Documente Academic

Documente Profesional

Documente Cultură

CROSBY Master Link & Shackles

Încărcat de

aiyubi2Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

CROSBY Master Link & Shackles

Încărcat de

aiyubi2Drepturi de autor:

Formate disponibile

Welded Master Links

A-344

Alloy Steel - Quenched and Tempered.

Individually Proof Tested to values shown, with certification.

Proof Tested with 60% inside width special fixtures sized to prevent

localized point leading per ASME A-952 , reference page 251.

Meets or exceeds all requirements of ASME B30.26 including

identification, ductility, design factor, proof load and temperature

requirements. Importantly, these links meet other critical performance

requirements including fatigue life, impact properties and material

traceability, not addressed by ASME B30.26.

Each link has a Product Identification Code (PIC) for material

traceability, along with the size and the name Crosby or CG.

Large inside width and length to allow additional room for sling

hardware and crane hook.

Engineered Flat for use with S-1325A coupler link.

Master links are type approved to DNV Certification Notes 2.7-1Offshore Containers. These Crosby master links are 100% proof tested,

MPI and impact tested. The tests are conducted by Crosby and 3.1 test

certification is available upon request. Refer to page 147 for Crosby

COLD TUFF master links that meet the additional requirements of

DNV rules for certification of lifting applications - Loose Gear.

A-347

A-344

Welded Master Link with Engineered Flat

Working

Dimensions

Engineered

Weight

Load

Proof

(in.)

Flat Size

A-344

Each

Limit

Load

for S-1325A

(in.)

(mm) Stock No

(lbs.)

(lbs.)*

(lbs.)**

A

B

C

G

(in.)

7/16

12

1256862

0.66

3500

8800

.47

2.36

4.72

.24

1/4

1/2

13

1256932

0.79

5500

14000

.51

2.36

4.72

.26

1/4

11/16

17

1257002

1.85

9000

22700

.67

3.54

6.30

.33

3/8

3/4

19

1257072

2.36

14700

36800

.75

3.54

6.30

.33

3/8

7/8

22

1257212

3.55

18700

46800

.87

3.94

7.10

.41

1/2

1

26

1257282

5.22

25300

63400

.98

4.53

8.10

.53

1/2

1-1/8

28

1257382

8.33

28600

71700

1.10

5.71

10.83

.53

1/2

1-7/32

31

1257422

10.3

37400

93700

1.22

5.71

10.83

.61

5/8

1-7/16

36

1257492

15.1

52900

132200

1.42

6.10

11.20

1-9/16

40

1257532

19.6

61900

154900

1.57

6.30

11.80

1-3/4

45

1257562

28.1

84400

211100

1.77

7.10

13.40

2

51

1257632

38.1

99200

248000

2.00

8.50

15.30

*Ultimate Load is 5 times the Working Load Limit. Applications with wire rope and synthetic sling generally require a design

factor of 5. Based on single leg sling (in-line load), or resultant load on multiple legs with an included angle less than or equal to

120 degrees.

**Proof Test Load equals or exceeds the requirement of ASTM A952(8.1) and ASME B30.9.

For use with chain slings, refer to page 217 for sling ratings and page 214 for proper master link selection.

Size

A-347

Welded Master Link Assembly with Engineered Flat

Size

(in.)

1/2

11/16

3/4

7/8

1-1/8

1-7/32

1-9/16

1-3/4

2

(mm)

13/12

17/13

19/13

22/17

28/22

31/25

40/31

45/36

51/45

Working

A-347 Weight

Load

Stock

Each

Limit

No

(lbs.)

(lbs.)*

1257692

1.80

5300

1257762

3.40

9000

1257832

4.00

9300

1257972

7.20

17600

1258142

15.4

31900

1258182

20.8

37500

1258332

40.5

61900

1258402

58.2

84400

1258462

95.0

99200

Proof

Load

(lbs.)**

13200

22700

23400

44100

79800

93700

154900

211100

248000

Dimensions

(in.)

