Documente Academic

Documente Profesional

Documente Cultură

1947 54 Chevrolet IFS Kit

Încărcat de

Alonso Ibarra0 evaluări0% au considerat acest document util (0 voturi)

23 vizualizări13 paginiThe 2 1947-54 Chevrolet IFS Kit 2 / 1 / 2013 rev0 is the finest IFS kit available for 1947-54 chevy pickups with stock frames. The lower assembly has the IFS crossmember, frame boxing plates, and motor mounts welded as one unit. The upper control arm towers locate the upper control arms and coilovers.

Descriere originală:

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThe 2 1947-54 Chevrolet IFS Kit 2 / 1 / 2013 rev0 is the finest IFS kit available for 1947-54 chevy pickups with stock frames. The lower assembly has the IFS crossmember, frame boxing plates, and motor mounts welded as one unit. The upper control arm towers locate the upper control arms and coilovers.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

23 vizualizări13 pagini1947 54 Chevrolet IFS Kit

Încărcat de

Alonso IbarraThe 2 1947-54 Chevrolet IFS Kit 2 / 1 / 2013 rev0 is the finest IFS kit available for 1947-54 chevy pickups with stock frames. The lower assembly has the IFS crossmember, frame boxing plates, and motor mounts welded as one unit. The upper control arm towers locate the upper control arms and coilovers.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 13

1

1947-54 Chevrolet IFS Kit 2/1/2013 Rev0

1947-54 Chevrolet 3100 IFS Kit

Congratulations on your purchase on what we believe is the finest IFS kit available for 1947-54

Chevrolet pickups with stock frames. We have invested many hours into designing a kit that

will be effective, easy to install, and offer years of dependable service and deliver excellent

drivability. To ensure a smooth installation, please read these instructions carefully dont

forget to measure twice and cut once. If you have any questions about the installation, please

give us a call.

Main Kit Components

1. Lower assembly: This assembly has the IFS crossmember, frame boxing plates, and

motor mounts welded as one unit. With all these components welded together, engine

placement is pre-configured and the frame is strengthened where it needs to be. The

2

1947-54 Chevrolet IFS Kit 2/1/2013 Rev0

stock core support will locate the front/rear location of this assembly, which ensures the

wheelbase will be within specifications.

2. Upper Control Arm Towers: These assemblies locate the upper control arms and

coilovers. A jig is provided to ensure these are accurately located on the frame.

3. Sway bar mounting plates: These plates will weld to the bottom of the frame rail and

provide threaded holes for the sway bar brackets.

Installation

1. If possible, it is advisable to start with a clean frame that has been degreased and

sandblasted.

2. Remove front shock mounts and both front and rear leaf shackle hangers (front hanger is

an iron casting inside the frame rail). These items are riveted from the factory and can be

removed by grinding the rivet heads or using an air hammer with a chisel attachment. The

rivet shank can then be removed with a punch and hammer.

3. The original front engine mount crossmember may remain in place, however, the lower

webbing that joins the crossmember to the frame rails must be removed so tab A (see

figure 1) on the lower assembly box plates sits flush against the original engine mount

crossmember. Some frames may have a wider lower frame rail flange that must also be

trimmed up to the engine crossmember as shown in figure 2. The width of the lower

flange must match the upper flange, which is about 2-1/4.

Figure 1 - Box Plate Tabs

3

1947-54 Chevrolet IFS Kit 2/1/2013 Rev0

Figure 2 - Flange Trimming View from Bottom

4

1947-54 Chevrolet IFS Kit 2/1/2013 Rev0

4. Slide the lower assembly into place with tab A (shown in figure 1) resting against the

original engine mount crossmember. The top face of the 2x4 IFS crossmember flange

should rest against the frame rail bottom. Please note figure 3, where the inside upper rail

surface may need to be notched slightly for the boxing plates to slide in due to variances in

the original frame. Please note the engine mounts are tacked to the 2x4 crossmember and

not the boxing plates; this allows the boxing plates to move as needed without effecting

the engine mount placement.

