Documente Academic

Documente Profesional

Documente Cultură

Kerb Specs

Încărcat de

ganmoses0 evaluări0% au considerat acest document util (0 voturi)

112 vizualizări3 paginiRTA specs for Kerb stone

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentRTA specs for Kerb stone

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

112 vizualizări3 paginiKerb Specs

Încărcat de

ganmosesRTA specs for Kerb stone

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 3

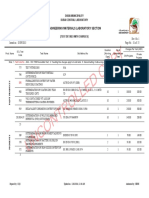

Project R999/1: Jumeirah Creek - Sheikh Zayed Road Crossing

General Specifications Volume 2 Part I

August 2013 Tender Documents Page 5/4

SECTION 5 - ANCILLARY WORKS

5/1 PAVING DESCRIPTION

5/1.1 This work shall consist of covering certain areas (footpaths, parking areas,

etc.) with paving blocks in accordance with the Specifications, the Drawings

and the Engineer's instructions.

5/2 PAVING BLOCKS

5/2.1 Paving blocks shall be concrete blocks, coloured where specified, laid on a

sand laying course. Their thickness shall be 6 cm on sidewalks and 8 cm on

parking areas unless otherwise shown on the Drawings or instructed by the

Engineer.

5/3 OVERALL REQUIREMENTS FOR PAVING BLOCKS

5/3.1 The materials, dimensions and tolerances, test for compressive strength, test

for water absorption and certificate of compliance for paving blocks shall

conform to the requirements of Local Order No. 44/90. Water absorption and

abrasion resistance shall be carried out in accordance with the requirements

of the particular specification.

5/4 BLOCK LAYING REQUIREMENTS

LAYING COURSE

5/4.1 The laying course shall consist of sharp black sand containing not more than

3% material finer than 75 micron by weight and not more than 10% retained

on 4 mm sieve. The sand shall be obtained from a single source, allowed to

drain before use and shall be covered with suitable sheeting to minimize

moisture changes. (Permissible sulphate (as SO3) and chloride (as CL) shall

not exceed 0.3% and 0.5% respectively) (Expressed as a percentage by

weight) when tested to BS EN 1744-1: 1998: and BS 812 Part 117 Appendix C

respectively.

5/4.2 The profile of the laying course before compaction shall be similar to that of

the finished surface. During laying the sand shall be uniform in moisture

content and shall be carefully, screened to form a smooth compacted surface

to receive the paving blocks. The maximum deviation from the design levels

shall be 5 mm.

5/4.3 The edge restraints to the paved area shall be laid in advance of the laying

course and all permanent obstacles within the area, such as manhole covers,

shall be adjusted to the correct finished levels.

Project R999/1: Jumeirah Creek - Sheikh Zayed Road Crossing

General Specifications Volume 2 Part I

August 2013 Tender Documents Page 5/5

SURFACE COURSE

5/4.4 The paving blocks shall be laid on the sand laying course in such manner as

not to disturb the blocks already laid. Each block shall be placed firmly against

its neighbour so that they fit closely together. The joints between blocks shall

not exceed 3 mm. Laying of the paving blocks shall commence at right angles

to the main pavement axis starting at one end of the area. The paving blocks

shall be laid in a herringbone pattern unless otherwise shown on the drawings

or instructed by the Engineer at 45

o

to the main pavement axis.

5/4.5 Where blocks do not fit the edge restraints or other obstructions such as

manholes or upstands the gaps shall be filled using cut blocks.

5/4.6 Blocks shall be cut using only a mechanical block splitter.

5/4.7 Dimensional accuracy, uniformity of joint gaps, alignment and squareness

shall be checked after laying the first three rows of blocks and thereafter at

regular intervals. If joints begin to open the blocks shall be knocked together

using a hide mallet.

5/4.8 After each 20 sq.m. or such area that has been agreed with the Engineer, has

been laid the blocks shall be compacted to the required levels using a plate

vibrator.

5/4.9 The plate vibrator shall have a plate area of 0.20 to 0.35 sq.m. and have a

compaction force of 12-24 Kn and a frequency of approximately 75 to 100 Hz.

