Documente Academic

Documente Profesional

Documente Cultură

Vnx.su Дачия Соленза Engine-f8q

Încărcat de

cvn2Descriere originală:

Drepturi de autor

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Vnx.su Дачия Соленза Engine-f8q

Încărcat de

cvn2Drepturi de autor:

REPAIR MANUAL

DACIA

MR 526 -1 MECHANICS

ENGINE: F8Q

GEARBOX: JH1

TAPV: B41G, B41E, B41F

Ref: 6001999072 MAY 2004 English version

The reparation methods prescribed by the manufacturer in the present document are established subject to

technical specifications in force at the document issuing date.

These are subject to modifications brought by the manufacturer at the fabrication of different assemblies,

subassemblies or accessories of its vehicles.

All rights reserved to SC Automobile Dacia SA.

Reproduction or translating even partially of this present document is forbidden without the written

authorisation of AUTOMOBILE DACIA S.A.

vnx.su

SPECIFICATIONS

Engine Clutch - Gearbox .................................. 01-1

Vehicle identification .......................................... 01-2

LIFTING

Mobile jack Adjustable supports ..................... 02-1

Elevator positioned under vehicle body .............. 02-2

TOWING

All types .............................................................. 03-1

LUBRICANTS AND INGREDIENTS

Condition ............................................................ 04-1

DRAINING - FILLING

Engine.................................................................. 05-1

Gearbox .............................................................. 05-2

Power steering ..................................................... 05-3

VALUES AND SETTINGS

Dimensions.......................................................... 07-1

Weights (kg) ........................................................ 07-2

Capacity - Quality................................................ 07-3

Accessories belts tension ..................................... 07-4

Wheels, Tires ....................................................... 07-5

Brakes.................................................................. 07-6

Dimensions under carriage body ......................... 07-7

Checking values of the front axle angles.............. 07-8

Checking values of the rear axle angles .............. 07-9

ENGINE AND LOWER ENGINE UNITS

Ingredients............................................................ 10-1

Identification ....................................................... 10-2

Oil consumption ................................................. 10-3

Oil pressure ......................................................... 10-4

Power train .......................................................... 10-5

Engine-gearbox separation .................................. 10-10

Replacement of standard equipped engine .......... 10-11

Tightening moments ........................................... 10-12

Characteristics ..................................................... 10-13

Special tools......................................................... 10-18

Dismounting Remounting................................. 10-19

Lower crankcase .................................................. 10-39

Oil pump.............................................................. 10-40

Crankshaft sealing gasket towards distribution ....10-41

Multi-purpose support ......................................... 10-42

UPPER AND FRONT ENGINE UNITS

Distribution belt ................................................... 11-1

Cylinder head gasket .......................................... 11-5

FUEL MIXTURE

Intake manifold ................................................... 12-1

Exhaust manifold ................................................. 12-2

PUMP SUPPLY

Fuel stop in case of collision ............................... 13-1

Characteristics ................................................... 13-2

Particularities ...................................................... 13-4

Cleanliness rules .................................................. 13-6

Elements location................................................. 13-8

Operation ............................................................. 13-10

Injection indicator................................................ 13-12

Anti-starting function .......................................... 13-13

Idle running rotation correction ........................... 13-14

Pre / Post heating control ................................... 13-15

Injectors .............................................................. 13-17

Decreased flow electric valve and stop electric

valve .................................................................. 13-18

Increased flow electric valve and advance

electric valve ...................................................... 13-20

Injection pump connector..................................... 13-22

Injection pump ..................................................... 13-24

Injection pump pressing on ................................. 13-27

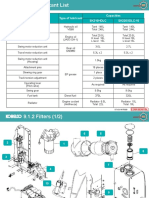

Fuel filter ............................................................. 13-29

Water temperature centralised control

(G.C.T.A.) ........................................................... 13-30

Acceleration pedal captor .................................... 13-31

Diagnosis - Generalities ...................................... 13-32

Diagnosis - damages interpretation ..................... 13-34

Diagnosis - Help ................................................. 13-66

Diagnosis - Conformity checking ....................... 13-67

Failure locating algorithm ................................... 13-70

ANTIPOLLUTION

Oil vapors re-aspiration........................................ 14-1

Exhaust gases recycling (E.G.R.)......................... 14-2

STARTING AND CHARGING

Alternator ............................................................ 16-1

Starter .................................................................. 16-6

COOLING - EXHAUST - FUEL TANK

Characteristics...................................................... 19-1

Draining - Filling - Purging ................................. 19-2

Checking............................................................... 19-3

Cooling system diagram........................................ 19-4

Water pump .......................................................... 19-5

Radiator cooling ................................................... 19-6

General poinds vehicle

0

01

02

03

04

05

07

Engine and pripheriques

1

10

11

12

13

14

16

19

vnx.su

Cooling motor fan ............................................... 19-7

Diagnostic failures interpretation at vehicles

without air conditioning....................................... 19-8

Exhaust assembly ................................................ 19-9

Filling cap ............................................................ 19-12

Tank draining ...................................................... 19-13

Dismounting Remounting ................................ 19-14

Fuel circuit diagram ............................................ 19-16

Tank diagram ....................................................... 19-17

Suction assembly Fuel pump ............................... 19-18

Engine suspension................................................. 19-21

CLUTCH

Identification......................................................... 20-1

Diagnostic............................................................. 20-2

Clutch disk Mechanism..................................... 20-5

Engine flywheel ................................................. 20-6

MANUAL GEARBOX

Sectional view .................................................... 21-1

Identification ...................................................... 21-2

Tightening moments ............................................ 21-3

Ratios .................................................................. 21-4

Capacity, lubricants .......................................... 21-5

Particurarities .................................................... 21-6

Ingredients .......................................................... 21-7

Parts that are replaced after

each dismonting ................................................. 21-8

Necessary special tools ...................................... 21-9

Gearbox dismounting ........................................ 21-10

Replacement of the planetary sealing

gasket (on the vehicle) ....................................... 21-30

Replacement of the 5-th gear synchroniser

and pinion (on the vehicle) .................................. 21-32

DRIVE SHAFTS

Front transversal transmission ........................ 29-1

Bellows - Bearing assembly to

the gearbox .......................................................... 29-4

Bellows to wheel .................................................. 29-7

Bellows to gearbox .............................................. 29-12

Bellows to wheel .................................................. 29-15

GENERAL

General principle schedule

of the brake circuit ............................................ 30-1

Tightening moments (in daNm) ....................... 30-2

Composition and dimensions

of the main braking system elements ............... 30-6

Braking system diagnostic ................................ 30-7

Brake connections and ducts ............................ 30-12

Brake fluid ......................................................... 30-13

Braking system purging .................................... 30-14

The influence of angles ...................................... 30-16

Angles checking principle ................................. 30-17

Front axles checking and adjustment ............. 30-18

FRONT BEARING ELEMENTS

Characteristics ..................................................... 31-1

Suspension arm ................................................. 31-2

Elastic bushings of the suspension arm ........... 31-5

Suspension ball joint .......................................... 31-6

