Documente Academic

Documente Profesional

Documente Cultură

PINO DISCO Influence Ofcrosslinkedpolyethylenestructureonwearofjointreplacements

Încărcat de

José santanaDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

PINO DISCO Influence Ofcrosslinkedpolyethylenestructureonwearofjointreplacements

Încărcat de

José santanaDrepturi de autor:

Formate disponibile

Inuence of crosslinked polyethylene structure on wear of joint replacements

Alastair Kilgour

, Alistair Elck

Institute for Materials and Processes, The University of Edinburgh, Edinburgh EH9 3JL, UK

a r t i c l e i n f o

Article history:

Received 21 July 2008

Received in revised form

21 November 2008

Accepted 28 November 2008

Keywords:

Polymer

Wear

Scanning electron

a b s t r a c t

Crosslinking is known to increase the wear resistance of ultra-high molecular weight polyethylene

(UHMWPE) used as an acetabular cup in total hip replacement. The same wear benet is not afforded

when UHMWPE is used as a tibial component. A programmable multi-directional motion and dynamic

load tribometer has been used to investigate ultra-structural development in both unirradiated (PE)

and highly crosslinked (100kGy) UHMWPE (+PE). To investigate surface anisotropy in UHMWPE, both

linear-reciprocating and elliptical wear paths were applied. Following three million elliptical cycles,

crosslinking reduced wear by up to 92%. Under reciprocating motion, mean steady state wear of PE

and +PE groups was not signicantly different (p 0.652). Raman spectra indicated a de-crystallisation

zone on the near surface of PE and +PE reciprocating pins. This was attributed to large strain

development in conjunction with slow lamellar removal and renewal of new surface material in the

lower wearing specimens. SEM images of fragmented lamellae supported this observation.

& 2008 Elsevier Ltd. All rights reserved.

1. Introduction

The perceived role of pin-on-plate wear testers in orthopaedic

research has been to rank material combinations in terms of their

efcacy as bearing couples [16]. Materials which show good

performance (low friction, low wear, good abrasive resistance), in

these preliminary investigations will then be studied further on

full joint simulators. Simulators closely approximate the physio-

logical conditions found in the natural joint. For the majority of

cases, the bearing material combination in use for total hip

replacement (THR) has changed little conceptually since its

introduction in the early 1960s [7]; a hard wearing metallic/

ceramic ball component articulates against a low wear polymer

socket. The polymer in question is ultra-high molecular weight

polyethylene (UHMWPE) which forms an extremely effective

bearing component. The discovery that UHMWPE micron and

sub-micron particles can induce a pathogenic response in

periprosthetic tissue [810], causing late-stage failure after some

1015 years has stimulated work into understanding the origins of

wear. The failure mode is not wearing-out of the acetabular

component but rather wear-mediated osteolysis causing loss of

bony support around the implant [9]. Pain due to micro-motion

and joint instability results in joint revision surgery [11]. Revision

surgery can be technically challenging and the operational lifetime

of revised components often being shorter than the primary

implant. The increasing number of young, active patients receiving

THR places greater tribological demands on these bearings.

For applications in orthopaedics, crosslinking of UHMWPE

through either gamma irradiation or electron beam radiation in an

inert environment, has been shown to reduce wear in pin-on-plate

tests [1214], hip simulator studies [15], and preliminary short-

term radiograph follow-up studies [16,17]. Irradiation doses used

commercially range from 50 to 105kGy. Exposing UHMWPE to

radiation is not a recent development. As early as 1968, UHMWPE

acetabular components were traditionally sterilised using a

comparatively low 25kGy dose of gamma irradiation in air.

Dumbleton and Shen report early attempts to increase the wear

resistance of UHMWPE by exposing the material to elevated doses

of gamma irradiation (levels well beyond those for sterilisation) to

induce pronounced chain scission, free radical formation and

subsequent crosslinking [18,19]. Wear tests were conducted on a

simple ring-on-disc machine. However, in comparison to uni-

rradiated material, an increase in coefcient of friction and wear

rate was associated with the highly irradiated specimens. Findings

were attributed to newly created crosslinks preventing the

formation of a stable transfer-lm on the metal counterface. These

wear tests were, however, conducted in the absence of lubrication.

It has since been established from pin-on-plate work that wear

tests conducted in the presence of serum have been found to

consistently produce worn surfaces more representative of those

from explanted components [3]. Furthermore, contemporary wear

tests in dilute bovine calf serum have consistently shown cross-

linked material to offer greater wear resistance.

Recent hypotheses for the apparent increase in wear resistance

of polyethylene after crosslinking are based on theories of

retardation in the re-orientation of crystalline lamellar in response

to friction forces. Tie-molecules within the inter-crystalline

ARTICLE IN PRESS

Contents lists available at ScienceDirect

journal homepage: www.elsevier.com/locate/triboint

Tribology International

0301-679X/$ - see front matter & 2008 Elsevier Ltd. All rights reserved.

doi:10.1016/j.triboint.2008.11.011

Corresponding author.

E-mail address: Alastair.Kilgour@googlemail.com (A. Kilgour).

Tribology International ] (]]]]) ]]]]]]

Please cite this article as: Kilgour A, Elck A. Inuence of crosslinked polyethylene structure on wear of joint replacements. Tribol Int

(2009), doi:10.1016/j.triboint.2008.11.011

amorphous domains give an increased resistance to reorientation

[12,20]. Wear of an UHMWPE acetabular cup occurs mostly on the

surface, a result of micro-adhesion and abrasive wear mechanisms

[21]. Under repeated cyclic loading and frictional stresses at the

articulating surface, an anisotropic and orientated layer develops

in response to strain accumulation [22]. The discovery of

microstructural alignment in response to quasi-linear motion of

early wear screening devices [23] and the consequent strain

hardening [24] offered an explanation for the divergent wear rates

produced in early pin-on-plate studies when compared to

considerable in vivo wear rates [25]. Microstructural orientation

in one axis is thought to precipitate accelerated wear from a

perpendicular motion; the cross-shear direction [24,26]. The

complex, cross-shearing motion paths found in the hip joint are

a result of abduction/adduction and internal/external rotation

about the exion/extension path. Debris produced in response to

multi-directional motion on a strain hardened surface is released

through fracture [22] and rupture [26] of material drawn out of

the surface as particles are incrementally enlarged and released

[27]. As a result of crosslinking, the addition of increased

carboncarbon covalent bonds between the amorphous molecules

is thought to retard chain movement and produce a worn surface

more resistant to bular pull-out [15,28]. Frictional strain has also

been proposed to produce a near-surface plasticity zone [20]. This

sub-surface zone, a precursor to wear, has been shown to occur on

crosslinked specimens albeit to a smaller depth beneath the

surface. This suggests the transfer of strain through inter-lamellae

communication is more conned in crosslinked material. How-

ever, multi-axial loading tests revealed more pronounced orienta-

tion in highly crosslinked polyethylenes over their conventional

counterparts, especially in higher molecular weight samples,

adding to uncertainty as to the role of tie-molecules and

interlamellar communication [29]. It has been reported that

crosslinking does not prevent microstructural mobility [30], but

the contribution of such a polymer network to the wear resistance

under cyclic loading and shear stresses is still not clear.

To date there have been few pin-on-plate studies on ortho-

paedic grade crosslinked UHMWPE [1214,31,32], and fewer still

on microstructural characterisation [32]. Zhou et al. reported on

microstructural disparity between unmodied and 100kGy

gamma irradiated UHMWPE [32]. Wear tests were conducted on

a reciprocating pin-on-disc machine, the polymer pin loaded in a

constant manner onto a reciprocating cobalt chrome disc. Under

average nominal contact pressures between 20 and 30MPa they

attributed a fourfold increase in wear resistance of the crosslinked

material to greater resistance to plastic ow. Tests conducted on

motion machines with limited cross-shear angles, more repre-

sentative of knee motion have reported marginal differences in

wear rates as function of radiation dose [30]. Further studies on

this material have been conducted on machines, which produce

limited translation and rotation [14,31]; polymer test pins are

loaded under constant force onto a reciprocating test plate, or

counter-bearing. In such cases the pin rotates via drive gears to

operate in synchronisation with the oscillating plate. The nature

of the rotating pin inherently creates non-uniform tribological

conditions across the wear surface. Each point on an increasing

radius from the pin centre will experience a different wear path,

creating a complex worn surface. This tribological setup is more

suitable for wear ranking bearing couples under constant load and

sinusoidal velocity, than used to probe microstructural evolution.