A

.51

.67

.75

.87

1.10

1.22

1.57

1.77

2.00

B

2.36

3.54

3.54

3.94

5.71

5.71

6.30

7.10

7.50

C

4.72

6.30

6.30

7.10

10.83

10.83

11.80

13.40

13.80

D

.47

.51

.51

.67

.87

.98

1.22

1.42

1.80

E

3.35

4.72

4.72

6.30

7.10

8.10

10.63

11.20

13.40

F

1.77

2.36

2.36

3.54

3.94

4.53

5.50

6.10

7.10

G

.24

.26

.26

.33

.41

.53

Engineered

Flat Size

for

S-1325

(in.)

1/4

1/4

5/16

3/8

1/2

*Ultimate Load is 5 times the Working Load Limit. Applications with wire rope and synthetic sling generally require a design

factor of 5. The maximum individual sublink working load limit is 75% of the assembly working load limit.

** Proof Test Load equals or exceeds the requirement of ASTM A952(8.1) and ASME B30.9.

For use with chain slings, refer to page 217 for sling ratings and page 214 for proper master link selection.

146

Copyright 2011 The Crosby Group LLC

All Rights Reserved

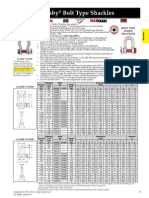

Crosby Bolt Type Shackles

G-2130 / S-2130

G-2130 Bolt Type Anchor shackles

with thin head bolt - nut with

cotter pin. Meets the performance

requirements of Federal

Specification RR-C-271F Type IVA,

Grade A, Class 3, except for those

provisions required of the contractor.

For additional information, see

page 426.

G-2130 / S-2130

G-2150 / S-2150

Capacities 1/3 thru 150 metric tons, grade 6.

Working Load Limit and grade 6 permanently shown on every shackle.

Forged Quenched and Tempered, with alloy pins.

Hot Dip galvanized or Self Colored. (85, 120, and 150 metric ton shackles

are all hot dip galvanized bows and the bolts are Dimetcoted and painted red)

Fatigue rated (1/3t - 55t).

Shackles 25t and larger are RFID EQUIPPED.

Approved for use at -40 degree C (-40 degree F) to 204 degree C (400 degree F).

Meets or exceeds all requirements of ASME B30.26.

Shackles 85 metric tons and larger are individually proof tested to 2.0 times the

working load limit.

Shackles 120 metric tons and larger are proof tested, Magnetic Particle Inspected and

provided with Serialized Pin and Bow.

Type Approval and certification in accordance with ABS 2006 Steel Vessel Rules

1-1-17.7, and ABS Guide for Certification of Cranes.

3.1 Certification as standard available for charpy and statistical proof test for pg 73

only up to 25 tons to DNV2.7-1 and EN13889.

Crosby 2t through 25t G2130 anchor shackles are type approved to DNV Certification

Notes 2.7-1- Offshore Containers. These Crosby shackles are statistical proof and

impact tested to 42 joules (31 ft-Lbs.) min. ave. at -20 degree C (-4 degree F). The tests

are conducted by Crosby and 3.1 test certification is available upon request. Refer to

page 76 for Crosby COLD TUFF shackles that meet the additional requirements of

DNV rules for certification of lifting applications - Loose Gear.

All other 2130 and all 2150 shackles can meet charpy requirements of 42 joules

(31 ft-Lbs) avg at -20 degree C (-4 degree F) upon special request.

Look for the Red Pin . . . the mark of genuine Crosby quality.

Nominal

Size

(in.)

3/16

1/4

5/16

3/8

7/16

1/2

5/8

3/4

7/8

1

1-1/8

1-1/4

1-3/8

1-1/2

1-3/4

2

2-1/2

3

3-1/2

4

Working

Load

Limit

(t)*

1/3

1/2

3/4

1

1-1/2

2

3-1/4

4-3/4

6-1/2

8-1/2

9-1/2

12

13-1/2

17

25

35

55

85

120

150

Stock

No.

G-2130

1019464

1019466

1019468

1019470

1019471

1019472

1019490

1019515

1019533

1019551

1019579

1019597

1019613

1019631

1019659

1019677

1019695

1019711

1019739

1019757

S-2130

1019481

1019506

1019524

1019542

1019560

1019588

1019604

1019622

1019640

1019668

1019686

1019702

Weight

Each

(lbs.)

