Documente Academic

Documente Profesional

Documente Cultură

Bus Superstructure

Încărcat de

Kabilan MuthukannanDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Bus Superstructure

Încărcat de

Kabilan MuthukannanDrepturi de autor:

Formate disponibile

G.U.

Journal of Science

23(1): 71-79 (2010)

www.gujs.org

Corresponding author: turgut.gursel@ege.edu.tr

Analysis of the Superstructure of a Designed Bus

in Accordance with Regulations ECE R 66

K. Turgut GRSEL

1

, Serap GRSESL

1

1

Ege University, Faculty of Engineering, Department of Mechanical Engineering, zmir, Turkey

Received: 18.02.2009 Revised: 28.04.2009 Accepted: 13.05.2009

ABSTRACT

Compliance with certain technical standards and requirements in designing and producing vehicles is necessary

for vehicle manufacturers. Within this scope, Regulation ECE R 66 Large Passenger Vehicles - The Strength

of the Superstructures was studied in this investigation regarding the Motor Vehicles Type Approval

Directive. A finite element model of the superstructure of a designed bus was created and analysed according

to ECE R 66 requirements and the results were compared with the test results of a section of the bus

superstructure.

Key Words: Bus, Superstructure, Roll-over test, ECE R 66 Regulations, Finite element analysis

1. INTRODUCTION

In this study, a section of the superstructure of a

designed bus was modelled with the software CATIA

by means of investigating the Regulation ECE R 66

concerning the superstructure strength of passenger

transportation vehicles. The model was analyzed using

the finite element method. In solution, the

displacements and the deformations at the joints were

examined and the results were compared with those of

the roll-over test performed according to the conditions

of the regulations [1, 2].

Despite the fact that intensive investigations are carried

out on this subject, due to commercial competition and

consequent secrecy, few papers are available. Abe et al

[3] simulated the three-dimensional behaviour of two

vehicles at collision using dynamic models numerically

and compared the calculated results with real vehicles

collision test data in their study.

Takubo and Mizuno [4] analyzed sport utility vessel

(SUV) accidents using statistics and the case study

method accessing a national accident database and

detailed accident investigative data. Among the case

studies, one rollover accident was analyzed.

The study of Parenteau et al [5] was to estimate the

distribution of rollover accidents occurring in the field

and to compare the vehicle kinematics in the

predominant field crash modes with available

laboratory tests. For this purpose, the authors analyzed

US accident data to identify types and circumstances of

accidents for vehicle rollovers.

Eger and Kiencke [6] investigated the influence of

various parameters and their variations on rollover

accidents in their study in order to show that even

simple models could deliver important properties of

vehicle rollover.

Dias and et al in [7] present a new method for

predicting the rollover limit of buses, based on a

theoretical model and dynamics test. These tests

performed on the road under real conditions and the

developed mathematical model should be able to

predict a reliable rollover limit of a bus.

Castejon and et al [8] exhibit a developed simulation

technique for the rollover test of buses, which is applied

to a new concept of lightweight bus wholly made of

composites. After the rollover simulations based on this

developed technique are applied to the composite bus, a

prototype of the bus was built and tested.

72 G.U. J. Sci.,23(1):71-79 (2010)/ K. Turgut GRSEL

1

, Serap GRSESL

1

Hoskins and El-Gindy in [9] perform a simulation of an

FMVSS 208 rollover dolly test of a generic pickup

truck model. They use data from published real-world

rollover dolly tests of large passenger cars to validate

the simulations, and the pickup truck model having

properties similar to that of the cars used by other

researchers in their rollover tests. The vehicle dynamic

responses during the rollovers and the simulation were

analyzed and compared with each other.

Renfroe and et al [10] develop a simple technique to

evaluate the limits of the roll characteristics of a

vehicle. The analysis enables quantification of the

effects of springs, dampers, roll centre location, masses

and centre of gravity locations on the propensity to roll

under the on-road manoeuvre conditions.

Dahlberg and Stensson in [11] present a method to

determine dynamic rollover threshold of heavy trucks

and apply a parameter sensivity study. They investigate

the influences on the steady-state rollover threshold and

dynamic rollover threshold from roll stiffnesses and roll

centre heights.

Koppel and et al [12] aim in their study to determine,

how important vehicle safety is in the new vehicle

purchase process. They find out that the consumers

recently rank safety-related factors (e.g. EuroNCAP

safety ratings, advanced breaking systems, front

passenger airbags, etc) as more important than non-

safety-related features such as price, reliability,

navigation systems etc.

Kwasniewski and et al in [13] describe an assessment

program for paratransit buses concerning their

crashworthiness and safety of passengers. They use the

nonlinear explicit dynamic code LS-DYNA to

demonstrate a numerical approach for a bus structure

approval.

2. NECESSITY OF TECHNICAL REGULATIONS

IN AUTOMOTIVE INDUSTRY

In the automotive industry, technical regulations are

needed because of the reasons below:

For providing life safety and reducing accidents.

For providing international cooperation for

determining the minimum technical conditions in

systems and parts of vehicles.

Because of rapidly increasing traffic density with the

increase in the number of vehicles produced.

Hence compliance with technical standards and

requirements in designing and producing vehicles is

necessary for vehicle manufacturers. Additionally

traffic laws of developed countries require that vehicles

manufactured must be in conformity with the structure

of main roads and traffic safety from the point of view

of vehicle production and usage. During the production

stage of vehicles, corresponding ministries of the

countries are authorized to legislate for Motor Vehicle

Type Approval Directives and other Regulations

connected with these Directives.

