Documente Academic

Documente Profesional

Documente Cultură

ESP

Încărcat de

Sreejith Jithu0 evaluări0% au considerat acest document util (0 voturi)

14 vizualizări17 paginiElectrostatic precipitation

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentElectrostatic precipitation

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

14 vizualizări17 paginiESP

Încărcat de

Sreejith JithuElectrostatic precipitation

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 17

Introduction to Precipitators (Back to top)

An electrostatic precipitator is a large, industrial emission-control unit. It is

designed to trap and remove dust particles from the exhaust gas stream of an

industrial process. Precipitators are used in these industries:

Power/Electric

Cement

Chemicals

Metals

Paper

In many industrial plants, particulate matter created in the industrial process is

carried as dust in the hot exhaust gases. These dust-laden gases pass through an

electrostatic precipitator that collects most of the dust. Cleaned gas then passes

out of the precipitator and through a stack to the atmosphere. Precipitators

typically collect 99.9% or more of

the dust from the gas stream.

Precipitators function by

electrostatically charging the dust

particles in the gas stream. The

charged particles are then attracted

to and deposited on plates or other

collection devices. When enough

dust has accumulated, the collectors

are shaken to dislodge the dust,

causing it to fall with the force of

gravity to hoppers below. The dust is then removed by a conveyor system for

disposal or recycling.

Depending upon dust characteristics and the gas volume to be treated, there are

many different sizes, types and designs of electrostatic precipitators. Very large

power plants may actually have multiple precipitators for each unit.

Basic Principles (Back to top)

Electrostatic precipitation removes particles from the exhaust gas stream of an

industrial process. Often the process involves combustion, but it can be any

industrial process that would otherwise emit particles to the atmosphere. Six

activities typically take place:

Ionization - Charging of particles

Migration - Transporting the charged particles to the collecting surfaces

Collection - Precipitation of the charged particles onto the collecting

surfaces

Charge Dissipation - Neutralizing the charged particles on the collecting

surfaces

Particle Dislodging - Removing the particles from the collecting surface

to the hopper

Particle Removal - Conveying the particles from the hopper to a disposal

point

Troubleshooting

Checklists

Available

Documents

Precipitator Tutorial

1 - ESP Operation

2 - ESP Components

3 - ESP Design Parameters

4 - ESP Design Review

5 - Industrial Applications

for ESPs

6 - ESP Operation &

Maintenance

Product Manuals

The major precipitator components that accomplish these activities are as follows:

Discharge Electrodes

Power Components

Precipitator Controls

Rapping Systems

Purge Air Systems

Flue Gas Conditioning

Design & Performance Requirements (Back to top)

Designing a precipitator for optimum performance requires proper sizing of the

precipitator in addition to optimizing precipitator efficiency. While some users

rely on the precipitator manufacturer to determine proper sizing and design

parameters, others choose to either take a more active role in this process or hire

outside engineering firms.

Precipitator performance depends on its size and collecting efficiency. Important

parameters include the collecting area and the gas volume to be treated. Other key

factors in precipitator performance include the electrical power input and dust

chemistry.

Precipitator sizing

The sizing process is complex as each precipitator manufacturer has a

unique method of sizing, often involving the use of computer models and

always involving a good dose of judgment. No computer model on its

own can assess all the variables that affect precipitator performance.

Collecting Efficiency

Based on specific gas volume and dust load, calculations are used to

predict the required size of a precipitator to achieve a desired collecting

efficiency.

Power Input

Power input is comprised of the voltage and current in an electrical field.

Increasing the power input improves precipitator collecting efficiency

under normal conditions.

Process Variables (Back to top)

Gas characteristics and particle properties define how well a precipitator will

work in a given application. The main process variables to consider are:

Gas flow rate

The gas flow rate in a power plant is defined by coal quality, boiler load,

excess air rate and boiler design. Where there is no combustion, the gas

flow rate will have process-specific determinants.

Particle size and size distribution

The size distribution in a power plant is defined by coal quality, the coal

mill settings and burner design. Particle size for non-combustion

processes will have similar determinants.

Particle resistivity

The resistivity of fly ash or other particles is influenced by the chemical

composition and the gas temperature.

Gas temperature

Following are details of these process variables:

1. Gas Flow Rate

A precipitator operates best with a gas velocity of 3.5 - 5.5 ft/sec. At

higher velocity, particle re-entrainment increases rapidly. If velocity is

too low, performance may suffer from poor gas flow distribution or from

particle dropout in the ductwork.

2. Particle Size

A precipitator collects particles most easily when the particle size is

coarse. The generation of the charging corona in the inlet field may be

suppressed if the gas stream has too many small particles (less than 1

m).