.06

.11

.22

.33

.49

.79

1.68

2.72

3.95

5.66

8.27

11.71

15.83

19.00

33.91

52.25

98.25

154.00

265.00

338.00

BOLT TYPE

CHAIN

SHACKLES

G-2150 / S-2150

G-2150 Bolt Type Chain shackles.

Thin hex head bolt - nut with

cotter pin. Meets the performance

requirements of Federal

Specification RR-C271F Type

IVB, Grade A, Class 3, except

for those provisions required of

the contractors. For additional

information, see page 426.

Dimensions

(in.)

A

.38

.47

.53

.66

.75

.81

1.06

1.25

1.44

1.69

1.81

2.03

2.25

2.38

2.88

3.25

4.13

5.00

5.25

5.50

B

.25

.31

.38

.44

.50

.64

.77

.89

1.02

1.15

1.25

1.40

1.53

1.66

2.04

2.30

2.80

3.30

3.76

4.26

C

.88

1.13

1.22

1.44

1.69

1.88

2.38

2.81

3.31

3.75

4.25

4.69

5.25

5.75

7.00

7.75

10.50

13.00

14.63

14.50

D

.19

.25

.31

.38

.44

.50

.63

.75

.88

1.00

1.13

1.29

1.42

1.53

1.84

2.08

2.71

3.12

3.62

4.00

E

.60

.78

.84

1.03

1.16

1.31

1.69

2.00

2.28

2.69

2.91

3.25

3.63

3.88

5.00

5.75

7.25

7.88

9.00

10.00

F

.56

.61

.75

.91

1.06

1.19

1.50

1.81

2.09

2.38

2.69

3.00

3.31

3.63

4.19

4.81

5.69

6.50

8.00

9.00

Tolerance

+/H

1.47

1.84

2.09

2.49

2.91

3.28

4.19

4.97

5.83

6.56

7.47

8.25

9.16

10.00

12.34

13.68

17.90

21.50

24.88

25.68

L

.98

1.28

1.47

1.78

2.03

2.31

2.94

3.50

4.03

4.69

5.16

5.75

6.38

6.88

8.80

10.15

12.75

14.62

17.02

18.00

N

.19

.25

.31

.38

.44

.50

.69

.81

.97

1.06

1.25

1.38

1.50

1.62

2.25

2.40

3.13

3.62

4.38

4.56

C

.06

.06

.06

.13

.13

.13

.13

.25

.25

.25

.25

.25

.25

.25

.25

.25

.25

.25

.25

.25

A

.06

.06

.06

.06

.06

.06

.06

.06

.06

.06

.06

.06

.13

.13

.13

.13

.25

.25

.25

.25

Working

Stock

Dimensions

Tolerance

Nominal Load

No.

Weight

(in.)

+/Size

Limit

Each

(in.)

(t)*

G-2150 S-2150

(lbs.)