Figure 3 - Notch inside rail as required

5

1947-54 Chevrolet IFS Kit 2/1/2013 Rev0

5. Verify correct front-to-rear location by measuring the distance between the front leaf

hanger hole and front of 2x4 IFS crossmember. The correct location should be

approximately 17-1/4, plus or minus 1/8. See figure 4. If the location is correct, tack

weld the boxing plates into place.

Figure 4 - Verifying Correct Location View from LH Side

6

1947-54 Chevrolet IFS Kit 2/1/2013 Rev0

6. Using the boxing plates as a template, mark the rail where cuts need to be made for

steering rack clearance. Cut the rail with any desired method, and insert supplied half

rounds and tack into place. Keep in mind the circular cutouts must be perpendicular to

the vehicle centerline and not the outside rail face (which is at a 4 degree angle to the

vehicle centerline). Use a straightedge to make sure your layout lines line up with each

other as in figure 5.

Figure 5 - Rack clearance cutouts View from Bottom

7

1947-54 Chevrolet IFS Kit 2/1/2013 Rev0

7. Bolt the supplied upper tower jig to the IFS crossmember as shown in figure 6, then bolt

the upper towers to the jig.

Figure 6 - Upper Tower Jig Placement - View from LH Side

8. Check the gap between the tower assembly and frame rail. For best weld penetration, it is

advisable to have a small gap between the two components, at least the thickness of MIG

welding wire. Grind the upper tower if necessary. If the fit is satisfactory, begin tack

welding the upper towers to the frame rail.

8

1947-54 Chevrolet IFS Kit 2/1/2013 Rev0

9. Place the threaded sway bar mounting plates in the position shown in figure 7 and mark

the hole centers on the frame rail. Remove the mount plates and drill the frame rail at the

marked locations with a 7/16 or larger drill bit to allow the bolt to pass through the frame

rail when fastening the sway bar bushing bracket. Place the sway bar mount plates back

into position and weld into place.

Figure 7 - Sway Bar Mount Plate Locations View from Bottom

9

1947-54 Chevrolet IFS Kit 2/1/2013 Rev0

10. The engine mount plates are heavily tacked to the 2x4 crossmember, preventing them

from moving during final welding. However, if there is some concern of the engine mount

bosses not maintaining their 16.5 width, simply use a piece of angle iron drilled at 16.5

and bolt securely to the mounting bosses. Before final welding, tack the engine mount

plates to the boxing plates.

Figure 8 - Checking Motor Mount Width View from Front

11. When you are satisfied with the overall fit and finish, you can now fully weld all

components to the frame.

Assembly

1. Using table 1 as a guide, attach the upper and lower control arms with their respective

fasters to the threaded bosses. While both upper control arms are the same, the lowers

are not. Orientate the lower control arm such the 3/8 threaded boss (which attaches

to the sway bar linkage) points forward. Do not tighten the bolts.

2. Attach the spindle to the ball joints. Orientate the spindle such the larger taper boss

connects to the lower ball joint (see figure 10 for a reference picture). Tighten the

castle nuts until snug.

3. Insert the coilover mockup jig into place and temporarily attach with the hardware

listed in table 1. This will keep the spindle at approximately the proper ride height

through the rest of the build process.

10

1947-54 Chevrolet IFS Kit 2/1/2013 Rev0

4. Attach the steering rack to the crossmember, and snug the bolts. Be sure the rack is

centered in its travel, and mark the pinions location on the casting so this point can be

referenced later.

5. Thread the outer tie rod onto the inner tie rod shaft, then connect the outer tie rod to

the spindle steering arm and snug the castle nut. Repeat for the opposite side.

6. Roughly align the camber and toe, with the chassis sitting level, using the following

methods:

a. Adjust the camber first by adjusting the tie rod until the spindle is steering

approximately straight. Place a level on a vertical machined surface on the

spindle and adjust the upper control arm rod ends equally until the spindle is

vertical, or 0 degrees camber. Repeat for the opposite side

b. Adjust toe by clamping a straightedge to both spindles as in figure 9. Adjust the

tie rods until measurement A matches measurement B; at this point the spindles

are parallel with each other. Now the thrust angle can be set, which means the

tires will roll in a direction parallel to the vehicle centerline. To do this, take a

straight-line measurement from the tip of the straightedge to a known point that

resides on the vehicle centerline (the middle slots in the core support work well).