A well designed pin-on-plate tribometer has the potential to offer

in-sight into fundamental wear mechanisms under controlled

conditions.

Advances in pin-on-plate design have led to a number of

contemporary desktop machines capable of producing conven-

tional UHMWPE wear data in what is considered the clinical

range, assessed through linear penetration rates and wear factor

comparisons [31,33,34]. Our hypothesis was to use a custom built,

novel, pin-on-plate wear machine capable of programmable

dynamic load and motion to compare wear, topography, and

morphology in PE and +PE materials. This novel multi-

directional pin-on-plate tribometer was used to investigate

whether crosslinks aid plasticity mechanisms by improving

interlamellar communication, aiding reorientation whilst resist-

ing chain fracture. Or, alternatively, whether cross-links anchor

the resultant microstructure, alleviating alignment in the pre-

ferential sliding direction reducing susceptibility to wear as a

result of cross-shear.

2. Materials and methods

2.1. Materials

Two groups of materials were supplied by Smith and Nephew

Inc. The virgin material and control group were ram extruded

GUR1050 bar stock. The second group underwent a subsequent

gamma irradiation dose of 100kGy at room temperature. A post-

irradiation above melt stabilisation process at 1501C quenched

remaining residual free radicals from the bulk. The rod stock was

nally machined into pins of 5mm diameter and parted-off in

20mm lengths. Elevated crosslink density levels were characterised

through swelling experiments according to the ASTM standard for

the determination of swell ratio [35]. The swelling ratio, described

as the volume of a swollen polymer network divided by the volume

of the original unswollen network [36] indicates the maximum

amount of liquid that such a network can hold. The ability to

dissolve or absorb the solvent and swell is dependant on the

crosslink density, the structural integrity under equilibrium swel-

ling conditions and the afnity (interaction parameter) between

the polymer and the swelling solvent. It is difcult to physically

measure the volume of the swollen network. Instead, masses were

recorded and converted to volume using a predened ratio relating

the density of polymer to that of the solvent at the equilibrium

swelling temperature. Swelling was performed on three specimens

from each group. Crosslink density was then calculated according

to the method of Flory and Rehner [37].

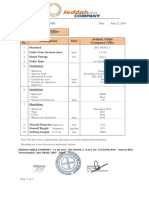

2.2. Wear tests

In accordance with ASTM F732 [38], a six-station wear-tester

(Fig. 1) was designed and built capable of programmable dynamic

loading and motion proles [39]. The ASTM standard denotes the

clinical relevance of wear methods implemented in conjunction

with machines designed to evaluate simplied specimen geome-

tries, offering guidelines for the type of motion, pin and plate

conditions and appropriate test protocols.

The machine is a biaxial device with two degrees of freedom.

Two programmable stepper controlled linear slides provide the

necessary mechanics, allowing the carriage to translate along the

x and, y axes and interpolate between the two. Test pins are

loaded independently in the z-axis by six electric coil actuators.

The arrangement is such that the actuators are free to follow and

consistently load the polymer test pins as wear occurs. Test pins

did not rotate relative to the plate, ensuring a uniform wear path

across the complete pin contact area. The six test plates were xed

in individual lubricant chambers, four on the motion carriage to

provide constrained motion in the xy plane (Fig. 2) and two

stationary loaded soak controls.

A schematic showing key components and a single station are

shown in Fig. 3. Four polymer test pins from each material group

were subjected to linear reciprocating and multi-directional

ARTICLE IN PRESS

A. Kilgour, A. Elck / Tribology International ] (]]]]) ]]]]]] 2

Please cite this article as: Kilgour A, Elck A. Inuence of crosslinked polyethylene structure on wear of joint replacements. Tribol Int

(2009), doi:10.1016/j.triboint.2008.11.011

elliptical motion, articulating against medical grade cobalt

chrome alloy plates, polished (Buehler, Alpha) to an average

femoral implant nish [40] of 0.01mm Ra (Zygo, NV100). Wear

paths were chosen to approximate the length of those found from

gait analysis [4143]. Linear reciprocating (stroke length 25mm)

and elliptical (20mm major and 10mm minor axes, respectively)

wear paths were applied (Table 1). The elliptical path was applied

to better approximate the more open quasi-elliptical wear paths

observed in vivo. A low 2:1 aspect ratio (AR) of the ellipse was

used to provide this open wear path.

Lower aspect ratios have been found to restrict lamellae

alignment [44] and at these ratios, discrepancies in the orienta-

tion softening model [26] suggest some of the underlying

assumptions maybe overly simplied [27,34]. A double peak

dynamic load prole [45,46] with peaks 1 and 2 of 94.5 and 48.3N

(corresponding to nominal contact stresses of 4.7 and 2.4MPa

during the stance phase) was synchronised to each motion cycle,

the heel-strike occurring at the point of maximum exion, as

shown in Fig. 4. The swing phase was programmed to account for

50% of each cycle. Load was not recorded continuously but

instead, data collected at the beginning and end of each test

period throughout the duration of the wear test. Wear was

assessed through gravimetric analysis every 250,000 cycles using

a Mettler balance with a resolution of 70.001mg. Each pin was

cleaned and dried in a method described in ASTM F732.

Subsequently, pins were weighed in order, each four times, giving

a resultant repeatability of 70.05mg. All tests were run in

newborn calf serum (Harlan Sera lab) diluted 1:1.5 with Ringers

solution to a physiological protein concentration of 22g/l (10ml of

serum:15ml of Ringers solution per chamber). To inhibit bacterial

growth, 0.2wt% sodium azide was added. All pin-on-plate stations

were lubricated independently. The serum was kept at 37721C

through PID control.

ARTICLE IN PRESS

Fig. 1. The six-station wear test device; shown with the dust cover lid open

exposing the four load and motion stations and two load only stations.

Fig. 2. Detailed view of the four load and motion stations. Each chamber is

supported by four columns providing future capacity to mount strain gauges or

install a 3-axis load cell beneath each chamber for friction and continuous load

measurement. Heating resistors, mounted on the underside of each stainless steel

base provide necessary energy to heat chamber lubricant.

Fig. 3. Simplied schematic of the design with one station shown: (1) electric coil actuator; (2) loading arm; (3) pivot housing; (4) test pin holder; (5) acrylic chamber wall;

(6) axis 1; (7) axis 0; (8) stainless steel collar; (9) CoCrMo test plate; (10) o-ring seal; (11) Tufnol base; and (12) stainless steel base.

Table 1

Test parameters.

Material GUR 10500kGy GUR 1050100kGy

Test Linear Elliptical Linear Elliptical

Duration (km) 150 150 150 150

Cycles (10

6

) 3 3 3 3

Stroke length (mm) 25.00 25.00

Cycle circumference (mm) 49.67 49.67

Av sliding speed (mms

1

) 50.65 50.17 50.65 50.17

A. Kilgour, A. Elck / Tribology International ] (]]]]) ]]]]]] 3

Please cite this article as: Kilgour A, Elck A. Inuence of crosslinked polyethylene structure on wear of joint replacements. Tribol Int

(2009), doi:10.1016/j.triboint.2008.11.011

2.3. Vibrational spectroscopy

Raman spectroscopy was used to assess near-surface crystal-

linity before and after each wear test. This non-invasive, non-

destructive analysis technique has previously been used to

calculate polyethylene crystallinity [4749] and UHMWPE acet-

abular cup crystallinity [5053]. Crystallinity is often used to

summarise the morphological constituents that form the bulk

material. Changes in the ratio of crystalline to amorphous

domains can signify changes in mechanical behaviour [54] hence,

wear resistance of the polymer [20]. The internal Raman

vibrational band structure of polyethylene is well studied

[47,49]. The 1416cm

1

band is associated with CH

2

bending in

the orthorhombic crystal phase and the 1296cm

1

and broader

second peak around 1303cm

1

is associated with amorphous CH

2

twisting phase. According to Strobl [49] polyethylene crystallinity

can be calculated from the ratio

%Crystallinity I

1414

=I

1293

I

1305

0:46

A Renishaw InVia system was used to measure Raman spectra at

room temperature. Excitation of Raman bands was achieved by a

785nm laser ca 30mW, focused through a 50 objective. Spectra

were gathered in confocal mode to minimise scattering volume.