A

B

D

F

G

K

M

P

R

G

A

1/4

1/2

1019768

.13

.47

.31

.25

.62

.91

1.59

.97

1.56

.25

.06

.06

5/16

3/4

1019770

.23

.53

.38

.31

.75

1.07

1.91

1.15

1.82

.31

.06

.06

3/8

1

1019772

.33

.66

.44

.38

.92

1.28

2.31

1.42

2.17

.38

.13

.06

7/16

1-1/2

1019774

.49

.75

.50

.44

1.06

1.48

2.67

1.63

2.51

.44

.13

.06

1/2

2

1019775 1019784

.75

.81

.64

.50

1.18

1.66

3.03

1.81

2.80

.50

.13

.06

5/8

3-1/4

1019793 1019800

1.47

1.06

.77

.63

1.50

2.04 3.76 2.32 3.56

.63

.13

.06

3/4

4-3/4

1019819 1019828

2.52

1.25

.89

.75

1.81

2.40 4.53 2.75 4.15

.81

.25

.06

7/8

6-1/2

1019837 1019846

3.85

1.44

1.02

.88

2.10

2.86 5.33 3.20 4.82

.97

.25

.06

1

8-1/2

1019855 1019864

5.55

1.69

1.15

1.00

2.38 3.24 5.94 3.69 5.39

1.00

.25

.06

1-1/8

9-1/2

1019873 1019882

7.60

1.81

1.25

1.13

2.68 3.61 6.78 4.07 5.90

1.25

.25

.06

1-1/4

12

1019891 1019908 10.81

2.03

1.40

1.25

3.00 3.97

7.50

4.53 6.69

1.38

.25

.06

1-3/8

13-1/2 1019917 1019926 13.75

2.25

1.53

1.38

3.31 4.43 8.28

5.01

7.21

1.50

.25

.13

1-1/2

17

1019935 1019944 18.50

2.38

1.66

1.50

3.62 4.87 9.05 5.38

7.73

1.62

.25

.13

1-3/4

25

1019953 1019962

31.40

2.88 2.04

1.75

4.19 5.82 10.97 6.38 9.33 2.12

.25

.13

2

35

1019971 1019980 46.75

3.25 2.30

2.10

5.00 6.82 12.74 7.25 10.41 2.36

.25

.13

2-1/2

55

1019999 1020004 85.00

4.12 2.80 2.63 5.68 8.07 14.85 9.38 13.58 2.63

.25

.25

3

85

1020013

124.25

5.00 3.25 3.00 6.50 8.56 16.87 11.00 15.13 3.50

.25

.25

* NOTE: Maximum Proof Load is 2.0 times the Working Load Limit. Minimum Ultimate Strength is 6 times the Working Load

Limit. For Working Load Limit reduction due to side loading applications, see page 80.

Individually Proof Tested with certification.

Furnished in Anchor style only and furnished with Round Head Bolts with welded handles.

Copyright 2011 The Crosby Group LLC

All Rights Reserved

Shackles

BOLT TYPE

ANCHOR

SHACKLES

73

Welded Master Links

A-344

Alloy Steel - Quenched and Tempered.

Individually Proof Tested to values shown, with certification.

Proof Tested with 60% inside width special fixtures sized to prevent localized point leading per

ASME A-952 , reference page 251.

Meets or exceeds all requirements of ASME B30.26 including identification, ductility, design

factor, proof load and temperature requirements. Importantly, these links meet other critical

performance requirements including fatigue life, impact properties and material traceability,

not addressed by ASME B30.26.

Meets the performance requirements of EN1677-4:2001.

Each link has a Product Identification Code (PIC) for material traceability, along with the size

and the name Crosby or CG.

Large inside width and length to allow additional room for sling hardware and crane hook.

Engineered Flat for use with S-1325A coupler link.

Crosby 32mm to 51mm 342/345 master links are type approved to DNV Certification Notes

2.7-1- Offshore Containers. These Crosby master links are 100% proof tested, MPI and impact

tested. The tests are conducted by Crosby and 3.1 test certification is available upon request.

Refer to page 147 for Crosby COLD TUFF master links that meet the additional requirements

of DNV rules for certification of lifting applications - Loose Gear

A-347

A-344 Welded Master Link with Engineered Flat

Working

Dimensions

Engineered

Weight

Load

Proof

(mm)

Flat Size for

A-344

Each

Limit

Load

S-1325A

(mm)

(in.)

A

B

C

G

Stock No.

(kg)*

(t)*

(kN)**

(mm)

