Documente Academic

Documente Profesional

Documente Cultură

Rain Bird - Valves Manuals 009

Încărcat de

miclarkDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Rain Bird - Valves Manuals 009

Încărcat de

miclarkDrepturi de autor:

Formate disponibile

1

B BB BIRD IRD IRD IRD

R RR RAIN AIN AIN AIN

PREFERRED BY PROFESSIONALS WORLDWIDE

General Information 2

Tips on Installation 2

Installation Steps 3

Wiring the Valve 4

Determining Valve Wire Size 5

Manually Activating the System 6

Trouble Shooting Guide 7

Flow Control Stem 8

Filters 8

Winterization 8

CONTENTS:

DV Installation Instructions

English

2

GENERAL INFORMATION

THE DV SERIES OF VALVES OFFERS AN ARRAY OF PRODUCTS in both sizes and features to meet the stan-

dard installation needs for residential and light commercial irrigation requirements.

The valves offered are a " (20/27) non-flow control valve and a series of 1" (26/34) valves

with or without flow control and threaded or slip x slip configurations on the inlet and outlet

ports. The combination of forms available offers maximum versatility to the installing con-

tractor.

The " valve should be used on laterals with flow rates of 3 to 22 GPM (0.75 to 5.0 m

3

/h or

11.4 to 83.4 L/m) or may be used on a drip master valve set-up with an RBY-075-200MX

filter at flow rates as low as .2 GPM (0.05 m

3

/h or 0.8 L/m).

The 1" valve series may be used on laterals with flows of 3 to 40 GPM (0.75 to 10 m

3

/h or

11.4 to 151.6 L/m).

In either " or 1" size, it is recommended that velocities be kept below 51/2 ft./sec. (1.68 m/

sec.) DV valves will perform in an operating range of 15 to 150psi (l to 10 bars or 100 to

1.000 kPa.).

TIPS ON INSTALLATION

Adequately flush the main water source prior to plumbing in the valves

VALVES ARE NOT BACK FLOW PREVENTION DEVICES. You will need to in-stall the appropriate device as

mandated by local ordinance prior to the installation of the irrigation valve. Ensure that the se-

lected device offers adequate flow and pressure to the downstream portion of the system to op-

erate the sprinklers.

Local practice may also dictate the installation of a master valve or isolation shut off valve

prior to installation of the DV valve. This will be very useful in shutting down a portion of the

irrigation system without affecting the entire system.

Check the electrical specifications of the controller being in-stalled on the job to ensure that

you have adequate inrush and holding current to electrically activate the valves. This is par-

ticularly important if you intend to wire more than one valve to a controller station. The DV

solenoid is rated at .30 A. 24 VAC (7.2 VA) inrush and .19 A. 24 VAC (4.6 VA) holding cur-

rent to maintain activation of the solenoid for the scheduled run time. Except for the EZ-1,

all Rain Bird controllers will allow you to run two valves plus a master valve at one time. The

EZ-1 allows one valve plus a master or two valves without a master valve.

Local practice will dictate standard installation procedures. However, it is always recom-

mended that valves be installed in a valve box to allow access if servicing is required. This

process will also allow easier identification of where the valves are actually installed on the

job site.

3

Notice the directional arrows on the inlet and out-

let ports which indicate the flow path of the water.

Valves cannot be reversed. Ensure that you are

installing the valve correctly. As a hint, you will

find that the solenoid is always positioned on the

downstream side of the valve where the water will

be exiting to service the sprinklers.

The standard and 1" DV comes with female

threads. Use a or 1" male by slip adapter to

connect the valve to the water source. Use two

wraps of teflon tape on the male threads of the

adapters and screw them into the two water ports

of the valve. Finger tighten the adapters into posi-

tion and then turn one to two additional turns us-

ing a wrench to ensure water tight connections.

Do not over tighten the adapter, or you could

force the adapter to extrude over the solenoid exit

port. The valve will not activate in this condition.

Once properly attached, glue the slip portion of

the adapter into the supply side pipe. Complete

this step for all valves on a given master or isola-

tion valve.

