Documente Academic

Documente Profesional

Documente Cultură

Maxon M PAKT Iom 2007 08

Încărcat de

John HowardDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Maxon M PAKT Iom 2007 08

Încărcat de

John HowardDrepturi de autor:

Formate disponibile

Low Temperature Burners - M-PAKT

w w w . m a x o n c o r p . c o m

combustion systems for industry

Maxon reserves the right to alter specifications and data without prior notice.

2005 Copyright Maxon Corporation. All rights reserved.

1- 1.7 - 13

E - i - 8/07

Installation and Operating Instructions for M-PAKT

Burners

Application Requirements

Vi ew port

A view port to observe burner flame is essential to inspect flame aspect. Locate the view port downstream of the flame, looking

back to the burner block. Make sure the complete flame can be evaluated.

Support burner air and gas pi ping

The M-PAKT

Burner shall not be used as support for the piping to the burner. Gas and air piping shall be supported in such a way

that no additional loads will be created on the burner.

Burner mounting flange l oads

Check burner weight and reinforce burner mounting flange or combustion chamber/furnace back wall if necessary to take

complete burner weight.

Ratio control

M-PAKT

burners may be operated with 40 to 70% excess air. Consult page 1-1.7-7 for required sleeve materials per application.

MAXON recommends the use of characterized fuel/air ratio control through SMARTLINK MRV

or MICRO-RATIO

valves.

Consult MAXON for specific recommendations based upon the burner application and performance requirements.

Flame supervision

M-PAKT

Burners require the use of UV or IR flame scanners. Some models of flame sensor may not respond well to ultra low

NOx flame signatures. Consult sensor manufacturers for specific recommendations.

Fuel s

M-PAKT

Burners are designed to operate on natural gas, propane and butane. Specific emissions performance can be affected

by fuel. Contact MAXON for recommendations on alternative fuels.

Installation Instructions

Storage of M-PAKT

Burners

M-PAKT

Burners shall be stored dry (inside).

Handling of M-PAKT

Burners

M-PAKT

Burners are shipped as complete units. Handle burners with care during unpacking, transport, lifting and installation.

Use proper equipment. Any impact on the burner could result in damage.

Flange the burner to the installation

Bolt the burner to the installations burner mounting flange. Use proper gasketing. Tighten the flange bolting with correct torque.

Retighten all bolts after first firing and regularly after commissioning.

Low Temperature Burners - M-PAKT

w w w . m a x o n c o r p . c o m

combustion systems for industry

Maxon reserves the right to alter specifications and data without prior notice.

2005CopyrightMaxonCorporation All rights reserved

1-1.7 -14

E - i - 8/07

Start-up Instructions for M-PAKT

Burner

Read complete instructions before proceeding, and familiarize yourself with all the systems equipment components. Verify that

your equipment has been installed in accordance with the original manufacturers current instructions and complies with all

applicable codes and standards.

Typical ignition sequence

Pre-purge of burner and installation, according to the applicable codes and the installations requirements.

Combustion air control valve shall be in the minimum position to allow minimum combustion air flow to the burner.

Pre-ignition (typically 2s sparking in air).

Open pilot gas and continue to spark the ignitor (typically 5s).

Stop sparking, continue to power the pilot gas valves and start flame check. Trip burner if no flame from here on.

Check pilot flame stability (typical 5s to prove stable pilot).

Open main gas valves and allow enough time to have main gas in the burner (typical 5s +time required to have main gas in the

burner.

Close the pilot gas valves.

Release to modulation (allow modulation of the burner).

Above sequence shall be completed to include all required safety checks during the start-up of the burner (process and burner

safeties).

Locate one pilot gas valve as close as possible to the pilot burner gas inlet, to have fast ignition of the pilot burner.

CAUTION: Initial adjustment and light-off should be undertaken only by trained and experienced

personnel familiar with combustion systems, with control/safety circuitry, and with knowledge of the

overall installation. Instructions provided by the company and/or individuals responsible for the

manufacture and/or overall installation of complete system incorporating MAXON burner take

precedence over these provided by MAXON. If MAXON instructions conflict with any codes or

regulations, contact MAXON before attempting start-up. Use only an interrupted pilot with the

M-PAKT

burner. Do not use M-PAKT

Burners with main gas shut off valves having extended opening

times (> 6 seconds). Delayed introduction of main fuel can create strong light offs and thermal damage

to burner internals.