As in figure 9, adjust the left and right tie rods equally until measurement C equals

measurement D. When completed, double check that measurement A matches B

and adjust if necessary.

At the point the alignment is close and the vehicle can be driven to a shop for the final

alignment. Refer to table 2 for final alignment specifications.

7. When the vehicle is ready to be driven, remove the coilover mockup jig and bolt in the

coilover assembled with springs, with the valve adjuster facing the outside of the

vehicle. With the vehicle on the ground, adjust the spanner nuts until the coilover

length is approximately 13-1/4. At this point the control arm bolts may be tightened to

the specifications shown on table 1. After the vehicle has been driven for several miles,

the spanner nuts may need to be re-adjusted as the springs settle and control arm bolts

can be checked for proper torque.

11

1947-54 Chevrolet IFS Kit 2/1/2013 Rev0

Figure 9 Basic Toe Alignment

Figure 10 - Ride Height Specifications

12

1947-54 Chevrolet IFS Kit 2/1/2013 Rev0

Figure 11 - Ride Height Specifications Spindle C/L to Frame Bottom

Table 1 - Fastener Torque Specifications

Size Thread Pitch Type Torque Lubrication

LCA Pivot 5/8 NF CS 79 Anti-seize

UCA Pivot 1/2 NF CS 38 Anti-seize

Upper C/O 1/2 NF CS 35

Lower C/O 1/2 NF SHCS 20 Anti-Seize

Sway Bar

Frame Brackets 3/8 NC CS 20

Lower Link 3/8 NF CS 20

Steering Rack 5/8 NF CS 56

Ball Joint

Upper 9/16 NF Slot Nut 75-90

Lower 9/16 NF Slot Nut 75-90

Tie Rod 1/2 NF Slot Nut 50

Fastener Data

L

o

c

a

t

i

o

n

Table 2 - Alignment Specifications

Suspension Type Toe (Inches) Camber (Deg.) Caster (Deg.)

Deluxe IFS 1/32 to 1/16 (In) 0 to -0.25 +1.5 to +3.0

Alignment Guide

13

1947-54 Chevrolet IFS Kit 2/1/2013 Rev0

Figure 12 - RH Reference Photo

S-ar putea să vă placă și

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

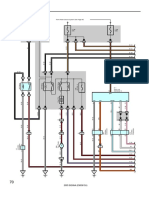

- AODE-4R75E VacTest PDFDocument2 paginiAODE-4R75E VacTest PDFAlonso IbarraÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Fusesdiagram Com Audi Fuses and Relay Audi A3 8p HTMLDocument54 paginiFusesdiagram Com Audi Fuses and Relay Audi A3 8p HTMLAlonso Ibarra100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Build A Bicycle FrameDocument42 paginiBuild A Bicycle FrameAlonso IbarraÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- 2006 Nissan X Trail 38615Document50 pagini2006 Nissan X Trail 38615Alonso IbarraÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- 2006 Nissan X Trail 38615Document50 pagini2006 Nissan X Trail 38615Alonso IbarraÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Fusesdiagram Com Audi Fuses and Relay Audi A3 8p HTMLDocument54 paginiFusesdiagram Com Audi Fuses and Relay Audi A3 8p HTMLAlonso Ibarra100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- 09 Fuses and Circuit Brakers SedanDocument25 pagini09 Fuses and Circuit Brakers SedanAlonso Ibarra100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- 44re DodgeDocument1 pagină44re DodgeAlonso IbarraÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Color Change Rotary SW To Absolute Encoder 0011 TTD 2000 10 PDFDocument16 paginiColor Change Rotary SW To Absolute Encoder 0011 TTD 2000 10 PDFAlonso IbarraÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Building An Electronic Fuel Injector Tester HACK A WEEKDocument5 paginiBuilding An Electronic Fuel Injector Tester HACK A WEEKAlonso IbarraÎncă nu există evaluări