Very small particles (0.2 - 0.4m) are the most difficult to collect

because the fundamental field-charging mechanism is overwhelmed by

diffusion charging due to random collisions with free ions.

3. Particle Resistivity

Resistivity is resistance to electrical conduction. The higher the

resistivity, the harder it is for a particle to transfer its electrical charge.

Resistivity is influenced by the chemical composition of the gas stream,

particle temperature and gas temperature. Resistivity should be kept in

the range of 108 - 1010 ohm-cm.

High resistivity can reduce precipitator performance. For example, in

combustion processes, burning reduced-sulfur coal increases resistivity

and reduces the collecting efficiency of the precipitator. Sodium and iron

oxides in the fly ash can reduce resistivity and improve performance,

especially at higher operating temperatures.

On the other hand, low resistivity can also be a problem. For example (in

combustion processes), unburned carbon reduces precipitator

performance because it is so conductive and loses its electrical charge so

quickly that it is easily re-entrained from the collecting plate.

4. Gas Temperature

The effect of gas temperature on precipitator collecting efficiency, given

its influence on particle resistivity, can be significant.

5. Interactions to Consider

Particle size distribution and particle resistivity affect the cohesiveness

of the layer of precipitated material on the collecting plates and the

ability of the rapping system to dislodge this layer for transport into the

precipitator hopper without excessive re-entrainment.

About Discharge Electrodes (Back to top)

Discharge electrodes emit charging current and provide voltage that generates an

electrical field between the discharge electrodes and the collecting plates. The

electrical field forces dust particles in the gas stream to migrate toward the

collecting plates. The particles then precipitate onto the collecting plates.

Common types of discharge electrodes include:

Straight round wires

Twisted wire pairs

Barbed discharge wires

Rigid masts

Rigid frames

Rigid spiked pipes

Spiral wires

Discharge electrodes are typically supported from the upper discharge frame and

are held in alignment between the upper and lower discharge frames. The upper

discharge frame is in turn supported from the roof of the precipitator casing.

High-voltage insulators are incorporated into the support system. In weighted

wire systems, the discharge electrodes are held taut by weights at the lower end of

the wires.

About Collecting Plates (Back to top)

Collecting plates are designed to receive and retain the precipitated particles until

they are intentionally removed into the hopper. Collecting plates are also part of

the electrical power circuit of the precipitator. These collecting plate functions are

incorporated into the precipitator design. Plate baffles shield the precipitated

particles from the gas flow while smooth surfaces provide for high operating

voltage.

Collecting plates are suspended from the precipitator casing and form the gas

passages within the precipitator. While the design of the collecting plates varies

by manufacturer, there are two common designs:

Plates supported from anvil beams at either end

The anvil beam is also the point of impact for the collecting rapper

Plates supported with hooks directly from the precipitator casing

Two or more collecting plates are connected at or near the center by

rapper beams, which then serve as impact points for the rapping system

Top, center, or bottom spacer bars may be used to maintain collecting plate

alignment and sustain electrical clearances to the discharge system.

About Power Supplies and Controls (Back to top)

The power supply system is designed to provide voltage to the electrical field (or

bus section) at the highest possible level. The voltage must be controlled to avoid

causing sustained arcing or sparking between the electrodes and the collecting

plates.

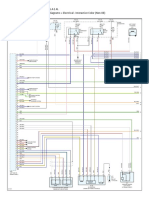

Click here to view a precipitator power system animated schematic showing

representative components.

Electrically, a precipitator is divided into a grid, with electrical fields in series (in

the direction of the gas flow) and one or more bus sections in parallel (cross-wise

to the gas flow). When electrical fields are in series, the power supply for each

field can be adjusted to optimize operation of that field. Likewise, having more

than one electrical bus section in parallel allows adjustments to compensate for

their differences, so that power input can be optimized. The power supply system

has four basic components:

Automatic voltage

control

Step-up transformer

High-voltage rectifier

Sensing device

1. Voltage control

Automatic voltage

control varies the power

to the transformer-

rectifier in response to

signals received from

sensors in the precipitator and the transformer-rectifier itself. It monitors

the electrical conditions inside the precipitator, protects the internal

components from arc-over damages, and protects the transformer-

rectifier and other components in the primary circuit.

The ideal automatic voltage control would produce the maximum

collecting efficiency by holding the operating voltage of the precipitator

at a level just below the spark-over voltage. However, this level cannot

be achieved given that conditions change from moment to moment.

Instead, the automatic voltage control increases output from the

transformer-rectifier until a spark occurs. Then the control resets to a

lower power level, and the power increases again until the next spark

occurs.

