comparison to a typical biomass pelletization process [20]. The

torrefaction process consists of several steps such as drying,

torrefaction and cooling. The pelletization process comprises

the steps of drying, size reduction, steam pre-conditioning,

densication and cooling. Combining the torrefaction and

pelletization process leads to the introduction of torrefaction

in the pelletization step and the removal of the steam pre-

conditioning from the pelletization step.

Currently ECN operates a 50e100 kg/h pilot plant where

biomass pellets are produced from a broad range of biomass

streams, such as wood chips, agricultural residues and

various residues from the food and feed processing industry

[51]. These so-called 2nd generation pellets have superior

properties in terms of high energy density (1.5e2 conven-

tional pellets), excellent grindability and water resistant

nature (eliminating/reducing biological degradation and

spontaneous heating, and enabling outdoor storage).

4.2. Torrefaction and gasication

Torrefaction is mainly used as pre-treatment technology to

upgrade the biomass to a higher quality biofuel. This biofuel

can be used in other conversion methods to produce bio-

energy. The main application of torreed biomass (wood) is

as a renewable fuel for combustion or gasication. Prins et al.

[2] studied the possibility of more efcient biomass gasica-

tion via torrefaction in different systems; air-blown circu-

lating uidized bed gasication of wood, wood torrefaction

and circulating uidized bed gasication of torreed wood,

and wood torrefaction integrated with entrained ow gasi-

cation of torreed wood.

The main idea behind combining biomass torrefaction and

gasicationis that the heat produced during gasicationinthe

form of steam is recovered for application in the torrefaction

stage. The advantages of torrefaction as a pre-treatment prior

to gasication in three concepts are compared with each

other. In Fig. 15aec [2] three different gasication schemes are

presented.

Fig. 15a shows biomass (wood) gasication in circulating

uidized bed (CFB). The CFB gasier is operated below

1000

C at atmospheric conditions to avoid problems with

ash softening and melting. Air is used as gasifying medium.

The steam is exported at 280

C at 45 bar.

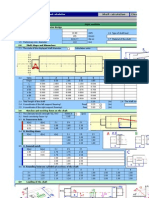

Table 3 e Properties of wood, torreed biomass, wood

and BO

2

pellets [27].

Properties Unit Wood Torreed

biomass

Wood pellets TOP pellets

Low High Low High

Moisture %wt 35% 3% 10% 7% 5% 1%

LHV

Normal MJ/kg 10.5 19.9 15.6 16.2 19.9 21.6

Dry MJ/kg 17.7 20.4 17.7 17.7 20.4 22.7

Mass

density

kg/m

3

550 230 500 650 750 850

Energy

density

GJ/m

3

5.8 4.6 7.8 10.5 14.9 18.4

Fig. 14 e Pelletization, torrefaction and TOP process schemes [20].

b i o ma s s a nd b i o e ne r gy 3 5 ( 2 0 1 1 ) 3 7 4 8 e3 7 6 2 3757

Biomass upgrading by torrefaction for the production of biofuels: A review

4

Torrefaction Technology

Biomass Torrefaction

Torrefaction is used as a pre-treatment step for biomass conversion techniques such as gasification

and co-firing. The thermal treatment not only destructs the fibrous structure and tenacity of

biomass, but is also known to increase the calorific value. Also after torrefaction the biomass has

more hydrophobic characteristics that make storage of torrefied biomass more attractive above

non-torrefied biomass, because of the rotting behavior.

Biomass upgrading by torrefaction for the production of biofuels

Torrefaction

250 C

1M 1E

Biomass

0.3M 0.1E

Torrefied Gases

0.7M 0.9E

Torrefied

Biomass

1.3 E/M 1 E/M

5

Torrefaction Technology

6

Value Propositions

Value Propositions

- :v a:ua .v +e+ao++e. aaa .

- a+e+.a:a u. au+Io e+aa++ +u

- u a.a ao++ev aIo o

- a aa aa+.vaa.aoa.