These regulations contain control processes consisting

of testing motor vehicle types or systems and parts of

these vehicles with certain methods and involve

procedures of documentation of the results

appropriateness to the technical regulations. Vehicles

can only be manufactured after this process called type

approval. Traffic registration of a vehicle cannot be

performed before the type approval has been issued. In

this study, the analyses necessary for obtaining the type

approval for a new bus type whose manufacture is

planned, were performed.

3. BUS PRODUCTION AND REGULATION

APPLICATIONS TO BUSSES

3.1. Bus Production

According to Motor Vehicle Type Approval

Regulations, a bus is a vehicle with an engine, which

has more than 8 seats excluding its driver, transports

passengers and whose laden mass exceeds five tons. It

is possible to classify bus production into two groups.

These are:

Chassis and body produced separately as two parts

(chassis and body)

Chassis and body produced together as one part

(monocoque chassis-body)

3.1.1. Separately produced chassis and body

Chassis structures of busses are the rectangular-like

structures that are constructed by joining two parallel

main beams with the gap elements as seen in Figure 1.

They bear the whole body and loads of passengers that

amount to an average of 71 kg per person. This type of

structure has the special name chassis, on which the

motor and transmission systems are assembled, and it

possesses moving capability like a vehicle, without

having any superstructure (carcass system) as given in

Figure 2.

Figure 1. Assembling chassis [14, 15].

G.U. J. Sci., 23(1):71-79 (2010)/ K. Turgut GRSEL

1

, Serap GRSESL

1

73

Figure 2. Drive-train assembled on chassis.

The superstructure of a bus consists of pillars and a

metal sheet covering which forms a closed safe

volume. Additionally, the body contains components

such as doors, windows, air-conditioning systems and

emergency exits within its structure. Figure 3 shows a

bus superstructure to be assembled on the chassis. The

main elements of this system consist of main beams

named pillars, strength increasing interior beams and

reinforcement bars which all together form doors,

windows etc. and carry the whole structure and static as

well as dynamic loads.

Figure 3. Superstructure of the designed bus [16].

3.1.2. Monocoque chassis and body

The floor carcass both functions as a chassis and bears

the passenger platform. Hence the monocoque chassis

and body complete each other to form a vehicle, and

this type of chassis cannot move independently. The

fact that there is no separate chassis lightens the vehicle

mass. Generally this structure is preferred for vehicles

with air suspension and for busses whose floor is

required to be closer to the ground. This means a drop

in the gravity center of the bus, which improves the

vehicle stability substantially.

4. ROLL-OVER TEST ACCORDING TO ECE R

66

4.1. Aim of the Test in the Regulation

Nowadays, the safety against roll-over of vehicles

transporting passengers is very important. In the world,

this subject is under the control of formal sanction

associations such as the EC (European Community),

ECE (Economic Commission for Europe) and FMVSS

(Federal Motor Vehicle Safety Standards).

Due to the abundance of limits enacted by these

associations for the provision of sufficient life safety

during vehicle roll-overs and crashes, at the design

stages computer simulations of vehicle accidents have

been very important. The main aim of Regulation ECE

R 66 is to design and produce bus superstructures

satisfying the requirement that passengers and driver in

the passenger department must remain alive in the

standard roll-over conditions defined in the

Regulations. The Regulation therefore defines a

residual space as given in Figure 4 [1, 2]. If this

residual space, represented here by a trapezoid that is

placed in the passenger department within the bus

cross-section to be tested, is not damaged during and

after the test, it means that this bus structure has been

designed and manufactured in a way which

significantly minimizes the injury risk of passengers

and driver during an accident.

4.2. Characteristics of the Bus

The characteristic dimensions and weight distributions

of the designed unladen bus are determined in the

design stage as follows:

Figure 4. Dimensions of the platform of the residual

space [16].

Distributions of weights of unladen bus

Mg = 9170 kg Unladen kerb mass of the vehicle

Mf = 2770 kg Weight of front axle

Mr = 6400 kg Weight of rear axle

ML = 4470 kg Weight of left side of vehicle

MR = 4700 kg Weight of right side of vehicle

Dimensions of the bus

L = 4160 mm Span width of axle

FT = 1866 mm Width between the front tire centers

rdyn =

409 mm

Diameter of the tire for 245/70 R

19.5

W = 2355 mm Overall width of the vehicle

H = 3350 mm Height of the vehicle

Center of the gravity of the bus

lF = 4909 mm

Distance of the front of the vehicle

from the centre of gravity of the

vehicle

lR = 3921 mm

Distance of the rear of the vehicle

from the centre of gravity of the

vehicle

100 mm

150 mm

Joining point of

the platform to

the cross section

Side surface of

vehicle

300 mm

906,5 mm

74 G.U. J. Sci.,23(1):71-79 (2010)/ K. Turgut GRSEL

1

, Serap GRSESL

1

t = 234 mm

Distance between gravity center of

the vehicle and longitudinal section

center plane ABOD as given in

Figure 5 and 6 (Determined as in

Table 1)

a = 2904 mm

Distance of gravity center of the

vehicle from the front axle

(Determined as in Table 1 and Figure

6)

b = 1256 mm

Distance of gravity center of the

vehicle from the rear axle

(Determined as in Table 1 and Figure

6)

HS = 1036 mm

Averaged height of the centre of

gravity of the unladen vehicle

(Determined and shown as in Table 1

and in Figure 6)

hf+hf

'

= 83 mm

Fall of the centre of gravity

(Graphically determined and

measured as in Figure 7)

The position of the centre of gravity of the bus was

calculated in Table 1 and HS was determined to be

1036 mm.