The DV S x S eliminates the need for the adapter.

In this case, simply glue the pipe directly into the

supply side pipe. Use only minimal primer and

glue to eliminate possible contamination of the

valve ports from glue residue.

In cold weather climates, it is more common to

use poly pipe. Use appropriate installation tech-

niques as specified by the manufacturer to prop-

erly attach and secure the poly adapter to the

valve. Local practice will dictate the number of

clamps used to secure the adapter.

Slowly charge the water supply system to the in-

stalled valves. When water first enters the sys-

tem, the valves will open until the upper di-

aphragm chamber charges and shuts down the

valve.

INSTALLATION STEPS

Adequately flush the main water source prior to plumbing in the valves

TAKE ALL NECESSARY STEPS TO CONNECT TO YOUR PRIMARY WATER SOURCE. Install master valves, isolation valves

4

WIRING THE VALVE

THE DV SOLENOID COMES WITH TWO LEAD WIRES, BOTH BLACK. Either one may be used as the common or as the hot wire

back to the controller.

Select a wire gauge which will allow you to run back to the controller with minimal loss (see table on the next

page). Most of-ten, multi-strand, direct burial wire will be preferable.

All valves going back to the same controller can utilize the same common wire. If the valves are mainfolded,

simply wire the valves together using water tight connectors and run one common wire back to the controller.

If the valves are separated, run one common line and slice it to the remote valve common at each location.

Each individual station must be wired separately to activate. Select a wire color and use a water tight electrical

connector to wire the valve back to the controller. This wire runs directly from the valve back to the controller

and is not ganged with any other wires. The use of Rain Bird ST-03 waterproof connectors are recommended

for all water tight connections.

Hook up all wires back into the controller by positioning a hot wire for each valve onto a controller terminal

strip and connecting all the commons back to the correct position on the controller.

5

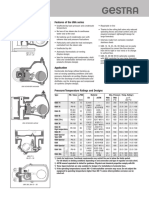

DETERMINING VALVE WIRE SIZES

DETERMINE ACTUAL DISTANCE, along wire run, from controller out to the first valve on a circuit and between

each succeeding valve on a multiple valve circuit (as show in the example below).

Calculate the equivalent circuit length for each valve circuit on the controller.

Example: Solenoid elec. control valves with 24 VAC transformer controllers, with 150 psi water pressure

at valves.

Equivalent Length Calculations:

:

Station #l - Equivalent Length = I valve x 200 ft. = 200 ft.

Station #2 - Equivalent Length = (I valve x 100 ft.) + (2 valves x 300 ft.) =700 ft.

Selecting Common Ground Wire Size - Using longest equivalent length calculated above, go to the ap-

propriate valve chart (based on transformer voltage, 24 VAC, and water pressure at valve) and select

ground wire and control wire combination that are as near the same size as possible (ground wire size

should always be equal to - or one size larger than. the control wire size.)

In the example above, circuit for station #2 has longest equivalent length of 700 feet. In chart (for this ex-

ample use high pressure chart for 150 psi water pressure at valve and 24 VAC transformer) select a wire

size combination of size 16 and 18 wire. Select common ground wire as size 16 wire. Since one common

ground wire shall be used for all valves on the controller, you have established the common ground wire

size for that controller of size 16 wire.

Sizing Circuit Wires - Using the common ground wire selected (size #16)- proceed to select each control

wire size from the chart, using the calculated equivalent length for each circuit.

Station # 1 - Equivalent Length = 1 valve x 200 ft. = 200 ft. Select size # 18 control wire.

Station #2 - Equivalent Length = 1 valve x 700 ft. = 700 ft. Select size # 18 control wire.

