Documente Academic

Documente Profesional

Documente Cultură

Install Manual Pump

Încărcat de

Katibi VanhasDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Install Manual Pump

Încărcat de

Katibi VanhasDrepturi de autor:

Formate disponibile

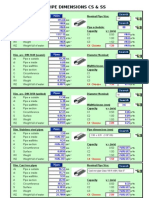

FPS ISO Series

Installation Operations &

Maintenance Instructions

2

USERS RECORD

Pump Model Number: _______________________

Pump Serial Number: ________________________

Impeller Diameter: __________________________

Motor kW: _________________________________

Motor Speed: _______________________________

Purchased From: ____________________________

ISO Pumps

2

3

ISO Pumps

3

1. General

FPS ISO pumps are designed manufactured to give trouble free and satisfactory service if

they are properly installed and maintained.

This manual does not take into account on any on site safety regulations which may apply. It

is intended to provide the user with essential information required for installing operating

and maintaining the Franklin ISO pump.

Examine the pump when it is received to be sure there has been no damage in shipping.

Should any be evident, report it immediately to the transport company and ask to have it

inspected. Check the name plate of the pump to ensure you have received the correct pump.

In standard construction the operating conditions should not exceed

beyond the maximum operating pressure of 16Bar and temperature of 80C.

For pumping products other than water and liquid temperatures higher

than 80C, please contact Franklin Electric for advice.

The Pump set must only be handled by skilled, trained personnel.

The manufacturer accepts no liability for the pump sets if the instructions

in this manual are not complied with.

Make sure that all electrical connections and works have been carried

out by a certifed electrician. All electrical installation, connections and

protections must comply with all local, state and national regulations.

2. Location

Positions the pump unit as close as possible to the liquid being pumped and ensure that

lowest suction lift is achieved in conjunction with using the shortest length of suction pipe.

Refer to the pump performance curve (NPSHr) to determine the maximum allowable suction

lift. Ensure that the pump motor is at least 150mm from the nearest obstruction to enable

proper air fow to cool the motor.

!

ATTENTION

4

ISO Pumps

3. Installation

All pipe work should be correctly aligned with the pump and frmly supported so that no

external loads are imposed on the pump body. In case of the direct coupled units, the pump

shaft must be free to turn after the pump has been has been bolted in position and pipe

work connected.

3.1 Suction Piping

Suction piping must be free from air leak. Suction piping should be the same size or

larger than the suction inlet of the pump. Tapered eccentric reducers should be used

when using larger diameter pipe (Refer the sketch below). The pump should be ftted

with a straight pipe of length not less than 3 times the pipe diameter. Make sure that the

suction pipe well below the liquid level to prevent vortexing and the consequent entry of

air into the suction pipe. Suction pipe line should have continual fall from pump to liquid

source to prevent the formation of air pockets. Where there is suction lift a reputable

foot valve with water opening of equal or large than that of the suction pipe must be

ftted.

3.2 Discharge Piping

Discharge pipe should be selected of a size suitable to carry the required capacity, such

that the friction head created is not excessive. To avoid the formation of air pockets

in the discharge piping, (i.e. At the high points) vent cocks must be placed to expel

any accumulation of air which may affect the discharge capacity of the pump. It is

recommended a non return valve is ftted on the discharge side (Refer diagram below

for typical pipe work on the discharge side).

Eccentric Taper Pipe

Straight Pipe

Gatevalve

Priming Plug

90 Bend

Non-return Valve

Concentric Taper

5

ISO Pumps

4. Direct Coupled Pumps

Flexible coupling must be ftted and aligned in accordance with the coupling

manufacturers recommendations. If the couplings are not properly aligned, premature

bearing failure may occur. Coupling alignment also must be checked once the pump is

bolted to the foundation.

5. Starting

Ensure that the foot valve is of good quality and holds prime when the pump is under

suction lift. A non return valve can be used under fooded suction.

Close the discharge gate valve.

Prime the pump. Pump casing and the suction line must be flled with the liquid being

pumped, either by direct flling or if the suction pipe is larger and longer, a diaphragm

pump can be used on the suction side to expel the air in the line and prime the pump.

Turn the pump shaft slowly in order to expel the air trapped in the impeller.

Ensure that the drive shaft rotation conforms to the direction of rotation indicated by

the arrow on the casing.

Start the unit now and when the pump reaches the full speed open the gate valve

slowly till the desired fow is reached.

If no liquid is delivered stop the pump immediately and check for leaks in the suction

side and check the foot valve, re-prime the pump and fow the above procedure.

Do not run the pump dry for prolong period of time as the

mechanical seal can get damaged and the pump will start leaking.

6. Maintenance

Check the unit regularly for any leaks and smooth operation to prevent seal failure and

damage to the pump and motor.

Check the bearing temperature regularly by feeling the bearing cover to prevent

premature bearing failure.

Check the liquid quality regularly to prevent the internals of the pump from damage by

foreign materials.