Figure 5. Vertical transverse and median longitudinal

plane according to ECE R 29 [2].

4.3. Selection of the Superstructure Section

For the roll-over test, a section of the bus superstructure

was selected that was situated between two similar

pillars and possessed reinforcement elements and

complete windows on both sides as given in Figure 8.

In the selected section, weights representing sheet metal

plates, window panes, bars for ceiling baggage, seat

rails and seats were placed at their original positions in

the passenger compartment. By means of all the

weights and their distributions, the vertical position of

the gravity center of the section to be tested, was

accommodated close to that of the whole vehicle's

center of gravity. The mass of the section is 746 kg and

it amounts to 8.14 % of the whole mass of the bus.

4.4. Preparation of the "Residual Space" Platform

For the preparation of the residual space platform to

be placed in the superstructure section that will be

tested, the distance between the axes of the two exterior

passenger seats in the bus is used as given in Figure 4

and explained in Reference [1, 2]. So, in the designed

bus, the distance between the axes of the two exterior

passenger seats was measured as 1813 mm. Figure 4

exhibits dimensions of the residual space platform

which were determined by using the following

distances.

Lower edge length of the trapezoid: 2 (906.5+150) =

2113 mm

Upper edge length of the trapezoid: 2 (906.5-100) =

1613mm

Height of the trapezoid: hT = 750 mm (

Given in ECE R 66)

4.5. Roll-over Test

The roll-over test and its execution are explained

explicitly in Reference [1, 2]. The course of the roll-

over test performed on the section representing the

whole superstructure of the designed bus, which was

produced for experimental research by BMC Industry

and Trade Inc., is shown in Figure 7 and 9 [14]. After

the roll-over test, it was determined that no deformation

occurred in the residual space platform representing the

area of the passenger department. This means that the

section and/or superstructure of the bus were designed

properly according to the Regulations ECE R 66.

G.U. J. Sci., 23(1):71-79 (2010)/ K. Turgut GRSEL

1

, Serap GRSESL

1

75

Table 1. Determination of the location of gravity center of the bus.

Section Static moment (kgm) Distance (mm) Explanation

Longitudinal-section ) ( x FT M x M

R L

= 40 . 956 = x

4 . 23 t

Figure 6

Cross-section a M a L M

f r

= ) (

62 . 1256

4 . 2903

b

a

Figure 6

Forces acting on bus

with = 2.9

tan

9 . 2

cos )

r

(

cos ) (

=

=

+

= +

g

M

M L

S

H

for

L M M

a a

g

M

1036 =

S

H

Averaged height of

the centre of gravity

of the unladen vehicle

Figure 6

Auxiliary

Calculations

a

M

L M M

a

g

r

+

=

) (

(*)

L

M

M

a

g

r

= (**)

Eq. (**) is put into Eq. (*)

L

M

M

a

g

=

S

H

a

= tan

tan

=

g

S

M

M L

H

Figure 6

Figure 6. Characteristic distances in transverse and longitudinal bus section as well as forces acting on bus in angle of

[16].

76 G.U. J. Sci.,23(1):71-79 (2010)/ K. Turgut GRSEL

1

, Serap GRSESL

1

Figure 7. Course of centre of gravity of the designed

bus section during the roll-over test [16].

Figure 8. Selected carcass section Model of BMC bus

[16].

Figure 9. Roll-over test [16].

5. STRUCTURAL ANALYSIS

5.1. Analysis of the Superstructure of the Bus by

Energy Absorption Method

Energy absorption of the bus superstructure in a roll-

over test can be determined in accordance with

Regulations ECE R 66 as follows and assumptions of

the regulations listed below apply also to this analysis:

Body structure of the bus is a rectangle.

The hanger system is joined rigidly.

The motion of the bus section is just a roll motion of

a rigid body.

The total energy to be absorbed in a roll-over test can be

determined by equation (1a) or (1b):

=

H

H

H

H

W

H

W

Mg E

S

S

8 . 0 8 . 0

2 2

75 . 0

2 2 2

2

*

[Nm](1a)

( )

f f

h h Mg E + = 75 . 0

*

[Nm] (1b)

Putting all values given above into Eq. (1a) delivers the

total energy to be absorbed by the superstructure of the

designed bus in a possible roll-over accident.

=

35 . 3

1.036

8 . 0 8 . 0 35 . 3

35 . 3 2

355 . 2

1.036

2

2.355

81 . 9 9170 75 . 0

2 2 2

2

*

E

kJ Nm E 4 . 45 45370

*

= =

The main bearers forming the vehicles body should be

a complete ring circle. These closed rings increase

strength of the bus superstructure about 30% more than

the main bearers consisting of open rings (Figure 8 and

10). The superstructure of the designed bus to be

analyzed consists of eight closed rings that are

accommodated from the front to back of the bus, and

the rings from the front to the gravity center of the bus

are called front rings, while those from the gravity

center to the back of the bus are called back rings.

The superstructure-section of the bus to be tested is

abutted on the third (F3) and the fourth (F4) frame

bearer, which has the number 3 as given in Figure 10.