24 VAC

150 PSI CONTROL WIRE SIZE 125 PSI CONTROL WIRE SIZE 100 PSI CONTROL WIRE SIZE 80 PSI CONTROL WIRE SIZE

18 16 14 12 18 16 14 12 18 16 14 12 18 16 14 12

18 600 730 860 960 18 1400 1720 2000 2240 18 2300 2820 3290 3680 18 3000 3680 4290 4800

16 730 950 1170 1370 16 1720 2200 2730 3190 16 2820 3660 4490 5240 16 3680 4770 5850 6840

14 860 1170 1510 1860 14 2000 2730 3530 4340 14 3290 4490 5800 7130 14 4290 5850 7570 9300

12 960 1370 1860 2410 12 2240 3190 4340 5620 12 3680 5240 7130 9240 12 4800 6840 9300 12050

C

O

M

M

O

N

W

I

R

E

S

I

Z

E

6

MANUALLY ACTIVATING THE SYSTEM

THE DV VALVE SERIES OFFERS TWO WAYS OF MANUALLY ACTIVATING THE SYSTEM.

The solenoid allows manual activation of the system with internal downstream bleed. Utilizing this

method will eliminate water in the valve box. On the side of the solenoid arrows indicate the on and

off position. You need turn only turn CCW to manually activate the valve using the solenoid. Since

the solenoid seat is subject to system pressure, it may be difficult to turn in high pressure situations.

Turn turn CW to close the valve after flushing.

The external bleed screw offers an alternative manual option. Because it is assisted by the pressure

of the sys-tem. it may is easier to engage than the solenoid under high pressures. It is located on top

of the bonnet assembly and may be turned to activate the valve. You will only need to turn it one turn

before water starts to exit the valve directly below the bleed screw. Do not turn any further as the

screw is not captive and could come out.

Use the external bleed screw to flush the valve prior to electrically activating it. Continue piping the

system until completion of the valve installation. Activate the valves electrically from the controller to

ensure proper functioning.

7

WATER WILL NOT SHUT OFF

Time setting is incorrect at controller Reset watering time

Valve in maual ON position Tighten solenoid. Tighten bleed screw

Diaphragm filter blocked Turn water off. Remove bonnet screws. Clean filter

or replace wiht 210746 diaphragm kit

Dirty or damaged solenoid Turn water off. Clean or replace solenoid

WATER LEAKS THROUGH SPRINKLER WHEN OFF

Dirt on diaphragm Use bleed screw to manually flush the valve.

Valve in maual ON position Tighten solenoid. Tighten bleed screw

Solenoid O-ring damaged or twisted Turn water off. Inspect O-ring. Reinstall or replace

O-ring

Diaphragm damaged Turn water off. Remove bonnet screws. Replace

diaphragm with 210746 kit if damaged

Dirt in solenoid Turn water off. Remove solenoid, solenoid filter

and plunger retainer, clean. Replace solenoid if

damaged

Water leaking from bonnet Tighten bonnet screws

VALVE WILL NOT TURN ON ELECRICALLY

Controller power off Turn controller power on

Station not on See controller instructions

Water supply is off Turn water supply on

Damaged solenoid Turn water off. Wishout disconnecting wires, swap

solenoid with a good valve and retest with water

on. Replace solenoid or repair field wiring if neces-

sary

Male pipe adapter overtightened on valve outlet

side

Turn water off. Remove solenoid. Check for block-

age of dump port passage by inserting paperclip. If

blocked, reinstall male pipe adapter

Flow control stem not open Open flow control stem

LOW OR INADEQUATE FLOW THROUGH VALVE

Water running elsewhere reducing pressure Water when supply pressure is higher

Too many sprinklers on circuit Remove some sprayhead(s) from circuit until pres-

sure increases

Upstream gate valve not fully open Open gate valve fully

Flow control stem not open (DVF) Open flow control stem

TROUBLE SHOOTING GUIDE

8

THE FLOW CONTROL STEM ALLOWS YOU TO REDUCE VALVE

OUTPUT PRESSURE by turning down the stem until the

desired effect is seen in the sprinkler operation.

You may turn the handle with your fingers or use a

slotted screwdriver.

FILTERS

THE DV SERIES HAS TWO FILTERS IN THE WATER FLOW PATH TO REDUCE PLUGGING OF THE VALVE PORTS.