Constantly monitor the water level in the supply tank to prevent the pump from

running dry and from cavitation if the pump is under suction lift.

Regularly monitor the pressure gauges and the absorbed current of the motor. If

abnormal take proper precautionary measure.

If the pump is expected to be left unused for an extended period of time, drain

the water in the casing, open the casing and spray the inside of the pump with rust

inhibiting agent and store in an appropriate place.

!

ATTENTION

6

ISO Pumps

7. Trouble Shooting

1. No water or the capacity is less than specifed.

Excessive suction lift.

Check Pump NPSHr.

Blocked suction.

Pump not holding prime.

Speed is too slow.

In correct direction of rotation.

Air or gasses in the water.

Impeller is partially blocked.

Discharge head is too high.

2. Bearings are too Hot

Couplings are not aligned correctly.

Bearings lack lubrication or worn bearings.

Unsupported pipeline load on the pump.

3. Power consumption is too high

Dynamic head calculation is incorrect. Discharge head is too low.

Pump speed is too high.

SG of the pumped liquid may be greater than 1.

The motor shaft is not in line with the pump shaft or the pump shaft is bent.

Blocked pump.

4. Excessive Vibration

Pump base is not tightened properly to the foundation or the unit is not properly

mounted on the foundation.

Motor shaft is not aligned to the pump shaft

Impeller is not balanced.

Worn out bearings

Faulty coupling or the coupling is not aligned properly.

5. Noisy operation

Impeller is jammed with foreign object.

Impeller is touching the casing.

Worn out or faulty bearings

Cavitaion.

6. Excessive internal wear of the Pump

Cavitation.

Presence of excessive air or gas in the product pumped.

Presence of solids in the water.

Corrosive liquid.

7

ISO Pumps

8. Disassembly Procedure

It is important that the pressure in the pump must be released

and the pump is isolated from all pipe work.

1. Remove the back plate casing bolts.

2. Unscrew the impeller nut about two turns and drive a pair of wooden wedge gently

between the impeller and the back plate. This procedure must be carried with care

so that the impeller is not damaged. Give the impeller nut a sharp blow, using a

hammer and a piece of hard wood to spring the impeller from the taper. Remove

the impeller nut and sealing washer and slide the impeller out. Lift out the impeller

key from the shaft and slide the rotating part of the mechanical seal out.

3. Loosen and remove the joint bolts between the back plate and the bearing housing

(or bell housing in case of close coupled pumps) and remove the back plate. Remove

the stationary face of the mechanical seal by gently taping it out with a piece of

wood.

4. Disassemble the retaining bolts between bearing housing and remove the bearing

cover (Only for direct coupled pumps) shaft and bearing. For close couple pumps

undo the grub screws on the stub shaft and slide the stub shaft from the motor

shaft.

9. Assembly Procedure

The assembly sequence of the ISO pumps are carried out in reverse order of the

disassembly sequence.

It is always a good practice to change the mechanical seal when

overhauling or repairing an ISO pump.

All mating faces of the pumps should be cleaned during assembly.

When mounting the O ring to the casing, grease should be applied

to prevent it from falling off or folding while assembling.

!

ATTENTION

!

ATTENTION

!

ATTENTION

8

ISO Pumps

FPS ISO Series

ISO Bare Shaft Pump Parts Description

Item Description

02 Bearing Cap (Rear)

03 Bearing Cap (Front)

04 Mechanical Seal

06 Fastener Set

07 Volute (Casing)

10 Impeller Key - Woodruff

11 Impeller Nut

12A O-Ring

13 Impeller

19 Shaft DC

01 Bearing Housing

39 Intermediate Cover

Item Description

50 Impeller Washer

51A Oil Seal - Front

51B Oil Seal - Rear

52 Bearing - Ball

53 Support Foot

54 Shaft Key - Input Drive

45 Wear-ring Casing Front (Option)

46 Wear-ring Intermediate cover Rear (Option)

47 & 48 Wear-ring Impeller Front & Rear (Option)

64 Plugs - Casing Drain

64A Plugs - Casing Suct & Disch

9

ISO Pumps

FPS ISO Series

ISO Stub Shaft Pump Parts Description

Item Description

01 Motor End Adaptor

04 Gland / Mechanical Seal

06 Fastener Set

07 Volute (Casing)

10 Impeller Key

11 Impeller Nut

12A O-Ring

13 Impeller

17 Muff Coupling

18 Muff Coupling Screws

19 Shaft CC

39 Intermediate Cover

50 Impeller Washer

45 Wear-ring Casing Front (Option)

46 Wear-ring Intermediate cover Rear (Option)

47 & 48 Wear-ring Impeller Front & Rear (Option)

64 Plugs - Casing Drain

64A Plugs - Casing Suct & Disch

Notes

10

11

FE476 03/10

AUSTRALIA / NEW ZEALAND

Franklin Electric (Australia) Pty. Ltd.