5/4.10 A minimum of two passes of the plate vibrator shall be made in each direction,

i.e. at 90 degrees to each other. Vibration shall continue until no further

compaction of the sand layer is apparent. The laying course shall have a

compacted thickness of 50 mm. Fine dry sand with a particle size of 0.3mm

shall then be brushed over the paving, and further passes of the plate vibrator

made in each direction, until the sand is no longer absorbed into the joints.

5/4.11 The plate vibrator shall not pass closer than 1 m to a temporarily unrestrained

edge during laying.

5/4.12 No paving shall be left uncompacted overnight except for the 1 m strip at the

temporarily unrestrained edge.

5/4.13 On completion, the finished surface level, shall be within 5 mm of the design

level and the maximum deviation within the compacted surface, measured by

a 3 m straight edge shall not exceed 3 mm. The level of any two adjacent

blocks shall not differ by more than 1 mm. Any areas of paving which do not

comply with these tolerances shall be removed, the sand laying course

adjusted and the paving blocks relaid to the correct levels.

5/5 KERBS DESCRIPTION

5/5.1 This work shall consist of the construction of kerbs in accordance with the

Specifications and in conformity with the lines, grades and typical sections

shown on the Drawings or established by the Engineer. These Specifications

refer to the following types of precast kerbs to be constructed: Non-Mountable

Project R999/1: Jumeirah Creek - Sheikh Zayed Road Crossing

General Specifications Volume 2 Part I

August 2013 Tender Documents Page 5/6

Kerbs, Dropped Kerb, Heel Kerb, Quadrants and Flush Kerb. All Kerbs and

edgings shall be hydraulically pressed and shall comply with the requirements

of BS 7263: 2001 Part 1. They shall be uniform in colour, free from cracks,

flaws or other defects and they shall have well defined arises.

5/6 MATERIALS AND MANUFACTURE OF KERBS

5/6.1 Materials shall conform to the requirements specified in Part 4 "Concrete" of

the Specifications and as specified herein.

5/6.2 Kerbs shall be prepared with a concrete mixture containing not less than 400

Kg/m3 of Sulphate Resisting Portland Cement. The aggregate shall meet the

requirements of the General Specifications for concrete work.

5/6.3 Deleted.

5/6.4 Non-Mountable Kerb, Dropped Kerb, Flush Kerb and Heel Kerb elements shall

only be precast from concrete produced in a fully automatic batching plant.

Sampling shall be done as per BS 7263 : 2001 : Part 1 : latest edition.

5/6.5 Deleted.

5/6.6 The Consultant shall collect samples as per standard sampling method and

submit them for testing. All results shall pass before commencing this work.

5/6.7 Elements shall be manufactured to the dimensions shown on the Drawings.

5/6.8 Non-Mountable and Dropped Precast Kerbs shall be formed by elements

900 mm long where required to be laid in straight lines but may be reduced to

250 mm long or curved kerbs shall be used where required to be laid to curves

depending on the radii of the curves.

5/6.9 The finished product shall be of solid appearance with clean planar faces, be

free of segregation, honeycombing, pits, broken corners or other defects and

there shall be no evidence of external rendering.

5/6.10 Bull noses and curved faces shall be of constant radius with a smooth change

from radius to plain face.

5/6.11 Tolerances of manufacture shall be three (3) millimetres in any one dimension

and end faces shall be truly perpendicular to the base.

5/6.12 Transverse strength and water absorption requirements shall be in

accordance with BS 7263 : 2001 Part 1 latest edition.

5/7 KERB LAYING

5/7.1 Elements shall be set to the lines and grades shown on the Drawings. Under

no circumstances will it be permitted for levels to be set by direct

measurement from pavement layers.