The depth resolution of the system was calculated at less than

10mm. Depth proling was performed by focusing the laser beam

at increasing depth beneath the surface. Ten scans were taken at

each depth. Scattering volume (V) was approximated as a cylinder

of length (l)10mm, with a cross-section equal to the focused

laser spot (d) 1mm,

V p d

2

=4 10 7:85mm

3

On each pin and at each scanning depth (surface, sub 12.5, 25 and

37.5mm), 10 spectra were recorded. Therefore, the volume of

material fromeach pin contributing to the crystallinity calculation

per depth was 78mm

3

. Hence, the average scattering volume

from four worn pins was 314mm

3

per depth. UHMWPE lamellae

are typically on the order of 50nm 1mm, depth and length,

respectively. The ten scans performed will therefore, include a

substantial population of crystals in an effort to statistically

represent the bulk material.

2.4. Scanning electron microscopy

Field emission scanning electron microscopy (Hitachi S-5000)

was used to qualitatively evaluate the extent of wear-induced

lamellar re-orientation and topographical wear features following

the completion of three million wear cycles. Oxidising acids

have historically been used to etch chemically resistant semi-

crystalline polymers to reveal microstructural detail [55]. The acid

preferentially diffuses into and attacks the disordered less tightly

packed amorphous domains [56], leaving the crystalline tightly

packed chains within the lamellae proud of the surface. A less

oxidizing acid, permanganic etchant has been shown to reveal

lamellar structures with more detail [57,58]. This technique has

previously been applied to orthopaedic UHMWPE to assess the

friction oriented response of lamellae after simple pin-on-plate

wear studies [32,59] and in hip simulator studies [20]. Worn pins

were sectioned in half to permit separate imaging of topography

and microstructure, Fig. 5.

3. Results

3.1. Swelling

Swelling experiments clearly differentiated PE from +PE as

shown in Fig. 6. Unirradiated material (PE) was found to swell

over 10 times more than crosslinked. This was attributed to

elevated crosslink levels reducing the number of possible chain

conformations limiting the swell-ability, and the improved

structural integrity making the network less prone to chain

stretch and solvent absorption. From FloryRehner network

swelling model, the average molecular weight between crosslinks

was 238,080 and 5663g/mol for PE and +PE, respectively.

3.2. Wear tests

Unirradiated and crosslinked wear volume with respect to

linear reciprocating sliding distance is shown in Fig. 7. Both

groups exhibit similar wear rates, with two exceptions. The

irregular accelerated wear rates of conventional pins at (i) and (ii)

ARTICLE IN PRESS

100

80

60

40

20

0

L

o

a

d

(

N

)

L

o

a

d

(

N

)

F

l

e

x

i

o

n

/

E

x

t

e

n

s

i

o

n

(

m

m

)

F

l

e

x

i

o

n

/

E

x

t

e

n

s

i

o

n

(

m

m

)

A

d

d

u

c

t

i

o

n

/

A

b

d

u

c

t

i

o

n

(

m

m

)

A

d

d

u

c

t

i

o

n

/

A

b

d

u

c

t

i

o

n

(

m

m

) -2

0

2

4

6

8

10

12

14

16

18

20

22

24

26

100

80

60

40

20

0

12

10

8

6

4

2

0

-2

-4

-6

-8

-10

-12

12

8

6

4

2

0

-2

-4

-8

-10

-12

Fig. 4. Synchronised load and motion proles for (a) linear reciprocating wear and (b) elliptical wear.

A. Kilgour, A. Elck / Tribology International ] (]]]]) ]]]]]] 4

Please cite this article as: Kilgour A, Elck A. Inuence of crosslinked polyethylene structure on wear of joint replacements. Tribol Int

(2009), doi:10.1016/j.triboint.2008.11.011

are a result of low lubricant levels during those periods. Never-

theless, the difference in mean steady-state wear between PE

and +PE under reciprocating motion was not signicant (Student

T-Test p 0.652), Fig. 8.

Fig. 9 shows the volume of PE and +PE material removed with

respect to sliding distance under multi-directional motion. The

elliptical wear path produced signicantly higher mean wear rates

in unirradiated pins (Welshs T-Test po0.05); 100kGy irradiation

was shown to reduce wear at the completion of three million

elliptical cycles by 92%.

Because all groups exhibited an approximately linear relation-

ship with sliding distance, a steady-state wear coefcient; a

measure of wear volume produced with respect to normal load

and total sliding distance was calculated according to Archard

[60]. The coefcient, originally developed for metal-on-metal dry

sliding and modelled on adhesive wear is not without burden

when applied to soft-on-hard rubbing in the presence of proteins.

However, it is often adopted as a way of communicating the

probability that UHMWPE debris will be released from the

articulating surface. In these calculations we applied the average

force per cycle, 42.872.8N (S.D.), calculated from integrating

under the load prole. The steady-state wear factors for both

material groups subjected to reciprocating motion were two orders

of magnitude lower than wear data calculated from retrieved or

radiographic studies of conventional UHMWPE (Table 2). Under

ARTICLE IN PRESS

35

30

25

20

15

10

5

0

-PE +PE

S

w

e

l

l

i

n

g

r

a

t

i

o

Fig. 6. Effect of radiation dose on swelling ratio.

Worn surface

Worn surface

Worn surface

Etch to reveal extent of near-surface

lamellae alignment

SEM for topographic information

(ripples, folds, cracks, debris)

Fig. 5. Worn pin surfaces were sectioned longitudinally to permit topography and morphology studies.

2.5

2

1.5

1

0.5

0

0 20 40 60 80 100 120 140 160

sliding distance (km)

W

e

a

r

v

o

l

u

m

e

(

m

m

3

)

(i)

(ii)

(1, 2)

Fig. 7. Wear graphs under linear reciprocating motion of: (1) PE pins, note at (I)

chamber 1 ran dry and (II) chamber 4 lubricant level ran low, both causing

elevated wear rates and (2) +PE pins.

4.00

3.50

3.00

2.50

2.00

1.50

1.00

0.50

0.00

-PE linear +PE linear +PE elliptical -PE elliptical

w

e

a

r

r

a

t

e

(

m

g

/

m

i

l

l

i

o

n

)

Fig. 8. Comparison of the average wear rates of unirradiated and irradiated

material under both linear reciprocating and elliptical sliding.

A. Kilgour, A. Elck / Tribology International ] (]]]]) ]]]]]] 5

Please cite this article as: Kilgour A, Elck A. Inuence of crosslinked polyethylene structure on wear of joint replacements. Tribol Int

(2009), doi:10.1016/j.triboint.2008.11.011

elliptical motion, the wear coefcient and linear penetration rates

for the unirradiated group were in good agreement with clinical

data, supporting the importance of open wear paths in pin-on-

plate studies. The elliptical +PE wear factor was an order of

magnitude lower than that of the unirradiated group subjected to

the same motion, and an order of magnitude higher than either

group under reciprocating wear.

3.3. Raman spectroscopy

Fig. 10 plots the changes in crystallinity of unirradiated

UHMWPE with respect to depth of Raman scattering. The group

subjected to elliptical motion showed no statistically signicant

change in surface and sub-surface crystallinity when compared to

the unworn control, Fig. 10a and b, respectively. The mean load-

soak crystallinity was consistently around 50%, Fig. 10b. A drop in

crystallinity caused by linear reciprocating motion was apparent.

The average surface crystallinity of 49.8% is 5% lower than either

the unworn control or those surfaces worn in a multi-directional

manner. Lower crystallinity in this group was consistently found

up to the maximum depth recorded of sub-37.5mm, Fig. 10d.

+PE control crystallinity was 53.6171.80% within the rst

37.5mm of material, Fig. 11a. A gradual increase in +PE crystallinity

was observed for groups; Fig. 11bd as the scattering volume

moved deeper beneath the surface. Under elliptical motion, a

mean surface crystallinity of 51.1171.59 was similar to that of the

unworn control surface, 53.1671.92% (ANOVA p 0.112). +PE pins

followed a similar trend to that of the unirradiated material;

linear motion resulted in the largest reduction in surface crystal-

linity, 47.7874.371%. This was statistically lower than the +PE

control surface crystallinity (ANOVA po0.05). Lower crystallinity

values were consistently found in all crosslinked groups.

3.4. Scanning electron microscopy

3.4.1. Unirradiated

Parallel ripples were imaged on the surface of the more rapidly

wearing unirradiated pins under elliptical motion, Fig. 12a.