Brake lining (pads) ............................................ 31-7

Checking the brake pads wear ......................... 31-9

Brake caliper ...................................................... 31-10

Brake disk ........................................................... 31-12

Steering knuckle ................................................. 31-13

Steering knuckle bearing (35 x 65 x 35) ......... 31-15

Front suspension ................................................ 31-16

Shock absorber, Spring ...................................... 31-17

Spring shock absorber assembly ................... 31-18

Anti roll bar ........................................................ 31-20

Power train support .......................................... 31-21

REAR BEARING ELEMENTS

Characteristics ................................................... 33-1

Rear axle ............................................................. 33-2

Rear suspension ................................................. 33-4

Shock absorber ................................................... 33-5

Spring................................................................. 33-6

Brake drum ........................................................ 33-7

Brake cylinder .................................................... 33-8

Brake shoes ......................................................... 33-10

Bearing ................................................................ 33-13

WHEELS AND TYRES

Characteristics ................................................... 35-1

Wheels balancing ............................................... 35-4

STEERING ASSEMBLY

Steering rod with axial ball joint ......................... 36-1

Manual steering box .......................................... 36-3

Anti-noise bearing ............................................... 36-4

Bellows................................................................ 36-5

Steering box pusher ........................................... 36-6

Power steering general ........................................ 36-7

Power steering box ............................................ 36-8

Pusher of the power seering box .......................... 36-11

Power steering pump ......................................... 36-12

Steering column ................................................. 36-14

MECHANICAL ELEMENTS CONTROLS

Brake pump........................................................ 37-1

Servobrake ......................................................... 37-3

Air filter servobrake retainer valve .............. 37-7

20

21

29

30

31

33

35

36

37

Transmission

2

Chasis

3

vnx.su

Vacuum pump ...................................................... 37-8

Handbrake - adjustment ...................................... 37-9

Handbrake control lever ...................................... 37-10

Handbrake secondary cables ............................ 37-12

Brake flexible hoses ........................................... 37-13

Brake pressure controller .................................. 37-15

Gears control ..................................................... 37-17

Clutch and brake pedals ................................... 37-19

Clutch cable ........................................................ 37-20

Pedals support ................................................... 37-22

Acceleration control .......................................... 37-23

vnx.su

01 - 1

SPECIFICATIONS

Engine Clutch - Gearbox

01

VEHICLE TYPE

ENGINE

TYPE

CYLINDER

CAPACITY

(cm

3

)

CLUTCH

TYPE

GEARBOX

TYPE

B 41 G

B 41 E

B 41 F

F8Q-636 1870 200 CPOV

3700

JH1 - 055

VEHICLE TYPE IDENTIFICATION

B : Carriage body type (5 doors)

41 : Project code

G, E, F : Motorization index

G EURO 96

E EURO 00

F 1504

vnx.su

01 - 2

SPECIFICATIONS

01

Vehicle identification

The identification plate is located inside the vehicle, on the right middle pillar- area A.

The IDENTIFICATION PLATE, self-adhesive type, has the bellow presentedconfiguration,

with two distinctive area presentingmanufactureridentification data and identification data APV

type.

A

C

D

F

B

H

G

I

J

E

MANUFACTURERS

IDENTIFICATION DATA

A. Manufacturers name

B. Community reception number or

homologation number.

C. Identification number.

D. Total authorized weight of the loaded

vehicle.

E. Total authorized running weight

F. Total weight on front axle.

G. Total weight on rear axle.

H. Additional inscription.

I. Manufacturing date inscription

J. Consignment number.

APV IDENTIFICATION DATA

1.1. Code type auto APV

1.2. Manufacturing number

2.1. Equipping level code

2.2. Additional code for limited serial

definition

2.3. Additional code for special serial

definition

3.1. Carriage body color code

3.2. Seats upholstery code

3.3. Interior matching code

4.1. Technicaldefinition code

4.2. Optional equipping code

VEHICLE IDENTIFICATION PLATE LOCATION

vnx.su

01 - 3

SPECIFICATIONS

01

Vehicle identification

SYMBOLS MEANING

1.1. Code type auto APV 4 characters

Example: B41E has the meaning:

B carriage body type

41- project code

E - motorization level

2.1 Equipping level code- 3 characters

Example : E0;E1; E1 P ; E2; E2 P.

2.3 Additional code for special serial

definition - 6 characters

Example : SAN513

3.1 Carriage body color code 6

characters

Example : 011A; 021B; TE01B;

3.3 Interior matching code 6 characters

Example :HARM01

4.1 Technical definition code 6 characters

1.2 Manufacturing number 7 characters

2.2 Additional code limited serial definition

6 characters

Example : SAN913

3.2 Seats upholstery code 6 characters

Example :DRAP01; DRAP02.

4.2 Optional equipping code 9 characters

Example: ACFK_MRTV

A Normal suspension.

C Temperate climate countries

F Climate control

K Without pre-filter

M Mechanical steering

R Without variable shock

absorbers.

T Without trim corrector

V Without wheels anti-blocking

(without ABS).

Example of written oval plate:

vnx.su

02 - 1

02

LIFTING

Safety sign (particularly cautions to be observed in case of an intervention)

SPECIAL TOOLS

Cha 280-02 Adequate support on mobile jack

Cha 408-01 Adjusting support on mobile jack

Cha 408-02 Adjusting support on mobile jack

Mobile jack Adjustable supports

The use of a mobile jack implies the

obligatory use of adjustable supports.

It is forbidden the vehicle lifting using

other supporting points (suspensionarms, etc)

than the ones provided by manufacturer.

LATERAL MOBILE JACK

In order to lift vehicle front or rear part,

the same supporting points provided for the

vehicle jack are to be used.

This type of jack, is using sockets

(supports) Cha 408-01 or Cha 408-02,

equipped with the support Cha 280-02.

Place it on under the thresholdat the front

door level and the floor closing plate shall be

positioned in the channel of the support.

ADJUSTABLE SUPPORTS

The adjustable supports, may be placed under

the carriage body, in two ways:

- under the reinforcements provided for the

lifting vehicle withthe vehicle jack;

- under the supports placed behind the

reinforcements.

The positioningof the adjustable supports in

the vehicle rear areas is performed by lateral lift-

ing of the vehicle, by means of a mobile jack.

vnx.su

02 - 2

LIFTING

FRONT

02

Elevator positioned under vehicle body

SAFETY SIGN

Situations to be considered:

1. SITUATION OF VEHICLE COMPONENTS DISMOUNTING

When there are not available four columns elevators, two columns elevators may be used, in

this case, lifting slides shall be placed under the floor closing plate, at the supporting points level

of the vehicle jack

2. PARTICULARLY SITUATION OF POWER-TRAIN DISMOUNTING RE-

MOUNTING

In this specific case, the vehicle carriage body shall be consolidated with the two columns

elevator arms using special slides.

REAR

These must be obligatory placed at the right of the supporting points of the vehicle jack and

must be locked in the holes/windows made in the floor closing plate.

vnx.su

03 - 1

03

TOWING

ATTENTION !

NEVER USE AS TOWING POINTS, THE TRANSMISSION AXLES (PLAN-

ETARY SHAFTS).

The towing points, front, or rear, are to be used only for vehicles towing on wheels.

These points cannot be anyhow used for drawing out the damaged vehicle from a trench

(hole), or for direct or indirect vehicle lifting on a transport platform.

FRONT (right) REAR (left)

All types

vnx.su

04 - 1

PRODUCT PLACE WHERE IT IS USED

OILING (GREASING)

Grease

OLISTA LONG TIME 3EP R100137188

Grease

ELF CARDREXA RNT2

Grease

MOLYKOTE 33M

Grease

UM 185 Li2M

White grease (Teroson)

Guiding tube, clutch release fork

Right transmission joint G.I

Transmission joint G.E.

Gearbox control rod protection bellows

Attachment buffer on anti-roll bar

Handbrake control lever shaft

Steering rack, pinion, oil seal ring (steering

box)

Steering connecting rod bellows

Handbrake secondary cables

Doors hinges, front bonnet, hatchback

LUBRICANTS CONSUMABLES

04

Condition

vnx.su

04 - 2

LUBRICANTS INGREDIENTS

PRODUCT

PLACE WHERE IT IS USED

ETANARE

LOCTITE 518

LOCTITE 5900

(RHODORSEAL 5661)

Sealing paste Wurth

Kit DURCISSEUR

Mastic ROMTIX 1308

Mastic TERODICHT elastic

Gearbox crankcases assembling

Thread of the reverse driving contact

Crankshaft bearing cap no.1

Camshaft bearing caps (1) and (5)

Exhaust

Crankshaft bearing cap no.1

Plate elements joint area

Windscreen gasket, hatchback

SOLDERING

LOCTITE 243

(FRENETANCH)

FIXAMED R58

Crankshaft flywheel screw

Engine balance wheel screw

Gearbox secondary shaft screw

Steering connecting-rod

Attachment screws of the brake caliper fork

CLEANING

LOCTITE 7200

METALLREINIGER

(DECAPJOINT)

Aluminum parts surfaces

04

Condition

vnx.su

05 - 1

DRAINING AND FILLING

Draining : plug (2) Filling : plug (1)

SPECIAL TOOLS - wrench MOT 1018

05

Engine

2

vnx.su

05 - 2

DRAINING AND FILLING

Drain : plug (2)

Fill : plug(1)

05

Gearbox

Special tools - wrench MOT 1018

1

vnx.su

05 - 3

DRAINING AND FILLING

05

Power steering

ATTENTION !