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Bearing Capacity of SoilsDocument138 paginiBearing Capacity of SoilsMuqeem Khan100% (1)

- Angle of Repose & Angle of FrictionDocument4 paginiAngle of Repose & Angle of Frictionganmoses50% (2)

- SSINA - Designer's Handbook - Stainless Steel FastenersDocument23 paginiSSINA - Designer's Handbook - Stainless Steel FastenersSerguei DobrinÎncă nu există evaluări

- Thomsen, Wallace - 1995 - Displacement Based Design of Reinforced Concrete Structural Walls An Experimental Investigation of Walls With - YazıDocument375 paginiThomsen, Wallace - 1995 - Displacement Based Design of Reinforced Concrete Structural Walls An Experimental Investigation of Walls With - YazıÖzlem Temel YalçınÎncă nu există evaluări

- BoilersDocument47 paginiBoilersAshish RawatÎncă nu există evaluări

- JKR 2012 SITE INVESTIGATION SCHEDULE OF RATESDocument0 paginiJKR 2012 SITE INVESTIGATION SCHEDULE OF RATESAjoy Zulfadhli0% (1)

- sp001 5thedition ChecklistsDocument14 paginisp001 5thedition ChecklistsJavier Mauricio Higuera MoraÎncă nu există evaluări

- FPI FiberglassbookDocument164 paginiFPI FiberglassbookA_ValsamisÎncă nu există evaluări

- Road Geometric Design Manual PDFDocument690 paginiRoad Geometric Design Manual PDFganmosesÎncă nu există evaluări

- Soil Compaction Earthworks - Notes PDFDocument47 paginiSoil Compaction Earthworks - Notes PDFGnabBangÎncă nu există evaluări

- Admixtures in ConcreteDocument15 paginiAdmixtures in ConcreteSundara LingamÎncă nu există evaluări

- A4 80Document2 paginiA4 80alwezalokÎncă nu există evaluări

- A4 80Document2 paginiA4 80alwezalokÎncă nu există evaluări

- GMP For HvacDocument21 paginiGMP For HvacOmar BaroudiÎncă nu există evaluări

- IC - B1 - SW - SP03 - v1.0 - Week 3Document4 paginiIC - B1 - SW - SP03 - v1.0 - Week 3ganmoses100% (2)

- Arihant - Mat Solvedpaper 2012Document26 paginiArihant - Mat Solvedpaper 2012Extra MarksÎncă nu există evaluări

- Specifications Part1Document3 paginiSpecifications Part1ganmosesÎncă nu există evaluări

- Geogroup Company, Soil Investigation, Geogroup Laboratory, Soil Mechanics Testing PDFDocument115 paginiGeogroup Company, Soil Investigation, Geogroup Laboratory, Soil Mechanics Testing PDFChan Hoi KitÎncă nu există evaluări

- 002 Waterstop FactsDocument0 pagini002 Waterstop FactsganmosesÎncă nu există evaluări

- Heavy PlatesDocument41 paginiHeavy PlatesganmosesÎncă nu există evaluări

- Admixtures For ConcreteDocument4 paginiAdmixtures For ConcreteMuhammad Shahbaz KhokharÎncă nu există evaluări

- 316 316L Data SheetDocument2 pagini316 316L Data SheetHanna ChanÎncă nu există evaluări

- Epoxy or Polyurethane Foam?: Stories and Photos by Jay SchmidDocument4 paginiEpoxy or Polyurethane Foam?: Stories and Photos by Jay SchmidganmosesÎncă nu există evaluări

- 316 316L Data Bulletin PDFDocument0 pagini316 316L Data Bulletin PDFRKLNÎncă nu există evaluări

- Aalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFDocument3 paginiAalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFganmosesÎncă nu există evaluări

- Underpass DWGDocument1 paginăUnderpass DWGganmosesÎncă nu există evaluări

- DCL Test ChargesDocument1 paginăDCL Test ChargesganmosesÎncă nu există evaluări

- SpeedyDocument4 paginiSpeedyBudhi KurniawanÎncă nu există evaluări

- GeoMatt Datasheet TB11 Ed1 2017 ASTM ADDocument1 paginăGeoMatt Datasheet TB11 Ed1 2017 ASTM ADganmosesÎncă nu există evaluări

- GeoMatt Datasheet TB11 Ed1 2017 ASTM ADDocument1 paginăGeoMatt Datasheet TB11 Ed1 2017 ASTM ADganmosesÎncă nu există evaluări

- Nitomortar FC PDFDocument2 paginiNitomortar FC PDFganmosesÎncă nu există evaluări

