Documente Academic

Documente Profesional

Documente Cultură

Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part9

Încărcat de

linghuchong0 evaluări0% au considerat acest document util (0 voturi)

17 vizualizări4 paginiA design carried out on the basis of the truss model requires an area of longitudinal steel, in add ition to the one required for flexure, due to the presence of torsion. The concrete contribution to the torsional resistance of the section varies linearly depending upon the magnitude of the nominal shear stress Tu. In the CEB-Refined method, "be" is taken equal to d e / 6, where de is the diameter of the circle inscribed into the perimeter "un

Descriere originală:

Titlu original

Proposed Design Procedures for Shear and Torsion in Reinforced and Prestressed Concrete Ramirez_part9

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentA design carried out on the basis of the truss model requires an area of longitudinal steel, in add ition to the one required for flexure, due to the presence of torsion. The concrete contribution to the torsional resistance of the section varies linearly depending upon the magnitude of the nominal shear stress Tu. In the CEB-Refined method, "be" is taken equal to d e / 6, where de is the diameter of the circle inscribed into the perimeter "un

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

17 vizualizări4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part9

Încărcat de

linghuchongA design carried out on the basis of the truss model requires an area of longitudinal steel, in add ition to the one required for flexure, due to the presence of torsion. The concrete contribution to the torsional resistance of the section varies linearly depending upon the magnitude of the nominal shear stress Tu. In the CEB-Refined method, "be" is taken equal to d e / 6, where de is the diameter of the circle inscribed into the perimeter "un

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 4

17

longitudinal chords in the truss model. A design carried out on the

basis of the truss model requires an area of longitudinal steel, in

add ition to the one required for flexure, due to the presence of

torsion.

T U

Al (T) = _u __ _

f..td 2

-cota

(2.8)

Equation 2.8 results from Eq. 3.30 derived in Sec. 3.4 of Report

248-2. A,(T) is the total area of longitudinal steel required to resist

the torsional moment T

u

' "u" represents the perimeter connecting the

centers of the longitudinal chords of the truss model.

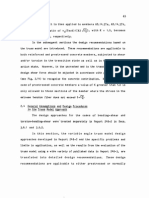

As in the case of shear, the concrete contribution to the

torsional resistance of the section varies linearly depending upon the

magnitude of the nominal shear stress produced by the torsional moment

Tu. Figure 2.4 illustrates the concrete contribution as suggested in

the CEB-Refined method.

As can be seen from Fig. 2.4 the concrete contributions to the

torsional and shear capacity of the section are the same in terms of

shear stresses. In Fig. 2.4 the values of the shear stresses Qrd remain

the same as those values given in Fig. 2.2.

The nominal shear stress due to torsion (v) is given by Eq. 2.9

(2.9)

which is the shear stress produced in a thin walled tube by the presence

of a torsional moment assuming a constant shear flow around the

per imeter of the cross section.

In Eq. 2.9 "be" represents the

18

Vc=concrete contribution

uncracked Transition Full Truss action

I

I

: Vc= (7.5Qrd- Vud)

2.5Qrd ...... ------t .....

2.5Qrd 7.5Qrd

Ultimate Shear Stress due to Torsion

Vud=Tu

2Aobe

Fig. 2.4 Additional concrete contribution in the transition range

effective wall thickness of this assumed thin-walled tube. This term

has been discussed in Sec. 2.6.1 of Report 248-3. In the CEB-Refined

method, "be" is taken equal to d

e

/6, where de is the diameter of the

circle inscribed into the perimeter "un formed by the centroids of the

longitudinal bars forming the truss model of the cross section in

consideration.

From Fig. 2.4, it can be seen that the maximum value of the

concrete contribution occurs at low torsional shear stress levels and is

given by

(2.10)

19

Hence, the concrete contribution [v

c

] in terms of shear stress

and ~ can be obtained from Eqs. 2.9, 2.10 and the resistance safety

factor for the concrete, 1.5 introduced in the CEB-Refined method.

(2.11)

Expressing Eq. 2.11 in terms of k.[7[ and substituting the

values of Qrd yields k values ranging from 2.3 to 3.4 which are the same

magnitude as those in the case of shear. ACI 318-71 (2) and the AASHTO

Standard Specifications (1) allow a nominal concrete contribution in the

case of pure torsion of Vt = 2.4 Jf': which is a lower bound value

c '

for the CEB-Refined method.

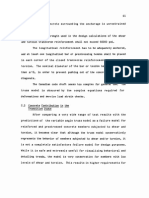

In order to prevent failures due to crushing of the web, an

upper limit to the torsional strength of

(2.12)

is given. In terms of fc and with a resistance safety factor of 1.5 as

suggested by the CEB Code, this yields a maximum shear stress of

T

V = max _ 0.167 f' sin2a

max 2A

O

b

e

c

(2.13)

A comparison of this upper limit with the ACI (2) and AASHTO (1)

limit of 12.ff'c for values of Ci of 45 and 30 degrees is shown in

Fig. 2.5.

In the case of combined torsion and shear the reinforcement for

torsion and for shear are determ ined separately and then added.

However, when torsion and shear interact on a section the additional

20

1500

1000

500

Vmax: maximum torsional stress

5000

ACI-AASHTO

(12.jfc)

10000

fb

(pI i)

Fig. 2.5 Upper limits for the ultimate torsional stress

acting on a cross section

resistance of the concrete Vc for shear and Tc for torsion, are

considered equal to zero. The acting design torque and shear force Tu

and Vu must meet the condition

[Tu/Tmax] + [Vu/V

max

] < 1.0 (2.14)

where Tmax and V

max

are given by Eqs. 2.13 and 2.6, respectively.