For filling and addition, only oil DACIA of class DEXTRON II D is to be used.

Circuit capacity: 1 liter.

CIRCUIT FILLING

Fill the reservoir with oil.

In order to fill the circuit with oil, easy rotate the steering wheel in both directions so that

steering rack is performing a complete stroke.

Check the oil level in the reservoir and addition if the case.

Start the engine, easy rotate the steering wheel in both directions so that steering rack is

performing a complete stroke.

Restore the oil level in the reservoir till MAXI level.

LEVEL CHECKING

Each 10,000 km, check the oil level in the reservoir, that must be between the MINI-MAXI

marks.

vnx.su

VALUES AND SETTINGS

07

07 - 1

Dimensions

Dimensions (mm)

Total length: 4083

Total width: G = 1664

Total height:

* empty H = 1379

* loaded (authorized maximum total weight) 1329

Wheel base * empty A = 2476

* loaded 2479

Front wheel track width, ground level measurement:

* empty E = 1429

* loaded 1428

Rear wheel track width, ground level measurement F = 1348

Ground clearance (K)

* empty -

* loaded 120

vnx.su

VALUES AND SETTINGS

07

07 - 2

Weights (kg)

Model

Vehicle type

Unloadedvehicle weight

Maximum authorized weight

on axle

Maximum technical

admissible weight of the

loaded vehicle

Maximum technical admissible towing

weight (trailerwithout braking system)

Maximum technicaladmissible towing

Weight (trailer with braking system)

Maximum admissible weight of the

assembly

Maximum load on towinghook

Towing hook weight

1,9D

750

800

450

800

2260

40

20

R5A71T

1085

642

443

Total

Front

Rear

Front

Rear

Total

Front

Rear

R5A717

1085

642

443

R5A71D

1085

642

443

1460

728

732

1460

728

732

1460

728

732

vnx.su

VALUES AND SETTINGS

07

07 - 3

Capacity - Quality

DENOMINATION QUALITY CAPACITY (l)

(approximate )

Engine oil DACIA OIL DIESEL SAE 10 W 40; ACEA B3; API CF 4.6*

Gearbox oil SAE 75 W 80 W; API GL 5 3.5

DACIA OIL EXTRAGEAR

Breaking fluid SAE J 1703 DOT 4 0.450

Cooling fluid 50% antigel GLACEOL RX typeD

50% distilled water 6

Oil circuit power assisted steering DEXRON II D 1

* to be adjusted at dipstick

vnx.su

VALUES AND SETTINGS

07

07 - 4

Accessories belt tension

SPECIAL TOOLS

MOT 1505 Device for belts tension measurement

The value of accessories belt tension is:

142 - 167 Hz - for vehicles without power steering

167 - 170 Hz - for vehicles with power steering

Accessories belt tensionin method:

Belt tensioning is to be performed at cold engine (environment temperature)

Mount the new belt

Tension the belt until obtaining the prescribed tensioning value.

Lock the tensioner.

Rotate the engine three crankshaft turns

Place the reading head of MOT 1505 device in the measurement area and check if the value

of the belt tensioningis found among the prescribed tensioning values; re-adjust if necessary.

REMARK:

A dismounted belt is never remounted, but replaced.

A

B

E

Vehicles with DA

A

B

E

D

A - crankshaft

B alternator

E - water pump

D - power steering pump

- tensioning checking point

Vehicles without DA

vnx.su

VALUES AND SETTINGS

07

07 - 5

Wheels, Tires

Vehicle

B 41 G

B 41 E

B 41 F

Wheels

5.5J144 CH43

5.5B134CH46

Tires

165 / 65R14

165 / 70R13

Inflating pressure (bars) (1)

Front Rear

Empty/Loaded Empty/Loaded

2.0/2.2 2.0/2.1

2.0/2.2 2.0/2.1

(1) Maximum loaded, wheels on the ground.

- tightening moment of the wheels screws : 7.5 daNm;

- wheel axial run out : maximum 1 mm;

- wheel radial rubout : maximum 1 mm.

The increase of tire temperature during driving implies a growth of the tire pressure with

0.2 0.3 bars compared with the prescribed values.

In case of tires pressure checking immediately after vehicle driving, consider this growth of

pressure.

vnx.su

VALUES AND SETTINGS

07

07 - 6

Brakes

Vehicl e

Normal

20

Minim

19

Normal

228

Minim

229

Front

0.03

Rear

-

Brake disk width and drums diameter (mm)

Front Rear

Maxim disk

axial run out

Vehicl e

Normal

14

Minim

7

Normal

5

Minim

0.5 mm

above the

rivets

SAE J 1703 DOT 4

Gaskets thickness (mm)

Front Rear Brake fluid

B 41 G

B 41 E

B 41 F

B 41 G

B 41 E

B 41 F

vnx.su

VALUES AND SETTINGS

07

07 - 7

Dimensions under carriage body

DIMENSIONS UNDER CARRIAGE BODY CONDITIONING

ADJUSTMENT OPERATIONS OF THE STEERING ANGLES

H1, H4 - to be measured in front wheel axle, consequently rear wheel axle.

H2 - to be measured between the lower side of the power train support.

H5 to be measured between the elastic joint axle of the rear axle arm and the ground.

vnx.su

VALUES AND SETTINGS

07

07 - 8

Checking values of the front axle angles

ADJUSTMENTS

Not adjustable

Not adjustable

Not adjustable

Adjustable by

rotatingthe tie

rod of the

steering rod

-

VEHICLE

POSITION

H5 - H2 = 100

H5 - H2 = 90

H5 - H2 = 80

H5 - H2 = 70

H5 - H2 = 60

H1 - H2 = 105

H1 - H2 = 98

H1 - H2 = 91

H1 - H2 = 85

H1 - H2 = 78

H1 - H2 = 71

H1 - H2 = 64

H1 - H2 = 105

H1 - H2 = 98

H1 - H2 = 91

H1 - H2 = 85

H1 - H2 = 78

H1 - H2 = 71

H1 - H2 = 64

Not loaded

Not loaded

VALUES

0

0

03'

0

0

20'

0

0

36' 30'

0

0

53'

1

0

10'

Right / left maxim

difference = of 1

0

-0

0

16'

-0

0

10'

-0

0

02'

0

0

06' 30'

0

0

15'

0

0

24'

0

0

35'

Right / left maxim

difference = of 1

0

13

0

36'

13

0

25'

13

0

14'

13

0

03' 30'

12

0

50'

12

0

38'

12

0

24'

Right / left maxim

difference = of 1

0

Toe in:

0

0

10' 10'

(for one wheel

0

0

05' 05')

-

ANGLES

CAMBER

CASTER

BALL JOINT

TOTALPARALLELISM

ELASTIC BUSHINGS

TIGHTENING

vnx.su

VALUES AND SETTINGS

07

07 - 9

Checking values of the rear axle angles

ADJUSTMENTS

Not adjustable

Not adjustable

VEHICLE

POSITION

Unloaded

Unloaded

Unloaded

VALUES

0

0

30' 10'

(For two wheels)

Closing

0

0

30' 10'

2,9 mm 1 mm

ANGLES

CAMBER

PARALLELISM

ELASTIC BUSHINGS

TIGHTENING

PRELIMINARY OPERATIONS TO BE OBSERVED BEFORE

CHECKING THE STEERING ANGLES

1. Area (checking surface) it must be as horizontal as possible.

2. Wheels, tires check (from equipping point of view) to have same type of wheels and

tires on both axles (dimensions, inflating pressure, wear degree). A pronounced wear is not

allowing the correct horizontal positioning.