- Grain Size AnalysisDocument5 paginiGrain Size AnalysisganmosesÎncă nu există evaluări

- Conventional AC DesignDocument42 paginiConventional AC Designabdikarim_omarÎncă nu există evaluări

- DG3 Sheeting PDFDocument8 paginiDG3 Sheeting PDFganmosesÎncă nu există evaluări

- 42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Soba Za IgruDocument2 pagini42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Soba Za Igruvelikimag87Încă nu există evaluări

- Diagram of The HouseDocument16 paginiDiagram of The HouseBeatriz OliveiraÎncă nu există evaluări

- Matrial ListDocument1 paginăMatrial ListRukksana SayyedÎncă nu există evaluări

- Machine Elements Design QuestionsDocument20 paginiMachine Elements Design QuestionsArjun Arumugaswamy100% (4)

- Computational Fluid Dynamics Simulation of The Progress of Fire Smoke in Large Space, Building AtriaDocument7 paginiComputational Fluid Dynamics Simulation of The Progress of Fire Smoke in Large Space, Building AtriaAravind KumarÎncă nu există evaluări

- Bypass Thermostats: Installation InstructionsDocument1 paginăBypass Thermostats: Installation InstructionsBassieÎncă nu există evaluări

- Tricocat PDFDocument44 paginiTricocat PDFJuan PabloÎncă nu există evaluări

- TDS - Bronco Pre HDPE Membrane (S)Document3 paginiTDS - Bronco Pre HDPE Membrane (S)Shreyansh UdaniÎncă nu există evaluări

- Ga Marta ViewDocument188 paginiGa Marta ViewAndes PutraÎncă nu există evaluări

- 1.1 General Background: Seminar Report 2021Document20 pagini1.1 General Background: Seminar Report 2021Classic PrintersÎncă nu există evaluări

- CVE4002 Lecture 05 Timber FramingDocument67 paginiCVE4002 Lecture 05 Timber FramingKeith YangÎncă nu există evaluări

- Material PTFE PT009807: Technical Data Sheet in Accordance With ASTMDocument2 paginiMaterial PTFE PT009807: Technical Data Sheet in Accordance With ASTMCAT CYLINDERÎncă nu există evaluări

- Proper Maintenance of InstrumentsDocument92 paginiProper Maintenance of InstrumentsDimi DimoÎncă nu există evaluări

- Econax General CatalogueDocument28 paginiEconax General CataloguePRISHA A/P STEVEN MoeÎncă nu există evaluări

- Carbothane 134 HG PDSDocument4 paginiCarbothane 134 HG PDSTeknik produksi wikonÎncă nu există evaluări

- Etabs 20.3 Segmented GRDocument2 paginiEtabs 20.3 Segmented GRHjshj ShjhjÎncă nu există evaluări

- QCD Fire Pump Check ListDocument3 paginiQCD Fire Pump Check ListAnoirÎncă nu există evaluări

- Pawling - Entrance MatsDocument12 paginiPawling - Entrance Matsmk779900mkÎncă nu există evaluări

- Code of Pactice For Dead and Imposed Loads 2011Document30 paginiCode of Pactice For Dead and Imposed Loads 2011iyhkÎncă nu există evaluări

- Fuse in XpandercrossDocument16 paginiFuse in XpandercrossMUHAMMAD IKHWANUDINÎncă nu există evaluări

- DATA BOOK FOR CONSTRUCTION PROJECTSDocument66 paginiDATA BOOK FOR CONSTRUCTION PROJECTSvishnukesavieam10% (1)

- 2000 IBC Handbook Seismic & WindDocument11 pagini2000 IBC Handbook Seismic & WindcristinelbÎncă nu există evaluări

- F7az Em12kDocument1 paginăF7az Em12kKara WhiteÎncă nu există evaluări

- Asphalt DistressesDocument31 paginiAsphalt DistressesWillard Apeng100% (1)

- Cassette Inverter (2020) Technical Specification SheetDocument1 paginăCassette Inverter (2020) Technical Specification SheetOwais AhmedÎncă nu există evaluări