12

7/16

1256862

.30

1.60

39

12.0

60.0

120

6.50

6

13

1/2

1256932

.36

2.50

61

13.0

60.0

120

6.50

7-8

17

11/16

1257002

.86

4.10

101

17.0

90.0

160

8.50

10

19

3/4

1257072

1.08

6.70

164

19.0

90.0

160

8.50

10

20

3/4

1257082

1.17

6.70

164

20.0

80.0

150

22

7/8

1257214

1.59

8.50

208

22.0

90.0

170

22

7/8

1257212

1.63

8.50

208

22.0

100

180

10.5

13

22

7/8

1257215

2.39

6.30

154

22.0

145

275

25

1

1257282

2.43

11.5

282

25.0

115

210

13.5

16

25

1

1257302

2.31

11.5

282

25.0

100

190

25

1

1257332

3.35

8.90

218

25.0

145

275

28

1-1/8

1257352

3.22

12.9

316

28.0

110

210

28

1-1/8

1257382

3.91

13.0

319

28.0

145

275

13.5

16

31

1-7/32

1257422

4.86

17.0

417

31.0

145

275

15.5

32

1-1/4

1257442

5.30

17.0

417

32.0

140

270

36

1-7/16

1257492

6.87

24.0

588

36.0

155

285

38

1-1/2

1257502

7.63

31.5

772

38.0

140

270

40

1-9/16 1257532

8.96

28.1

689

40.0

160

300

45

1-3/4

1257569

10.31

32.0

785

45.0

140

250

45

1-3/4

1257564

12.70

38.3

939

45.0

170

320

45

1-3/4

1257562

12.82

38.3

939

45.0

180

340

50

1-31/32 1257582

17.60

45.0

1103

50.0

200

380

51

2

1257632

18.72

45.0

1103

51.0

215

390

57

2-1/4

1257652

24.5

65.3

1601

57.0

203

406

Ultimate Load is 5 times the Working Load Limit. Applications with wire rope and synthetic sling generally require a design

factor of 5. Based on single leg sling (in-line load), or resultant load on multiple legs with an included angle less than or equal

to 120 degrees. ** Proof Test Load equals or exceeds the requirement of ASTM A952(8.1) and ASME B30.9.

For use with chain slings, refer to page 216 for sling ratings and page 214 for proper master link selection.

Size

A-347

Welded Master Link Assembly with Engineered Flat

Dimensions

Engineered

Weight

Working

Proof

(mm)

Flat Size for

A-347

Each Load Limit Load

S-1325A

(mm)

(in.) Stock No.

(kg)

(t)*

(kN)**

A

B

C

D

E

F

G

(mm)

13/12

1/2

1257692

.81

2.40

59

13.0 60.0 120 12.0 85.0 45.0 6.00

6

17/13 11/16 1257762

1.56

4.10

101

17.0 90.0 160 13.0 120 60.0 6.50

7

19/13

3/4

1257832

1.80

4.25

104

19.0 90.0 160 13.0 120 60.0 6.50

8

22/20

7/8

1257977

3.93

8.50

208

22.0 90.0 170 20.0 150 80.0

22/17

7/8

1257972

3.35

7.98

196

22.0 100

180 17.0 160 90.0 8.50

10

22/16

7/8

1257979

3.53

5.80

142

22.0 145

275 16.0 120 60.0

25/20

1

1258122

4.65

10.7

262

25.0 100

190 20.0 150 80.0

25/19

1

1258102

5.51

8.90

218

25.0 145

275 19.0 160 90.0

28/22 1-1/8 1258162

6.40

12.9

316

28.0 110

210 22.0 170 90.0

28/22 1-1/8 1258142

7.17

14.5

355

28.0 145

275 22.0 180

100 10.5

13

31/25 1-7/32 1258182

9.72

17.0

417

31.0 145

275 25.0 210

115 13.5

16

32/25 1-1/4 1258202

9.92

17.0

417

32.0 140

270 25.0 190

100

36/28 1-3/8 1258222

12.20

23.6

579

36.0 145

275 28.0 190

100

38/32 1-1/2 1258224

18.23

28.1

689

38.0 140

270 32.0 270

140

40/31 1-9/16 1258332

18.68

28.1

689

40.0 160

300 31.0 275

145

45/38 1-3/4 1258422

27.96

38.3

939

45.0 170

320 38.0 270

140

45/36 1-3/4 1258402

26.56

38.3

939

45.0 180

340 36.0 285

155

32.86

45.0

1103

50.0 200 380 38.0 270

140

50/38

2

1258442

51/45

2

1258462

42.92

45.0

1103

51.0 190

350 45.0 340

180

57/50

2-1/4 1258482

59.70

67.0

1643

57.0 203 406 50.0 380 200

*Ultimate Load is 5 times the Working Load Limit. The maximum individual sublink working load limit is 75% of the assembly

working load limit except for 2-1/2and 2-3/4, which are 100% of assembly working load limit. Applications with wire

rope and synthetic sling generally require a design factor of 5. ** Proof Test Load equals or exceeds the requirement of ASTM

A952(8.1) and ASME B30.9.

For use with chain slings, refer to page 216 for sling ratings and page 214 for proper master link selection.