3. Suspension check the shock absorbers, springs condition and height symmetry under

carriage body.

4. Joints check the elastic joints condition, steering and suspension ball joints clearance,

bearings clearances of the front and rear axles

5. Radial and axial run out of the wheels must not be over 1 mm. This will be compensated

with the reading instruments.

6. Manufacturers method each vehicle manufactureris providing the checking conditions,

axles weights repartition, and presentation of under carriage body heights, not loaded.

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 1

Ingredients

TYPE UTILIZATION

LOCTITE 5900 Bearing covers (1) and camshaft (5), bearing

RHODORSEAL 5661 cover no. (1) and crankshaft

OIL 10W40 ACEA B3 API CF Parts lubrication during mounting

LOCTITE 243 Engine flywheel placing area on crankshaft

LOCTITE 7200 Cylinder head cleaning on the gasket seating

METALLREINIGER surface.

KIT DURCISSEUR Sealing of the bearing cover No.(1) crankshaft

Engine oil capacity: 4.6 liter (with filter).

Used engine oil quality: Dacia Oil Diesel 10W40 ACEA B3 API CF.

Parts which are to be replaced when they have been dismounted:

- all sealing gaskets

- valves guides

- cylinder head screws

- crankshaft bearing caps screws

- camshaft pulley screw

- crankshaft pulley screw

- connecting rods caps screws

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 2

000 0 0 00

0 000000

Identification

The engine identification is performed by means of a metallic plate, which is stuck on

the engine block.

A engine type

B engine homologation letter

D RENAULT identity code

E engine index

F engine fabrication series

G code for assembling factory

A B D E

G F

Vehicle Type

Code VDS

Code vehicle

Engine

Gearbox

Cylinder

capacity

(cm

3

)

Bore

(mm)

Stroke

(mm)

Volume

ratio

B 41 G

B 41 E

B 41 F

R 5A 71D

R 5A 717

R 5A 71T

F8Q-636 JH1-055 1870 80 93 21,5

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 3

Oil consumption

OIL CONSUMPTION MEASURING

a) Oil filling at maximal level

This operation is to be performed when the engine is warm (an engine fan rotation) and

after a stabilization of 15 minutes, necessary to the oil complete draining into the lower

crankshaft.

Check the oil at the oil-indicating rod.

Fill to the maximal level.

Seal the draining and filling taps (mark them with paint, for further checking if these

have not been dismounted

b) Customer driving time

Ask the customer to drive for about 2000 km or until the oil reaches the minimal level.

c) Refilling to the maximal level

This operation is to be performed when the engine is warm (an engine fan rotation) and

after a stabilization of 15 minutes.

Check the oil at the oil-indicating rod.

Fill to the maximal level.

Write down the oil quantity and the driven mileage after filling to the maximal level.

d) Oil consumption measuring

Oil filled quantity (liter)

OIL CONSUMPTION =

kilometers (thousand)

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 4

Oil pressure

Necessary special tools

MOT 836 - 05 Oil pressure measuring kit

CHECKING

The oil pressure is to be checked when the engine is warm (about 80C).

For the F8Q engine, components B+F from oil pressure measurement kit MOT 836-05

are to be used.

The pressure value should be:

1.2 bars at 1000 rpm

3.5 bars at 3000 rpm

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 5

Power train

Dismounting and remounting of the power train is to be performed on the upper part of

the engine compartment by means of a mobile lifting device.

DISMOUNTING

Place the vehicle on a two-column elevator.

Dismount:

- battery

- air filter inlet pipe

- air filter assembly

- engine hood

- front wheels

TIGHTENING MOMENTS (daNm)

Attachment screws of the right support on the engine 6.2

Attachment nut of the hydro-elastic buffer 3.7

Attachment nit of the left elastic buffer 6.2

Wheels bolts 7.5

Attachment screws of the power train support-battery 2.1

Attachment nut of the lower connecting-rod on the gearbox casing 6.2

Attachment screw of the control rod on gearbox connecting-rod 2.7

High pressure pipe on DA pump 2.1

1

Drain:

- the cooling circuit on the water

pump inlet pipe,

- oil off the gearbox.

- oil off the engine if necessary.

- oil from the power steering circuit

(vehicles with power steering).

Dismount :

- engine shield

- attachment nuts of the

descending pipe on the exhaust pipe.

Lower connecting-rod (1).

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 6

Power train

Swing over the steering-knuckle and

extract the planetary gearing from the

planetary gear of the gearbox.

Disengage the left planetary gearing as

follows:

- dismount the steering-knuckle nut;

- dismount the attachment screws of

the planetary gearing on the gearbox;

- dismount the brake caliper assembly;

- dismount the two attachment screws

of the shock absorber on the steering-

knuckle;

- swing over the steering-knuckle and

dismount the planetary gearing.

Dismount the fuse box from the engine

compartment.

Disconnect the engine wiring from the

front wiring.

3 4

Disconnect :

- connector of the reverse driving

contact

- connector of the speed captor.

Disengage the right planetary gearing

as follows:

- dismount the brake caliper assembly;

- dismount the two attachment screws

(2) of the shock absorber on the steering-

knuckle.

Disconnect:

- connector (3) from the injection checking

unit (UCE) (pull flap (4) and then disconnect);

- connector from the diesel filter

- connector of shock sensor

- connector of engine cooling motor fan

- connector of spark plugs pre-heating

relay

- mass wires from the gearbox.

To be uncoupled:

- acceleration cable ( 7) from the

acceleration pedal position captor (8);

Dismount the battery protection shield.

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 7

Dismount the connection screw

between the gears lever and the gearbox

control steering-rod.

Power train

Disconnect by means of the elastic clips

pliers MOT 1202-01:

- hoses from the radiator;

- hoses from the thermostat support;

- hoses from the venting vessel;

- venting vessel.

- fuel supply pipe (A) and return pipe;

detach from clips the fuel pipes.

Dismount the clutch control cable from

the gearbox.

Dismount:

- hoses from oil reservoir for power

steering by means of pliers MOT 1202-

01;

- high pressure pipe from power

steering pump.

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 8

Power train

Dismount the hydro-elastic buffer nut (on

the right side).

Remove the power train and place it on a

support.

Disconnect:

- servobrake connection (1) from the

vacuum pump;

- connector of the water temperature

sensor (2);

- connector of the air temperature sensor

(3);

- connector EGR (4);

5

1

2

3

4

Detach from clips the cable for right

headlamp adjustment and position it along

the carriage body.

Sustain the power train using the two

lifting supports by means of a mobile lifting

device (mobile crane);

Dismount the four attachment screws of

the power train-battery and the nut (5) of

the elastic buffer.

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 9

Power train

REMOUNTING

Perform the dismounting operations in the reverse order.

Tighten to the required moment all screws and nuts

Perform :

- filling up and purging of the cooling circuit (see chapter 19 Filling and purging);

- filling with oil of the engine and gearbox;

- Filling of the power steering circuit (see chapter 05 Draining / Filling power

steering circuit) for vehicles equipped with power steering

Adjust the clutch control fork stroke (see chater 37 Clutch control adjustment).

Adjust the clutch control fork (see chapter 37 Clutch control adjustment)

REMARK:

At each operation requiring battery disconnecting, when reconnecting this one, insert

the radio code written on the vehicle-buying invoice.