- aoa aa a Operating Cost

I..Iuu +a+a aauu Co-firing

34

!"#$%& ( )*)+, -.+"/ -*0)0 1.")& 2&,,&)0 3&%0$0 4,+-5 2&,,&)0

More recenL sLudles on Lhe producLlon and loglsLlcal cosLs of Lorrefled pelleLs conflrm Lhe facL LhaL

hlgher converslon cosLs on Lhe slde of Lorrefled pelleLs are almosL fully compensaLed by lower loglsLlc

and handllng cosLs - especlally when looklng aL a supply chaln lncludlng ocean shlpplng. ln Lhe case of

Lhe kLMA sLudy

16

(llgure 3) Lhese were 8.6 t/C! for whlLe elleLs and 8.8 t/C! dellvered for Lorrefled

pelleLs.

!"#$%& 6 -*0) -*72+%"0*/ 1**8 2&,,&)0 3&%0$0 )*%%&9"&8 1**8 2&,,&)0

16

kLMA, 2012, presenLaLlon

U

S

$

/

G

J

wood pellet torrefied pellet

IEA bioenergy task 40 Possible effect of torrefaction on biomass trade (IEA bioenergy)

1 ton

0.75 ton

1.4 m

3

0.68 m

3

7

Pretreatment of the biomass using torrefaction is considered

the optimum solution since torrefied material, particularly

pelletized torrefied wood, is very similar to fossil coal and

burns cleaner. Several large research projects are under way

to speed up the development of torrefied pellets, both in

Canada and Europe. The target is set for large-scale

introduction of torrefied pellets around 2014-2015.

8

S-ar putea să vă placă și

- Viet Nam: Energy Sector Assessment, Strategy, and Road MapDe la EverandViet Nam: Energy Sector Assessment, Strategy, and Road MapÎncă nu există evaluări

- Chlorine: International Thermodynamic Tables of the Fluid StateDe la EverandChlorine: International Thermodynamic Tables of the Fluid StateÎncă nu există evaluări

- Torrified Pellette Manufaturing June 23Document22 paginiTorrified Pellette Manufaturing June 23koustuv mitra100% (1)

- Torrefaction-Based BO - Technology For Biomass Upgrading Into Commodity Solid Fuel. Pilot-Scale Testing and DemonstrationDocument10 paginiTorrefaction-Based BO - Technology For Biomass Upgrading Into Commodity Solid Fuel. Pilot-Scale Testing and DemonstrationmarkodzajicÎncă nu există evaluări

- Cenospheres From Fly AshDocument3 paginiCenospheres From Fly AshAjay SharmaÎncă nu există evaluări

- GLOBAL PELLET MARKETS & BIOMASS CO-FIRING GROWTHDocument28 paginiGLOBAL PELLET MARKETS & BIOMASS CO-FIRING GROWTHNorzuriani Mohamed SeberiÎncă nu există evaluări

- Chemical Composition of Fly AshDocument29 paginiChemical Composition of Fly AshLavu Anil ChowdaryÎncă nu există evaluări

- Flyash ManagementDocument13 paginiFlyash ManagementShahinshaÎncă nu există evaluări

- Refuse Disposal Management in PCMCDocument6 paginiRefuse Disposal Management in PCMCGRD JournalsÎncă nu există evaluări

- Disposal of Waste Tyres For Energy Recovery and Safe Environment-ReviewDocument18 paginiDisposal of Waste Tyres For Energy Recovery and Safe Environment-ReviewshlogonÎncă nu există evaluări

- Application of Highwall Mining in IndiaDocument12 paginiApplication of Highwall Mining in IndiaSatish kumarÎncă nu există evaluări

- Uses of Zinc: General Galvanizing. Fasteners Can Also Be Immersed and Then Centrifuged Whilst The Coating Is StillDocument8 paginiUses of Zinc: General Galvanizing. Fasteners Can Also Be Immersed and Then Centrifuged Whilst The Coating Is StillardiansyahhandikaÎncă nu există evaluări

- Carbon Dioxide Utilization in Ready-Mixed Concrete ProductionDocument24 paginiCarbon Dioxide Utilization in Ready-Mixed Concrete Productionjack21ab100% (1)

- Portland CementDocument58 paginiPortland CementNani DeskaaÎncă nu există evaluări

- Status Paper On Utilisation of Refuse Derived Fuel (RDF) in IndiaDocument18 paginiStatus Paper On Utilisation of Refuse Derived Fuel (RDF) in IndiaSupratik RoyÎncă nu există evaluări