At the end of the roll-over test, the resulting fall of the

center of gravity (h

f

+ h'

f

) of the superstructure-section

was measured and graphically found out to be about 83

cm. By means of this value, the energy absorbed by the

section rolled-over in the test is determined by Eq. (2)

as E

3

= 6.08 kJ.

) (

3 f f

h h mg E + = (2)

08 . 6 1000 / ) 25 . 0 58 . 0 ( 81 . 9 746

3

= + = E kJ

Figure 10. Representative closed rings of the bus

superstructure [16].

5.2. Analysis of the Bus Superstructure using FEM

and Results

The model of the superstructure of the designed bus was

prepared in CATIA software. In order to decrease the

CPU-time in analyses, any parts of the superstructure

h

f

h

f

'

G

G

G

G

G.U. J. Sci., 23(1):71-79 (2010)/ K. Turgut GRSEL

1

, Serap GRSESL

1

77

that are irrelevant for the stiffness of the section were

neglected. In addition, the test section possesses some

auxiliary elements for execution of the test, which do

not contribute to its stiffness. The floor carcass

functioning as a chassis and body was modelled and the

chassis and body were meshed with Solid elements

and Shell 63 elements, respectively, and then the file

was transferred into ANSYS software (Figure 11) [17,

18]. In analysis it was assumed that elastic deformations

are negligibly small. Deformations obtained in analysis,

which occurred in all rings of the modelled bus after

roll-over simulation, were determined as follows:

Rings Front side Rings Rear side

1F d

1

=0.70488 m 1R d

5

=0.93406 m

2F d

2

=0.68665 m 2R d

6

=1.00533 m

3F d

3

=0.74543 m 3R d

7

=1.04984 m

4F d

4

=0.83854 m -- ------------

Figure 11. Model of the designed bus superstructure

without sheet metal.

The absorption energy obtained from the analysis was

calculated as:

46 . 5 1000 / 0.7455 81 . 9 746

3 3

= = = mgd E kJ

By means of the displacement amounts obtained from

the analysis as mentioned above and as seen in Figure

12-13, the energy that would be absorbed by all

superstructure-sections was determined as in Table 2:

Figure 12. Analysis of the model under loading.

Figure 13. Residual space after roll-over test.

Table 2. Energy that would be absorbed by all

superstructure-sections.

Front side Rear side

E

1

= E

3

(d

1

/d

3

)= 5.75 kJ E5 = E3 (d5/d3) = 7.62 kJ

E

2

= E

3

(d

2

/d

3

)= 5.60 kJ E6 = E3 (d6/d3) = 8.20 kJ

E

3

= E

3

(d

3

/d

3

)= 5.46 kJ

Result of the analysis

E

3

=6.08 kJ

Result of the test

E7 = E3 (d7/d3) = 8.563 kJ

E

4

= E

3

(d

4

/d

3

) = 6.84 kJ -----

E

F,Total

= 24.27 kJ E

R, Total

= 24.383 kJ

E

Total

= E

Fi

+ E

Ri

= 48.653 kJ

78 G.U. J. Sci.,23(1):71-79 (2010)/ K. Turgut GRSEL

1

, Serap GRSESL

1

It can be concluded that the results of the test and

analysis for section E3 are very close. The energies to

be absorbed by the other sections were calculated by

means of the reliable value of section E3. The distance

of all main bearers to the gravity center of the bus (l)

was determined as follows:

Front side Rear side

l

F1

= 4.30 m l

R1

= 0.71 m

l

F2

=3.40 m l

R2

= 2.18 m

l

F3

= 2.33 m l

R3

= 3.55 m

l

F4

= 0.80 m ------------

E

Fi

.

l

Fi

= 63.4 kJ E

Ri

.

l

Ri

= 53.69 kJ

Averaged distances of the main bearers accommodated

at the front and at the rear of the gravity center of the

bus can be determined by equations (3).

=

=

=

=

=

n i

i

Fi

n i

i

Fi Fi

F

E

l E

L

1

1

) (

=

=

=

=

=

p i

i

Ri

p i

i

Ri Ri

R

E

l E

L

1

1

) (

(3)

LF=63.4024.27=2.61 m LR=53.6924.383=2.20 m

If all obtained values are assessed as given in Table 3, it

results that the energy absorbed in all superstructure-

sections is 7-36 % higher than the required values and

thus the superstructure of the designed bus fulfils the

Regulation conditions. Moreover the calculated values

L

F

and L

R

are sufficient.

Table 3. Evaluation of the obtained results.

Conditions Determined values Result

E Total E* 48.653kJ>45.40kJ

Suitable for

Regulation

E F ,Total 0.4 E* 24.27 kJ>18.16 kJ

Suitable for

Regulation

E R ,Total 0.4 E* 24.383 kJ>18.16 kJ

Suitable for

Regulation

LF 0.4 lF 2.61 m>1.96 m

Suitable for

Regulation

LR 0.4 lR 2.20 m>1.57 m

Suitable for

Regulation

6. RESULTS AND CONCLUSION

In this study, the roll-over test of the superstructure-

section of a designed bus was performed according to

Regulation ECE R66 and the approximate values of the

displacements at the main bearers were obtained (Figure

14). Further, with these values the energy absorbed by

main bearers was calculated. Additionally, the modelled

superstructure of the bus was analyzed so that the

energy all bus sections would absorb was determined

(with the help of the section test results). By means of

the results obtained, it is concluded that the results of

the roll-over test of the bus superstructure-section can

be approached by finite element analyses. Important

parameters in the design stage primarily arose from:

Vehicle characteristics, especially the position of the

gravity center of the whole bus and superstructure-

section.