One filter is on the diaphragm to filter the upper chamber supply water. Do not remove the di-

aphragm filter because the valve will not operate. The other filter is in the solenoid to prevent

plug-ging of the solenoid ports and to keep debris off the plunger if the solenoid is removed. Both

filters are sized to allow the proper flow of water to achieve the desired hydraulic effects.

FLOW CONTROL SYSTEM

WINTERIZATION

AS WITH ALL IRRIGATION COMPONENTS, it is important to properly winterize the valves prior to the first hard

freeze. Local practices will dictate how this is done, but blowing the system generally provides the best

protection. Failure to properly winterize may result in dam-age to the valves as water captured in the

valves freezes.

Compressed air source should not exceed 60 psi.

Upon completion of the winterization process, move the controller to the stand-by mode.

9

B BB BIRD IRD IRD IRD

R RR RAIN AIN AIN AIN

PREFERRED BY PROFESSIONALS WORLDWIDE

Rain Bird Sales, Inc.

Customer Support Center

6640 S. Bonney Ave.

Tucson, AZ 85706

1-800-RAIN BIRD

FAX (520) 434-6289

2000 Rain Bird Sprinkler Mfg. Corp.

Registered Trademark of Rain Bird Sprinkler Mfg. Corp.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Deluxe Murphy Bed Plan FullDocument22 paginiDeluxe Murphy Bed Plan Fullperffecto100% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Total Home Inspection ChecklistDocument7 paginiTotal Home Inspection ChecklistpcsriÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Wj001 Barristers BookcaseDocument7 paginiWj001 Barristers BookcasemiclarkÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- WJ157 Easy Chair Side TablesDocument9 paginiWJ157 Easy Chair Side Tablesmiclark100% (1)

- Valve Trim Material and SpecDocument28 paginiValve Trim Material and SpecRamesh KrishnanÎncă nu există evaluări

- SG21-3 Operation and Maintenance ManualDocument154 paginiSG21-3 Operation and Maintenance ManualPurnama Abhie100% (2)

- Bombas CasappaDocument36 paginiBombas CasappaIldebrando Montaño MedinaÎncă nu există evaluări

- Polyester Resin ManufactureDocument49 paginiPolyester Resin ManufactureGreg Voloshenko100% (9)

- Top Drive Inspection PDFDocument20 paginiTop Drive Inspection PDFAhmed Imtiaz Rao100% (6)

- LG Arun Gse2Document15 paginiLG Arun Gse2Claudiu RaduÎncă nu există evaluări

- 1,2,3 - Water Supply and DistributionDocument5 pagini1,2,3 - Water Supply and DistributionKaren JohnsonÎncă nu există evaluări

- AlarmsDocument38 paginiAlarmsJosephine Balansag Amolo100% (2)

- Transmission Fluid and Filter Service Recommendations (Allison TES-439) PDFDocument7 paginiTransmission Fluid and Filter Service Recommendations (Allison TES-439) PDFAnibal Rios100% (1)

- Used Boiler O&M ManualDocument194 paginiUsed Boiler O&M ManualAlexis CruzÎncă nu există evaluări

- Htaccess CheatsheetDocument3 paginiHtaccess Cheatsheetaperta100% (2)

- Model View Controller (MVC) in PHP Tutorial PDFDocument543 paginiModel View Controller (MVC) in PHP Tutorial PDFmiclarkÎncă nu există evaluări

- Blood Pressure TrackerDocument2 paginiBlood Pressure TrackermiclarkÎncă nu există evaluări

- Laundry Pedestal Cut ListDocument1 paginăLaundry Pedestal Cut ListmiclarkÎncă nu există evaluări

- Properly Lighting Your ShopDocument1 paginăProperly Lighting Your ShopmiclarkÎncă nu există evaluări

- Wj028 Trundle BedDocument9 paginiWj028 Trundle BedmiclarkÎncă nu există evaluări

- Radial Arm Saw ManualDocument86 paginiRadial Arm Saw ManualdanstraussÎncă nu există evaluări

- WJ013 AC Dining ChairsDocument11 paginiWJ013 AC Dining ChairsmiclarkÎncă nu există evaluări