Low Temperature Burners - M-PAKT

w w w . m a x o n c o r p . c o m

combustion systems for industry

Maxon reserves the right to alter specifications and data without prior notice.

2005 Copyright Maxon Corporation. All rights reserved.

1- 1.7 - 15

E - i - 8/07

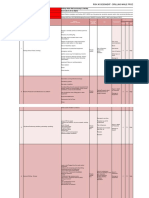

Setting appropri ate fuel pressure at any point

Step 1:

To properly adjust the fuel/air ratio of the M-PAKT

Burner at any firing rate, first measure the differential air pressure between the

burner air test connection and the firing chamber.

Step 2:

Then multiply the air pressure value by the appropriate pressure factor, m, shown in the tables below.

Step 3:

Next, measure the fuel pressure differential between the burner fuel test connection and the firing chamber and adjust the fuel

pressure with characterized fuel control valve at that point to the value calculated in Step #2.

Example:

On a 2.5M M-PAKT

Burner near half-fire, the differential air pressure reading is 2.2 wc . To figure the appropriate fuel pressure,

multiply 2.2 wc by the m factor 0.99. The result is 2.18 wc . Set the differential fuel pressure to 2.18 wc .

Packaged Burners

Size 0.4M 0.9M 1.5M 2.5M 3.5M

Max Capacity MBtu/h 0.41 0.9 1.6 2.5 3.5

Max Fuel Pressure wc 4.1 10.4 8.6 10.3 14.4

Min Fuel Pressure wc 1.4 1.6 2.0 2.0 1.9

Max Air Pressure wc 8.8 8.8 10.1 10.4 10.3

Min Air Pressure wc 0.3 0.3 0.3 0.3 0.3

m --- 0.47 1.18 0.85 0.99 1.4

EB Burners

Size EB2 EB3 EB4 EB5 EB6 EB7

Max Capacity MBtu/h 0.8 1.7 2.7 4.5 5.8 8.4

Max Fuel Pressure wc 12.1 37.2 24 32.6 37 60

Min Fuel Pressure wc 0.6 0.4 0.7 0.6 0.7 0.7

Max Air Pressure wc 29.4 29.7 28 32.9 27.5 27.2

Min Air Pressure wc 0.3 0.3 0.3 0.3 0.3 0.3

m --- 0.41 1.25 0.86 0.99 1.35 2.21

Low Temperature Burners - M-PAKT

w w w . m a x o n c o r p . c o m

combustion systems for industry

Maxon reserves the right to alter specifications and data without prior notice.

2005CopyrightMaxonCorporation All rights reserved

1-1.7 -16

E - i - 8/07

Start-up Instructions

Fuel/Air Relationships - Packaged M-PAKT

Burner

Fuel/Air Relationships - EB M-PAKT

Burner

Fuel and Air Pressure Requirements

Differential Pressure at Burner Test Connections

0.0

5.0

10.0

15.0

20.0

25.0

30.0

0.0 2.0 4.0 6.0 8.0 10.0 12.0

Combustion Air Pressure (" w.c.)

N

a

t

u

r

a

l

G

a

s

P

r

e

s

s

u

r

e

(

"

w

.

c

.

)

0.4M

0.9M

1.5M

2.5M

3.5M

Fuel and Air Pressure Requirements

Differential Pressure at Burner Test Connections

0.0

10.0

20.0

30.0

40.0

50.0

60.0

70.0

0.0 5.0 10.0 15.0 20.0 25.0 30.0

Combustion Air Pressure (" w.c.)

N

a

t

u

r

a

l

G

a

s

P

r

e

s

s

u

r

e

(

"

w

.

c

.

)

EB2

EB3

EB4

EB5

EB6

Low Temperature Burners - M-PAKT

w w w . m a x o n c o r p . c o m

combustion systems for industry

Maxon reserves the right to alter specifications and data without prior notice.

2005 Copyright Maxon Corporation. All rights reserved.

1- 1.7 - 17

E - i - 8/07

Maintenance and Inspection Instructions

Safety requirements

Regular inspection, testing and recalibrate of combustion equipment according to the installation manual is an integral part of its

safety. Inspection activities and frequencies shall be carried out as specified in the installation manual.

