Documente Academic

Documente Profesional

Documente Cultură

Tugas Supply Chain Management

Încărcat de

Robert Park0 evaluări0% au considerat acest document util (0 voturi)

107 vizualizări11 paginiResume

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentResume

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

107 vizualizări11 paginiTugas Supply Chain Management

Încărcat de

Robert ParkResume

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 11

Tugas Supply Chain Management

Nama : Muhammad Rizki Ardiansyah

Kelas : S1 MTU 2012

Nim : 22411209

The design of new products in the supply chain

management perspective

In a supply chain perspective, the design of new

products is one of the vital function that is parallel with

other functions

such as material procurement, production, and

distribution.

According to Fisher, the function of the supply chain

is basically divided into physical function and

market mediation function.

Designing new products included in the group

market mediation function with market research

activities, and after-sales service.

said, because the design of the product is an

attempt to accommodate the aspirations of the

customers so that the products will conform to the

desired

Desire diverse customers and higher as well as

intense competition encourages companies to

increasingly innovative in creating new products.

Consumer tastes are dynamic with the ability to

anticipate supply chain life cycle resulting in

innovative products become increasingly shorter.

Product life cycles are getting shorter carries many

implications for how companies compete in the

market and how to manage supply chain activities.

Time To Market Factors For Competitive Advantage

In handling innovative products, speed of launching

new designs are very important.

Time To Market is the time between the idea of

product design in the product began to be

marketed.

The process from idea to design a search could be

ready to launch a long and frequent repetitions to

tailor the design to the latest information obtained

by the designer.

Phases of activity in the design of new products, in

general are:Idea Generation :

Business / Technical Assesment

Product Concept

Product Engineering & Design

Prototype Design

Test & Pilot Production

Manufacturing Ramp Up

Launch

The length of time between an idea to launch a new

product to markets vary from one product to the other

products.There are many ways you can do the company

to shorten Time To Market, is

1) The involvement of many parties including

representatives of the (functional) within the company

and external parties such as suppliers and customers,

2) good project management,

3) Team 3 solid product designer, dynamic, and

energetic, as well as,

4) technology that supports.

Keterlibatan pihak-pihak yang berkepentingan sangat

penting dilakukan seawal mungkin untuk menghindari

adanya perubahan mendasar pada rancangan produk

setelah memasuki fase-fase akhir

Dalam rangka mengurangi pengulangan-pengulangan

yang mahal dan lama, berbagai aktivitas yang terkait

dengan perancangan dan peluncuran produk baru

dikerjakan lebih dini.

1) Misalnya, perancangan proses manufaktur sudah

dimulai sebelum rancangan produk selesai dibuat.

2) Praktek yang melibatkan fungsi-fungsi lain sejak dini

dalam perancangan produk serta secara simultan

melakukan kegiatan yang tadinya dikerjakan secara

sequential (satu sesudah yang lain) dinamakan

dengan concurrent engineering

Supplier Involvement Designing New Products

Traditionally, suppliers are often chosen after draft

Products are completed and ready for production.

Today, many companies are choosing suppliers

before Product design process begins so that the

supplier can be involved in product design.

They are required to give ten pliers input material

what is suitable for the design of new products and

whether The suppliers will be supplying material

needed.

Survey conducted by Handfield et al. (1999)

showed that the involvement of key suppliers clalam

process New product design offers significant

benefits.

Some of the benefits include cost savings materials,

improving the quality and compatibility of materials

with their designs, as well as reduction in design

time and manufacturing time.

According to Handfield & Nichols (2002), not all

suppliers have to involved early in the design of

new products.

Supplier for complex items and suppliers critical

need to be involved from the beginning, whereas

suppliers for materials or components that are

simple and relatively standard could be involved

only in the final phases of product design.

Of course, suppliers need to be INVOLVED early if

they have the skills (expertise) that can provide

significant input input in the development of new

products.