- Cement GrindingDocument19 paginiCement GrindingCao Ngoc AnhÎncă nu există evaluări

- Alufer - Bauxite Factsheet PDFDocument2 paginiAlufer - Bauxite Factsheet PDFRaraÎncă nu există evaluări

- Energy: Key Drivers of CCUS Project EconomicsDocument55 paginiEnergy: Key Drivers of CCUS Project EconomicsDanielÎncă nu există evaluări

- Paper On Diversification of Power Producer Into Pellet Manufacturing ProcessDocument5 paginiPaper On Diversification of Power Producer Into Pellet Manufacturing ProcessRavi SatyapalÎncă nu există evaluări

- Basic Concepts of Coal ExplorationDocument11 paginiBasic Concepts of Coal ExplorationAvipsha ChakrabortyÎncă nu există evaluări

- Marcona Copper ProjectDocument5 paginiMarcona Copper ProjectGeorgi SavovÎncă nu există evaluări

- Are View of Geo Polymer ConcreteDocument5 paginiAre View of Geo Polymer ConcreteshivaÎncă nu există evaluări

- Cogenerationof Power Utilising Waste Heatin Cement ManufactureDocument12 paginiCogenerationof Power Utilising Waste Heatin Cement ManufactureRedouane RadwanÎncă nu există evaluări

- Urea 6Document28 paginiUrea 6Pragati Kshatriya100% (1)

- CarbonCure Whitepaper Impact of CO2 Utilization in Fresh Concrete On Corrosion of Steel ReinforcementDocument6 paginiCarbonCure Whitepaper Impact of CO2 Utilization in Fresh Concrete On Corrosion of Steel ReinforcementSakineÎncă nu există evaluări

- Reducing Biogas Power Generation Costs by Removal of SiloxanesDocument17 paginiReducing Biogas Power Generation Costs by Removal of SiloxanesMinh TranÎncă nu există evaluări

- Scaling The Ccus Industry To Achieve - FinalDocument9 paginiScaling The Ccus Industry To Achieve - FinalTac LeungÎncă nu există evaluări

- Representation of Coal and Coal Derivatives in Process ModellingDocument16 paginiRepresentation of Coal and Coal Derivatives in Process ModellingPrateek PatelÎncă nu există evaluări

- Biogas Digester - Final PDFDocument28 paginiBiogas Digester - Final PDFzubair aliÎncă nu există evaluări

- Process and Economic Considerations in Copper MetallurgyDocument53 paginiProcess and Economic Considerations in Copper Metallurgydars23Încă nu există evaluări

- Physical and Thermal Treatment of Phosphate OresDocument26 paginiPhysical and Thermal Treatment of Phosphate OresManoel Carlos Cerqueira100% (2)

- Productive Recycling of BOF Sludge in Integrated PlantDocument5 paginiProductive Recycling of BOF Sludge in Integrated PlantJorge MadiasÎncă nu există evaluări

- BM11 - 2008-08-08 Deloitte Pellet Cost StudyDocument70 paginiBM11 - 2008-08-08 Deloitte Pellet Cost Studym0k123_11264014067% (3)

- Penggunaan Biofuel B30 Pada Kendaraan Diesel PDFDocument22 paginiPenggunaan Biofuel B30 Pada Kendaraan Diesel PDFYogik Indra LukmantoÎncă nu există evaluări

- VSK process specification for small cement plantsDocument3 paginiVSK process specification for small cement plantsArjun Chetri BhandariÎncă nu există evaluări

- 118Document9 pagini118Suhail KhanÎncă nu există evaluări

- Biogas TechnologyDocument7 paginiBiogas TechnologyMuhire PatrickÎncă nu există evaluări

- Alternative Fuels Coming On Strong in The Cement Industry - Cement Lime GypsumDocument10 paginiAlternative Fuels Coming On Strong in The Cement Industry - Cement Lime GypsumDavid Jamwa ChandiÎncă nu există evaluări

- Europe's Onshore and Offshore Wind Energy PotentialDocument91 paginiEurope's Onshore and Offshore Wind Energy PotentialSuDokuÎncă nu există evaluări

- Finance Project On ACC CEMENTDocument87 paginiFinance Project On ACC CEMENTShilpan Shah80% (5)