Vi sual i nspections

Regular visual inspection of all connections (air and gas piping to the burner, bolting of the burner to the furnace) and burner flame

size and aspect are essential.

Spare parts

Keep local stock of spark ignitor. It is not recommended to keep local stock of other burner parts. Consult installation manual for

burner spare parts and system accessories.

S-ar putea să vă placă și

- Megafire ManualDocument6 paginiMegafire ManualBehnam NoorizadehÎncă nu există evaluări

- E Valupak M Specs InstructionsDocument8 paginiE Valupak M Specs Instructionsmgk80Încă nu există evaluări

- Maxon M PAKT Bro 2007 08Document4 paginiMaxon M PAKT Bro 2007 08John HowardÎncă nu există evaluări

- Manual For Industrial Burner: Heavy Oil/Natural Gas Ebs GNQ SeriesDocument78 paginiManual For Industrial Burner: Heavy Oil/Natural Gas Ebs GNQ SeriesJhons Albert Arnez AlcocerÎncă nu există evaluări

- Furnace Manual 120v Updated 2013Document21 paginiFurnace Manual 120v Updated 2013api-251989125Încă nu există evaluări

- General Instructions For Safe Operation of High Pressure CompressorsDocument6 paginiGeneral Instructions For Safe Operation of High Pressure CompressorsTansu MavunacıÎncă nu există evaluări

- Catalogo Quemador Maxton CyclomaxDocument8 paginiCatalogo Quemador Maxton CyclomaxJuanCamiloRestrepoÎncă nu există evaluări

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Manual Powerflame C PDFDocument56 paginiManual Powerflame C PDFRoberto MnedezÎncă nu există evaluări

- SADC System ExplainedDocument8 paginiSADC System ExplainedpallavishraddhaÎncă nu există evaluări

- Stromberg 175Document17 paginiStromberg 175vanapeer100% (10)

- Megafire ManualDocument16 paginiMegafire ManualBehnam NoorizadehÎncă nu există evaluări

- (VOLKSWAGEN) Manual de Taller Volkswagen CC 1990 1991Document15 pagini(VOLKSWAGEN) Manual de Taller Volkswagen CC 1990 1991Luis TroieÎncă nu există evaluări

- Kinemax Gas or Oil Burners: Bulletin 4200Document26 paginiKinemax Gas or Oil Burners: Bulletin 4200agua1829Încă nu există evaluări

- R 232 MS5001 Technical DescriptionDocument7 paginiR 232 MS5001 Technical Descriptionscribdkhatn100% (4)

- Boiler Manual Updated 20131Document50 paginiBoiler Manual Updated 20131api-251989125Încă nu există evaluări

- Waste Oil Fired Boiler Installation ManualDocument50 paginiWaste Oil Fired Boiler Installation ManualJimi DbonoÎncă nu există evaluări

- SB3-0-101Document13 paginiSB3-0-101jussmeeeÎncă nu există evaluări

- Olusterm Olejovy Horak NavodDocument19 paginiOlusterm Olejovy Horak NavodozuskacÎncă nu există evaluări

- BMS GuideDocument63 paginiBMS GuideArindam Misra100% (4)

- Trinity & Matrix: Natural To LP Conversion InstructionsDocument4 paginiTrinity & Matrix: Natural To LP Conversion InstructionsFREDÎncă nu există evaluări

- Wesman Thermal Engineering Processes Pvt Ltd Fuel Firing Equipment Operation and Maintenance ManualDocument23 paginiWesman Thermal Engineering Processes Pvt Ltd Fuel Firing Equipment Operation and Maintenance ManualSaibabu Sai100% (1)

- Radiant Manual Updated 2013Document19 paginiRadiant Manual Updated 2013api-251989125Încă nu există evaluări

- CJK5 - Equipment Specification (En 2011)Document12 paginiCJK5 - Equipment Specification (En 2011)Christian ThompsonÎncă nu există evaluări

- Installation Instructions: LO-NOX™ Line Burners Page 5800-S-1Document6 paginiInstallation Instructions: LO-NOX™ Line Burners Page 5800-S-1Nicolás Becker CastellaroÎncă nu există evaluări

- Power Plant OperationDocument199 paginiPower Plant OperationVijay Bhargav Badam83% (6)