Financial Impact of New Product Delays

Financial Impact of Delay Delay in launching new

products into the market could

brought many negative effects.

First, competitors may also launch new products

and can capture market share early.

Second, an extension of time in designing new

products could resulting in huge cost overrun.

As a result, as shown in Figure 3.2, the company

not just late getting income (revenue) of new

products, but also have to cover the costs greater

development.

As a result, a slight delay in launching products to

result in a large enough market to delay the

company New point.oduk achieve breakeven

conditions

design for supply chain management

Nowadays transportation and inventory costs is

supply chain cost drivers (cost driver supply chain) that

large

portion.

Therefore, the things that need to be considered in

designing new products should not only issue easy

to manufacture, sell feasibility, cost, and time

development of the draft, but also other things such

as environmental aspects and aspects of the supply

chain management.

The design of products that consider supply chain

management is called design for SCM

In general design for SCM consider things like:

Ease to store, send, and restore the product

Design flexibility to changes in the customer

demand

Modularity: the number of components or the same

capital that can used to make different end products

Aspects of localization: the draft is concerned

whether or not most of the final assembly activities

(finalization) conducted in the area marketing

Reuseability of draft

Some large companies use the principles The in

designing their products.

Activities to complement the printer with user guide

speaking local (national) as well as the power supply

assembly called localization.

As shown in Figure 3.3 below, was HP

manufactures printers and perform localization

processes in the plant. Existing distribution centers

in various countries simply do distribution activities.

Due to the long delivery lead times, often demand

distributor turns on when the printer is in journey

from the factory to the distribution center.

However, because it is through the localization

process, the excess product in one country can not

be shipped to other countries (except by re-

localization process).

Given the costs incurred by the forecast errors Such

large enough, HP finally changing supply activities

Review

A product design is not just enough to be seen from

the aspect of technical production and marketing,

but also from aspekaspek supply chain

management.

New economic era characterized by intense

competition require many companies to launch

products new to the market quickly.

It takes not only the ability to produce a draft good

product, but also the ability to manage projects

elisien product design and effective. In addition, the

ability to manage the development and launch new

products to the market is also determined by close

cooperation between functions within the company

and active involvement of parties outside the

company, especially WHO suppliers will supply

components, systems, or modulmodul are ready to

be assembled.

Bibliography

http://ilmuteknikindustri.wordpress.com/2011/02/01/

supply-chain-management-manajemen-rantai-

pasok/

https://www.google.co.id/url?sa=t&rct=j&q=&esrc=s

&source=web&cd=1&cad=rja&uact=8&ved=0CBkQ

FjAA&url=http%3A%2F%2Fzakki.dosen.narotama.a

c.id%2Ffiles%2F2011%2F12%2F3-Perancangan-

Produk-Baru-dlm-

SCM.pdf&ei=uGbvU76KMpS48gX61oCgCw&usg=

AFQjCNHS1bztgVhgrczi_3tuXJap9aSwFg&bvm=bv

.73231344,d.dGc

S-ar putea să vă placă și

- Chapter 3Document38 paginiChapter 3Puneet Goel0% (1)

- Chapter 3 OM EditedDocument19 paginiChapter 3 OM EditedSeid KassawÎncă nu există evaluări

- ANKIT A Synopsis ReportDocument17 paginiANKIT A Synopsis ReportANKIT PANWARÎncă nu există evaluări

- New Product Development WikipediaDocument9 paginiNew Product Development WikipediaBreylin CastilloÎncă nu există evaluări

- 15me835 PLCM Module 3Document24 pagini15me835 PLCM Module 3prashanth prabhuÎncă nu există evaluări

- New Product DevelopmentDocument9 paginiNew Product Developmenthmltdt9221Încă nu există evaluări

- New Product Development - WikipediaDocument52 paginiNew Product Development - Wikipediaatreyee dalal chowdhuryÎncă nu există evaluări