The displacements in main bearers

The total energy that the closed rings of the

superstructure-section absorb.

It resulted that the residual space platform was damaged

neither according to the calculations as well as the roll-

over test performed with respect to Regulation ECE

R66 nor in the finite element analyses. In other words, it

was succeeded in proving the safety of the designed bus

in the roll-over test. So it was concluded that the

superstructure of the bus is a successful design that can

protect the passengers and drivers during a possible

accident and following roll-over.

Figure 14. Comparison of the test results to the one of

the FEA.

REFERENCES

[1] Large Passenger Vehicles Strength of

Superstructure, United Nations Agreement, ECE

Regulation No: 66, Issue: 1 (1999).

[2] nternet: Regulations of Economic Commission for

Europe,UNECE,

http://europa.eu.int/comm/enterprise/automotive/di

rectives, (2004).

[3] Abe, M., Morisawa, M., Sato, T.B., Kobayashi, K.,

Three-dimensional behaviour simulation of

vehicle-to-vehicle collision by dynamic model,

JSAE Review, 20:101-108 (1999).

[4] Takubo, N., Mizuno, K.,Accident analysis of

sports utility vehicles: human factors from

statistical analysis and case studies, JSAE

Review, 21:103-108 (2000).

[5] Parenteau, C.S., Viano, D.C., Shah, M., Gopal, M.,

Davies, J., Nichols, D., Broden, J., Field

relevance of a suite of rollover tests to real-world

G.U. J. Sci., 23(1):71-79 (2010)/ K. Turgut GRSEL

1

, Serap GRSESL

1

79

crashes and injuries, Accident Analysis and

Prevention, 25:103-110 (2003).

[6] Eger, R., Kiencke, U., Modeling of rollover

sequences, Control Engineering Practice,

11:209-216 (2003).

[7] Diaz, V., Fernandez, M.G., Roman, J.L.S.,

Ramirez, M., Garcia, A., A new methology for

predicting the rollover limit of buses, Int. J. of

Vehicle Design, 34(4):340-353 (2004).

[8] Castejon, L., Miravete, A., Cuartero, J.,

Composite bus rollover simulation and testing,

Int. J. of Heavy Vehicle Systems,13(4):281297

(2006).

[9] Hoskins, M.H., El-Gindy, M., Virtual rollover

tests, Int. J. of Heavy Vehicle

Systems,13(1,2):107124 (2006).

[10] Renfroe, D., Roberts, A., Gilbert, M., Vehicle

rollover maximum limits, Int. J. of Vehicle

Design, 40(1,2,3):144158 (2006).

[11] Dahlberg, E., Stensson, A, The dynamic rollover

threshold a heavy truck sensivity study Int. J. of

Vehicle Design, 40(1,2,3):228250 (2006).

[12] Koppel, S., Charlton, J., Fildes, B., Fitzharris, M.,

How important is vehicle safety in the new

vehicle purchase process? Accident Analysis and

Prevention, 40:944-1004 (2008).

[13] Kwasniewski, L., Bojanowski, C., Siervogel, J.,

Wekezer, J.W., Cichocki, K., Crash and safety

assessment program for paratransit buses Int. J.

of Impact Engineering, 36:235242 (2009).

[14] BMC, Vehicle and chassis catalogue (2003).

[15] nternet: BMC Model Katalou

http://www.bmc.com.tr , (2004).

[16] Gursesli, S., Analysis of a bus superstructure

according to Regulations ECE R 66, M.Sc.

Thesis, Ege University Institute of Science, 23-39,

(2004).

[17] Reddy, J.N., Introduction to the Finite Element

Method, 2

nd

ed., McGraw Hill, New York,

(1993).

[18] ANSYS, Theory of Ansys (help files) (2001).

Nomenclature / Abbreviations

EC European Community

ECE Economic Commission for Europe

FMVSS Federal Motor Vehicle Safety Standards

MVTAD Motor Vehicles Type Approval Directive

ISO International Standard Organisation

CAD /

CAM

Computer Aided Design /

Computer Aided Manufacturing

FEM /

FEA

Finite Element Method /

Finite Element Analysis

M Unladen kerb mass of the vehicle (kg)

g Acceleration due to gravity (m/s

2

)

W The overall width of the vehicle (m)

Hs The height of the centre of gravity of the unladen vehicle (m)

H The height of the vehicle (m)

lF Distance of the front of the vehicle from centre of gravity of the vehicle (m)

lR Distance of the rear of the vehicle from centre of gravity of the vehicle (m)

E* Total energy to be absorbed (kJ)

LF,R Weighted average distance of the declared pillars to the front / rear of the centre of gravity of

the vehicle (m)

lFi Distance from the centre of gravity of the i

th

pillar forward the centre of gravity of the vehicle

lRi Distance from the centre of gravity of the i

th

pillar rearward the centre of gravity of the vehicle

S-ar putea să vă placă și

- Crosswind Sensitivity of Passenger Cars and The Influence of ChassisDocument6 paginiCrosswind Sensitivity of Passenger Cars and The Influence of ChassisInternational Journal of computational Engineering research (IJCER)Încă nu există evaluări