Size

146

Copyright 2011 The Crosby Group LLC

All Rights Reserved

Crosby Bolt Type Shackles

G-2130 / S-2130

G-2130 Bolt Type Anchor

shackles with thin head bolt nut with cotter pin. Meets the

performance requirements of

Federal Specification RR-C-271F

Type IVA, Grade A, Class 3, except

for those provisions required of

the contractor. For additional

information, see page 450.

G-2130 / S-2130

G-2150 / S-2150

Capacities 1/3 thru 150 metric tons, grade 6.

Working Load Limit and grade 6 permanently shown on every shackle.

Forged Quenched and Tempered, with alloy pins.

Hot Dip galvanized or Self Colored. (85, 120, and 150-metric ton shackles

are all hot dip galvanized bows and the bolts are Dimetcoted and painted red)

Fatigue rated (1/3t - 55t).

Shackles 25t and larger are RFID EQUIPPED.

Approved for use at -40 degree C (-40 degree F) to 204 degree C (400 degree F).

2t through 25t bow and bolt are Certified to meet charpy impact testing of 42

joules (31 ft-Ibs.) min. ave. at -20 degree C (-4 degree F)

Meets or exceeds all requirements of ASME B30.26.

Sizes 1/2t-25t meet the performance requirements of EN13889:2003.

Shackles 55 metric tons and smaller can be furnished proof tested with certificates to

designated standards, such as ABS, DNV, Lloyds, or other certification when requested

at time of order.

Shackles 120 metric tons and larger are proof tested, Magnetic Particle Inspected and

provided with Serialized Pin and Bow.

Type Approval and certification in accordance with ABS 2006 Steel Vessel Rules 1-117.7, and ABS Guide for Certification of Cranes.

3.1 Certification as standard available for charpy and statistical proof test for pg 73 only

up to 25 tons to DNV2.7-1 and EN13889.

Crosby 2t through 25t G2130 anchor shackles are type approved to DNV Certification

Notes 2.7-1- Offshore Containers. These Crosby shackles are statistical proof and impact

tested. The tests are conducted by Crosby and 3.1 test certification is available upon

request. Refer to page 76 for Crosby COLD TUFF shackles that meet the additional

requirements of DNV rules for certification of lifting applications - Loose Gear.

All other 2130 and all 2150 shackles can meet charpy requirements of 42 joules

(31 ft-Lbs) avg at -20 degree C (-4 degree F) upon special request.

Look for the Red Pin . . . the mark of genuine Crosby quality.

Nominal

Size

(in.)

3/16

1/4

5/16

3/8

7/16

1/2

5/8

3/4

7/8

1

1-1/8

1-1/4

1-3/8

1-1/2

1-3/4

2

2-1/2

3

3-1/2

4

Working

Load

Limit

(t)*

1/3

1/2

3/4

1

1-1/2

2

3-1/4

4-3/4

6-1/2

8-1/2

9-1/2

12

13-1/2

17

25

35

55

85

120

150

Stock

No.

G-2130

1019464

1019466

1019468

1019470

1019471

1019472

1019490

1019515

1019533

1019551

1019579

1019597

1019613

1019613

1019659

1019677

1019695

1019711

1019739

1019757

S-2130

1019481

1019506

1019524

1019542

1019560

1019588

1019604

1019622

1019622

1019668

1019686

1019702

Weight

Each

(kg)

.03

.05

.10

.15

.22

.36

.62

1.23

1.79

2.28

3.75

5.31

7.18

8.62

15.4

23.7

44.6

70

120

153

BOLT TYPE

CHAIN

SHACKLES

G-2150 / S-2150

G-2150 Bolt Type Chain shackles.

Thin hex head bolt - nut with

cotter pin. Meets the performance

requirements of Federal

Specification RR-C-271F Type

IVB, Grade A, Class 3, except

for those provisions required of

the contractors. For additional

information, see page 450.