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 10

Engine-gearbox separation

TIGHTENING MOMENTS (daNm)

RPM sensor 0.8

Starter attachment screw 4.4

Gearbox attachment on the engine:

- M 10 nuts 4.4

- M 10-90 screws 4.4

- M10 35 screws 2.1

DISMOUNTING

Dismount the RPM sensor attachment screws (1)

Detach the starter electrical connections.

Dismount the starter

Disconnect the electric connector (2) of the reverse driving contact.

Dismount the engine wiring attachment on the gearbox.

Dismount the engine-gearbox assembling screws and nuts.

REMOUNTING

Perform the dismounting operations in the reverse order.

Tighten to the required moment all screws and nuts.

2

1

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 11

Replacement of standard equipped engine

PREPARATION OF USED ENGINE FOR RETURNING

The engine must be cleaned and drained (oil and cooling fluid)

DISMOUNTING

Leave on the used engine or nearby in the returning box:

- air filter;

- accessories belt and its tensioner;

- oil dipper rod and its guide;

- clutch disc and mechanism;

- engine flywheel;

- high pressure pipes;

- injection pump;

- injector and pre-heating spark plugs;

- vacuum pump and EGR valve;

- inlet and exhaust manifold

- distribution casings;

- water pump;

- oil filter

- thermostat box;

- crankshaft gear;

- distribution belt tightening cam;

- oil pressure controller.

REMOUNTING

Before mounting the new engine, the engine compartment must be cleaned.

Check the condition of the cooling radiator. Clean it or replace it if necessary.

Check the condition of the cooling circuit hoses. Replace if those are damaged or worn.

The attachment clips must be in perfect condition in order to ensure the cooling circuit

tightness.

Clean the gases evacuation vessel and check its valve. Replace if necessary.

Replace the thermostat.

Perform a visual inspection of the exhaust and intake manifold condition (especially

the assembling surface with the cylinder head). Replace the manifold gasket.

Perform the engine oil filling (adjust at dipper rod). Use only oil recommended by the

manufacturer.

Perform the filling and purging of the cooling circuit according to the method described

in chapter 19 Filling-Purging of the cooling circuit. Use only cooling fluid type

recommended by the manufacturer.

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 12

Tightening moments

TIGHTENING MOMENTS (daNm)

Alternator attachment

vehicles without DA

- nut M 10 . ...3.8

- nut M 8 . 1.9

vehicles with DA

- nut M 10 ... 4.4

- nut M 8 . 2.5

Attachment screws of DA pump support ...... 4.4

Injectors supply pipes (high pressure) .......2.5

Injection pipe attachment 2.5

Injection pump pulley nut .......5.5

Intake exhaust manifold fixing ... 2.7

Air filter attachment ....0.8

Port injectors .....7

Pre-heating spark plugs ......1.5 2

E.G.R. attachment ....... 0.8

Gases tube attachment on exhaust manifold .............1.9

Water pump pipe attachment .....3.8

Camshaft gear screw ... 5

Cylinder head cover nuts..... 1.2

Camshaft bearing covers screws. 2

Engine flywheel screws. 5 5.5

Lower crankcase screws. 1.2 1.5

Connection rods covers screws 4.5 5

Bearing covers screws...... 6.5

Crankshaft pulley screw..... 2 + 115 15

Water pump attachment screws.................. 1.6

Water pump pulley screws... 2

Oil pump attachment screws.............. 2 2.5

Distribution belt tensioning nut.. 5

Starter attachment screws .......... 4.4

Clutch mechanisme attachment screws 5

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 13

Characteristics

CYLINDER HEAD

The cylinder head is aluminum made and

it is provided with turbulence chambers.

Cylinder head height = 159.5 0.2 mm.

The cylinder head is not to be rectified.

The maximal deformation of the gasket

plane is 0.05 mm.

Cylinder head moments will by respected

the discribed method (see chapter 10 Dis-

mounting - Remounting).

The cylinder head is to be re-tightened.

TURBULENCE CHAMBERS

- over-height compared with the cylinder

head:

y = 0.01 0.04 mm;

- cylinder head slot diameter (d):

d = 37.5 mm

- channel angle compared with the cylin-

der head ():

= 35

E = 1.4 mm.

B. A one-hole gasket is to be used for

an over-height within 0. 613 mm

(inclusive) and 0.767 mm (exclusive).

E = 1.5 mm.

C. A three-holes gasket is to be used

for an over-height higher than 0.767 mm

E = 1.6 mm.

NOTICE:

The necessary holes for the gasket

thickness identification are placed in a

25-mm area as against its edge. Any

other hole is not to be taken into

consideration, in case it is placed out of

the above-mentioned area.

The gasket thickness identification

mark (R) may be seen even with the cylin-

der head mounted.

CYLINDER HEAD GASKET

The cylinder head gasket (E) thickness var-

ies according to the pistons maximal over-

height, as follows:

A. A two-holes gasket is to be used for an

over-height lower than 0.613 mm

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 14

Characteristics

The cylinder head gasket thickness is

to be obligatory recalculated according to

the pistons over-height in case one of the

following elements is replaced:

- crankshaft,

- cylinders crankcase,

- connecting rods

- pistons.

Otherwise the cylinder head gasket is

to be replaced with a same thickness one.

Remark:

Only the maximum over-height is to

be taken into consideration.

VALVES

Valve rod diameter 8 mm

Sealing face angle:

- intake 120

- exhaust 90

Tray diameter:

- intake 35.2 0.1 mm

- exhaust 31.5 0.1 mm

Valves retraction in regard to cylinder

head gasket plane.

- admission : 0.85 0.09 mm

- exhaust : 0.97 0.09 mm.

VALVES SEATS

Sealing face angle ():

- intake 120

- exhaust 90

Sealing face width (X): 1.8 mm

External diameter (D):

- intake 36.8 mm

- exhaust 32.6 mm

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 15

Characteristics

VALVES GUIDES

The valves guides are identical for both

intake and exhaust. They are provided with

oil-rings for sealing the valves rods.

Internal diameter 8 mm

External diameter

- nominal 13 mm

- repair (marked with 2 channels) 13.30 mm

Guides position as against the

gasket plane (A) 43.25 mm

Cylinder head bore for guide

- nominal 12.9 mm

- repair 13.20 mm

VALVES SPRINGS

The valves springs are identical for both

intake and exhaust.

Length in free state 47.2 mm

Length under a load of:

- 23 2 daNm 37.9 mm

- 70.5 3.5 daNm 27.4 mm

Length of the stuck coils 25.77 mm

Coil diameter 4 mm

Internal diameter 21.5 mm

CAMSHAFT

The engine is provided with a camshaft

having the cams on its head, mounted in

the cylinder head and driven by the distri-

bution belt .

The camshaft cams operate the valves

by tappets

Replacing the tappets, only with cold

engine, regulates the thermal clearance.

Thermal clearance values:

- intake: 0.20 0.05 mm,

- exhaust: 0.40 0.05 mm.

Axial clearance (mm)

Number of bearings

Distribution diagram

0,05 0,13

5

ADA A ADE E

- 2 45 45 - 4

A

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 16

TAPPETS

The tappet with conform thickness (y)

is to be chosen for getting the thermal

clearance.

As spare parts, there are 24 classes of

tappets, with thickness (y) within 7.550

and 8.150 mm.

The thickness increases every

0.025 mm.

Tappets external diameter:

35 mm.

PISTONS

As spare part , there is only one class

(M).

The piston is to be mounted: with the

turbulence chamber towards the oil filter.

The pistons diameter (D) is to be mea-

sured at a distance A = 60 mm from the

piston head.

D = 80 mm.

BOLTS

The bolts are freely mounted in the

connecting rod and piston. They are axially

kept by means of a security device.

Length (mm) 63

Internal diameter (mm) 13.3

External diameter (mm) 24

RINGS

Thickness (mm)

- Compression ring 2

- Sealing ring 2

- Oiling ring 3

The rings are to be mounted with the mark

TOP towards the piston head and the

grooves separated at 120.