- RNL-A-07 Rollover Analysis of Bus Body Structure VolvoDocument7 paginiRNL-A-07 Rollover Analysis of Bus Body Structure VolvoAlejandro ZamoraÎncă nu există evaluări

- An Investigation On The RollOver Crashworthiness oDocument19 paginiAn Investigation On The RollOver Crashworthiness oViet Hung NguyenÎncă nu există evaluări

- Terramechanics and Off-Road Vehicle Engineering: Terrain Behaviour, Off-Road Vehicle Performance and DesignDe la EverandTerramechanics and Off-Road Vehicle Engineering: Terrain Behaviour, Off-Road Vehicle Performance and DesignEvaluare: 5 din 5 stele5/5 (1)

- Frontal Occupant Safety Simulations For Coach and Bus PassengersDocument8 paginiFrontal Occupant Safety Simulations For Coach and Bus PassengersShubham ChawlaÎncă nu există evaluări

- Lightweight Optimization of Bus Frame Structure Considering Rollover SafetyDocument12 paginiLightweight Optimization of Bus Frame Structure Considering Rollover SafetyAnkush khuranaÎncă nu există evaluări

- Design and Fabrication of A Student Competition Based Racing CarDocument6 paginiDesign and Fabrication of A Student Competition Based Racing CarpachieduÎncă nu există evaluări

- Scitech 2019 FINAL PAPER RevisedDocument17 paginiScitech 2019 FINAL PAPER RevisedbabyabhiraÎncă nu există evaluări

- Model Updating On BIWDocument12 paginiModel Updating On BIWIamzura AbdullahÎncă nu există evaluări

- Development of Semi-Active Road-Friendly Truck SuspensionsDocument10 paginiDevelopment of Semi-Active Road-Friendly Truck SuspensionsLe ThanhÎncă nu există evaluări

- Study On The Selection of Sections Applicable To Truck Platooning in The Expressway NetworkDocument13 paginiStudy On The Selection of Sections Applicable To Truck Platooning in The Expressway NetworkKAMÎncă nu există evaluări

- Measurement and Analysis of Vehicle Comfort and Road QualityDocument8 paginiMeasurement and Analysis of Vehicle Comfort and Road QualityChethan GowdaÎncă nu există evaluări

- Editors' Perspectives:: Road Vehicle Suspension Design, Dynamics, and ControlDocument34 paginiEditors' Perspectives:: Road Vehicle Suspension Design, Dynamics, and ControlTech DudeÎncă nu există evaluări

- A Critical Review of Vehicle Pavement Interaction Mechanism in Evaluating Flexible Pavement Performance CharacteristicsDocument36 paginiA Critical Review of Vehicle Pavement Interaction Mechanism in Evaluating Flexible Pavement Performance CharacteristicsRobel TeweldeÎncă nu există evaluări

- Applsci 13 05903Document25 paginiApplsci 13 05903Phạm Hải ĐăngÎncă nu există evaluări

- AITPM2002 Haldane&BunkerDocument10 paginiAITPM2002 Haldane&BunkerkannasrkÎncă nu există evaluări

- Bus ImpactDocument6 paginiBus Impactapi-3762972Încă nu există evaluări

- Ijsrmjournal,+2256 Article+Text 5432 1 2 20190608Document7 paginiIjsrmjournal,+2256 Article+Text 5432 1 2 20190608ahmadÎncă nu există evaluări

- Kamil RRA 1Document13 paginiKamil RRA 1P24 Innovation CenterÎncă nu există evaluări

- Prediction of Wheel WearDocument20 paginiPrediction of Wheel Wearbenssj100% (1)

- Modeling of The Suspension of A Passenger Bus by Finite Element SoftwareDocument3 paginiModeling of The Suspension of A Passenger Bus by Finite Element SoftwarePrasad KhatiÎncă nu există evaluări

- Applsci 12 05121Document12 paginiApplsci 12 05121Nojus DekerisÎncă nu există evaluări

- Study of Frontal Impact of A Passenger Bus: Manjunath Rao T S, Madan JDocument8 paginiStudy of Frontal Impact of A Passenger Bus: Manjunath Rao T S, Madan Jtsmanjurao100% (6)

- Thesis Proposal HassanDocument4 paginiThesis Proposal Hassanehsan ahmadÎncă nu există evaluări

- RTDF2007-46015: Developing Strategies For Maintaining Tank Car Integrity During Train AccidentsDocument10 paginiRTDF2007-46015: Developing Strategies For Maintaining Tank Car Integrity During Train Accidentsmarc53042Încă nu există evaluări

- Design Project.: Dynamic Analysis of A Truck ChassisDocument11 paginiDesign Project.: Dynamic Analysis of A Truck Chassisbassel alzawyÎncă nu există evaluări

- Considerations For Mechanistic Design of Concrete Sleepers and Elastic Fastening Systems in North AmericaDocument8 paginiConsiderations For Mechanistic Design of Concrete Sleepers and Elastic Fastening Systems in North AmericaMin Chan MoonÎncă nu există evaluări

- Physica A: Sheng Jin, Dianhai Wang, Pengfei Tao, Pingfan LiDocument9 paginiPhysica A: Sheng Jin, Dianhai Wang, Pengfei Tao, Pingfan Lijohncena3Încă nu există evaluări