- 4000 Word's AssignmentDocument13 pagini4000 Word's AssignmentAbdurrhmanÎncă nu există evaluări

- Process Management Engineering Design Ideation Design ManufacturingDocument5 paginiProcess Management Engineering Design Ideation Design ManufacturingPraWin KharateÎncă nu există evaluări

- Production & Operations ManagementDocument0 paginiProduction & Operations ManagementAbdul AzisÎncă nu există evaluări

- Chapter Two Design of The Operations/production Systems 2.1. Product-Service Design and DevelopmentDocument42 paginiChapter Two Design of The Operations/production Systems 2.1. Product-Service Design and DevelopmentYared TeshomeÎncă nu există evaluări

- PDD LectureDocument25 paginiPDD LectureNandani SinghÎncă nu există evaluări

- Topic 7 Design For Quality Product and Product Excellence StudentsDocument7 paginiTopic 7 Design For Quality Product and Product Excellence StudentsMonica Pablo SabadoÎncă nu există evaluări

- Chapter Five (Managing For Product Quality)Document5 paginiChapter Five (Managing For Product Quality)Marica ShaneÎncă nu există evaluări

- SCM Project Report On Industry 4.0 Supply Chains Management: Group 5Document9 paginiSCM Project Report On Industry 4.0 Supply Chains Management: Group 5TanyaYadavÎncă nu există evaluări

- CHAPTER III (Product and Service Design)Document16 paginiCHAPTER III (Product and Service Design)YonatanÎncă nu există evaluări

- CH 5 Product DesignDocument18 paginiCH 5 Product DesignMahi VirmaniÎncă nu există evaluări

- Chapter 4 PDDDocument5 paginiChapter 4 PDDshan ahmedÎncă nu există evaluări

- DT Notes Unit 1,2,3Document83 paginiDT Notes Unit 1,2,3Akriti JaiswalÎncă nu există evaluări

- Product Design 01Document6 paginiProduct Design 01Mounesh7Încă nu există evaluări

- Process Design and AnalysisDocument20 paginiProcess Design and AnalysisSaroj MishraÎncă nu există evaluări

- B2B Chapter 12 - GRP PresentationDocument18 paginiB2B Chapter 12 - GRP PresentationsbhongadeÎncă nu există evaluări

- Project Management On New Product Development and New Product Launch in The Automotive Industry Project Management Represents The Combination Between KnowDocument7 paginiProject Management On New Product Development and New Product Launch in The Automotive Industry Project Management Represents The Combination Between KnowapoorvaÎncă nu există evaluări

- 3 Product Service Design and DevtDocument22 pagini3 Product Service Design and DevtShone DripÎncă nu există evaluări

- Ingeniero de ProductoDocument27 paginiIngeniero de ProductoJuan Diego Arroyave SernaÎncă nu există evaluări

- Case StudyDocument15 paginiCase StudychitranshhÎncă nu există evaluări

- Chapter Two Design of The Operations/production Systems 2.1. Product-Service Design and DevelopmentDocument46 paginiChapter Two Design of The Operations/production Systems 2.1. Product-Service Design and DevelopmentThomasGetyeÎncă nu există evaluări

- Product Design CriteriaDocument8 paginiProduct Design CriteriaMohamed K MarahÎncă nu există evaluări

- The Increasing Importance of Product DesignDocument7 paginiThe Increasing Importance of Product DesignTrang QuýtÎncă nu există evaluări

- PPC - Unit 2 - Part 2Document10 paginiPPC - Unit 2 - Part 2virk42000Încă nu există evaluări

- Product and Service DesignDocument4 paginiProduct and Service Designjth55936zwohocomÎncă nu există evaluări

- Product Design & Development PDFDocument6 paginiProduct Design & Development PDFAnonymous 26tZJAYÎncă nu există evaluări

- New Product DevelopmentDocument7 paginiNew Product DevelopmentDeepthi VadlaÎncă nu există evaluări