Tearing, folding and cracking were all imaged at higher magni-

cation, Fig. 12b. Linear reciprocating produced light scratches,

the edges of which were folded, plastically deformed producing

brils running perpendicular to the motion path. Areas of PE

were re-organised into domains running parallel to the surface in

the direction of wear, Fig. 12c. In areas where this formation was

highly developed, elongated brils were observed extending from

the surface, Fig. 12d.

Following etching, distinct microstructural developments

were imaged in response to wear path. Worn surfaces subjected

to multi-directional motion exhibited random lamellar orienta-

tion and similar lamellar size and breadth to that of the unworn

control surface (Fig. 13a and b), the white arrow indicates the

primary elliptical wear axis. Higher magnication conrmed

similarities between the two groups, Fig. 13d and e. Alignment

and lamellar break-up mechanisms were less obvious on the worn

elliptical surfaces. Evidence of texture development was more

prominent under linear reciprocating motion. Large domains

of lamellae were imaged orientated in the direction of wear

(Fig. 13c). At higher magnication, evidence of lamellar break-up

and fragmentation (Fig. 13f) was revealed. This was substantiated

with Raman data which conrmed lower crystallinity in the linear

reciprocating group.

ARTICLE IN PRESS

14

12

10

8

6

4

2

0

0 20 40 60 80 100 120 140 160

(2)

(i)

(1)

W

e

a

r

v

o

l

u

m

e

(

m

m

3

)

Sliding distance (km)

Fig. 9. Wear graphs under elliptical motion of: (1) PE pins, note at (i) chamber 3

lubricant level ran low causing an increase in wear rate and (2) +PE pins.

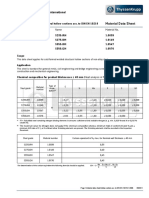

Table 2

Comparison of wear factors and linear penetration rates.

Material Wear path Wear factor

( 10

6

mm

3

/Nm)

Penetration

(mm/yr)

PE Reciprocating 0.03 0.003

+PE Reciprocating 0.04 0.0026

PE Elliptical 1.6 0.18

+PE Elliptical 0.13 0.01

Conventional Clinical [56] 2 0.15

Fig. 10. PE crystallinity for (a) three million elliptical cycles; (b) control surface;

(c) three million load only cycles; and (d) three million linear reciprocating cycles.

Fig. 11. Highly crosslinked UHMWPE crystallinity for: (a) unworn control (b) three

million elliptical cycles; (c) three million load only cycles; and (d) three million

linear reciprocating cycles.

A. Kilgour, A. Elck / Tribology International ] (]]]]) ]]]]]] 6

Please cite this article as: Kilgour A, Elck A. Inuence of crosslinked polyethylene structure on wear of joint replacements. Tribol Int

(2009), doi:10.1016/j.triboint.2008.11.011

3.4.2. Irradiated

The micrographs of +PE surfaces worn under elliptical motion

were highly smooth, indicated by the lack of contrast picked on

the FE-SEM. Sub-micron debris was also imaged on the surface,

Fig. 14a. In other areas a granular texture was observed; the beads

appeared on the order of 500nm in width, Fig. 14b. This texture

was found highly developed in some regions. Beads were drawn

out into folded elongated strands running across the primary

elliptical wear axis, Fig. 14c. Finally, small parallel ripples were

consistently imaged on +PE linear reciprocating surfaces, Fig. 14d.

The wavelengths of these features were approximately 1mm, and

were found transverse to the direction of sliding.

Fig. 15 shows microstructure images of +PE subjected to three

million linear and elliptical cycles in comparison to the unworn

control, Fig. 15a. Both Fig. 15b and c shows a degree of surface

lamellae orientation and mobility in response to the different

motion paths, less so under the elliptical path. Lamellar were imaged

folded, bent and broken in response to friction forces. Fig. 15d shows,

at higher magnication the post-irradiated unworn lamellar size,

shape and distinct lack of preferential alignment. In contrast, the low

wearing surfaces of Fig. 15e and f (linear and elliptical wear,

respectively) showed increasing signs of lamellar break-up and

micro-domains of stack rotation and close packing. The distinction

between linear and elliptical motion on microstructural develop-

ment was found to be less clear in crosslinked material.

4. Discussion

To date, few studies have attempted to link microstructural

evolution and wear rate of unirradiated and irradiated orthopae-

dic polyethylene. Such information could improve understanding

of the role of crosslinking on wear reduction and debris size and

shape. The wear performance of both highly crosslinked and

conventional polyethylene is intimately related to the sliding

conditions. The experimental results presented herein conrm the

notion that crosslinking reduces volumetric wear in UHMWPE,

when sliding takes the form of open motion tracks possessing a

cross-shearing action. Linear-reciprocating motion, dened as

having zero cross-shear [26], did not exhibit a statistically

signicant difference in the mean steady-state wear rates

between the two material groups. These results support the

ndings of Wang et al. [30] who previously investigated this

motion dependant behaviour by wear testing UHMWPE exposed

to 0100kGy on both knee and hip simulators. The tibial

components, tested on a knee simulator with limited cross-shear,

were found to wear similarly for all radiation dosages. In contrast,

acetabular components tested on a hip simulator were shown to

have exponentially decreasing wear rate with increasing radiation

dose. In this study, +PE worn under elliptical motion was found to

wear signicantly less than PE, supporting the motion depen-

dant wear response of crosslinked polyethylene.

The use of dynamic loading in pin-on-plate studies has been

adopted by few investigators. Muratoglu et al. used a dynamically

loaded (Paul-type, 445N peak 1, 290N peak 2), bi-directional

(10mm5mm rectangular wear path) tribometer to investigate

wear rate reduction for UHMWPE with a radiation dose of 100kGy

in comparison to unirradiated material. They report wear rates

for unirradiated material as 9.8mg/million cycles reducing to

1.6mg/million cycles for irradiated; an 84% reduction in wear rate

[12]. The wear rate of +PE subjected to elliptical motion in the

ARTICLE IN PRESS

Fig. 12. Scanning electron micrographs of surface topography after three million cycles for: (a) PE elliptical wear showing regular ripples across surface. Mag. 800; (b)

PE elliptical wear with tearing, folding and opening of surface cracks running 451 across primary wear axis, Mag. 8000; (c) PE linear wear showing light scratching

and bril tearing, Mag. 2000; and (d) PE linear wear showing origin of bular debris fromhighly textured surface (see black arrow), Mag. 4000. White arrows indicate

primary wear direction.

A. Kilgour, A. Elck / Tribology International ] (]]]]) ]]]]]] 7

Please cite this article as: Kilgour A, Elck A. Inuence of crosslinked polyethylene structure on wear of joint replacements. Tribol Int

(2009), doi:10.1016/j.triboint.2008.11.011

current study was found to be 0.26mg/million cycles substantially

lower than that of Muratoglu et al. Wear factors were not reported

for the bi-directional tests so a direct comparison between the

tribological conditions, with respect to sliding distance and

nominal load is not possible. However, the sliding distance per

cycle of the ellipse used in this work is 50 mm in comparison to

the total rectangular sliding path length of 30 mm. This equates to

the pins used in this study sliding an additional 20km per million

cycles. From Archards equation, volumetric wear is proportional

to contact force and sliding distance, therefore the increased

ARTICLE IN PRESS

Fig. 13. Scanning electron micrographs after three million cycles for: (a) PE control surface; (b) PE elliptical wearno preferential alignment observed; (c) PE linear

reciprocating weartexture development and alignment; (d) magnied control surface; (e) PE lamellae after three million elliptical cycles; and (f) PEreciprocating

motion produced fragmented lamellae. White arrows indicate axis of primary wear path.

Fig. 14. Scanning electron micrographs of surface topography after three million cycles for: (a) +PE elliptical wear showing micron and sub-micron debris on a highly

smooth worn surface Mag. 2500; (b) +PE elliptical wear with granular texture, Mag. 10000 ; (c) +PE elliptical wear, adhesive drawing out from initial granular texture,

Mag. 10000; and (d) +PE linear wear showing ripple formation perpendicular to sliding direction, Mag. 8000. White arrows indicate primary axis of wear path.