- Comprehensive Truck Size and Weight Limits Study: Tom Kearney, FHWA Ben Ritchey, CDM SmithDocument28 paginiComprehensive Truck Size and Weight Limits Study: Tom Kearney, FHWA Ben Ritchey, CDM SmithgiovasÎncă nu există evaluări

- Barth Et Al. 2004 - Modal Emissions Model For Heavy-Duty Diesel VehiclesDocument12 paginiBarth Et Al. 2004 - Modal Emissions Model For Heavy-Duty Diesel VehiclesPedro MunizÎncă nu există evaluări

- Symmetry: The Usage of Alternative Materials To Optimize Bus Frame StructureDocument11 paginiSymmetry: The Usage of Alternative Materials To Optimize Bus Frame StructureTarun K. KhattaÎncă nu există evaluări

- Biw AnalysisDocument15 paginiBiw Analysiskeepingbusy100% (1)

- Crash Analysis of Car Chassis Frame UsinDocument19 paginiCrash Analysis of Car Chassis Frame Usinuday chavanÎncă nu există evaluări

- Document 11Document22 paginiDocument 11fredyÎncă nu există evaluări

- Modelling of Highway Bridge Traffic Loading - Some Recent AdvancesDocument9 paginiModelling of Highway Bridge Traffic Loading - Some Recent AdvancesKhalilÎncă nu există evaluări

- 03 Shokouhfar ConcordiaUniv PDocument12 pagini03 Shokouhfar ConcordiaUniv Pyemane gebremichalÎncă nu există evaluări

- Considerations On Longitudinal Dynamic Effects ofDocument17 paginiConsiderations On Longitudinal Dynamic Effects ofAdrian StroeÎncă nu există evaluări

- An Enhanced Fuel Consumption Machine Learning Model Used in VehiclesDocument6 paginiAn Enhanced Fuel Consumption Machine Learning Model Used in VehiclesVarsha MashettyÎncă nu există evaluări

- AES T1 Research Assignment Topics.Document3 paginiAES T1 Research Assignment Topics.Rahul RathodÎncă nu există evaluări

- 33 Crash SafetyDocument18 pagini33 Crash SafetysibieÎncă nu există evaluări

- Comparative Study of Flexible and Rigid Pavements For Different Soil and Traffic ConditionsDocument10 paginiComparative Study of Flexible and Rigid Pavements For Different Soil and Traffic ConditionsMano DragonÎncă nu există evaluări

- Construction of A Parametrized Tracked Vehicle Model and Its Simulation in MSC - ADAMS ProgramDocument9 paginiConstruction of A Parametrized Tracked Vehicle Model and Its Simulation in MSC - ADAMS Programpraveen karunanithiÎncă nu există evaluări

- Rollover Analysis of Passenger Bus As Per AIS-031Document11 paginiRollover Analysis of Passenger Bus As Per AIS-031Ivan ObandoÎncă nu există evaluări

- Virtual Testing of Counterbalance Forklift TrucksDocument16 paginiVirtual Testing of Counterbalance Forklift TrucksReginald D'SouzaÎncă nu există evaluări

- Neural Network Surrogate Models For Aerodynamic Analysis in Truck Platoons Implications On Autonomous Freight DeliveryDocument10 paginiNeural Network Surrogate Models For Aerodynamic Analysis in Truck Platoons Implications On Autonomous Freight DeliveryrublasterÎncă nu există evaluări

- Monitoring Bridge Dynamic Behaviour Using An Instrumented Two Axle Vehicle P.J. Mcgetrick, A. González & E.J.ObrienDocument8 paginiMonitoring Bridge Dynamic Behaviour Using An Instrumented Two Axle Vehicle P.J. Mcgetrick, A. González & E.J.ObrienArturo GonzalezÎncă nu există evaluări

- J TRC 2016 02 012Document16 paginiJ TRC 2016 02 012Edwin Pastot CentenoÎncă nu există evaluări

- Statics and Dynamics Structural AnalysisDocument12 paginiStatics and Dynamics Structural AnalysisVaibhav JadhavÎncă nu există evaluări

- Reveiw GeometryDocument11 paginiReveiw GeometrySeid AbduÎncă nu există evaluări

- RIVAS UIC WP5 D5 1 V02 Final 01Document53 paginiRIVAS UIC WP5 D5 1 V02 Final 01Pedro HenriquesÎncă nu există evaluări

- 11 Chapter 02 PDFDocument28 pagini11 Chapter 02 PDFjoel perieraÎncă nu există evaluări

- Design Project.: Dynamic Analysis of A Truck ChassisDocument11 paginiDesign Project.: Dynamic Analysis of A Truck Chassisbassel alzawyÎncă nu există evaluări

- Modified Method For Estimating The Static Lateral Stability of Vehicles As Amended by The Design ChangesDocument8 paginiModified Method For Estimating The Static Lateral Stability of Vehicles As Amended by The Design ChangesOluwaloseyi SekoniÎncă nu există evaluări

- SM3357Document13 paginiSM3357Glorius CarmenÎncă nu există evaluări

- 000 NVSD 2019 0353.R1 - Clean - EditableDocument23 pagini000 NVSD 2019 0353.R1 - Clean - EditableCloudIIIÎncă nu există evaluări

- A Comparison of Optimal Semi-Active Suspension SysDocument9 paginiA Comparison of Optimal Semi-Active Suspension SysN'GOLO MAMADOU KONEÎncă nu există evaluări

- Iajicte 2022 8 1 12Document11 paginiIajicte 2022 8 1 12uday chavanÎncă nu există evaluări