Automatic Voltage Controllers (for Electrostatic Precipitators)

An electronic device used to control the application of D.C. power into a field of

an electrostatic precipitator. (PIC OF MVC4 FACE PANEL AND PIC OF

INTERFACE BOARD)

Theory

Optimize power application The primary purpose of a voltage controller is to

deliver as much useful electrical power to the corresponding electrostatic

precipitator field(s) as possible. This is not an easy job; electrical characteristics

in the field(s) are constantly changing, which is why a voltage controller is

required.

Spark reaction When the voltage applied to the electrostatic precipitator field

is too high for the conditions at the time, a spark over (or corona discharge) will

occur. Detrimentally high amounts of current can occur during a spark over if not

properly controlled, which could damage the fields. A voltage controller will

monitor the primary and secondary voltage and current of the circuit, and detect a

spark over condition. Once detected, the power applied to the field will be

immediately cut off or reduced, which will stop the spark. After a short amount of

time the power will be ramped back up, and the process will start over.

Protect system components by adhering to component limitations The

Transformer Rectifier set (TR set) can be damaged by excessive amounts of

current or voltage flowing through it. Each TR set has voltage and current limits

established by the manufacturer, which are labeled on an attached nameplate (PIC

OF A NAMEPLATE). These nameplate limit values (typically primary and

secondary current, and voltage) are programmed into the voltage controller.

Through metering circuits, the voltage controller will monitor these values, and

ensure these limits are not exceeded.

Tripping When a condition occurs that the voltage controller cannot control,

often times the voltage controller will trip. A trip means the voltage controller (by

way of the contactor) will shut off the individual precipitator power circuit. A

short inside the electrostatic precipitator field caused by a fallen discharge

electrode (wire), or a shorted out Silicone Controlled Rectifier are examples of

conditions that a voltage controller cannot control. (PIC OF CLOSE-UP OF TRIP

LIGHT ON MVC4 FACE PANEL)

Operation

To maximize electrostatic precipitator efficiency a voltage controller usually

attempts to increase the electrical power delivered to the field. However in some

conditions a voltage controller must just maintain power at a constant level.

Increased electrical power into the electrostatic precipitator directly correlates

with better precipitator performance, but there is a limit. If too much voltages is

applied for a given condition (as mentioned in the spark reaction section), a spark

over will occur. During a spark over precipitator performance in that field will

drop to zero, rendering that field temporarily ineffective.

To overcome the crippling effect that spark over has to increasing the electrical

power in the precipitator field, spark response algorithms have been developed

that will interrupt power upon detection of a spark, then ramp power back up to a

high level. These response algorithms can greatly influence overall precipitator

performance.

1. Transformer-Rectifiers

The transformer-rectifier rating should be matched to the load imposed

by the electrical field or bus section. The power supply will perform best

when the transformer-rectifiers operate at 70 - 90% of the rated capacity,

without excessive sparking. This reduces the maximum continuous-load

voltage and corona power inputs. Practical operating voltages for

transformer-rectifiers depend on:

o Collecting plate spacing

o Gas and dust conditions

o Collecting plate and discharge electrode geometry

At secondary current levels over 1500 mA, internal impedance of a

transformer-rectifier is low, which makes stable automatic voltage

control more difficult to achieve. The design of the transformer-rectifier

should call for the highest possible impedance that is commensurate with

the application and performance requirements. Often, this limits the size

of the electrical field or bus section.

It is general practice to add additional impedance in the form of a

current-limiting reactor in the primary circuit. This reactor will limit the

primary current during arcing and also improve the wave shape of the

voltage/current fed into the transformer-rectifier.

2. Corona current density

Corona current density should be in the range of 10 - 100 mA/1000 ft2

of plate area. (Calculate this using secondary current divided by

collecting area of the electrical field or bus section.) The actual level

depends upon:

o Location of electrical field or bus section to be energized

o Collecting plate area

o Gas and dust conditions

o Collecting electrode and discharge wire geometry

About Gas Distribution Systems (Back to top)

One electrical field or bus section of an electrostatic precipitator is by itself an

independent precipitator. Its operation is governed by the inlet gas and dust

conditions, as well as the collecting plate and discharge electrode geometries.

Within this electrical field or bus section, one gas passage is also an independent

precipitator - governed by the same factors. (Note that the gas passage shares the

voltage level with the adjacent gas passages of the same electrical field or bus

section, but not the corona current level, which can be different in each gas

passage.)

This points to the importance of creating similar gas and dust conditions 1) at the

inlet of each electrical field or bus section, and 2) further at the inlet of each gas

passage of the electrical field or bus section. Ideally, uniformity is desired in:

Gas velocity

Gas temperature

Dust loading

Gas velocity distribution can be most effectively influenced by the use of gas

distribution devices.

The quality of gas velocity distribution can be measured in a scaled-down model

of the precipitator and its ductwork, and also in the precipitator itself. Typical

criteria are based on ICAC (Institute of Clean Air Companies) recommendations

using average gas velocities or on a calculated RMS statistical representation of

the gas velocity pattern.