A. Kilgour, A. Elck / Tribology International ] (]]]]) ]]]]]] 8

Please cite this article as: Kilgour A, Elck A. Inuence of crosslinked polyethylene structure on wear of joint replacements. Tribol Int

(2009), doi:10.1016/j.triboint.2008.11.011

sliding distance used in the present study would be expected to

produce higher not lower wear rates per million cycles. In

addition, Muratoglu et al. employed 9mm diameter pins onto

which a heel-strike peak contact stress of 7MPa was applied

equating to a peak force of 445N; higher than the peak force of

94.3N used in the present study. The effect of dynamic loading on

the wear rate is likely to be complex as additional modes of

lubrication may be experienced between different load proles

and over statically loaded instruments. Detailed comparison

between the static and two exemplars of dynamically loaded

pin-on-plate testing is beyond the scope of this discussion.

Recognition of the importance of cross-shear in the wear of

cross-linked UHMWPE resulted in multi-directional pin-on-plate

studies on retrotted linear-reciprocating machines. Often a

statically loaded pin is rotated; either at a constant angular

velocity or oscillated over a given arc, both synchronised with a

reciprocating plate. Such instruments have shown further reduc-

tions in wear rate of crosslinked material, albeit to a lesser extent.

Galvin et al. report a 73% reduction in 100kGy material rubbing

against a smooth counterface in comparison to unirradiated

material [14]. The reduced benet in wear resistance for cross-

linking found by Galvin et al. may result from the variable

tribological conditions experienced at the wear surface. The

rotating pin-on-oscillating plate design results in a continuously

variable wear path along the radius of the face of the pin; each

path possessing different degrees of cross-shear. Those points on

the pin surface nearer the centre will travel in a more linear

fashion, be subjected to limited multi-directionality and trace

paths with higher aspect ratios. High AR wear paths have been

found to cause lower wear rates in conventional UHMWPE [33,34]

which may explain the reduced difference between wear of non-

crosslinked and crosslinked material on this machine. Galvin et al.

report a wear factor of 610

8

mm

3

/Nm for 100kGy material

experiencing 601 of pin rotation against a smooth counterface.

This is an order of magnitude lower than the elliptical wear factor

of 1.310

7

mm

3

/Nm found in this paper. However, they also

report a wear factor of 2.210

7

mm

3

/Nm for their unirradiated

material which is an order of magnitude lower than the value

reported herein and that reported from clinical studies. From this

study, a wear factor of 1.610

6

mm

3

/Nm for unirradiated

polyethylene under elliptical motion is in good agreement with

published clinical wear rates of 2.110

6

mm

3

/Nm [61]. Conven-

tional UHMWPE will typically be sterilised to 30kGy. The modest

level of crosslinking achieved at these radiation doses do not

provide the dramatic wear resistance offered by heavily irradiated

UHMWPE. Our non-crosslinked material would, therefore be

expected to show similar wear behaviour to clinical data, and is in

good agreement with the wear of conventional material (Table 2).

Hip simulator studies have also shown signicant wear savings

in crosslinked material. Mckellop et al. found an 87% reduction in

wear rate of UHMWPE gamma irradiated at 95kGy compared to

cups machined from bulk material irradiated at 33kGy [15]. This

is in good agreement with the 93% decrease in wear rate of +PE

reported in this study for samples subjected to elliptical sliding.

This level of agreement between the advanced pin-on-plate

tribometer described in this study and multi-directional joint

simulators conrms the value of the further developments in

tribometer design during the past decade.

A contemporary pin-on-disc tribometer, designed by Saikko

et al. has been used to investigate the effects of surface roughness

on wear of conventional and highly crosslinked UHMWPE.

Conventional UHMWPE was gamma-sterilised in nitrogen to

2540kGy and the highly crosslinked material, electron beam

irradiated to 95kGy [13]. Wear tests were conducted using a

circulatory translating pin-on-disc device (CTPOD). Wear data

were correlated to counterface surface roughness using a power

regression expression. The wear factor of conventional and

crosslinked material was expressed as k 5.8710

5

(Ra)

0.91

and k 7.8710

5

(Ra)

2.49

, respectively. On polished surfaces

equivalent to surfaces used in the current study (mean Ra

0.01mm), wear factors for conventional material of

k 1.210

6

mm

3

/Nm and for crosslinked, 1.910

9

mm

3

/Nm

can be calculated. The machine reported herein produces a

constantly changing shear vector throughout the elliptical cycle,

uniform across the pin surface. The CTPOD device was one of the

rst desktop machines to exert these tribological conditions in a

pin-on-disc device, doing so through a circular motion at the pin-

plate interface where, the pin remains stationary relative to the

ARTICLE IN PRESS

Fig. 15. Scanning electron micrographs after three million cycles for: (a) +PE control surface; (b) +PE linear weardomains of preferential alignment observed; (c) +PE

elliptical weardomains of alignment observed; (d) +PE control surface; (e) +PE linear weartexture development and lamellar fragmentation; and (f) +PEelliptical

motiondomains of fragmented lamellae. White arrows indicate axis of primary wear path.

A. Kilgour, A. Elck / Tribology International ] (]]]]) ]]]]]] 9

Please cite this article as: Kilgour A, Elck A. Inuence of crosslinked polyethylene structure on wear of joint replacements. Tribol Int

(2009), doi:10.1016/j.triboint.2008.11.011

plate. Therefore, both contemporary machines account for

the strain hardening behaviour of UHMWPE, producing multi-

directional friction forces on the polyethylene pin surface.

However, the crosslinked wear factor from Saikkos study is three

orders of magnitude lower than that for their conventional

material and two orders of magnitude lower than the crosslinked

wear factor reported in this study; 1.910

9

mm

3

/Nm vs.

1.310

7

mm

3

/Nm. This difference may be accounted for by

the weaker roughness and wear factor correlation found for

crosslinked material, particularly with a surface nish below a

value of around Ra 0.03mm. Under this surface roughness they

report a wear factor similar in magnitude to our study. They

further found a mean wear debris size generated from crosslinked

material articulating on smooth counterfaces smaller than those

particles generated from conventional material, 0.170.04 and

0.2170.09mm, respectively. At surfaces articially roughened to

approximate damaged femoral components, the mean difference

in particle size was not signicant; both materials produced mean

particle sizes approaching 0.38mm. The roughened surfaces, with

scratches in no preferential direction, may promote an abrasive

wear regime, which would dominate over an otherwise adhesive/

fatigue regime, shown by higher polymer wear rates. The effects

of surface roughness on wear were found to be more pronounced

in the crosslinked polyethylene, illustrated by a steeper regression

gradient. This is not surprising if we consider wear behaviour in

light of bulk polymer mechanical properties. The toughness of

crosslinked material has been shown to be less than that of

conventional material; ultimate tensile strength and strain are

degraded in highly crosslinked material [54]. A well known

relationship between polymer bulk mechanical properties and

resistance to abrasive wear is called the RatnerLancaster

relationship [62]. This correlates polymer wear to be inversely

proportional to the toughness of the polymer (the product of the

ultimate stress and strain at tensile break), supporting the greater

dependence of crosslinked material on surface roughness found in

the Saikko study.

Under rougher counter-surface conditions which result in

higher crosslinked wear rates, the polymer surface is worn more

quickly; a culmination of ploughing and fracture producing wear

debris before large plasticity levels and fatigue become the

dominant wear mechanism. However, on polished counterfaces

promoting an adhesive type wear regime, crosslinked material

may accumulate larger levels of plastic strain in the near surface

with respect to conventional material, due to a reduction in

surface turn-over. The reduction can be attributed to additional

cross-linked bonds increasing the cohesive strength of the

material. As a result, larger strain accumulation may increase

the occurrence of deformation mechanisms in the crystalline

domains causing lamellae fragmentation. De-crystallisation may

result in the generation and release of smaller wear particles than

those released from conventional material.

The evolution of microstructural change in the polyethylene is

of great inuence to the wear properties of this material. Edidin

et al. [20] presented transmission electron micrographs taken

from stained virgin and cross-linked acetabular cups after three

million cycles on a hip simulator. Sections taken to map the micro-

structure beneath the surface revealed lamellae re-orientation to a

sub-surface depth of 9 and 4mm for non-crosslinked and cross-

linked material, respectively. This modied sub-surface zone was

labelled the plasticity induced layer. In order to characterise the

depth at which the sub-surface plasticity layer extends, we

conducted depth proling using a confocal Raman microscope.