- Project Report On Precipitated Calcium CarbonateDocument6 paginiProject Report On Precipitated Calcium CarbonateEIRI Board of Consultants and PublishersÎncă nu există evaluări

- Feasibility Report For Production & Supply/Sale of Fly Ash Bricks in PakistanDocument5 paginiFeasibility Report For Production & Supply/Sale of Fly Ash Bricks in PakistanUmar YaqoobÎncă nu există evaluări

- QuickLime MSDS (2012)Document2 paginiQuickLime MSDS (2012)chinck83Încă nu există evaluări

- Cement & Admixtures HistoryDocument14 paginiCement & Admixtures HistoryGaneshÎncă nu există evaluări

- Plastic Waste To SyngasDocument10 paginiPlastic Waste To Syngaswaseemkhan49Încă nu există evaluări

- Application of The Shrinking Core Model For Copper Oxide LeachingDocument7 paginiApplication of The Shrinking Core Model For Copper Oxide LeachingLuis La TorreÎncă nu există evaluări

- SPL Utilization in Cement Steel IndustryDocument19 paginiSPL Utilization in Cement Steel IndustryVincent 2020Încă nu există evaluări

- Proceedings PDFDocument139 paginiProceedings PDFR RathiÎncă nu există evaluări

- Sewage Sludge Management in Germany PDFDocument104 paginiSewage Sludge Management in Germany PDFKenaia AdeleyeÎncă nu există evaluări

- 9.evaluation of Oil Sludge As An Alternative Fuel in The ProductionDocument6 pagini9.evaluation of Oil Sludge As An Alternative Fuel in The ProductionRati YuliarningsihÎncă nu există evaluări

- PowderDocument10 paginiPowder1977julÎncă nu există evaluări

- EMC NamkhainyambuuDocument21 paginiEMC NamkhainyambuuUrtaBaasanjargalÎncă nu există evaluări

- Reduce Raw Mill Energy Cement IndustryDocument9 paginiReduce Raw Mill Energy Cement Industryhasan_jafri_2Încă nu există evaluări

- Small Scale Cement Plants A Study in EconomicsDocument33 paginiSmall Scale Cement Plants A Study in EconomicsplutocowÎncă nu există evaluări

- Coal PreparationDocument4 paginiCoal PreparationMontmorencyÎncă nu există evaluări

- Optimization of Sugar Cane Bagasse Pretreatment Process Using RSMDocument10 paginiOptimization of Sugar Cane Bagasse Pretreatment Process Using RSMInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Benzene Removal From Gasoline - Aspen SimulationDocument18 paginiBenzene Removal From Gasoline - Aspen SimulationWesley Neutt0% (1)

- Environmental Benefits of Secondary Copper From Primary Copper Based On Life Cycle Assessment in China PDFDocument10 paginiEnvironmental Benefits of Secondary Copper From Primary Copper Based On Life Cycle Assessment in China PDFJean Carlos Ruiz ZapataÎncă nu există evaluări

- 5.9 MWe biomass gasification cogen plantDocument0 pagini5.9 MWe biomass gasification cogen plantApri ApriyantoÎncă nu există evaluări

- Environmentally Friendly Production of Pulp and PaperDe la EverandEnvironmentally Friendly Production of Pulp and PaperÎncă nu există evaluări

- Basic Principles of Ship Propulsion: ContentsDocument28 paginiBasic Principles of Ship Propulsion: Contentserhandtm96% (26)

- Enhancing The Circulation Analysis of A Recovery Boiler Through The Incorporation of 3-D Furnace Heat Transfer Results From COMO™Document5 paginiEnhancing The Circulation Analysis of A Recovery Boiler Through The Incorporation of 3-D Furnace Heat Transfer Results From COMO™Surasan ThepsiriÎncă nu există evaluări

- ASNT-L3 Qualifications PDFDocument3 paginiASNT-L3 Qualifications PDFElankumaran PeriakaruppanÎncă nu există evaluări

- Free Surface WavesDocument29 paginiFree Surface WavesSurasan ThepsiriÎncă nu există evaluări

- 1 การตรวจสอบการสร้างหม้อน้ำตามมาตรฐานASME2013Document24 pagini1 การตรวจสอบการสร้างหม้อน้ำตามมาตรฐานASME2013Surasan ThepsiriÎncă nu există evaluări