- 20150226035204english Manual of SKU192807Document4 pagini20150226035204english Manual of SKU192807Alonso IbarraÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Solar Powered Bio-Diesel RefineryDocument3 paginiSolar Powered Bio-Diesel RefineryIstarted JokeÎncă nu există evaluări

- Wind Turbine Blade AerodynamicsDocument10 paginiWind Turbine Blade AerodynamicsMahesh MunjalÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Pompa GrundfosDocument145 paginiPompa GrundfosIulian IonÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Tips For Minimizing Embroidery Interruptions 2-11-10Document7 paginiTips For Minimizing Embroidery Interruptions 2-11-10Nit VictorÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- WWW Columbiacoatings Com Basic Instructions Aspx PDFDocument3 paginiWWW Columbiacoatings Com Basic Instructions Aspx PDFAlonso IbarraÎncă nu există evaluări

- Conectando Dos CompresoresDocument5 paginiConectando Dos CompresoresAlonso IbarraÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Industry POWDER COAT Glossary - PDFDocument10 paginiIndustry POWDER COAT Glossary - PDFAlonso IbarraÎncă nu există evaluări

- Tdi Injectors Clening UpDocument13 paginiTdi Injectors Clening UpAlonso IbarraÎncă nu există evaluări

- 2012 Elixir™ 3 - Elixir 1 Service ManualDocument31 pagini2012 Elixir™ 3 - Elixir 1 Service Manualchrisban35Încă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- 2012 Elixir™ 3 - Elixir 1 Service ManualDocument31 pagini2012 Elixir™ 3 - Elixir 1 Service Manualchrisban35Încă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- 2005 Sienna PDFDocument14 pagini2005 Sienna PDFAlonso IbarraÎncă nu există evaluări

- FordPickup1948 56Document108 paginiFordPickup1948 56Alonso IbarraÎncă nu există evaluări

- 2012 Elixir™ 3 - Elixir 1 Service ManualDocument31 pagini2012 Elixir™ 3 - Elixir 1 Service Manualchrisban35Încă nu există evaluări

- Hobart 210 Ironman PDFDocument56 paginiHobart 210 Ironman PDFAlonso IbarraÎncă nu există evaluări

- Universal Stand For Vehicle Engines and Gearboxes - Google PDocument11 paginiUniversal Stand For Vehicle Engines and Gearboxes - Google PAlonso IbarraÎncă nu există evaluări

- Prices Lista de Precios Powder CoatDocument3 paginiPrices Lista de Precios Powder CoatAlonso IbarraÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- TRASH - Playbook - Dust 2 (01-20-19) PDFDocument5 paginiTRASH - Playbook - Dust 2 (01-20-19) PDFAnonymous 9ctaftÎncă nu există evaluări

- Amal Piccolo Class 9 - 30Document2 paginiAmal Piccolo Class 9 - 30bartsten333Încă nu există evaluări

- Asia Review Domingo With Cover Page v2Document21 paginiAsia Review Domingo With Cover Page v2Gintoki SakataÎncă nu există evaluări

- Color Monitor: Service ManualDocument20 paginiColor Monitor: Service Manualmalord958Încă nu există evaluări

- D V D FilmeleDocument10 paginiD V D FilmeleEddy MurariuÎncă nu există evaluări

- Transposing Instruments - Music TheoryDocument1 paginăTransposing Instruments - Music Theorygiorgio planesio100% (1)

- Bang - Olufsen - Beocenter 8000 8500 9000 9300 9500 Receiver Upgrade RepairDocument5 paginiBang - Olufsen - Beocenter 8000 8500 9000 9300 9500 Receiver Upgrade RepairMarco PastabluesÎncă nu există evaluări

- Chicken Curry: IngredientsDocument6 paginiChicken Curry: IngredientsMary Ann PateñoÎncă nu există evaluări