The Raman results presented here represent the percentage of

crystalline material at the surface and sub-surface after three

million linear and elliptical wear cycles. Unirradiated material,

worn under elliptical motion was shown to retain its original

unworn crystallinity up to the investigated depth of 25mm. This

indicates that deformation mechanisms for PE, in response to

multi-directional motion, may be constrained to the amorphous

domains, leaving the majority of lamellae undamaged (Fig. 13b or

e) and, hence, percentage crystallinity unchanged. In contrast,

under linear reciprocating motion the lower wearing PE was

found to experience de-crystallisation. FE-SEM images yield

evidence of crystalline fragmentation, with the appearance of

smaller crystals on the worn microstructures (Fig. 13c or f). The

accumulation of strain at, and beneath, the surface may result in a

transfer of the deformation mechanism from acting preferentially

within the amorphous domains to occurring, in addition, within

the crystalline lamellae. Although a drop in unirradiated crystal-

linity was found in response to reciprocating motion (in compar-

ison to the unworn control and elliptical motion), we observed

no statistical change in mean crystallinity between the surface

and sub-surface within this group. This suggests that the de-

crystallisation zone extends beyond the maximum sampled depth

of 37.5mm. Had the extent of sub-surface damage been less than

this, an increase in crystallinity with increasing depth should have

been observed as the microstructure returns to its native

conguration being no longer affected by the frictional forces at

the surface.

Edidin et al. suggest that cross-linking may constrain the

ability of the crystalline lamellae to re-orient resulting in a

smaller plasticity induced damage layer and lower wear rates. In

this study crosslinking has been shown to produce noticeable

reductions in wear rate under elliptical motion. Raman spectro-

scopy indicates that in response to sliding, both surface and sub-

surface crystallinity is reduced for +PE specimens. Under elliptical

motion, the nal surface crystallinity was lower than the unworn

control. This was supported by micrographs showing evidence of

areas consisting of fragmented lamellae. Linear motion caused the

largest drop in +PE crystallinity. Crosslinked material worn with

either a linear or elliptical motion exhibits a trend of increasing

crystallinity with depth beneath the surface. This suggests the

extent of surface stresses and strains diminishes as the distance

beneath the surface increases in agreement with contact

mechanics theorems e.g. Hertz. However, neither microstructure

approaches the crystallinity ratio of the unworn crosslinked

control material. This further indicates that the de-crystallised

damage layer may extend further than the maximum depth of

37.5mm explored in this study. The results presented here indicate

that crosslinked UHMWPE experiences a sub-surface damage

layer which contains re-oriented and fragmented lamellae

regardless of motion path. Under both types of motion, a

de-crystallisation regime was found to extend more than

37.5mm beneath the surface. More wear resistant surfaces may

develop higher levels of strain; the increased period taken for a

given amount of material to be removed results in a greater

chance for strain to accumulate. It was apparent that the slower

wearing surfaces, from either material group, exhibited the

greatest de-crystallisation at the completion of each wear test.

Broken lamellae, particularly in the highly wear resistance

crosslinked material may be nally released as sub-micron debris.

Further studies, indicate a larger sub-surface zone which may

extend up to and exceed 200mm beneath the surface [63]. Dryzek

et al. conducted pin-on-disc studies rubbing 10mm diameter

pellets of UHMWPE onto a stainless steel disc with nominal loads

of 100 and 150N. Sliding was in the absence of lubricant. X-ray

diffraction indicated 100m of sliding was enough to cause a

de-crystallised surface and sub-surface layer, well beyond 200mm

into the material. Clearly, the likely transfer-lm formation

and heat build-up experienced in Dryzek et al.s study disallow

a direct comparison. However, it does serve to illustrate that

the uni-directional nature of the pin-on-disc will, just like the

ARTICLE IN PRESS

A. Kilgour, A. Elck / Tribology International ] (]]]]) ]]]]]] 10

Please cite this article as: Kilgour A, Elck A. Inuence of crosslinked polyethylene structure on wear of joint replacements. Tribol Int

(2009), doi:10.1016/j.triboint.2008.11.011

linear-reciprocating motion applied here, cause strain hardening

and preferential lamellar alignment at substantial depths beneath

the surface beyond those expected from a consideration of the

contact mechanics. Under these simplied tribological conditions

we also nd a de-crystallised worn surface and sub-surface layer

in the unirradiated UHMWPE.

Davey et al. [44] conducted polarised Fourier-transform

infrared spectroscopy (FTIR) on retrieved UHMWPE acetabular

components. Cylindrical cores were taken perpendicular to the

worn surface and then sectioned on a microtome into 200mm

thick slices. They found the greatest amount of lamellar orienta-

tion occurring in the rst 200mm beneath the surface, although

microstructural re-arrangement was also apparent up to 400mm.

The Raman technique employed within this study indicates a sub-

surface damage layer consisting of a de-crystallisation zone

extending to a depth greater than 37mm. The only material and

wear path combination that showed no changes in surface

crystallinity under sliding was the unirradiated material worn

under elliptical motion.

Parallel ripples on the surface of high wear areas of explanted

UHMWPE cups were rst observed by Dowling et al. [64] using

SEM. The limitation of the ripples to occur in areas of the cup

exhibiting high wear suggests a contact area subjected to a high

degree of multi-directionality and the presence of adhesive or

fatigue wear mechanisms. Ripples from Dowlings study, this

study, and many more consistently report the feature with

wavelengths between 1 and 2mm. We imaged rippling on the

worn surface of unirradiated polyethylene under elliptical rubbing

(Fig. 12a), a tribological setup resulting in the highest wear. This

may suggest that rippling is a consequence of multi-directional

motion under dynamic loading, however, surface ripples have also

been recorded by Elck et al. [27] who suggests motion

approaching uni-directionality may be a requirement for this

topographical feature. In agreement, Bragdon et al. [65] found

only uniaxial reciprocating motion produced signicant ripples of

wavelength 1.5mm on the worn surface of non-irradiated 4150

UHMWPE pins. We also imaged rippling on the worn surface of

+PE subjected to linear motion (Fig. 14d). Due to the inconsistent

tribological conditions under which sightings of rippling have

been observed, the suggestion by Elck et al. that rippling may be

a transient phenomenon seems appropriate.

Uni-directional motion has been found to cause the greatest

degree of molecular orientation under a range of sliding motions

[66]. Sambasivan et al. also found signicant alignment in

response to linear reciprocating wear during a 5000 cycle test

period. In the current study microstructural re-orientation was

conrmed by eld-emission scanning electron microscopy. Micro-

structure evolution in response to motion path was highly distinct

in the unirradiated group. Signicant texture development

occurred under linear reciprocating motion. Lamellae were

orientated in a preferential manner which coincided with the

sliding direction (Fig. 13c). Surfaces worn under elliptical motion

showed considerably less re-arrangement and negligible crystal-

line degradation. Both these material characteristics could be

attributed to the higher wear rate caused by elliptical motion. A

faster wearing surface will leave less time for large strains to

develop in the surface. This may result in a worn surface showing

no preferential orientation or fragmented lamellae. Likewise, the

same unirradiated material subjected to linear motion was found

to wear more slowly, hence, would have more time to accumulate

higher levels of surface and sub-surface strain, resulting in greater

amounts of orientation and crystalline degradation. This is

supported by SEM images showing more frequently occurring

lamellar tilting, bending, rotation and ultimately fragmentation in

ultra-structures subjected to linear motion. Crosslinked material,

the more wear resistant material under both types of motion may

experience a similar effect. The slower wear rates could explain

the drop in crosslinked crystallinity, and the similarities of

microstructure deformation imaged on both worn linear and

elliptical microstructures.

SEM images of PE and +PE ultrastructures after linear motion

were similar. Both showed degrees of lamellar alignment and

crystalline deformation mechanisms. The difference in the two

polymer networks was revealed by swelling results. These

indicated elevated crosslinks occurring in the amorphous domains

of the +PE material. The presence of crosslinks did not signi-

cantly inhibit lamellae re-orientation, and did not increase the

wear resistance of +PE under simplied reciprocating motion.

Therefore, we postulate the increased wear resistance of cross-

linked material comes from the elevated tie-molecule densities in

amorphous domains, adding increased resistance to amorphous

deformation mechanisms such as interlamellar stack rotation,

interlamellar shear and interlamellar separation [67] in response

to crossing motion paths. The greater resistance to plastic

deformation and debris release from the surface creates a more

wear resistant surface. The increased structural integrity of the

amorphous domain may more effectively transfer strain to the

crystalline domains, supporting the de-crystallised surface and

sub-surface zones found in this study. Under physiological hip

stresses, accumulated strain may not be relieved from the surface

as debris, as would be in conventional material, but rather

transferred from amorphous to crystalline domains increasing the

time it takes to generate debris particles. Fragmented lamellae

may then provide the basis for sub-micron debris generation.