- Rule Quick Sheet 1Document3 paginiRule Quick Sheet 1miclarkÎncă nu există evaluări

- Radial Arm Saw ManualDocument86 paginiRadial Arm Saw ManualdanstraussÎncă nu există evaluări

- Standing Rib RoastDocument3 paginiStanding Rib RoastmiclarkÎncă nu există evaluări

- DW7463 Out Feed Table PartsDocument2 paginiDW7463 Out Feed Table PartsmiclarkÎncă nu există evaluări

- People Code Developer GuideDocument368 paginiPeople Code Developer Guidenapolitano0708Încă nu există evaluări

- vi Cheat Sheet GuideDocument1 paginăvi Cheat Sheet GuidemiclarkÎncă nu există evaluări

- 6AKM157WH2 Ver857115753050Document9 pagini6AKM157WH2 Ver857115753050Sergio OlivieriÎncă nu există evaluări

- Series 10: Seat 3/4-16 UNF-2B ISO 725 Bar Nom L/minDocument8 paginiSeries 10: Seat 3/4-16 UNF-2B ISO 725 Bar Nom L/minVendas HidrautrônicaÎncă nu există evaluări

- Una45 GestraDocument6 paginiUna45 Gestra123456jodaÎncă nu există evaluări

- Catalog 14 en 1630606Document552 paginiCatalog 14 en 1630606tanhieungoÎncă nu există evaluări

- FlowMaster User Manual V2.0Document36 paginiFlowMaster User Manual V2.0Agus MulyadiÎncă nu există evaluări

- LUBEWORKS-Catalogue BrochureDocument4 paginiLUBEWORKS-Catalogue Brochureventas freyreÎncă nu există evaluări

- Pressure Decay Tester: Application NoteDocument2 paginiPressure Decay Tester: Application Notejack macÎncă nu există evaluări

- Precision Hydraulics 12th Edition 2019 CTR VALVESDocument819 paginiPrecision Hydraulics 12th Edition 2019 CTR VALVESHassan KhattabÎncă nu există evaluări

- Alarm ValveDocument6 paginiAlarm ValveAnonymous ZPTCAz9Încă nu există evaluări

- Ashdown-Ingram - Ashdown-Ingram AC Catalogue 2017Document836 paginiAshdown-Ingram - Ashdown-Ingram AC Catalogue 2017Jimmy BarÎncă nu există evaluări

- 0056-2690 - Victor Edge Ess42 SeriesDocument64 pagini0056-2690 - Victor Edge Ess42 SeriesLuis PineresÎncă nu există evaluări

- Thermo Scientific Air Cadet: Vacuum/Pressure PumpsDocument6 paginiThermo Scientific Air Cadet: Vacuum/Pressure PumpsAMEL FCQFÎncă nu există evaluări

- Manual Elevador Launch TLT 245Document16 paginiManual Elevador Launch TLT 245Tonnyrafa64Încă nu există evaluări

- Standardy Techniczne Biura Techniki - Urządzenia Ciśnieniowe ENG - Rev5Document58 paginiStandardy Techniczne Biura Techniki - Urządzenia Ciśnieniowe ENG - Rev5arek74krakowÎncă nu există evaluări

- HDI-Compressor ManualDocument26 paginiHDI-Compressor ManualBALAÎncă nu există evaluări

- SSSV Evolution IntroductionDocument8 paginiSSSV Evolution IntroductionQaiser HafeezÎncă nu există evaluări

- Plant Piping Pressure Testing: (Exam For Inspectors Performing Test PKG & Sis Sheet Calculation Reviews)Document3 paginiPlant Piping Pressure Testing: (Exam For Inspectors Performing Test PKG & Sis Sheet Calculation Reviews)aslam.ambÎncă nu există evaluări

- Electrovalvula Serie 121 AscoDocument1 paginăElectrovalvula Serie 121 AscoBase SistemasÎncă nu există evaluări

- SNO-I-DS-003 - 0 Instrument Data Sheet For Control ValvesDocument191 paginiSNO-I-DS-003 - 0 Instrument Data Sheet For Control Valvesono_czeÎncă nu există evaluări