- The Multibody Systems Approach to Vehicle DynamicsDe la EverandThe Multibody Systems Approach to Vehicle DynamicsEvaluare: 5 din 5 stele5/5 (2)

- Nonlinear Optimization of Vehicle Safety Structures: Modeling of Structures Subjected to Large DeformationsDe la EverandNonlinear Optimization of Vehicle Safety Structures: Modeling of Structures Subjected to Large DeformationsEvaluare: 5 din 5 stele5/5 (1)

- Sec T & LDocument65 paginiSec T & LKabilan MuthukannanÎncă nu există evaluări

- Academic Reading Sample Task - Matching InformationDocument5 paginiAcademic Reading Sample Task - Matching InformationKabilan MuthukannanÎncă nu există evaluări

- 1 AAM Body-StructuresDocument84 pagini1 AAM Body-StructuresKabilan MuthukannanÎncă nu există evaluări

- Lenksysteme NKW eDocument40 paginiLenksysteme NKW eKabilan Muthukannan100% (2)

- Adams Drive ManualDocument10 paginiAdams Drive ManualKabilan MuthukannanÎncă nu există evaluări

- Machine Serial Number IdentificationDocument7 paginiMachine Serial Number Identificationعقيد السبئيÎncă nu există evaluări

- IATA Message FormsDocument20 paginiIATA Message FormsServet Basol95% (41)

- Cable Suspended Roof-23!10!09Document76 paginiCable Suspended Roof-23!10!09Sonal Sharma75% (4)

- 5w 30 Synthetic Oil ComparisonDocument12 pagini5w 30 Synthetic Oil ComparisonindeskeyÎncă nu există evaluări

- Business Proposal FinalDocument9 paginiBusiness Proposal FinalAndrewÎncă nu există evaluări

- Paulding County Progress November 12, 2014Document24 paginiPaulding County Progress November 12, 2014PauldingProgressÎncă nu există evaluări

- Aviation Rules of ThumbDocument4 paginiAviation Rules of Thumbpersili100% (9)

- BSW, BS,,AF, BA and Metric Tool Size EquivalentsDocument5 paginiBSW, BS,,AF, BA and Metric Tool Size Equivalentschuminh09Încă nu există evaluări

- Transportation Planning Chapter 3Document48 paginiTransportation Planning Chapter 3Khalid Yousaf100% (2)

- 3 - Guideline Energy Efficiency in The Confectionery IndustryDocument12 pagini3 - Guideline Energy Efficiency in The Confectionery IndustryNasional GotongroyongÎncă nu există evaluări

- RMTMP GokulgangaDocument60 paginiRMTMP GokulgangaShekhar ChapagainÎncă nu există evaluări

- Fluid CouplingDocument2 paginiFluid CouplingChakravarthi Naga0% (1)

- PDFViewer PDFDocument469 paginiPDFViewer PDFShubham SharmaÎncă nu există evaluări

- Soal No.60 Marlins ReadingDocument5 paginiSoal No.60 Marlins ReadingEPEKÎncă nu există evaluări

- Cat 621G 623G 627G NpiDocument51 paginiCat 621G 623G 627G NpiMahmmod Al-QawasmehÎncă nu există evaluări

- 2 StructuralDocument19 pagini2 Structurallayaljamal2Încă nu există evaluări

- 1988 Toyota Mr2 Aw11 Repair Manual WDocument1.065 pagini1988 Toyota Mr2 Aw11 Repair Manual WDonoven KornelsenÎncă nu există evaluări

- Construction of Multistorey BuildingDocument45 paginiConstruction of Multistorey BuildingSugam SehgalÎncă nu există evaluări

- Schematic Function Gen Part 1Document2 paginiSchematic Function Gen Part 1pecceriniÎncă nu există evaluări

- Ocimf BooksDocument4 paginiOcimf BooksCodruţ Erașcu100% (2)

- VMRDA Master Plan Approval GazetteDocument39 paginiVMRDA Master Plan Approval GazetteAvinash KumarÎncă nu există evaluări

- FLNGDocument8 paginiFLNGmoiseianÎncă nu există evaluări

- Seat Leon 1M ManualDocument270 paginiSeat Leon 1M ManualJanar Tähepõld100% (1)

- Backhoe LoaderDocument3 paginiBackhoe LoaderxenonÎncă nu există evaluări

- Lecture 3 Mechanistic-Empirical Pavement Desing Flex and RigidDocument56 paginiLecture 3 Mechanistic-Empirical Pavement Desing Flex and RigidThe HackerÎncă nu există evaluări

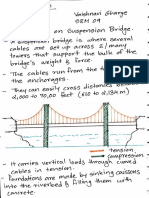

- TOS Suspension Bridge Sem 9Document3 paginiTOS Suspension Bridge Sem 9VAISHNAVI GHARGEÎncă nu există evaluări

- Territorial Waters or A Territorial SeaDocument14 paginiTerritorial Waters or A Territorial SeaAditya VermaÎncă nu există evaluări

- DO 082 s2017 PDFDocument69 paginiDO 082 s2017 PDFOlan RodolfoÎncă nu există evaluări

- Skid ControlDocument16 paginiSkid Controlsangeethsreeni100% (3)

- Battery Charging Technologies For Advanced Submarine RequirementsDocument4 paginiBattery Charging Technologies For Advanced Submarine Requirementsjwpaprk1100% (1)