- Final ProposalDocument44 paginiFinal Proposalfatsoe1Încă nu există evaluări

- Chapter 1 PDD1Document15 paginiChapter 1 PDD1kuba DefaruÎncă nu există evaluări

- POM Unit IIDocument13 paginiPOM Unit IIShiVâ SãiÎncă nu există evaluări

- Mgt345 Chapter 2Document8 paginiMgt345 Chapter 2Amyeera DanyialÎncă nu există evaluări

- Cost Analysis Through Life Cycle Analysis and Target CostingDocument35 paginiCost Analysis Through Life Cycle Analysis and Target CostingSunny KhsÎncă nu există evaluări

- BAB 6 (II) New Product DevpDocument19 paginiBAB 6 (II) New Product Devptrevorsum123Încă nu există evaluări

- New Product DevelopmentDocument7 paginiNew Product DevelopmentChris RessoÎncă nu există evaluări

- Case 3 - HP DeskjetDocument4 paginiCase 3 - HP DeskjetElbert Leo AstilleroÎncă nu există evaluări

- Pages From PDFDocument4 paginiPages From PDFSagung Ayu Mardani Valia PutriÎncă nu există evaluări

- A Method For Systematic Future Product Concept GenerationDocument15 paginiA Method For Systematic Future Product Concept GenerationMuhd FayyadhÎncă nu există evaluări

- Managing The New Product Development Pro PDFDocument16 paginiManaging The New Product Development Pro PDFkashemÎncă nu există evaluări

- Day 2 Chapter 2Document50 paginiDay 2 Chapter 2Rakesh UpadhyayÎncă nu există evaluări

- Second Chapter: Product and Service DesignDocument8 paginiSecond Chapter: Product and Service DesignMominul MominÎncă nu există evaluări

- m2MATERILA AMIEDocument4 paginim2MATERILA AMIEHemantkumar TungÎncă nu există evaluări

- ASSIGNMENT 1 Oct 2022 - OPM545 - FinalDocument7 paginiASSIGNMENT 1 Oct 2022 - OPM545 - FinalMuhammad Syafiq AbdullahÎncă nu există evaluări

- Product Design & DevelopmentDocument6 paginiProduct Design & Developmentdmjobs6369Încă nu există evaluări

- New Product DevelopmentDocument12 paginiNew Product DevelopmentDiane ChakanzahÎncă nu există evaluări

- Module 2 (Lessons 1 - 6)Document5 paginiModule 2 (Lessons 1 - 6)Pob ReÎncă nu există evaluări

- Product DevelopmentDocument6 paginiProduct DevelopmentDeonald Barcena TamodraÎncă nu există evaluări

- Enabliers of BPR IN MANUFACTRING - Production PlanningDocument8 paginiEnabliers of BPR IN MANUFACTRING - Production Planningneyom bitvooÎncă nu există evaluări

- Chapter ThreeDocument13 paginiChapter ThreetibligechtÎncă nu există evaluări

- Product Design and DevelopmentDocument27 paginiProduct Design and DevelopmentGur- FeatÎncă nu există evaluări

- Fundamentals of Design and ManufacturingDocument8 paginiFundamentals of Design and ManufacturingManasÎncă nu există evaluări

- Operations Management in Automotive Industries: From Industrial Strategies to Production Resources Management, Through the Industrialization Process and Supply Chain to Pursue Value CreationDe la EverandOperations Management in Automotive Industries: From Industrial Strategies to Production Resources Management, Through the Industrialization Process and Supply Chain to Pursue Value CreationÎncă nu există evaluări

- Medieval Realm Information SheetDocument2 paginiMedieval Realm Information Sheetapi-280058938Încă nu există evaluări

- Hylea Foods - Supplier Declaration of Conformity of Packaging 2019.PDF RespuestaDocument4 paginiHylea Foods - Supplier Declaration of Conformity of Packaging 2019.PDF RespuestaAlainÎncă nu există evaluări