In general, gas distribution devices consist of turning vanes in the inlet ductwork,

and perforated gas distribution plates in the inlet and/or outlet fields of the

precipitator.

About Rapping Systems (Back to top)

Rappers are time-controlled systems provided for removing dust from the

collecting plates and the discharge electrodes as well as for gas distribution

devices (optional) and for hopper walls (optional). Rapping systems may be

actuated by electrical or pneumatic power, or by mechanical means. Tumbling

hammers may also be used to dislodge ash. Rapping methods include:

Electric vibrators

Electric solenoid piston drop rappers

Pneumatic vibrating rappers

Tumbling hammers

Sonic horns (do not require transmission assemblies)

1. Discharge Electrode Rapping

In general, discharge electrodes should be kept as free as possible of

accumulated particulate. The rapping system for the discharge electrodes

should be operated on a continuous schedule with repeat times in the 2 -

4 minute range, depending on the size and inlet particulate loading of the

precipitator.

2. Collecting Plate Rapping

Collecting plate rapping must remove the bulk of the precipitated dust.

The collecting plates are supported from anvil beams or directly with

hooks from the precipitator casing. With anvil beam support, the impact

of the rapping system is directed into the beams located at the leading

and/or trailing edge of the collecting plates. For direct casing support, the

impact is directed into the rapper beams located at or near the center of

the top of the collecting plates.

The first electrical field generally collects about 60-80% of the inlet dust

load. The first field plates should be rapped often enough so that their

precipitated layer of particulate is about 3/8 - 1/2" thick. There is no

advantage in rapping more often since the precipitated dust has not yet

agglomerated to a sheet which requires a minimum layer thickness.

Sheet formation is essential to make the dust drop into the precipitator

hopper without re-entrainment into the gas stream. Rapping less

frequently typically results in a deterioration of the electrical power input

by adding an additional resistance into the power circuit. Once an

optimum rapping cycle has been found for the first electrical field (which

may vary across the face of a large precipitator), the optimum rapping

cycles for the downstream electrical fields can be established.

The collecting plate rapping system of the first field has a repeat time T

equal to the time it takes to build a 3/8 - 1/2"layer on the collecting

plates. The plates in the second field should have a repeat time of about

5T, and the plates in the third field should have a repeat time of 25T.

Ideally, these repeat times yield a deposited layer of 3/8-1/2" for the

plates in all three fields. Adjustment may be required for factors such as

dust resistivity, dust layer cohesiveness, gas temperature effects,

electrical field height and length, and the collecting area served by one

rapper.

3. Gas Distribution Plate and Hopper Wall Rapping

The gas distribution plates should also be kept free of excessive

particulate buildup and may require rapping on a continuous base with a

cycle time in the 10-20 minute range, depending on the inlet particulate

loading of the precipitator and the nature of the particulate. Gas

distribution plates in the outlet of the precipitator may be rapped less

often (every 30 - 60 minutes).

4. Improving Rapping System Performance

All precipitator rapping systems allow adjustment of rapping frequency,

normally starting with the highest frequency (the least time between

raps), progressing to the lowest frequency. The times that are actually

available may be limited. Rapping systems with pneumatic or electric

actuators allow variations of the rapping intensity. Pneumatic or electric

vibrators allow adjustments of the rapping time. State-of-the-art rapper

controls allow selection of rapping sequences, selection of individual

rappers, and provide anti-coincidence schemes which allow only one

rapper to operate at a given time.

Rapping systems can be optimized for top precipitator performance using

precipitator power input and stack opacity as criteria. Optimization of the rapping

system starts with the discharge electrode rapping system operating on its own

time schedule, for example with repeat times of 2 - 4 minutes. The rapping system

for the gas distribution screens in the inlet and outlet of the precipitator should

then be operated with repeat times of 2-3 minutes for the inlet and 2 - 3 hours for

the outlet screens.

The only rapping system requiring optimization is the collecting plate rapping

system. The optimization should start with the Collecting Plate Rapping Schedule

determined above. Next, the rapping frequency of the inlet field should be

increased or decreased until the electrical power input of the inlet field remains

constant. Next, the rapping frequency of the other fields should be adjusted in

sequence until their electrical power inputs remain constant. If the stack opacity

trace shows rapping spikes, the rapping intensity should be reduced while

observing the electrical power input of the precipitator.

The adjustment of the rapping system for optimum precipitator performance is a

slow process. It requires a substantial amount of time for stabilization after each

adjustment.

About Hoppers (Back to top)

Precipitator hoppers are designed to completely discharge dust load on demand.