Characteristics

Top

-0,01

-0,04

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 17

CONNECTING RODS

Connecting rod side clearance: 0.22 0.40

mm.

The connecting rod end is bushed.

The bushes are not to be replaced.

NOTICE: The connecting rods and their

covers are not to be marked by means of

punches, but by permanent markers.

CRANKSHAFT

Number of bearings 5

Bearings nominal

diameter (mm) 54.795 0.01

Pressure gauges

nominal diameter (mm) 48 0.02 / 0

Axial clearance (mm) 0.07 0.23

Axial half-bearings 2.30; 2.35;

thickness (mm) 2.40; 2.45

OIL PUMP

The oil pump is with gear wheels type,

driven by means of a chain by the

crankshaft.

Oil minimal pressure at 80C (bars):

- at 1000 rpm1.2

- at 3000 rpm3.5

Pistons coolers valves opening pres-

sure: 2.2 0.2 bars.

The followings are to be checked:

- Clearance A (mm): - minimum 0.100

- maximum 0.240

- Clearance B (mm): - minimum 0.020

- maximum 0.085

Characteristics

The crankshaft is not to be rectified.

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 18

NECESSARY SPECIAL TOOLS

Special tools

Nr DENOMINATION SERVICE CODE DACIA

crt ITEM NO.

1 Wrench for oil casing plug MOT 1018 1001101800

2 Device for mounting the camshaft sealing gasket MOT 988-02 1001098802

3 Device for mounting the crankshaft sealing gasket

towards engine flywheel MOT 991-01 1001099101

4 Device for mounting the crankshaft sealing gasket

towards distribution MOT 990-03 1001099003

5 Pliers for elastic clips. MOT 1202-01 1001120201

6 Comparing support MOT 251-01 1001025101

7 Plate for measurement of pistons over-height MOT 252-01 1001025201

8 Wrench for dismounting-remounting port-injectors MOT 997-01 1001099701

9 Rod for engine setting MOT 1054 1001105400

10 Pliers for dismounting the valves oil-sealing rings. MOT 1331 1001133500

11 Device for belt tensioning checking. MOT 1505 1001150500

12 Device for maintaining the injection pump pulley MOT 1200-01 1001120001

13 Flywheel retaining sector MOT 582 1001058200

14 Device for distribution gear blocking MOT 799-01 1001079901

15 Rod for setting the EPIC injection pump MOT 1520 1001152000

16 Sheave for setting the EPIC injection pump MOT 1522 1001152200

17 Extractor for injection pump pulley MOT 1525 1001152500

18 Device for power train sustaining MOT 547 1001054700

19 Wrench for oil filter MOT 555 1001055500

20 Device for dismounting the pistons coolers MOT 1485-01 1001148501

21 Device for mounting the pistons coolers MOT 1516 1001151601

22 Device for dismounting the pistons coolers

( to be used with 0MOT 1516) MOT 1516 -01 1001151601

23 Device for mounting connecting-rod bearings MOT 1492 1001149200

24 Device for mounting base bearings MOT 1493 1001149300

25 Wrench for dismounting/remounting high pressure pipes MOT 1566 1001156600

26 Port-injectors support for injectors dismounting

and calibrating MOT 1011-01 1001101101

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 19

CYLINDER HEAD

Dismounting - Remounting

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 20

DISMOUNTING

- drain the oil from the engine.

- drain the cooling fluid.

The followings are to be dismounted:

- the air filter,

- hoses from oil vapors recycling system,

- the alternator belt and its tensioning de-

vice,

- the alternator,

- the distribution crankcases,

- the distribution belt (see Chapter 11

Distribution Belt).

The followings are to be dismounted:

- the injectors supplying pipes,

- the incandescent sparking plugs sup-

plying wires,

- the injection pump (see Chapter 13

Injection Pump),

- the depression hose off the vacuum

pump,

- intake and exhaust manifold;

- camshaft gear, by means of the

blocking device MOT 799-01;

- upper distribution casing.

The cylinder head attachment screws

are to be unscrewed.

The cylinder head is to be dismounted

without rotate it (the cylinder head is

centered by means of two bushes (C)).

Dismount

- cylinder head cover;

- vacuum pump;

- engine lifting connecting-rods.

Dismounting - Remounting

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 21

The camshaft bearing covers are to be

dismounted (the covers order and direction

are to be marked prior their dismounting).

The followings are to be dismounted:

- the camshaft,

- the tappets (they are to be marked as

against the cylinder head),

- the injectors, by means of the

MOT 997-01 device,

- pre-heating spark plugs,

- the turbulence chambers,

- the thermostat support.

The following are to be dismounted:

- the valves springs,

- the valves,

- valves oil-sealing rings by means of the

pliers MOT 1335.

In order to get a right tightening of the

cylinder head screws, the oil that may be in

the cylinder head fixing holes is to be

extracted by means of a syringe.

ATTENTION !

Avoid residuals penetrating in the oil

channeling. There is the risk of channeling

plugging and therefore the camshaft fast

damaging.

It is very important not to scratch the

cylinder head on the gasket-seating surface.

The LOCTITE 7200 METALLREINIGER

is to be used for cleaning the gasket possible

stuck bits.

Spread out the substance on the area to be

cleaned, wait for about 10 minutes, and clean

with a wooden spatula.

During this operation, wear protection

gloves.

Dismounting - Remounting

1 2 3 4 5

MOT 997-01

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 22

The cylinder head flatness is checked by

means of a ruler and a kit of gauges.

Maximal permitted deformation: 0.05 mm.

The cylinder head is not to be rectified.

REMOUNTING

The new valves are to be placed on posi-

tion; the valves return as against the gasket

plane is to be checked by means of the MOT

251-01 and MOT 252-01 devices, as follows:

- intake: 0.85 0.09 mm

- exhaust: 0.97 0.09 mm

The valves are to be run-in on their

seats.

The valves are to be marked as against

the cylinder head.

The parts are to be oiled with engine

oil.

The followings are to be mounted in or-

der:

- the valves oil-sealing rings (1), by

means of a 12 mm tubular wrench,

- the valves (2),

- the lower hoods (3),

- the valve springs (4), (are identical for

both intake and exhaust),

- the upper hoods (5),

the half-cones (6).

Dismounting - Remounting

MOT 252-01

MOT 251-01

1

2

3

4

5

6

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 23

Dismounting - Remounting

The turbulence chambers (7) are to be

mounted.

Their over-height is to be checked by

means of the devices MOT 251-01 and

MOT 252-01:

x = 0.01 0.04 mm

Pre-heating spark plugs are to be

mounted and tightened at a moment of

1.5 2 daNm

The anti-flame washers (9) are to be

mounted observing their orientation. The

anti-flame washers (2) and the gaskets are

to be replaced every time the port-injec-

tors are to be dismounted.

The port-injectors are to be mounted and

tightened at a moment of (6.5 7.5 daNm)

The thermostat support is to be mounted.

2

9

7

MOT 252-01

MOT 251-01

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 24

THERMAL CLEARANCE

ADJUSTMENT

This operation is to be performed only

when the engine is cold. The method In

balance is used when checking the valves

clearance (the cylinder valves at the end of

the exhaust and the beginning of the intake).

The measured values are to be compared

with the reference ones:

- intake: 0.20 0.05 mm

- exhaust: 0.40 0.05 mm

In case the clearance (x) is not according

to the requirements, the respective tappet is

to be replaced with one having the adequate

thickness (y).

The value (y) squares with the tappet class

(there are 24 classes).

The value (y) is to be measured by a

MOT 252-01 plate, a magnetic plate support,

and a comparing gauge with a precision of

0.001 mm.

The comparing gauge is to be set on

zero.

The comparing feeler is to be lifted (not

to modify the assembly position).

The tappet is to be introduced and the

value (y) is to be measured.

The value (y) varies every 0.025 mm,

from 7.550 to 8.150.