Dimensions

(mm)

A

9.65

11.9

13.5

16.8

19.1

20.6

26.9

31.8

36.6

42.9

46.0

51.5

57.0

60.5

73.0

82.5

105

127

133

140

B

6.35

7.85

9.65

11.2

12.7

16.0

19.1

22.4

25.4

28.7

31.8

35.1

38.1

41.4

51.0

57.0

70.0

82.5

95.5

108

C

22.4

28.7

31.0

36.6

42.9

47.8

60.5

71.5

84.0

95.5

108

119

133

146

178

197

267

330

372

368

D

4.85

6.35

7.85

9.65

11.2

12.7

16.0

19.1

22.4

25.4

28.7

31.8

35.1

38.1

44.5

51.0

66.5

76.0

92.0

104

E

15.2

19.8

21.3

26.2

29.5

33.3

42.9

51.0

58.0

68.5

74.0

82.5

92.0

98.5

127

146

184

200

229

254

F

14.2

15.5

19.1

23.1

26.9

30.2

38.1

46.0

53.0

60.5

68.5

76.0

84.0

92.0

106

122

145

165

203

229

Tolerance

+/H

37.3

46.7

53.0

63.0

74.0

83.5

106

126

148

167

190

210

233

254

313

348

453

546

626

653

L

24.9

32.5

37.3

45.2

51.5

58.5

74.5

89.0

102

119

131

146

162

175

225

253

327

365

419

468

N

4.85

6.35

7.85

9.65

11.2

12.7

17.5

20.6

24.6

26.9

31.8

35.1

38.1

41.1

57.0

61.0

79.5

92.0

105

116

C

1.50

1.50

3.30

3.30

3.30

3.30

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

6.35

A

1.50

1.50

1.50

1.50

1.50

1.50

1.50

1.50

1.50

1.50

1.50

1.50

3.30

3.30

3.30

3.30

6.35

6.35

6.35

6.35

Working

Stock

Dimensions

Tolerance

Nominal Load

No.

Weight

(mm)

+/Size

Limit

Each

(in.)

(t)*

G-2150 S-2150

(kg)

A

B

D

F

G

K

M

P

R

G

A

1/4

1/2

1019768

.06

11.9

7.85

6.35 15.5

19.1 40.4 24.6 39.6 6.35

1.50

1.50

5/16

3/4

1019770

.10

13.5 9.65

7.85

19.1 25.4 48.5 29.5 46.2

7.85

1.50

1.50

3/8

1

1019772

.15

16.8

11.2

9.65 23.1

31.0

58.5 35.8 55.0 9.65 3.30

1.50

7/16

1-1/2

1019774

.22

19.1

12.7

11.2

26.9 36.1

67.5

41.1

63.5

11.2

3.30

1.50

1/2

2

1019775 1019784

.34

20.6 16.0

12.7 30.2

41.4

77.0

46.0

71.0

12.7 3.30

1.50

5/8

3-1/4

1019793 1019800

.67

26.9 19.1

16.0 38.1

51.0

95.5 58.5 89.5 16.0 3.30

1.50

3/4

4-3/4

1019819 1019828

1.14

31.8

22.4 19.1 46.0 60.5

115

70.0

103

20.6 6.35

1.50

7/8

6-1/2

1019837 1019846

1.74

36.6 25.4 22.4 53.0

71.5

135

81.0

120

24.6 6.35

1.50

1

8-1/2

1019855 1019864

2.52

42.9 28.7 25.4 60.5

81.0

151

93.5

135

25.4 6.35

1.50

1-1/8

9-1/2

1019873 1019882

3.45

46.0

31.8

28.7 68.5

91.0

172

103

150

31.8

6.35

1.50

1-1/4

12

1019891 1019908

4.90

51.5

35.1

31.8

76.0

100

191

115

165

35.1 6.35

1.50

1-3/8

13-1/2 1019917 1019926

6.24

57.0

38.1 35.1 84.0

111

210

127

183

38.1 6.35 3.30

1-1/2

17

1019935 1019944

8.39

60.5

41.4

38.1 92.0

122

230

137

196

41.1

6.35 3.30

1-3/4

25

1019953 1019962

14.2

73.0

51.0

44.5

106

146

279

162

230

54.0 6.35 3.30

2

35

1019971 1019980

21.2

82.5

57.0

51.0

122

172

312

184

264

60.0 6.35 3.30

2-1/2

55

1019999 1020004

38.6

105

70.0 66.5

145

203

377

238

344

66.5 6.35 6.35

3

85

1020013

56

127

82.5 76.0

165

216

429

279

419

89.0 6.35 6.35

* NOTE: Maximum Proof Load is 2.0 times the Working Load Limit. Minimum Ultimate Strength is 6 times the Working Load

Limit. For Working Load Limit reduction due to side loading applications, see page 80.