- Design of Input Gear-Shaft-ExamplerDocument11 paginiDesign of Input Gear-Shaft-ExamplerGuru PrasadÎncă nu există evaluări

- Service RecordDocument2 paginiService RecordSurasan ThepsiriÎncă nu există evaluări

- Basic Principles of Ship Propulsion: ContentsDocument28 paginiBasic Principles of Ship Propulsion: Contentserhandtm96% (26)

- NYS DOT Steel Construction Manual 3rd Edition - SCM - 3rd - Addm - 1 - 2010Document315 paginiNYS DOT Steel Construction Manual 3rd Edition - SCM - 3rd - Addm - 1 - 2010ullwnÎncă nu există evaluări

- Tutorial Menggunakan MathcadDocument15 paginiTutorial Menggunakan MathcadKOMPATRIOTÎncă nu există evaluări

- Karnataka Lift Rule 1976Document32 paginiKarnataka Lift Rule 1976api-3856475Încă nu există evaluări

- Cummins Isl CNGDocument25 paginiCummins Isl CNGSurasan Thepsiri100% (1)

- Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Act Act Act Act Act Act Act Act Act Act Act Act KPI - Operation PerspectiveDocument2 paginiJan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Act Act Act Act Act Act Act Act Act Act Act Act KPI - Operation PerspectiveSurasan ThepsiriÎncă nu există evaluări

- Inv10 Top10 UsDocument2 paginiInv10 Top10 UsSurasan ThepsiriÎncă nu există evaluări

- Teague's ShaftDocument151 paginiTeague's ShaftSurasan ThepsiriÎncă nu există evaluări

- Report Group CDocument17 paginiReport Group CSurasan ThepsiriÎncă nu există evaluări

- 07 Marine Diesel EnginesDocument26 pagini07 Marine Diesel EnginesSurasan ThepsiriÎncă nu există evaluări

- Lubrication Specification For Volvo L 60 eDocument1 paginăLubrication Specification For Volvo L 60 eSurasan ThepsiriÎncă nu există evaluări

- 03 Design ImpactsDocument29 pagini03 Design ImpactsSurasan ThepsiriÎncă nu există evaluări

- Smc7904wbra n2 Install v3Document1 paginăSmc7904wbra n2 Install v3Surasan ThepsiriÎncă nu există evaluări

- Air PollutionDocument121 paginiAir PollutionMatias MancillaÎncă nu există evaluări

- Alignment TrainingDocument41 paginiAlignment TrainingSurasan ThepsiriÎncă nu există evaluări

- Tutorial Menggunakan MathcadDocument15 paginiTutorial Menggunakan MathcadKOMPATRIOTÎncă nu există evaluări

- อบรมเรื่องไขควง฿สกัดDocument40 paginiอบรมเรื่องไขควง฿สกัดSurasan ThepsiriÎncă nu există evaluări

- Firesafety High BLDGDocument3 paginiFiresafety High BLDGmourinho22Încă nu există evaluări

- Created With Novapdf Printer - Please Register To Remove This MessageDocument1 paginăCreated With Novapdf Printer - Please Register To Remove This MessageSurasan ThepsiriÎncă nu există evaluări

- Crane Research StudyDocument235 paginiCrane Research Studyfairus88% (8)

- P831-101-00-R1 (Tug Boat)Document1 paginăP831-101-00-R1 (Tug Boat)Surasan ThepsiriÎncă nu există evaluări

- Crane Tiger ManualDocument26 paginiCrane Tiger ManualSurasan ThepsiriÎncă nu există evaluări

- Manually Configure Devices by Using Device Manager: Windows XPDocument4 paginiManually Configure Devices by Using Device Manager: Windows XPlucky_4u15Încă nu există evaluări

- What Are The Classes of Amplifiers? Basic Concepts On Class A, B & C AmplifiersDocument4 paginiWhat Are The Classes of Amplifiers? Basic Concepts On Class A, B & C AmplifiersLello FloÎncă nu există evaluări

- Learn To Develop World Class Maintenance Management Systems - UdemyDocument13 paginiLearn To Develop World Class Maintenance Management Systems - UdemySantosh NathanÎncă nu există evaluări

- Tourism Destination Marketing Using Facebook As A Promotional ToolDocument4 paginiTourism Destination Marketing Using Facebook As A Promotional ToolPrasanth KumarÎncă nu există evaluări