- Interchange 5th Edition Level 1 Quiz Units 9 and 10Document2 paginiInterchange 5th Edition Level 1 Quiz Units 9 and 10Eduardo Allgayer89% (36)

- Super ComputersDocument9 paginiSuper Computers/ditya JadhavÎncă nu există evaluări

- OAWeberrataDocument4 paginiOAWeberrataDayner Ruiz AvilesÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Music 9 Q3 SLM 6Document16 paginiMusic 9 Q3 SLM 6Paolo BrequilloÎncă nu există evaluări

- DramaturgyDocument3 paginiDramaturgytanusreeghoshÎncă nu există evaluări

- Guitar Fretboard WorkbookDocument80 paginiGuitar Fretboard WorkbookCarlson SiuÎncă nu există evaluări

- World of Darkness FirearmsDocument23 paginiWorld of Darkness FirearmsPreston Halcomb67% (9)

- Osram HBO Super Pressure Mercury Lamps Catalog 1977Document8 paginiOsram HBO Super Pressure Mercury Lamps Catalog 1977Alan MastersÎncă nu există evaluări

- 13 Oct VRC Hotel Reservation InformationDocument2 pagini13 Oct VRC Hotel Reservation InformationMisa AjversonÎncă nu există evaluări

- Web KameraDocument20 paginiWeb KameraDjerdj F. LazarÎncă nu există evaluări

- MrtlistDocument141 paginiMrtlistManish sharmaÎncă nu există evaluări

- Aparna Daundkar-Shinde - LinkedInDocument4 paginiAparna Daundkar-Shinde - LinkedInMH MÎncă nu există evaluări

- AC-525 Hardware Installation and User Guide 180608Document52 paginiAC-525 Hardware Installation and User Guide 180608Ulises González SeguraÎncă nu există evaluări

- Principles of MKTNG Q4 Module 2 For StudentsDocument15 paginiPrinciples of MKTNG Q4 Module 2 For StudentsRich Allen Mier UyÎncă nu există evaluări

- Descriptive Text ExamplesDocument3 paginiDescriptive Text ExamplesWilis Anisa LaksmiÎncă nu există evaluări

- Cpar ReviewerDocument7 paginiCpar ReviewerAngela Marie CenaÎncă nu există evaluări

- Badminton SafetyDocument4 paginiBadminton SafetyGrace Suzette ChiPandaÎncă nu există evaluări

- Bs en 485-4 1994 Gruix Tolerancies AluminiDocument6 paginiBs en 485-4 1994 Gruix Tolerancies AluminiAlbert Solsona100% (1)

- Week 2 Welcome To The Lord's TableDocument10 paginiWeek 2 Welcome To The Lord's TableShower of RosesÎncă nu există evaluări

- Garden PlansDocument6 paginiGarden PlansRoberto LandaÎncă nu există evaluări

- ApplicationDocument30 paginiApplicationAshat HaqÎncă nu există evaluări

- American English File 1-Writing and Speaking Questions: The Questions Are The Same As Speaking PartDocument6 paginiAmerican English File 1-Writing and Speaking Questions: The Questions Are The Same As Speaking PartIsmael Shahamat100% (1)

- The Darkest White: A Mountain Legend and the Avalanche That Took HimDe la EverandThe Darkest White: A Mountain Legend and the Avalanche That Took HimEvaluare: 4 din 5 stele4/5 (1)

- Training for the Uphill Athlete: A Manual for Mountain Runners and Ski MountaineersDe la EverandTraining for the Uphill Athlete: A Manual for Mountain Runners and Ski MountaineersEvaluare: 4.5 din 5 stele4.5/5 (8)

- Strong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerDe la EverandStrong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerEvaluare: 4 din 5 stele4/5 (5)

- Training for the Uphill Athlete: A Manual for Mountain Runners and Ski MountaineersDe la EverandTraining for the Uphill Athlete: A Manual for Mountain Runners and Ski MountaineersEvaluare: 5 din 5 stele5/5 (13)