Typically, precipitator hoppers are rectangular in cross-section with sides of at

least 60-degree slope. These hoppers are insulated from the neck above the

discharge flange with the insulation covering the entire hopper area. In addition,

the lower 1/4- 1/3 of the hopper wall may be heated. Discharge diameters are

generally 8" - 12".

1. Insulation

Insulation provides protection for facility personnel as well as working

to retain as much hopper wall temperature as possible. Hopper wall

temperature retention discourages condensation on the inside of the

hopper. Heaters are added to ensure hot metal surfaces immediately

above the fly ash discharge.

2. Facilitating hopper discharge

Hopper discharge problems are caused by compaction of the fly ash in

the hopper. Compaction characteristics are affected by moisture content,

particle size and shape, head of material, and vibration. The flow of fly

ash out of the hopper can be facilitated by the use of external vibrators.

These can operate on the outside wall of the hopper or on an internal

hopper baffle.

3. Hopper fluidizers

Hopper fluidizers have a membrane that permits air flow to the fly ash

directly above. This air flow fills the voids between the fly ash particles

at a slight pressure, changes the repose angle of the particles, and

promotes gravity flow.

4. Ash handling system

The fly ash handling system evacuates the fly ash from the hoppers, and

transports the fly ash to reprocessing or to disposal. The ash handling

system should be designed and operated to remove the collected fly ash

from the hoppers without causing re-entrainment into the gas flow

through the precipitator. The design of the ash handling system should

allow for flexibility of scheduling the hopper discharges according to the

fly ash being collected in these hoppers.

Either the precipitator hopper or the feeder hopper is used for temporarily storing

material prior to discharge. Three types of handling systems are in use:

Negative pressure or vacuum system

Connects to the hopper by a simple discharge valve

Positive pressure dilute phase system

Uses an airlock-type feeder; the feeder is separated from the hopper by

an inlet gate and from the conveying line by a discharge gate

Positive pressure dense phase system

Connects to the hopper with an airlock type feeder.

About Ductwork (Back to top)

Ductwork connects the precipitator with upstream and downstream equipment.

The design of the ductwork takes into consideration the following:

Low resistance to gas flow

Achieved by selecting a suitable cross-section for the ductwork and by

installing gas flow control devices, such as turning valves and flow

straighteners

Gas velocity distribution

Gas flow control devices are used to maintain good gas velocity

distribution

Minimal fallout of fly ash

Fallout can be minimized by using a suitable transport velocity

Minimal stratification of the fly ash

A suitable transport velocity also reduces fly ash stratification in the gas

stream

Low heat loss

The goal is to reduce the heat loss of the flue gas to a level that will

prevent acid or moisture condensation in the downstream equipment,

requiring the use of thermal insulation protected by external siding.

Structural integrity

Ductwork structure supports its total load, including wind and snow

loads. The design also allows for accumulated fly ash, negative/positive

operating pressure, and gas temperature. Expansion joints are used to

accommodate thermal growth.

About Gas Velocity Distribution (Back to top)

Efficient precipitator performance depends heavily upon having similar gas

conditions at the inlet of each electrical field or bus section and at the inlet of each

gas passage of the electrical field or bus section. Uniformity of gas velocity is

also desirable - good gas velocity distribution through a precipitator meets these

requirements:

85% of all measured gas velocities < 1.15 times the average gas velocity

99% of all measured gas velocities < 1.40 times the average gas velocity

1. Improving Gas Velocity Distribution

The gas velocity distribution in a precipitator can be customized

according to the design of the precipitator and the characteristics of the

dust particles. Traditionally, precipitators have been designed with

uniform gas velocity distribution through the electrical fields, to avoid

high-velocity areas that would cause re-entrainment. While this is still a

recommended practice, there is an advantage in some cases to

developing a velocity profile that brings more particles closer to the

hopper.

Both of these schemes have applications in site-specific conditions. Gas velocity

distribution can be controlled by the following:

Adding/improving gas flow control devices in the inlet ductwork

Adding/improving flow control devices in the inlet of the precipitator

Adding/improving flow control devices in the outlet of the precipitator

Adding a rapping system to the flow control devices (where applicable)

Adding/improving anti-sneak baffles at the peripheries of the electrical

fields

Adding/improving hopper baffles

Eliminating air leakages into the precipitator

About Re-entrainment (Back to top)

Reducing rapping re-entrainment to an acceptable level generally requires a

substantial improvement of the gas velocity distribution and the electrical power

density and uniformity, as well as an extended optimization program for the

collecting-plate rapping system.