- Ds04108bf Data Sheet (Nm4-108b)Document2 paginiDs04108bf Data Sheet (Nm4-108b)johnnygabrielÎncă nu există evaluări

- FMEA - Review - List - 916 PBDocument5 paginiFMEA - Review - List - 916 PBajeyan879Încă nu există evaluări

- Man Monitoring Diagnose System MmdsDocument10 paginiMan Monitoring Diagnose System Mmdsmartin100% (26)

- Constant Envelope Modulation TechniquesDocument21 paginiConstant Envelope Modulation TechniquesRizwan Shaik Peerla67% (3)

- bbs145 PDFDocument2 paginibbs145 PDFnageshwariÎncă nu există evaluări

- Capturing Deleted Records of Source in WarehouseCapturing Deleted Records of Source in WarehouseDocument2 paginiCapturing Deleted Records of Source in WarehouseCapturing Deleted Records of Source in WarehouseAsad HussainÎncă nu există evaluări

- IBM SkillsBuild Intern OfferDocument2 paginiIBM SkillsBuild Intern OfferMuhammed AkramÎncă nu există evaluări

- Python Modes and OperatorsDocument27 paginiPython Modes and OperatorsTejas BhagitÎncă nu există evaluări

- Catalog PDFDocument448 paginiCatalog PDFykuscuÎncă nu există evaluări

- 9700 RMC MGRDocument30 pagini9700 RMC MGRPravin Kamble100% (1)

- UI Field Level Security - v1 0 - ScopeDocument11 paginiUI Field Level Security - v1 0 - Scopefaraz_ec10Încă nu există evaluări

- Networking Devices ExplainedDocument33 paginiNetworking Devices ExplainedYlliw Escobanes100% (1)

- 0206 M Dars BrochureDocument2 pagini0206 M Dars BrochureAlexanderPetrovÎncă nu există evaluări

- Simulation and Implementation of A BPSK Modulator On FPGADocument14 paginiSimulation and Implementation of A BPSK Modulator On FPGAAnonymous 01LLHnZTSÎncă nu există evaluări

- Business Incubation in IndiaDocument15 paginiBusiness Incubation in IndiaraveendramanipalÎncă nu există evaluări

- 3 NetworkSecurity LABManualDocument33 pagini3 NetworkSecurity LABManualdahiyalkÎncă nu există evaluări

- Global Engineering Consultancy ProfileDocument6 paginiGlobal Engineering Consultancy ProfileOladunni AfolabiÎncă nu există evaluări

- Running Head: The Evolution of The Iphone 1Document8 paginiRunning Head: The Evolution of The Iphone 1Cierra BoldenÎncă nu există evaluări

- Myths and Legends in High-Performance ComputingDocument12 paginiMyths and Legends in High-Performance ComputingisnullÎncă nu există evaluări

- Gilgen Door Systems Tuersysteme Schiebetuer Fluchtweg Datenblatt P 08.01.02 Mehrpunktverriegelung en PDFDocument2 paginiGilgen Door Systems Tuersysteme Schiebetuer Fluchtweg Datenblatt P 08.01.02 Mehrpunktverriegelung en PDFDANIELÎncă nu există evaluări

- Barudan TESDocument42 paginiBarudan TESMartinandKimberly RayÎncă nu există evaluări

- Review of Terahertz Antennas and ChallengesDocument42 paginiReview of Terahertz Antennas and ChallengesKewin KusterÎncă nu există evaluări

- Manager Director CTO Telecommunications in Denver CO Resume Bruce RotvoldDocument4 paginiManager Director CTO Telecommunications in Denver CO Resume Bruce RotvoldBruceRotvoldÎncă nu există evaluări

- Pi Audit and TechnologyDocument22 paginiPi Audit and TechnologyHBL AFGHANISTANÎncă nu există evaluări

- As 2067-1984 Switchgear Assemblies and Ancillary EquipmentDocument56 paginiAs 2067-1984 Switchgear Assemblies and Ancillary EquipmentAnonymous EVFw59Încă nu există evaluări

- Beyerdynamic Accessories 1Document6 paginiBeyerdynamic Accessories 1Mario HdezÎncă nu există evaluări