106-110 Micro Circuit

Dandenong South, Victoria 3175

Australia

Toll Free: 1300 FRANKLIN

Fax: +61 3 9799 5050

Tel: +61 3 9799 5000

www.franklin-electric.com.au

UNITED STATES

Franklin Electric Co., Inc.

400 E. Spring Street, Bluffton, IN 46714 USA

Tel: +1.260.824.2900 Fax: +1.260.824.2909

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Injector - Wikipedia, The Free EncyclopediaDocument7 paginiInjector - Wikipedia, The Free EncyclopediaEbby OnyekweÎncă nu există evaluări

- Molecular Transport Equation and General Property BalanceDocument56 paginiMolecular Transport Equation and General Property BalanceJant Erbert Garboso100% (1)

- Hydraulic Circuit DiagramDocument2 paginiHydraulic Circuit Diagramjayath100% (1)

- Fabrication ProcedureDocument16 paginiFabrication ProcedureAryo WicaksonoÎncă nu există evaluări

- LP PDFDocument8 paginiLP PDFEshanth RajÎncă nu există evaluări

- Venturi Meters, Orifice Meters, and Flow Nozzles Measure The Volumetric Flow RateDocument2 paginiVenturi Meters, Orifice Meters, and Flow Nozzles Measure The Volumetric Flow RatearamÎncă nu există evaluări

- PB02-HRH-001 Hot Reheat Steam System: Saudi Arabian Oil CompanyDocument1 paginăPB02-HRH-001 Hot Reheat Steam System: Saudi Arabian Oil CompanyzhangÎncă nu există evaluări

- Daftar Tabel BajaDocument1 paginăDaftar Tabel BajaSuhardi HananÎncă nu există evaluări

- National Plumbing CodeDocument20 paginiNational Plumbing CodeDonixÎncă nu există evaluări

- Water Pumps and Pumping SystemsDocument38 paginiWater Pumps and Pumping SystemsmelgamalÎncă nu există evaluări

- Chapter 12 - Fluid MachineriesDocument98 paginiChapter 12 - Fluid MachineriesWaw0% (1)

- Price List 50-2017 - EN Low Res ItaliaDocument84 paginiPrice List 50-2017 - EN Low Res ItaliaivoniciuÎncă nu există evaluări

- Reducing Valve R 8Document2 paginiReducing Valve R 8Cristian Adrian AÎncă nu există evaluări

- Industrial Hydraulic CircuitsDocument43 paginiIndustrial Hydraulic CircuitsFidel Garcia GarciaÎncă nu există evaluări

- ASME B16: Standardization of Valves, Flanges, Fittings, and Gaskets # Standard DesignationDocument6 paginiASME B16: Standardization of Valves, Flanges, Fittings, and Gaskets # Standard DesignationNicolásMerinoGutiérrezÎncă nu există evaluări

- BernoulliDocument25 paginiBernoulliAlberto Preciados AlumbroÎncă nu există evaluări

- Samson ValveDocument4 paginiSamson ValveTri CuyÎncă nu există evaluări

- EN3552 Sicherheitseinrichtungen KatalogversionDocument10 paginiEN3552 Sicherheitseinrichtungen KatalogversionCarlos BernussiÎncă nu există evaluări

- Intake StructuresDocument14 paginiIntake Structuresnimm1962100% (1)

- Numerical Study Using FLUENT of The Separation andDocument24 paginiNumerical Study Using FLUENT of The Separation andAbhiroop DasÎncă nu există evaluări

- 9.line Size & Wall ThicknessDocument48 pagini9.line Size & Wall ThicknessClark PlúaÎncă nu există evaluări

- Trimfit Brass Bronze Globe ValveDocument1 paginăTrimfit Brass Bronze Globe ValveJohn HarveyÎncă nu există evaluări

- Additional Course Material: Physical Properties of FluidsDocument43 paginiAdditional Course Material: Physical Properties of Fluidssilswal1988Încă nu există evaluări

- Cherne Test Ball Pipe PlugsDocument2 paginiCherne Test Ball Pipe PlugsPromagEnviro.comÎncă nu există evaluări

- Dim of Pipes Flanges and FittingsDocument9 paginiDim of Pipes Flanges and Fittingsreach_arindomÎncă nu există evaluări

- Ibr Pipe & Fittings Tc-FinalDocument8 paginiIbr Pipe & Fittings Tc-FinalManikandan elumalaiÎncă nu există evaluări

- Lecture 4 - Governing Laws and Principles: Self Evaluation Questions and AnswersDocument22 paginiLecture 4 - Governing Laws and Principles: Self Evaluation Questions and AnswersMohamedÎncă nu există evaluări

- M9319 - R3 - Hydrocyclones For Cleaners & ConditionersDocument23 paginiM9319 - R3 - Hydrocyclones For Cleaners & ConditionersRicardo VillarÎncă nu există evaluări

- StrippingDocument17 paginiStrippingGhavban David0% (1)

- Artificial LiftDocument18 paginiArtificial LiftRasya RefanÎncă nu există evaluări