Factors Affecting Re-entrainment

Re-entrainment of collected particles is the major contributor to particulate

emissions of the precipitator. In some cases, re-entrainment accounts for 60 - 80%

of the residual. The major causes of re-entrainment are as follows:

Particles: Low cohesiveness

Low adhesion to collecting plates

Particle size

Low resistivity

Voltage

Controls:

Spark rate setting

Design: Collecting plate design

Discharge electrode design

Plate spacing

Rapping

System:

Frequency

Intensity

Duration (if applicable)

Electrical

Field:

Collecting plate and discharge electrode rapping

Sparking

Saltation

Erosion (localized high gas velocity)

Sneakage

Hopper: Hopper design

Leakage (hopper valve)

Hopper gas flow

About Corona Power (Back to top)

Precipitator corona power is the useful electrical power applied to the flue gas

stream to precipitate particles. Either precipitator collecting efficiency or outlet

residual can be expressed as a function of corona power in Watts/1000 acfm of

flue gas, or in Watts/1000 ft of collection area.

The separation of particles from the gas flow in an electrostatic precipitator

depends on the applied corona power. Corona power is the product of corona

current and voltage. Current is needed to charge the particles. Voltage is needed

to support an electrical field, which in turn transports the particles to the

collecting plates.

In the lower range of collecting efficiencies, relatively small increases in corona

power result in substantial increases in collecting efficiency. On the other hand, in

the upper ranges, even large increases in corona power will result in only small

efficiency increases.

Equally, in the lower range of the corona power levels, a small increase in the

corona power results in a substantial reduction in the gas stream particle content.

In the upper range of the corona power level, a large increase is required to reduce

the particle content.

Optimizing Corona Power

Optimum conditions depend upon the location of the field (inlet, center and

outlet), fly ash characteristics (resistivity) and physical conditions (collecting

plates and discharge wires). Corona power levels can be optimized by adjusting

or optimizing the following:

Gas

velocity:

Uniformity

Fly Ash:

Particle size Resistivity

Voltage

Controls:

Spark rate setting

Current & voltage limits

Design: Plate spacing

Collecting plate & discharge electrode design

Rapping

System:

Frequency & intensity

Support

Insulator:

Purge air system operation

About Performance Improvements (Back to top)

Improvement or optimization of precipitator operation can result in significant

savings. Many specific situations encourage a review of precipitator operation:

Deterioration of existing equipment

Tightening of air pollution emission regulations

Changes in products and/or production rates

Frequent forced outages

De-rating of production

To learn more about performance improvement programs, refer to the appropriate

section:

Gas Velocity Distribution

Corona Power

Re-entrainment

Process Improvements

Flue Gas/Fly Ash Conditioning

Equipment Improvements

Equipment Improvements (Back to top)

The objectives of equipment improvements are to optimize corona power, reduce

re-entrainment, and optimize gas velocity distribution inside the precipitator.

Some important topics to consider when planning equipment improvements

include:

1. Precipitator Size

When sizing the precipitator, it is important to provide a cross-section

that will maintain an acceptable gas velocity. It is also important to

provide for enough total discharge wire length and collecting plate area,

so that the desired specific corona current and electrical field can be

applied.

2. Gas Velocity Distribution

Improving gas velocity distribution in the precipitator reduces particle

re-entrainment and boosts precipitator efficiency. Typically, a uniform

gas velocity is desired, but there are site-specific exceptions. Gas

velocity distribution can be modified by using flow control devices and

baffles. Refer to the special section on gas velocity distribution.

3. Corona Power

The separation of dust particles from the gas flow in an electrostatic

precipitator depends on the applied corona power. Corona power is the

product of corona current and voltage. Current is needed to charge the

particles. Voltage is needed to support an electrical field, which in turn

transports the particles to the collecting plates. For additional

information, refer to Corona Power.

4. Sectionalization

The precipitator is divided into electrical sections that are cross-wise and

parallel to the gas flow to accommodate spatial differences in gas and

dust conditions. Optimization of corona power involves adjusting the

corona power (secondary voltage and current) in each electrical section

for optimum conditions.

5. Particle Re-entrainment

Minimizing re-entrainment of dust particles is important to improvement

of precipitator efficiency. Most precipitator equipment affects the re-

entrainment level. For a detailed discussion, visit the special section on

re-entrainment.

6. Additional Equipment

Performance improvement options include the installation of a second

precipitator in series with the existing precipitator; using fabric filters

downstream of the precipitator; and adding a second particle collector in

parallel with the existing collector. Other possibilities include sonic or

electrostatic particle agglomerators upstream of the precipitator; a

mechanical upstream collector; or an electrostatically-enhanced or

mechanical collector, or a filter downstream of the precipitator.

7. Review the General Equipment Requirements

Reviewing the Neundorfer Knowledge Base sections on equipment will

provide additional insight into performance improvements.