- PillingDocument4 paginiPillingRamesh IyerÎncă nu există evaluări

- Vdocuments - MX - Name As Found in CBR Company Name Name As Found in CBR Company Name NaeemDocument102 paginiVdocuments - MX - Name As Found in CBR Company Name Name As Found in CBR Company Name NaeemAli SyedÎncă nu există evaluări

- Market Analysis of Footwear Industry in India With Ref To LakhaniDocument74 paginiMarket Analysis of Footwear Industry in India With Ref To LakhaniVinod Upadhyay100% (7)

- Petroleum CSG: Hse Management System ProcedureDocument18 paginiPetroleum CSG: Hse Management System Proceduremarita202150% (2)

- Uniqlo and PenshoppeDocument5 paginiUniqlo and PenshoppeAJ Bautista0% (1)

- DecathlonDocument1 paginăDecathlonNeenaÎncă nu există evaluări

- Adidas MPRDocument41 paginiAdidas MPRAdewitiya Singh100% (1)

- Janome Sewist 525S Sewing Machine Instruction Book 525S (En)Document45 paginiJanome Sewist 525S Sewing Machine Instruction Book 525S (En)Will WannamakerÎncă nu există evaluări

- B-Plan - Mobile Retail StoreDocument31 paginiB-Plan - Mobile Retail StorePlaban Roy100% (1)

- Directory List Directory ListDocument5 paginiDirectory List Directory ListBadhon RoyÎncă nu există evaluări

- Adidas FinalDocument39 paginiAdidas Finalgulshan0% (1)

- Types of CheeseDocument3 paginiTypes of CheeseGaurang RaneÎncă nu există evaluări

- Request Letter WeebDocument1 paginăRequest Letter Weebapi-303076697Încă nu există evaluări

- A VCNDocument90 paginiA VCNNguyễn Công ThoạiÎncă nu există evaluări

- Thermoplastic Polyurethanes Bridge The Gap Between Rubber and PlasticsDocument4 paginiThermoplastic Polyurethanes Bridge The Gap Between Rubber and PlasticsA MahmoodÎncă nu există evaluări

- Company ProfileDocument9 paginiCompany ProfilenidhinambuÎncă nu există evaluări

- 2.history of Costume and Fashion The Medieval World 2005 PDFDocument65 pagini2.history of Costume and Fashion The Medieval World 2005 PDFNguyễn Thiện100% (1)

- Marketing EssayDocument6 paginiMarketing EssaySara MillsÎncă nu există evaluări

- Assignment: Survey Question SamplesDocument3 paginiAssignment: Survey Question SamplesIsrak Hasan AponÎncă nu există evaluări

- The Orkney HoodDocument10 paginiThe Orkney HoodJugurtha1782Încă nu există evaluări

- Scrolling ChartDocument648 paginiScrolling ChartCsapCticÎncă nu există evaluări

- Microeconomía - Capítulo 5Document31 paginiMicroeconomía - Capítulo 5Carlos García SandovalÎncă nu există evaluări

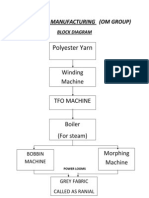

- Grey Cloth Manufacturing ProcessDocument8 paginiGrey Cloth Manufacturing ProcessPriya JainÎncă nu există evaluări

- Kotler Pom17e PPT 12Document47 paginiKotler Pom17e PPT 12solehah sapieÎncă nu există evaluări

- 2021-07-30 Adidas Global Supplier ListDocument122 pagini2021-07-30 Adidas Global Supplier ListSEDEF IMPEXÎncă nu există evaluări

- BigbazaarDocument10 paginiBigbazaarAmrit Mishra100% (1)

- Dentonic ReportDocument52 paginiDentonic ReportSyeda Benazir Burhan100% (2)

- Supply Chain Management in Big BazaarDocument25 paginiSupply Chain Management in Big Bazaarabhijit05582% (11)