Repeat the procedure for the tappets

presenting the valve clearance outside

tolerance.

Select the adequate tappets according

to the spare parts catalogue.

MOT 252-01

Cylinder valves

to be checked

Cylinder valves

in balance

1

3

4

2

4

2

1

3

Dismounting - Remounting

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 25

Dismounting - Remounting

The following are to be mounted:

- the camshaft,

- the camshaft bearings covers, observ-

ing the marking performed during the dis-

mounting.

A thin layer of RHODORSEAL 5661

is to be applied on the bearings covers (1)

and (5), according to the drawing

indications.

The pistons are to be positioned so

that neither of them is on its upper dead

point, in order to avoid the contact with

the valves, during the camshaft covers

tightening (the blocking mark on the

crankshaft is to be horizontally positioned).

The camshaft bearings covers screws

are to be progressively tightened at a

required moment of (2 daNm).

The camshaft axial clearance is to be

checked; the clearance should be within

0.05 and 0.13 mm.

The followings are to be mounted:

- the vacuum pump (2) and its gasket

(3),

- the camshaft-sealing gasket, by means of

the MOT 988-02 device.

MOT 1505

MOT 988-02

5

1

3 2

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 26

Dismounting - Remounting

- the camshaft gear its screw (4) is to be

tightened at a required moment of 5 daNm.

- the injection pump support its screws

are to be tightened at a required moment of

(2.5 daNm),

- the injection pump the screws are to be

progressively screwed by hand and then

tightened at 2.5 daNm (see Chapter 13

Injection Pump),

- the cylinder head cover,

- the injectors pipes, the injection pump

gear it is to be immobilized by means of the

MOT 1200-01 device and its nut is to be tight-

ened at 5.5 daNm.

4

MOT 1200-01

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 27

Dismounting - Remounting

CYLINDERS CRANKCASE

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 28

CYLINDERS CRANKCASE

The following are to be dismounted:

- the clutch,

- the engine flywheel (it is immobilized

by means of the MOT 582),

- the lower crankcase,

- the crankshaft gear,

- the distribution belt lower protection

plate,

- distribution belt rolling cam

- the distribution with oil-sealing ring

crankcase,

- the crankshaft sealing gasket support,

- water pump pulley,

- the water pump,

- oil filter by means of the MOT 555

wrench.

Mark the connecting rod covers

compared with the connecting rod body.

ATTENTION !

Do not use punches for connecting

rods and connecting rods caps marking

in order to avoid cracks occurring.

Use a permanent marker.

- water pump inlet pipe,

- the oil pump (the two attachment

screws are to be unscrewed and the pump

is to be turned over).

- oil pump drive gear and chain,

,

Dismounting - Remounting

DISMOUNTING

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 29

Dismounting - Remounting

The following are to be dismounted:

- the connecting rod covers and bear-

ings,

- the pistons connecting rod assem-

bly (the pistons are to be marked as against

the cylinders

- No.1 towards the flywheel),

- the bearings covers and bearings,

- the bearing No.1 oil-sealing ring,

- the crankshaft and the bearing for axial

clearance adjustment

- the bearings on the cylinders crank-

case.

The piston axle-maintaining locks are

to be extracted and the connecting rods are

to be dismounted (the axle is freely

mounted in the piston and connecting rod).

The rings are to be dismounted.

PISTONS COOLERS REPLACEMENT

COOLERS DISMOUNTING

- the cooler (1) is to be drilled with a 7

mm drill,

- extract the stopper (2) and spring (3).

NOTICE:

The ball (4) is not to be extracted in order

to avoid the splinter entering the oil circuit.

The remained splinter is to be removed by

means of a brush.

1

4

3

2

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 30

Dismounting - Remounting

The MOT 148501 is to be screwed in the

cooler and the latter is to be extracted.

PISTONS COOLERS MOUNTING

The cooler mounting is performed by

means of the MOT 1516-01 device.

The MOT 1516-01 device plate (3) is to

be mounted on the cylinders crankcase and

centered by mans of the centering device (2).

The screws (1) are to be tightened then

the centering device is to be removed.

The cooler is introduced in the device

rod.

NOTICE:

Pay attention when mounting the

cooler; the end (4) is to be directed

towards the cylinder center.

The cooler is to be positioned again and

again, until the pressing rod shoulder (5)

contacts the plate (3).

MOT 1485-01

MOT 1516-01

3

2

1

4

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 31

Dismounting - Remounting

Pay attention to the coolers direction.

A: coolers direction for cylinders 2 and 4.

B: coolers direction for cylinders 1 and 3.

REMOUNTING

The cylinders crankcase gasket areas and

the crankshaft oiling grooves are to be

cleaned.

The connecting rod bearings are identical

and they are not provided with groin.

They are to be mounted by means of the

MOT 1492 device.

The bearing support (1) is to be chosen

according to the engine shown in position (2).

The bearing support is to be mounted in

the device slot (3).

The connecting rod is to be mounted on

the device so that the lower part of the

connecting rod leg (4) contacts the centering

part.

5

3

3

2

4

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 32

Dismounting - Remounting

The bearing (5) is to be placed on the

bearing support (see the following drawing).

The bearing support is moved according

to the arrow so that the bearing hits the

connecting rod.

The connecting rod cover is to be placed

on the support so that the latter hits the

two studs (6) then the bearing (7) is to be

mounted on its support.

The bearing support is moved according

to the arrow so that the bearing hits the

cover.

The pistons are to be mounted with the

bolts and connecting rods.

5

7

6

The same operations are to be performed

for all the other connecting rods.

The followings are to be performed when

mounting the connecting rods covers

bearings:

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 33

Dismounting - Remounting

The axle / piston keeping locks are to

be mounted.

Remark:

The piston shaft maintaining locks are

to be replaced after each dismounting.

The rings are to be mounted on the pis-

ton as follows:

- the oiling ring (3),

- the sealing ring (2) with the TOP

mark upward,

- the compression ring (1) with the

TOP mark upward.

The rings are to be positioned at 120

from one another, with the oiling ring slot

in front of one of its channel full.

The ring slot is not to be adjusted.

The rings piston connecting rod

assembly is to be oiled and mounted in the

cylinders crankcase so that the turbulence

chamber is directed towards the oil filter

The bearings are not provided with groins

The bearings to be mounted in the cylin-

der crankcase are provided with oiling holes.

The MOT 1493 device is to be used for

the bearings mounting.

The MOT 1493 device is placed on the

cylinders crankcase.

MOT 1493

MOT 1493

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 34

Dismounting - Remounting

The bearing is to be mounted in the MOT

1493 device. Then the bearing is to be pushed

on the point (A) until it hits the point (B) of

the device.

The MOT 1493 device is to be placed on

the bearing cover.

The bearing is to be mounted in the device.

Then the bearing is to be pushed on the point

(A) until it hits the point (B) of the MOT 1493

device

The bearing-covers (3), (4) and (5) are

to mounted and tightened at 6.5 daNm.

The crankshaft axial clearance (j) is

to be checked:

j = 0.07 0.23 mm

The axial bearings may have: 2.30, 2.35,

2.40 and 2.45 mm.

The followings are to be mounted:

- the bearing cover (2); then it is to

be tightened at a required moment of

(6.5 daNm),

- the connecting rod covers; then they

to be tightened at 4.5 5 daNm.

The bearing (1) is to be sealed by silicon

injection.

a) Mounting of the gaskets

- If the channel thickness is lower to 5

mm, a 5.1 - mm thickness gasket is to be

used.

- If the channel thickness is greater than

5 mm, a 6 - mm thickness gasket is to be

used.

The gaskets are to be mounted with

channel towards exterior.

b) Silicon injection

The necessary kit for this operation

includes a 50 ml syringe and a 5 ml tube

of DURCISSEUR.

A

B

The oiled crankshaft and the axial bearings

are to be mounted (at bearing No.2).