For more information, see these related topics:

Gas Velocity Distribution

Corona Power

Re-entrainment

Discharge Electrodes

Collecting Plates

Power Supplies

Gas Distribution

Rapping Systems

Hoppers and Dust Handling

Ductwork

Combustion Process Improvements for Power Plants (Back to top)

Combustion process conditions mainly affect the corona power level. The

primary contributors to combustion process conditions and their effects include:

Coal

Flue gas flow rate

Flue gas moisture content

Fly ash resistivity

Fly ash inlet loading

Fly ash particle size

Coal mills

Fly ash particle size

Unburned carbon (LOI)

Furnace

Base load/swing load operation

Flue gas flow rate

Burners

Flue gas temperature

Fly ash resistivity

Unburned carbon (LOI)

Air pre-heaters

Rotation

Gas flow pattern

Gas temperature pattern

SO

3

distribution pattern

Coal

Bituminous coals from Eastern mines, sub-bituminous and lignite coals from

Western mines, and lignites from Texas mines are substantially different from

each other in the combustion process. Coal blending is now used for operational

and financial benefits. This results in a wide range of boiler and precipitator

operating conditions.

Precipitating fly ash from difficult coals can be improved with conditioning

systems. However, the furnace and its associated equipment can still cause

problems in the precipitator, particularly coal mills, burners, and air pre-heaters.

Coal Mills

The setting of the coal mills and classifiers defines the coal particle size which in

turn impacts the fly ash particle size. Larger coal particles are more difficult to

combust, but larger fly ash particles are easier to collect in the precipitator.

Furnace

Base-load operation of the boiler is usually better for precipitator operation than

swing-load operation due to more stable operating conditions. Boiler operation at

low loads may be as problematic for the precipitator as operating the boiler at its

maximum load level, due to fallout of fly ash in the ductwork, low gas

temperatures, and deterioration of the quality of the gas velocity distribution.

If low load operation cannot be avoided, the installation of additional gas flow

control devices in the inlet and outlet of the precipitator may prove beneficial.

Coal Burner

The operation of coal burners, together with the setting of the coal mills and their

classifiers, affects the percentage of unburned carbon (LOI or UBC) in the fly

ash. The use of Lo-NOx burners increases this percentage, and causes re-

entrainment and increased sparking in the precipitator. Further, the UBC tends to

absorb SO

3

, which in turn increases the fly ash resistivity. Over-fire air

optimization or coal-reburn systems may reduce UBC in the fly ash.

Air Pre-heater

Regenerative air pre-heaters cause temperature and SO

3

stratification in the

downstream gas flow. This problem is more severe in closely coupled systems,

where the precipitator is located close to the air pre-heater. Depending upon site-

specific conditions, flow mixing devices may be installed in the ductwork to the

precipitator, or flue gas conditioning systems may be used to equalize the gas

flow characteristics.

Fly Ash and Flue Gas Conditioning (Back to top)

Flue gas and fly ash characteristics at the inlet define precipitator operation. The

combination of flue gas analysis, flue gas temperature and fly ash chemistry

provides the base for fly ash resistivity. Typically, fly ash resistivity involves both

surface and volume resistivity. As gas temperature increases, surface conductivity

decreases and volume resistivity increases.

In lower gas temperature ranges, surface conductivity predominates. The current

passing through the precipitated fly ash layer is conducted in a film of weak

sulfuric acid on the surface of the particles. Formation of the acid film (from SO

3

and H

2

O) is influenced by the surface chemistry of the fly ash particles.

In higher gas temperature ranges, volume conductivity predominates. Current

conduction through the bodies (volume) of the precipitated fly ash particles is

governed by the total chemistry of the particles.

Fly ash resistivity can be modified (generally with the intent to reduce it) by

injecting one or more of the following upstream of the precipitator:

Sulfur trioxide (SO

3

)

Ammonia (NH

3

)

Water

Sulfur Trioxide and Ammonia Conditioning Systems

In most cases, a sulfur trioxide conditioning system is sufficient to reduce fly ash

resistivity to an acceptable level. The source of sulfur trioxide can be liquid sulfur

dioxide, molten elemental sulfur, or granulated sulfur. It is also possible to

convert native flue gas SO

2

to SO

3

.

In some instances, ammonia alone has been proven a suitable conditioning agent.

It forms an ammonia-based particulate to increase the space charge. The source of

ammonia may be liquid anhydrous or aqueous ammonia, or solid urea.

Finally, sulfur trioxide and ammonia may be used in combination. This solution

has been successful because it can lower fly ash resistivity and also form

ammonia bisulfate. The latter increases the adhesion of particles, and thus reduces

re-entrainment losses.