- Engine Fuel System Purging, On Wing - Maintenance PracticesDocument8 paginiEngine Fuel System Purging, On Wing - Maintenance Practicesphuong leÎncă nu există evaluări

- Installation and operating instructions for Weishaupt oil burners L, RL, and M Sizes 1 and 3Document40 paginiInstallation and operating instructions for Weishaupt oil burners L, RL, and M Sizes 1 and 3Игорь88% (16)

- QuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioDocument5 paginiQuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de Serviciohamilton mirandaÎncă nu există evaluări

- BURNER MANAGEMENT SYSTEMS GUIDEDocument7 paginiBURNER MANAGEMENT SYSTEMS GUIDECalÎncă nu există evaluări

- Continenta lFI System AdjustmentDocument11 paginiContinenta lFI System AdjustmentAnonymous o1NYRvUÎncă nu există evaluări

- Oilon 4A Monox en StandardDocument16 paginiOilon 4A Monox en StandardWilbert Consuelo CotrinaÎncă nu există evaluări

- Zenith 35-40 InatDocument15 paginiZenith 35-40 InatSinanToklucu67% (3)

- Cummins QSK 23 Fuel PumpDocument10 paginiCummins QSK 23 Fuel PumpPedro SchembriÎncă nu există evaluări

- BlueHeat Coolant Heater Installation GuideDocument28 paginiBlueHeat Coolant Heater Installation GuideZoltan Szekely50% (2)

- Holley Carb AdjustmentsDocument8 paginiHolley Carb AdjustmentsAaron SteeleÎncă nu există evaluări

- Nett Manual Universal-Fit ProductsDocument2 paginiNett Manual Universal-Fit ProductsJesus Santana GalvezÎncă nu există evaluări

- Ba InciniCone USADocument10 paginiBa InciniCone USAmickdoggettÎncă nu există evaluări

- BMS GUIDE FOR BOILER SAFETYDocument7 paginiBMS GUIDE FOR BOILER SAFETYchungttÎncă nu există evaluări

- 701Document35 pagini701tmtt44100% (1)

- Onan BGE Service ManualDocument158 paginiOnan BGE Service Manualjwergers71% (21)

- Controlling Fired Heaters: INTRODUCTION. The Purpose of A FiredDocument24 paginiControlling Fired Heaters: INTRODUCTION. The Purpose of A FiredAntonio MezzopreteÎncă nu există evaluări

- Cussons P9005 Two Shaft Gas Turbine Unit: Versatile Educational Tool for Gas Turbine ExperimentsDocument4 paginiCussons P9005 Two Shaft Gas Turbine Unit: Versatile Educational Tool for Gas Turbine ExperimentsHùng Fly100% (3)

- BlowerDocument491 paginiBlowerozdemir_kucukler86% (7)

- GodrejdDocument49 paginiGodrejdsandeshlikesÎncă nu există evaluări

- Burner Management System PresentationDocument63 paginiBurner Management System Presentationankur2061100% (1)

- QSV Gas Gen-Set Maintenance GuideDocument16 paginiQSV Gas Gen-Set Maintenance GuideJuan Jose RodriguezÎncă nu există evaluări

- Om 125 Max My17 enDocument60 paginiOm 125 Max My17 enhd1033Încă nu există evaluări

- EMCO Large Engine Catalog 2008Document137 paginiEMCO Large Engine Catalog 2008Robert KirkÎncă nu există evaluări

- Bosch ECI Injection - ECIDocument17 paginiBosch ECI Injection - ECIBeTOÎncă nu există evaluări

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDe la EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesÎncă nu există evaluări

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SDe la EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SÎncă nu există evaluări

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDe la EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementÎncă nu există evaluări

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualDe la EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualÎncă nu există evaluări

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsDe la EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsÎncă nu există evaluări

- Shwachman-Diamond Syndrome in A Child Presenting With Cystic Fibrosis-Type Symptoms and A False-Positive Sweat TestDocument6 paginiShwachman-Diamond Syndrome in A Child Presenting With Cystic Fibrosis-Type Symptoms and A False-Positive Sweat TestJohn HowardÎncă nu există evaluări

- Rx8 General Info ManualDocument49 paginiRx8 General Info ManualJohn HowardÎncă nu există evaluări