Individually Proof Tested with certification.

Furnished in Anchor style only and furnished with Round Head Bolts with welded handles.

Copyright 2011 The Crosby Group LLC

All Rights Reserved

Shackles

BOLT TYPE

ANCHOR

SHACKLES

73

S-ar putea să vă placă și

- Kukmc 0376 UsDocument12 paginiKukmc 0376 Usaiyubi2Încă nu există evaluări

- Fifthwheel - JOST JSK 38CDocument2 paginiFifthwheel - JOST JSK 38Caiyubi2100% (2)

- Kukmc 0378 UsDocument2 paginiKukmc 0378 Usaiyubi2Încă nu există evaluări

- Kukmc 0377 UsDocument2 paginiKukmc 0377 Usaiyubi2Încă nu există evaluări

- C-Line - Front & Back CoversDocument4 paginiC-Line - Front & Back Coversaiyubi2Încă nu există evaluări

- 200 60 IndustrialDocument8 pagini200 60 Industrialaiyubi2Încă nu există evaluări

- Kukmc 0328 UsDocument8 paginiKukmc 0328 Usaiyubi2Încă nu există evaluări

- Kukmc 0375 UsDocument4 paginiKukmc 0375 Usaiyubi2Încă nu există evaluări

- Kukmc 0328 UsDocument8 paginiKukmc 0328 Usaiyubi2Încă nu există evaluări

- MS100-00 (M-MA Series Meter Specs)Document6 paginiMS100-00 (M-MA Series Meter Specs)aiyubi2Încă nu există evaluări

- 400-20 (Meter Manual)Document28 pagini400-20 (Meter Manual)edwinramonÎncă nu există evaluări

- Coel Catalogue 2006 1Document58 paginiCoel Catalogue 2006 1Danilo MontesanoÎncă nu există evaluări

- Kukmc 0258 UsDocument2 paginiKukmc 0258 Usaiyubi2Încă nu există evaluări

- Hose Clamps and Ferrules for Assembly of Different FittingsDocument6 paginiHose Clamps and Ferrules for Assembly of Different Fittingsaiyubi2Încă nu există evaluări

- Repair Manual JSK 38Document38 paginiRepair Manual JSK 38aiyubi2Încă nu există evaluări

- Heavy duty fifth wheel couplings JSK 38 C-1-2Document2 paginiHeavy duty fifth wheel couplings JSK 38 C-1-2aiyubi2Încă nu există evaluări

- Wire Rope ThimblesDocument1 paginăWire Rope Thimblesaiyubi2Încă nu există evaluări

- DRIV-LOK Press Fit FastenersDocument28 paginiDRIV-LOK Press Fit Fastenersaiyubi2Încă nu există evaluări

- Blind FastenersDocument7 paginiBlind Fastenersaiyubi2Încă nu există evaluări

- Crosby G-2130Document1 paginăCrosby G-2130AekJayÎncă nu există evaluări

- DODGE Torque-Arm Speed Reducer Feature BenefitDocument4 paginiDODGE Torque-Arm Speed Reducer Feature Benefitaiyubi2Încă nu există evaluări

- Acf Fastener HandbookDocument84 paginiAcf Fastener Handbookninjanear2012100% (2)

- Crosby Mckissick Sheaves CatalogDocument29 paginiCrosby Mckissick Sheaves Catalogaiyubi2Încă nu există evaluări

- CROSBY Master Link & Shackles - MetricDocument2 paginiCROSBY Master Link & Shackles - Metricaiyubi2Încă nu există evaluări

- A-344, A-347 Master LinkDocument1 paginăA-344, A-347 Master LinkAekJayÎncă nu există evaluări

- A-344 & A347 Welded Master Link - ImperialDocument1 paginăA-344 & A347 Welded Master Link - Imperialaiyubi2Încă nu există evaluări

- Tranz Couplings CatalogDocument4 paginiTranz Couplings Catalogaiyubi2Încă nu există evaluări

- Universal JointsDocument10 paginiUniversal JointsshashanksekharÎncă nu există evaluări

- APEX U-Joint CatalogDocument28 paginiAPEX U-Joint Catalogaiyubi2Încă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)