5. Conclusions

The use of a novel six-station, programmable load and motion

wear machine to further the tribological investigation into wear

and sub-surface plasticity of ultra-high molecular weight poly-

ethylene has conrmed the importance of multi-directional

motion in pin-on-plate studies. Further, it has provided a basis

for non-destructive analysis techniques to characterise micro-

structure development. The signicance of uniform tribological

conditions across the pin contact area has allowed the wear

resistance of highly crosslinked polyethylene to be investigated.

Raman spectroscopy revealed a de-crystallised damage zone

beneath the worn surface extending to a distance greater than

37.5mm. This suggests the strain-induced damage zone is more

extensive than initially proposed.

Signicant lamellar alignment was only observed under linear

reciprocating motion, questioning the basis of orientation soft-

ening and accelerated wear under cross-shear. However, the

hypothesis that crosslinking does not inhibit lamellar mobility is

supported as SEM images revealed re-orientation under sliding.

The elevated number of carboncarbon covalent bonds may

increase the resistance to plastic deformation and brillar pull-

out when the microstructure shows no preferential alignment.

De-crystallised surface and sub-surface zones were found in the

lowest wearing groups i.e. unirradiated and crosslinked material

subjected to reciprocating motion. This was attributed to large

strain accumulation over a longer period of time providing a

mechanism for crystalline fragmentation. Lamellae fragments

may form the basis of sub-micron debris from the more wear

resistant crosslinked surfaces.

Acknowledgements

The authors would like to thank the Engineering and Physical

Sciences Research Council for funding the project, Smith and

ARTICLE IN PRESS

A. Kilgour, A. Elck / Tribology International ] (]]]]) ]]]]]] 11

Please cite this article as: Kilgour A, Elck A. Inuence of crosslinked polyethylene structure on wear of joint replacements. Tribol Int

(2009), doi:10.1016/j.triboint.2008.11.011

Nephew Inc. for supplying the samples, The Royal Society of

Edinburgh, Prof. Lisa Pruitt at the University of California, Berkeley

and Dr. Chris Jeffree for FESEM work at the University of

Edinburgh.

References

[1] Galante JO, Rostoker W. Wear in total hip prosthesesexperimental

evaluation of candidate materials. Acta Orthopaedica Scandinavica Supple-

mentum 1973(145):146.

[2] McKellop H, et al. Wear characteristics of UHMW polyethylene: a method for

accurately measuring extremely low wear rates. Journal of Biomedical

Materials Research 1978;12(6):895927.

[3] McKellop H, et al. Friction and wear properties of polymer, metal, and ceramic

prosthetic joint materials evaluated on a multichannel screening device.

Journal of Biomedical Materials Research 1981;15(5):61953.

[4] Rose RM, Cimino WR. Exploratory investigations on the structure dependence

of the wear resistance of polyethylene. Wear 1982;77(1):89104.

[5] Rostoker W, Galante JO. Contact pressure dependence of wear rates of ultra

high molecular weight polyethylene. Journal of Biomedical Materials

Research 1979;13(6):95764.

[6] Wright KWJ, Dobbs HS, Scales JT. Wear studies on prosthetic materials using

the pin-on-disc machine. Biomaterials 1982;3(1):418.

[7] Charnley J. Total hip replacement by low-friction arthroplasty. Clinical

Orthopaedics and Related Research 1970(72):721.

[8] Cooper RA, et al. Polyethylene debris-induced osteolysis and loosening in

uncemented total hip arthroplasty: a cause of late failure. The Journal of

Arthroplasty 1992;7(3):28590.

[9] Harris WH. The problem is osteolysis. Clinical Orthopaedics and Related

Research 1995(311):4653.

[10] Willert HG, Bertram H, Buchhorn GH. Osteolysis in alloarthroplasty of the

hipthe role of ultra-high-molecular-weight polyethylene wear particles.

Clinical Orthopaedics and Related Research 1990(258):95107.

[11] Bourne RB, et al. Pain in the thigh following total hip-replacement with a

porous-coated anatomic prosthesis for osteoarthrosisa 5-year follow-up

study. Journal of Bone and Joint SurgeryAmerican Volume 1994;76A(10):

146470.

[12] Muratoglu OK, et al. Unied wear model for highly crosslinked ultra-high

molecular weight polyethylenes (UHMWPE). Biomaterials 1999;20:146370.

[13] Saikko V, Calonius O, Kera nen J. Effect of counterface roughness on the wear

of conventional and crosslinked ultrahigh molecular weight polyethylene

studied with a multi-directional motion pin-on-disk device. Journal of

Biomedical Materials Research 2001;57(4):50612.

[14] Galvin A, et al. Wear of crosslinked polyethylene under different tribological

conditions. Journal of Materials Science: Materials in Medicine 2006;

17(3):23543.

[15] McKellop H, et al. Development of an extremely wear-resistant ultra high

molecular weight polythylene for total hip replacements. Journal of

Orthopaedic Research 1999;17(2):15767.

[16] Dorr LD, et al. Clinical performance of a durasul highly cross-linked

polyethylene acetabular liner for total hip arthroplasty at ve years. Journal

of Bone and Joint SurgeryAmerican Volume 2005;87A(8):181621.

[17] Heisel C, et al. Short-term in vivo wear of cross-linked polyethylene. Journal of

Bone and Joint SurgeryAmerican Volume 2004;86A(4):74851.

[18] Dumbleton JH, Shen C, Miller EH. Study of wear of some materials in

connection with total hip-replacement. Wear 1974;29(2):16371.

[19] Shen C, Dumbleton JH. Friction and wear behavior of irradiated very high

molecular-weight polyethylene. Wear 1974;30(3):34964.

[20] Edidin AA, et al. Plasticity-induced damage layer is a precursor to wear in

radiation-cross-linked UHMWPE acetabular components for total hip

replacement. The Journal of Arthroplasty 1999;14(5):61627.

[21] Mckellop HA, et al. The origin of submicron polyethylene wear debris in total

hip-arthroplasty. Clinical Orthopaedics and Related Research 1995(311):320.

[22] Jasty M, et al. Wear of polyethylene acetabular components in total hip

arthroplastyan analysis of one hundred and twenty-eight components

retrieved at autopsy or revision operations. Journal of Bone and Joint

SurgeryAmerican Volume 1997;79A(3):34958.

[23] Bragdon CR, et al. The importance of multidirectional motion on the wear of

polyethylene. Proceedings of the Institution of Mechanical Engineers [H]

1996;210(3):15765.

[24] Wang A, et al. Orientation softening in the deformation and wear of ultra-

high molecular weight polyethylene. Wear 1997;203204:23041.

[25] Charnley J. Wear of plastics materials in hip-joint. Plastics and Rubber 1976;

1(2):5963.

[26] Wang A. A unied theory of wear for ultra-high molecular weight

polyethylene in multi-directional sliding. Wear 2001;248(12):3847.

[27] Elck APD, et al. A re-appraisal of wear features of acetabular sockets using

atomic force microscopy. Wear 2002;253(78):83947.

[28] Deboer J, Vandenberg HJ, Pennings AJ. Crosslinking of ultrahigh molecular-

weight polyethylene in the oriented state with dicumylperoxide. Polymer

1984;25(4):5139.

[29] Kurtz SM, et al. Radiation and chemical crosslinking promote strain

hardening behavior and molecular alignment in ultra high molecular weight

polyethylene during multi-axial loading conditions. Biomaterials 1999;

20(16):144962.

[30] Wang A, et al. Lubrication and wear of ultra-high molecular weight

polyethylene in total joint replacements. Tribology International 1998;

31(13):1733.

[31] Joyce TJ, et al. A comparison of the wear of cross-linked polyethylene against

itself under reciprocating and multi-directional motion with different

lubricants. Wear 2001;250(112):20611.

[32] Zhou J, et al. Tribological and nanomechanical properties of unmodied and

crosslinked ultra-high molecular weight polyethylene for total joint replace-

ments. Journal of Tribology 2004;126(2):38694.

[33] Saikko V, Calonius O, Kera nen J. Effect of slide track shape on the wear of

ultra-high molecular weight polyethylene in a pin-on-disk wear simulation of

total hip prosthesis. Journal of Biomedical Materials Research 2004;

69B(2):1418.