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 35

Dismounting - Remounting

IMPORTANT:

The injection is to last at least 5

minutes, in order to avoid the syringe

mixture polymerization.

The cylinders crankcase and the bearing

cover areas (A) are to be cleaned and

degreased with thinner.

A thin layer of RHODORSEAL 5661

is to be applied on the cylinders crankcase

areas (B).

The bearing cover (1) is to be mounted

and tightened at 6.5 daNm.

Thirty milliliters (30 ml) of

RHODORSEAL 5661 are to be mixed with

one third (1/3) of the tube of DURCISSEUR

until obtaining a homogeneous mixture.

The mixture is to be introduced into the

syringe and then slowly injected into the

bearing cover grooves so that the sealing

between the bearing cover and the cylin-

ders crankcase is perfect.

Wait for the mixture polymerization and

remove the excess.

B

B

A

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 36

Dismounting - Remounting

The assembly rotation is to be checked.

Mount the sealing gasket from number 1

bearing by means of the device

MOT 991 01.

Mount the oil pump drive gear and chain.

The crankshaft cover centering bushes are

to be checked on the distribution side.

The support is to be mounted with a new

gasket.

Lubricate with oil the sealing gasket of

the crankshaft towards distribution.

Mount the sealing gasket by means of

the device MOT 990-03.

The oil pump centering bushes presence

is to be checked.

The oil pump is to be mounted and the

attachment screws are to be tightened at a

required moment of 2 2.5 daNm.

MOT 990-03

MOT 991-01

Mount

- water pump and tighten the

attachment screws to the required moment

of 1.6 daNm.

- water pump pulley and tighten the

attachment screws to the required moment

of 2 daNm.

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 37

The engine flywheel supporting area on

the crankshaft is to be lubricated with

LOCTITE 243.

The geared sector MOT 582 is to be

dismounted.

The screws are to be tightened at a

required moment of (5 5.5 daNm).

The geared sector MOT 582 is to be

dismounted.

The clutch is to be mounted (see the

Chapter 20 The Clutch) and its

attachment screws are to be tightened at 2

daNm.

The lower crankcase is to be provided

with a new gasket; its screws are to be

tightened at a required moment of (1.2

1.5 daNm).

Remark:

Observe that lining-up of the lower

casing and of the cylinders casing on the

assembly surface with the gearbox in

order to avoid the clutch casing

damaging.

CYLINDER HEAD REMOUNTING

- The followings are to be mounted:

- The cylinder head centering bushes;

- The cylinder head gasket.

NOTICE:

In case of replacing one of the following

elements

- the crankshaft,

- the cylinders crankcase,

- the connecting rods,

- the piston,

it is obligatory to recalculate the cylinder

head gasket thickness according to the

pistons area. Otherwise the cylinder head

gasket is to be replaced with an identical one.

In order to establish the gasket thickness

the pistons over-height is to be measured by

means of the devices MOT 251-01 and MOT

252-01.

The calamine is to be removed from the

pistons head.

The crankshaft is to be rotated towards the

running direction and the piston (1) and its

upper dead point.

The piston over-height is to be measured.

The operation is to be repeated for all the

other pistons.

Dismounting - Remounting

MOT 582

Mount :

- water pump inlet pipe equipped with

a new gasket,

- oil filter,

- lower protection casing of the

distribution belt,

- crankshaft gear,

- distribution belt tensioning cam.

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 38

NOTICE

The measurements are to be performed

on the engine longitudinal axe, in order to

avoid the errors caused by the piston turning

over.

IMPORTANT!

ONLY THE MAXIMAL OVER-HEIGHT IS

TO BE TAKEN INTO CONSIDERATION.

The followings are to be used to get a

maximal over-height of the piston:

- smaller than 0.613 mm : use a gasket pro-

vided with two identification holes (thickness

1.4 mm)

- between 0.613 mm (included) and 0.767

mm (included): use a gasket provided with

an identification hole (thickness 1.5 mm).

- higher than 0.767 mm: use a gasket

provided with three holes (thickness 1.6 mm).

The pistons are to be brought at half-

stroke, in order to avoid the contact with

their valves.

The cylinder head is to be centered on the

two centering bushes.

The cylinder head screws are to be

tightened at the required moment and oiled,

observing the following method:

The cylinder head screws are to be tight-

ened at 3 daNm, then at an angle of

80 4, observing the order indicated in

the drawing. Wait for 3 minutes.

2. CYLINDER HEAD TIGHTENING

The screws 1 and 2 are to be totally un-

screwed and tightened at 2.5 daNm, then

at an angle of 213 7.

The same is to be done for the screws

3-4, 5-6, 7-8 and 9-10.

The cylinder head is not to be re-tight-

ened.

The distribution belt is to be mounted

and tensioned at 61 5 Hz (see Chapter

11 The Distribution Belt).

The nut of the tightening roller is to be

obligatory tightened at 5 daNm.

Perform the pressing-on of the injection

pump. (see Chapter 13 Injection Pump

Pressing-on).

Then, the followings are to be mounted:

- the distribution covers,

- the crankshaft pulley its screw is to

be tightened at 2 daNm then at an angle of

115 15,

- the intake-exhaust manifold - its

screws are to be tightened at 2.7 daNm.

- the alternator and its belt the alter-

nator belt is to be tensioned at 127 5 Hz

(see Chapter 16 Alternator).

Dismounting - Remounting

CYLINDER HEAD TIGHTENING

METHOD

1. GASKET PRE-SETTING

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 39

For lower casing dismounting, dismounting of the power train is required.

DISMOUNTING

Dismount the power train 9 see chapter 10 Power train)

Dismount the lower casing attachment screws.

REMOUNTING

Clean the lower casing and the gasket seating surface on the cylinders casing.

Mount the lower casing equipped with a new gasket.

Perform the others operations in the reverse order.

TIGHTENING MOMENTS (daNm)

Lower crankcase attachment screws ............................................................... 1.5

Lower crankcase

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 40

DISMOUNTING

The followings are to be dismounted:

- the lower crankcase (see Chapter 10 Lower Crankcase),

- the two attachment screws of the oil pump on the cylinders crankcase.

The oil pump is turned over, the driving chain is to be extracted from the gear, and the

pump is to be dismounted.

The oil pump cover is to be dismounted.

The oil pump gear clearance is to be checked (see Chapter 10 Characteristics).

REMOUNTING

Perform the dismounting operations in the reverse order.

The engine is to be filled with oil.

The oil pressure at 80 is to be checked :

- at 1000 rpm1.2 bars,

- at 3000 rpm ...3.5 bars.

TIGHTENING MOMENTS (daNm)

Oil pump attachment screws .......................................... 2 2,5

Oil pump

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 41

GASKET REPLACEMENT

DISMOUNTING

The distribution belt is to be dismounted

(see Chapter 11 Distribution Belt).

The gear is to be dismounted from the

crankshaft.

The crankshaft-sealing gasket is to be

extracted.

REMOUNTING

The new sealing gasket is to be mounted

by means of the device MOT 990-03.

Before mounting, lubricate the sealing

gasket with engine oil.

The distribution belt is to be mounted (see

the method described in the Chapter 11

Distribution Belt).

Necessary Special Tools

MOT 1054 Engine pressing-on rod

MOT 990-03 Crankshaft sealing gasket mounting device

towards distribution

MOT 1505 Belts tension measurement device

TIGHTENING MOMENTS (daNm)

Crankcase pulley screw 2+11515

Distribution belt

tensioning roller nut 5

Alternator attachment screw 1.9

Crankshaft sealing gasket towards distribution

MOT 990-03

vnx.su

10

ENGINE AND LOWER ENGINE UNITS

10 - 42

Multi-purpose support

Only for vehicles equipped with power steering.

TIGHTENING MOMENTS (daNm)

Support attachment screw 4.4

DEMONTARE

Place the vehicle on a two-column elevator

Disconnect the battery

Dismount:

- alternator (see chapter 16

Alternator),