- Essay Organization and StructureDocument6 paginiEssay Organization and StructureJohn HowardÎncă nu există evaluări

- Lua Novelties 5.2Document28 paginiLua Novelties 5.2Mikes RajifvÎncă nu există evaluări

- New Guide Hc89x Series Datasheet Na WebDocument12 paginiNew Guide Hc89x Series Datasheet Na WebJohn HowardÎncă nu există evaluări

- TSQ GlossaryDocument255 paginiTSQ GlossaryJohn HowardÎncă nu există evaluări

- Vane Shear TestDocument14 paginiVane Shear TestJohn HowardÎncă nu există evaluări

- Lua 5.0 PDFDocument71 paginiLua 5.0 PDFermeyogioÎncă nu există evaluări

- Student evaluation form SEODocument1 paginăStudent evaluation form SEOJohn HowardÎncă nu există evaluări

- Trump University - Fortune Without Fear - Real Estate Riches in An Unceertain MarketDocument94 paginiTrump University - Fortune Without Fear - Real Estate Riches in An Unceertain MarketJohn HowardÎncă nu există evaluări

- Office ReadmeDocument1 paginăOffice Readmesagar323Încă nu există evaluări

- Typical electrical equipment loads guideDocument3 paginiTypical electrical equipment loads guideJohn HowardÎncă nu există evaluări

- Logic ProblemsDocument15 paginiLogic ProblemsJohn HowardÎncă nu există evaluări

- DMRCDocument15 paginiDMRCJohn HowardÎncă nu există evaluări

- Delhi Metro PresentationDocument26 paginiDelhi Metro PresentationJohn HowardÎncă nu există evaluări

- Bucket Lists CompiledDocument8 paginiBucket Lists CompiledJohn HowardÎncă nu există evaluări

- Maxon Smartfire Control System SpecDocument12 paginiMaxon Smartfire Control System SpecJohn HowardÎncă nu există evaluări

- LADS MaxonValvesDocument1 paginăLADS MaxonValvesJohn HowardÎncă nu există evaluări

- Trade of Motor Mechanic P2Document28 paginiTrade of Motor Mechanic P2John HowardÎncă nu există evaluări

- Tariq Mas DoudDocument66 paginiTariq Mas DoudJohn HowardÎncă nu există evaluări

- LADS MaxonBurnersDocument1 paginăLADS MaxonBurnersJohn HowardÎncă nu există evaluări

- Beaming SunlightDocument1 paginăBeaming SunlightJuan D.Încă nu există evaluări

- Product Sheet: 970 Smartradar AtiDocument4 paginiProduct Sheet: 970 Smartradar AtiJohn HowardÎncă nu există evaluări

- Ben Franklin Glass HarmonicaDocument11 paginiBen Franklin Glass HarmonicaJohn HowardÎncă nu există evaluări

- Kuroshitsuji Dollhouse PianoDocument1 paginăKuroshitsuji Dollhouse PianoDavid Camilo Tovar SarmientoÎncă nu există evaluări

- Summary of Art of StartDocument25 paginiSummary of Art of StartJohn HowardÎncă nu există evaluări

- Maxon Shut Off Valve Sizing ChartDocument3 paginiMaxon Shut Off Valve Sizing ChartJohn HowardÎncă nu există evaluări

- E-Leak TestingDocument3 paginiE-Leak TestingItziar MinondoÎncă nu există evaluări

- Maxon Smartfire Control System BroDocument2 paginiMaxon Smartfire Control System BroJohn HowardÎncă nu există evaluări

- Explosives: What Is An Explosive? Classify Explosives With Examples. What Is The Requirement of Good Explosives? (1+2+2)Document21 paginiExplosives: What Is An Explosive? Classify Explosives With Examples. What Is The Requirement of Good Explosives? (1+2+2)Sampanna DhakalÎncă nu există evaluări

- Design of Urban Electric Bus Systems Simulation and TCO AnalysisDocument29 paginiDesign of Urban Electric Bus Systems Simulation and TCO AnalysisMuhammad SaalihÎncă nu există evaluări

- Visco ThermDocument4 paginiVisco ThermArun SÎncă nu există evaluări

- III. Solid Propellant Rocket MotorsDocument18 paginiIII. Solid Propellant Rocket MotorsdÎncă nu există evaluări