Finally, the reinforcement must meet the following detailing

requirements. The minimum percentage of web reinforcement must be equal

to 0.0013 for web reinforcement made out of high strength steel or

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Cryogenic Air Separation, Histroy and Technological ProcessDocument20 paginiCryogenic Air Separation, Histroy and Technological ProcessJason Thomas100% (2)

- Refraction Through Lenses & Optical Instruments5Document144 paginiRefraction Through Lenses & Optical Instruments5geniusamahÎncă nu există evaluări

- Effect of Different Sand Grading On Strength Properties of Cement Grout PDFDocument8 paginiEffect of Different Sand Grading On Strength Properties of Cement Grout PDFyoussefÎncă nu există evaluări

- Lab Viva Questions and AnswersDocument38 paginiLab Viva Questions and AnswersGemechu Taye100% (1)

- Science 10 Second QuarterDocument3 paginiScience 10 Second Quarterprince adilan planas100% (5)

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part20Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part20linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part22Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part22linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part21Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part21linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part19Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part19linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part23Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part23linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part17Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part17linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part7Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part7linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part18Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part18linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part12Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part12linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part14Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part14linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part15Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part15linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part1Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part1linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part16Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part16linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part13Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part13linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part67Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part67linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part8Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part8linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part10Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part10linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part5Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part5linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part2Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part2linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part11Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part11linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part66Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part66linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part3Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part3linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part6Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part6linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part4Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part4linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part68Document2 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part68linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part61Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part61linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part65Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part65linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part60Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part60linghuchongÎncă nu există evaluări

- Proposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part59Document4 paginiProposed Design Procedures For Shear and Torsion in Reinforced and Prestressed Concrete Ramirez - Part59linghuchongÎncă nu există evaluări

- Ps2 GeoDocument9 paginiPs2 GeoRio Fae BautistaÎncă nu există evaluări

- LAB REport 7Document6 paginiLAB REport 7Misbah TehseenÎncă nu există evaluări

- SAP NonwovenDocument6 paginiSAP NonwovenPARAN THAMANÎncă nu există evaluări

- Solutions - Revision Book Chemistry PDFDocument89 paginiSolutions - Revision Book Chemistry PDFJatin GoyalÎncă nu există evaluări

- Balistik Dalam (Bab I, Ii, Iii,... )Document61 paginiBalistik Dalam (Bab I, Ii, Iii,... )Gilang Wicaksono WJÎncă nu există evaluări

- EXP 1 Lab Rep For PrintDocument6 paginiEXP 1 Lab Rep For PrintJohn leo-mar PadillaÎncă nu există evaluări

- Heat Mass TransferDocument221 paginiHeat Mass Transferjeas grejoyÎncă nu există evaluări

- Work Power Energy QuestionsDocument17 paginiWork Power Energy QuestionsAnupam MÎncă nu există evaluări

- Me8391 Engineering ThermodynamicsDocument1 paginăMe8391 Engineering ThermodynamicsAiam PandianÎncă nu există evaluări

- Water Level 3 Automatic Level Control Systems - Spirax SarcoDocument14 paginiWater Level 3 Automatic Level Control Systems - Spirax SarcoCayixÎncă nu există evaluări

- Flash & Fire Point TestDocument10 paginiFlash & Fire Point Testali najatÎncă nu există evaluări

- MPS en V3Document8 paginiMPS en V3words2zhigang_612545Încă nu există evaluări

- Technical Data: 65x50 FS2HA 5 7.5Document5 paginiTechnical Data: 65x50 FS2HA 5 7.5DavidThânÎncă nu există evaluări

- Problemas de Concentracion de EsfuerzosDocument7 paginiProblemas de Concentracion de EsfuerzosJonathan MendozaÎncă nu există evaluări

- Flow Regimes On Sieve Trays For Gas Liquid ContactingDocument196 paginiFlow Regimes On Sieve Trays For Gas Liquid ContactingGrant FirthÎncă nu există evaluări

- Silver BromideDocument3 paginiSilver Bromidepengujian psmbÎncă nu există evaluări

- Public Review Draft 2404Document115 paginiPublic Review Draft 2404Said100% (1)

- Steam Heat ExchangerDocument2 paginiSteam Heat ExchangerAbdul Hafeez AkramÎncă nu există evaluări

- Influence of Liquid and Gas Flow Rates On SulfuricDocument7 paginiInfluence of Liquid and Gas Flow Rates On SulfuricNathanÎncă nu există evaluări

- Failure Analysis of A Bucket Elevator Shaft: Technicalarticle-Peer-ReviewedDocument7 paginiFailure Analysis of A Bucket Elevator Shaft: Technicalarticle-Peer-Revieweddouglasncamilo100% (1)

- H 101A 20230329 Tecnopipe LP Jun2022Document1 paginăH 101A 20230329 Tecnopipe LP Jun2022JABUER TAHISIR PARRA CHALARCAÎncă nu există evaluări

- Mate1000 Sln21aDocument3 paginiMate1000 Sln21aclearcastingÎncă nu există evaluări

- Curtis Petroleum Reservoir Fluid PropertiesDocument6 paginiCurtis Petroleum Reservoir Fluid Propertiesbenjamin kenyeryÎncă nu există evaluări

- Electrical Imaging: 2D Resistivity Tomography As A Tool For Groundwater Studies at Mahmudia Village, West Sulaimani City, Kurdistan Region/ IraqiDocument1 paginăElectrical Imaging: 2D Resistivity Tomography As A Tool For Groundwater Studies at Mahmudia Village, West Sulaimani City, Kurdistan Region/ IraqiAcademecian group100% (1)

- Oscillation SDocument1 paginăOscillation SDhanBahadurÎncă nu există evaluări