[34] Turell M, Wang A, Bellare A. Quantication of the effect of cross-path motion

on the wear rate of ultra-high molecular weight polyethylene. Wear

2003;255(712):10349.

[35] ASTM D2765-01. Standard test methods for determination of gel content and

swell ratio of crosslinked ethylene plastics. ASTM International, 2006.

[36] Rodriguez F, et al. Principles of polymer systems. 5th ed. London: Taylor &

Francis; 2003.

[37] Flory PJ. Principles of polymer chemistry. Ithaca, NY: Cornell University Press;

1953.

[38] ASTM F732-00. Standard test method for wear testing of polymeric materials

for use in total joint prostheses. ASTM International, 2006.

[39] Kilgour A, Elck AP. Investigation of polyethylene structure and its bearing on

wear of joint replacments. In: World biomaterials congress, Amsterdam, 2008.

[40] Hall RM, et al. Wear in retrieved Charnley acetabular sockets. Proceedings of

the Institution of Mechanical Engineers 1996;210(3):197207. [0954-4119

(Print)].

[41] Ramamurti BS, et al. Loci of movement of selected points on the femoral head

during normal gait: three-dimensional computer simulation. The Journal of

Arthroplasty 1996;11(7):84552.

[42] Bennett DB, Orr JF, Baker R. Movement loci of selected points on the femoral

head for individual total hip arthroplasty patients using three-dimensional

computer simulation. The Journal of Arthroplasty 2000;15(7):90915.

[43] Saikko V, Calonius O. Slide track analysis of the relative motion between

femoral head and acetabular cup in walking and in hip simulators. Journal of

Biomechanics 2002;35(4):45564.

[44] Davey SM, et al. Measurement of molecular orientation in retrieved ultra-

high-molecular-weight polyethylene (UHMWPE) hip sockets using Fourier-

transform infrared spectroscopy. Strain 2004;40(4):20310.

[45] Bergmann G, Graichen F, Rohlmann A. Hip joint loading during walking and

running, measured in two patients. Journal of Biomechanics 1993;26(8):

96990.

[46] Paul JP. Forces transmitted by joints in the human body. Proceedings of the

Institution of Mechanical Engineers 1966;181:815.

[47] Glotin M, Mandelkern L. A Raman spectroscopic study of the morphological

structure of the polyethylenes. Colloid & Polymer Science 1982;260(2):

18292.

[48] Mandelkern L, Alamo RG, Kennedy MA. Interphase thickness of linear

polyethylene. Macromolecules 1990;23(21):47213.

[49] Strobl GR, Hagedorn W. Raman spectroscopic method for determining the

crystallinity of polyethylene. Journal of Polymer Science: Polymer Physics

Edition 1978; 118193.

[50] Affatato S, et al. The performance of gamma- and EtO-sterilised UHMWPE

acetabular cups tested under severe simulator conditions. Part 2: wear particle

characteristics with isolation protocols. Biomaterials 2003;24(22):404555.

[51] Affatato S, et al. Wear behaviour of cross-linked polyethylene assessed in vitro

under severe conditions. Biomaterials 2005;26(16):325967.

[52] Affatato S, et al. Effects of the sterilisation method on the wear of UHMWPE

acetabular cups tested in a hip joint simulator. Biomaterials 2002;23(6):

143946.

[53] Bertoluzza A, et al. Micro-Raman spectroscopy for the crystallinity character-

ization of UHMWPE hip cups run on joint simulators. Journal of Molecular

Structure 2000;521(13):8995.

[54] Pruitt LA. Deformation, yielding, fracture and fatigue behavior of conven-

tional and highly cross-linked ultra high molecular weight polyethylene.

Biomaterials 2005;26(8):90515.

[55] Olley RH, Hodge AM, Bassett DC. A permanganic etchant for polyolenes.

Journal of Polymer Science: Polymer Physics Edition 1979;17(4):62743.

[56] Sawyer LC, Grubb DT. Polymer microscopy. 2nd ed. New York: Chapman &

Hall Ltd; 1987.

[57] Olley RH, Bassett DC. An improved permanganic etchant for polyolenes.

Polymer 1982;23(12):170710.

[58] Shahin MM, Olley RH, Blissett MJ. Renement of etching techniques to reveal

lamellar proles in polyethylene banded spherulites. Journal of Polymer

Science Part B: Polymer Physics 1999;37(16):227986.

[59] Klapperich C, Komvopouolos K, Pruitt L. Tribological properties and micro-

structure evolution of ultra-high molecular weight polyethylene. Journal of

Tribology, Transactions of the ASME 1999;121(2):394403.

[60] Archard JF. Contact and rubbing of at surfaces. Journal of Applied Physics

1953;24(8):9818.

[61] Elck APD, et al. The effect of socket design, materials and liner thickness on

the wear of the porous coated anatomic total hip replacement. Proceedings of

ARTICLE IN PRESS

A. Kilgour, A. Elck / Tribology International ] (]]]]) ]]]]]] 12

Please cite this article as: Kilgour A, Elck A. Inuence of crosslinked polyethylene structure on wear of joint replacements. Tribol Int

(2009), doi:10.1016/j.triboint.2008.11.011

the Institution of Mechanical Engineers Part HJournal of Engineering in

Medicine 2001;215(H5):44757.

[62] Lancaster JK. Relationships between wear of polymers and their mechanical

properties. Industrial Lubrication and Tribology 1969;21(7):214.

[63] Dryzek E, Dryzek J. Measurement of subsurface zone in UHMWPE after

sliding against stainless steel using the new experimental method DSIP.

Radiation Physics and Chemistry 2007;76(2):1579.

[64] Dowling JM, et al. Characteristics of acetabular cups worn in human-

body. Journal of Bone and Joint SurgeryBritish Volume 1978;60(3):37582.

[65] Bragdon CR, et al. A new pin-on-disk wear testing method for simulating

wear of polyethylene on cobaltchrome alloy in total hip arthroplasty. The

Journal of Arthroplasty 2001;16(5):65865.

[66] Sambasivan S, et al. Molecular orientation of ultrahigh molecular weight

polyethylene induced by various sliding motions. Journal of Biomedical

Materials Research 2004;70B(2):27885.

[67] Lin L, Argon AS. Structure and plastic-deformation of polyethylene. Journal of

Materials Science 1994;29(2):294323.

ARTICLE IN PRESS

A. Kilgour, A. Elck / Tribology International ] (]]]]) ]]]]]] 13

Please cite this article as: Kilgour A, Elck A. Inuence of crosslinked polyethylene structure on wear of joint replacements. Tribol Int

(2009), doi:10.1016/j.triboint.2008.11.011

S-ar putea să vă placă și

- Tribology International: Sorin-Cristian Vladescu, Andrew V. Olver, Ian G. Pegg, Tom ReddyhoffDocument15 paginiTribology International: Sorin-Cristian Vladescu, Andrew V. Olver, Ian G. Pegg, Tom ReddyhoffJoel E ValenciaÎncă nu există evaluări

- Loading Rate Effect As A Function of The Span-To-Depth Ratio in Three-Point Bend Testing of Unidirectional Puitruded CompositesDocument7 paginiLoading Rate Effect As A Function of The Span-To-Depth Ratio in Three-Point Bend Testing of Unidirectional Puitruded CompositesShital ChaudhariÎncă nu există evaluări

- K.A. Laux, C.J. Schwartz: Article InfoDocument8 paginiK.A. Laux, C.J. Schwartz: Article InfoAhda Dapong Rizqy MaulanaÎncă nu există evaluări

- What Are The Wear Mechanisms and What Controls Them?Document10 paginiWhat Are The Wear Mechanisms and What Controls Them?Anurag KashyapÎncă nu există evaluări

- Influence of Stress Relaxation On ClampDocument16 paginiInfluence of Stress Relaxation On ClampgeppolaÎncă nu există evaluări

- A Unified Theory of Wear For Ultra-High Molecular Weight Polyethylene in Multi-Directional SlidingDocument10 paginiA Unified Theory of Wear For Ultra-High Molecular Weight Polyethylene in Multi-Directional SlidingJosé santanaÎncă nu există evaluări

- Project Group 10Document26 paginiProject Group 10amitgourav9Încă nu există evaluări

- The Effect of Contact Area On Wear in Relation To Fixed Bearing and Mobile Bearing Knee ReplacementsDocument9 paginiThe Effect of Contact Area On Wear in Relation To Fixed Bearing and Mobile Bearing Knee ReplacementsJoÎncă nu există evaluări