- Waste Tire Recycling Pyrolysis Equipment of Doing GroupDocument2 paginiWaste Tire Recycling Pyrolysis Equipment of Doing GrouppyrolysisoilÎncă nu există evaluări

- Wacker Neuson G100 Operator ManualDocument78 paginiWacker Neuson G100 Operator ManualCesar Palacios ToctoÎncă nu există evaluări

- MSDS: Papanicolaou Stain EA-50 HazardsDocument10 paginiMSDS: Papanicolaou Stain EA-50 HazardsNAMPEWO ELIZABETHÎncă nu există evaluări

- 3 - Calculations - Lecture 3Document42 pagini3 - Calculations - Lecture 3Ayush ModiÎncă nu există evaluări

- 125 Anfo - AmexDocument5 pagini125 Anfo - AmexJoyas MicaÎncă nu există evaluări

- Intercomparison of Methods To Estimate Black Carbon EmissionsDocument8 paginiIntercomparison of Methods To Estimate Black Carbon EmissionsJoy RoyÎncă nu există evaluări

- Today's Date and Fire Code RepealDocument9 paginiToday's Date and Fire Code RepealLito TayaoÎncă nu există evaluări

- Qa 00632 Cryogenic Engine in Rocket Propulsion Mechanical Seminar TopicDocument27 paginiQa 00632 Cryogenic Engine in Rocket Propulsion Mechanical Seminar TopicDhurai Rajiv GandhiÎncă nu există evaluări

- 16-Step Grate-Firing Wood Pellet Boiler Combustion CFD AnalysisDocument37 pagini16-Step Grate-Firing Wood Pellet Boiler Combustion CFD AnalysisNuttapon SangthongÎncă nu există evaluări

- Exercise Set 2newDocument16 paginiExercise Set 2newNurye NigusÎncă nu există evaluări

- Modelling and Analysis of Four Cylinder Piston With Different MaterialsDocument40 paginiModelling and Analysis of Four Cylinder Piston With Different MaterialsAjayÎncă nu există evaluări

- Excavation Hazards and Control MeasuresDocument22 paginiExcavation Hazards and Control MeasuresJick Micheal Jm100% (3)

- Fire Models Training Manual For Fso'S Volume 1: Fastlite: Home Office Fire Research and Development GroupDocument65 paginiFire Models Training Manual For Fso'S Volume 1: Fastlite: Home Office Fire Research and Development Groupkhashi110Încă nu există evaluări

- Boiler EfficiencyDocument32 paginiBoiler Efficiencyइंजी. महेन्द्र प्रताप सिंह100% (2)

- Bio mass & Bio fuels GuideDocument31 paginiBio mass & Bio fuels Guidevivek rameshÎncă nu există evaluări

- Gasifier Engine SystemDocument7 paginiGasifier Engine SystemRajkumar MeenaÎncă nu există evaluări

- Paper PublishedDocument6 paginiPaper PublishedTarun ChowdaryÎncă nu există evaluări

- 3rd I-CIPEC Babcock & Wilcox VolundDocument5 pagini3rd I-CIPEC Babcock & Wilcox VolundMatias MancillaÎncă nu există evaluări

- Euro and Bharat Stage Emission Norms AssignmentDocument23 paginiEuro and Bharat Stage Emission Norms AssignmentKrishna PrasadÎncă nu există evaluări

- Hazardous Area Classification GuideDocument48 paginiHazardous Area Classification GuideMoh Fahmi NajahiÎncă nu există evaluări

- Fireplaces Chimneys Flues PDFDocument22 paginiFireplaces Chimneys Flues PDFjeanyoper100% (1)

- D5 W4 Q1 Science FiveDocument6 paginiD5 W4 Q1 Science FiveAnn Kristell RadaÎncă nu există evaluări

- Read The Passages Given Below and Answer The Questions That Follow Each of ThemDocument60 paginiRead The Passages Given Below and Answer The Questions That Follow Each of Themrizwana fathima0% (1)

- Flow ThermDocument4 paginiFlow ThermDinesh KanaujiyaÎncă nu există evaluări

- Risk Assessment SIMOPS Drilling Vs Venting AlphaDocument7 paginiRisk Assessment SIMOPS Drilling Vs Venting AlphaLouise TeboÎncă nu există evaluări