Water Injection

The injection of water upstream of the precipitator lowers the gas temperature and

adds moisture to the flue gas. Both are beneficial in cold-side precipitator

applications. However, care must be taken that all of the water is evaporated and

that the walls in the ductwork or gas distribution devices do not get wet.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 1.1 Introduction To Networks - Networks Affect Our LivesDocument2 pagini1.1 Introduction To Networks - Networks Affect Our LivesCristian MoralesÎncă nu există evaluări

- Bentone 30 Msds (Eu-Be)Document6 paginiBentone 30 Msds (Eu-Be)Amir Ososs0% (1)

- Applicants at Huye Campus SiteDocument4 paginiApplicants at Huye Campus SiteHIRWA Cyuzuzo CedricÎncă nu există evaluări

- Competency-Based Learning GuideDocument10 paginiCompetency-Based Learning GuideOliver BC Sanchez100% (2)

- Keya PandeyDocument15 paginiKeya Pandeykeya pandeyÎncă nu există evaluări

- Arizona Supreme CT Order Dismisses Special ActionDocument3 paginiArizona Supreme CT Order Dismisses Special Actionpaul weichÎncă nu există evaluări

- Discursive Closure and Discursive Openings in SustainabilityDocument10 paginiDiscursive Closure and Discursive Openings in SustainabilityRenn MÎncă nu există evaluări

- Week 3 SEED in Role ActivityDocument2 paginiWeek 3 SEED in Role ActivityPrince DenhaagÎncă nu există evaluări

- Geneva IntrotoBankDebt172Document66 paginiGeneva IntrotoBankDebt172satishlad1288Încă nu există evaluări

- Understanding CTS Log MessagesDocument63 paginiUnderstanding CTS Log MessagesStudentÎncă nu există evaluări

- Sop EcuDocument11 paginiSop Ecuahmed saeedÎncă nu există evaluări

- I. ICT (Information & Communication Technology: LESSON 1: Introduction To ICTDocument2 paginiI. ICT (Information & Communication Technology: LESSON 1: Introduction To ICTEissa May VillanuevaÎncă nu există evaluări

- DrugDocument2 paginiDrugSaleha YounusÎncă nu există evaluări

- C.C++ - Assignment - Problem ListDocument7 paginiC.C++ - Assignment - Problem ListKaushik ChauhanÎncă nu există evaluări

- Cib DC22692Document16 paginiCib DC22692Ashutosh SharmaÎncă nu există evaluări

- Circular 09/2014 (ISM) : SubjectDocument7 paginiCircular 09/2014 (ISM) : SubjectDenise AhrendÎncă nu există evaluări

- Difference Between OS1 and OS2 Single Mode Fiber Cable - Fiber Optic Cabling SolutionsDocument2 paginiDifference Between OS1 and OS2 Single Mode Fiber Cable - Fiber Optic Cabling SolutionsDharma Teja TanetiÎncă nu există evaluări

- (Free Scores - Com) - Stumpf Werner Drive Blues en Mi Pour La Guitare 40562 PDFDocument2 pagini(Free Scores - Com) - Stumpf Werner Drive Blues en Mi Pour La Guitare 40562 PDFAntonio FresiÎncă nu există evaluări

- CTS experiments comparisonDocument2 paginiCTS experiments comparisonmanojkumarÎncă nu există evaluări

- ANDRITZ Company Presentation eDocument6 paginiANDRITZ Company Presentation eAnonymous OuY6oAMggxÎncă nu există evaluări

- Novirost Sample TeaserDocument2 paginiNovirost Sample TeaserVlatko KotevskiÎncă nu există evaluări

- Operation Roman Empire Indictment Part 1Document50 paginiOperation Roman Empire Indictment Part 1Southern California Public RadioÎncă nu există evaluări

- Diana's Innermost House: MagazineDocument42 paginiDiana's Innermost House: MagazinealexgoagaÎncă nu există evaluări

- Unit 5 - FitDocument4 paginiUnit 5 - FitAustin RebbyÎncă nu există evaluări

- Pig PDFDocument74 paginiPig PDFNasron NasirÎncă nu există evaluări

- Engine Controls (Powertrain Management) - ALLDATA RepairDocument4 paginiEngine Controls (Powertrain Management) - ALLDATA Repairmemo velascoÎncă nu există evaluări

- MCDO of Diesel Shed, AndalDocument12 paginiMCDO of Diesel Shed, AndalUpendra ChoudharyÎncă nu există evaluări

- Teleprotection Terminal InterfaceDocument6 paginiTeleprotection Terminal InterfaceHemanth Kumar MahadevaÎncă nu există evaluări

- Part I-Final Report On Soil InvestigationDocument16 paginiPart I-Final Report On Soil InvestigationmangjuhaiÎncă nu există evaluări

- Chapter 1: The Investment Environment: Problem SetsDocument5 paginiChapter 1: The Investment Environment: Problem SetsGrant LiÎncă nu există evaluări