Documente Academic

Documente Profesional

Documente Cultură

Storage Tank Calculation

Încărcat de

Paijo TejoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Storage Tank Calculation

Încărcat de

Paijo TejoDrepturi de autor:

Formate disponibile

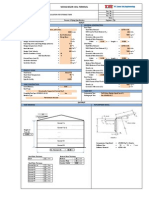

GENERAL DATA MATERIAL CONSTRUCTION

Design Code and Specification = Roof Plate

Roof Plate Material = ASTM A-36

Tank Nominal Capacity (V

nom

) = kLiter SMYS roof of Tank Material (F

yr

) = MPa

Location = East Kalimantan Density (U) = kg/m

3

Site = Miang Besar Corrosion Allowance (CA) = mm

Design Pressure at top of tank = kPa Standard Plate Dimension =

Design Vacuum at top of tank = kPa Widht = m x Lenght = m

Operating ratio (operating/design pressure) = Shell Plate

Design temperature of tank = C Shell Plate Material = ASTM A-36

Roof Life Load = kg/m

2

SMYS Shell of Tank Material (F

ys

) = MPa

Design Wind Velocity = km/h Density (U) = kg/m

3

Seismic Condition, Group = III Corrosion Allowance (CA) = mm

Site Classification = D Standard Plate Dimension =

Grounf Snow Load (S) = kg/m

2

Widht = m x Lenght = m

Insulation thickness = mm Bottom Plate

Insulation Density = kg/m

3

Bottom Plate Material = ASTM A-36

SMYS Bottom of Tank Material (F

yb

) = MPa

Density (U) = kg/m

3

PRODUCT STORE Corrosion Allowance (CA) = mm

Fluid Name = Standard Plate Dimension =

Flash Point Temperature = C Widht = m x Lenght = m

Fluid Class = Roof Frame

Specific Grafity = Frame Material = ASTM A-36

SMYS Frame of Roof Tank Material (F

yt

) = MPa

TANK CONSTRUCTION Density (U) = kg/m

3

Joint Efficiency = Corrosion Allowance (CA) = mm

Roof Type =

TANK TEST

Frangible Roof per API-650 5.10.2.6 = Hydrostatic Test : Full Water (Design Liquid Level 1)

Bottom Type = Radiograpic Test : Per API 650 A5.3

TANK DRAWING

Roof Plate Thickness

Roof : mm

1

Shell Plate Thickness

Course # n Course Qty (n) : Nos

Course #1 : mm

Course # (n-1) Course #2 : mm

Course #3 : mm

Height of Tank (H) ....... Course #4 : mm

m Course #5 : mm

....... Course #6 : mm

Course #7 : mm

Course #2

Coursel #1

Dia. Nominal (D) = m Bottom Plate Thickness

Bottom : mm

Annular Plate : mm

Annular Width : mm

Rev. No. :

Date :

Process & Piping Specification

MIANG BESAR COAL TERMINAL

CALCULATION FOR STORAGE TANK

Reference spec.: Tjo Engineer :

Doc. No. :

Job. No. :

INPUT

API 650, 11th edition, add 1 Nov.

Structurally Supported Conical Roof

7865

18.29

Yes

0

190

OUTPUT

12.60

7

250

7865

0

Diesel Oil

55

II

0.835

0.85

0

0

1

250

250

2

250

7865

Flat bottom non-Annular

6

6

6

7

7

8

9

1.828 6.096

12

3000

1

0

0.4

10

100

800

1.828 6.096

1.828 6.096

7865

2.5

9

6

9

Rev. No. :

Date :

Process & Piping Specification

MIANG BESAR COAL TERMINAL

CALCULATION FOR STORAGE TANK

Reference spec.: Tjo Engineer :

Doc. No. :

Job. No. :

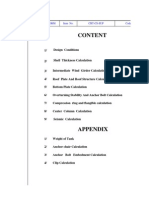

TANK DRAWING

SHELL RING #3 RING #2 RING #1 CENTER

RAFTER SUMMARY

RAFTER SUMMARY

GIRDER SUMMARY

TOP STIFFENER DETAIL

COLUMN SUMMARY

Compression Ring Detail = API-650 Fig F-2, Detail a

Stiffener Size = 70 x 70 x 7 mm

Stiffener Material = ASTM A-36

TOTAL 590.60

Ring Name

Ring Radius

Number of Girder Number of Rafter

m

#1 2.29 8 8

#2 4.57 16 16

#3

296.14 C 100x50x5 3 RING #3 6.920 16 2.67

97.03

2 RING #2 6.920 16 1.78 197.43

C 75x40x5

C 75x40x5

1 RING #1 6.920 8 1.75

TOTAL 993.73

No. Description

Weight /

Lenght

Quantity Lenght Weight

kg/m Nos m kg

Type of Girder

298.05

4 Shell 6.920 32 1794.63 397.40

C 75x40x5

C 75x40x5

3 #3 6.920 32 1345.98

99.57

2 #2 6.920 16 1794.63 198.70

C 75x40x5

C 75x40x5

1 #1 6.920 8 1798.56

8799.81

TOTAL 18370.53

No. Description

Weight /

Lenght

Quantity Lenght Weight

kg/m Nos m kg

Type of Rafter

Type of Column

200mm 40sch 40 Pipe

200mm 40sch 40 Pipe

CENTER 43.00 1 13.36 200mm 40sch 40 Pipe

3 200mm 40sch 40 Pipe

2 RING #2 43.00 8 12.98

1 RING #1 43.00 8

RING #3

574.55

Shell 9.14 0 32

13.17 4530.77

4465.41

No. Description

Weight /

Lenght

Quantity Lenght Weight

kg/m Nos mm kg

43.00 16 12.79

6.86 16 32

GIRDER

RAFTER

COLUMN

RAFTER

BRACING

D

A

T

A

D

R

A

W

I

N

G

R

E

S

U

L

T

T

a

n

k

N

o

m

i

n

a

l

C

a

p

a

c

i

t

y

(

V

n

o

m

)

=

k

L

i

t

e

r

M

i

n

i

m

u

m

O

p

e

r

a

t

i

n

g

V

o

l

u

m

e

(

V

m

i

n

)

=

m

3

S

h

e

l

l

P

l

a

t

e

O

v

e

r

f

i

l

l

P

r

o

t

e

c

t

i

o

n

L

e

v

e

l

R

e

q

u

i

r

e

m

e

n

t

(

V

o

f

f

)

=

m

3

S

t

a

n

d

a

r

d

P

l

a

t

e

D

i

m

e

n

s

i

o

n

=

T

a

n

k

N

o

m

i

n

a

l

C

a

p

a

c

i

t

y

(

V

n

o

m

)

=

m

3

W

i

d

h

t

=

m

x

L

e

n

g

h

t

=

m

M

a

x

i

m

u

m

C

a

p

a

c

i

t

y

(

V

m

a

x

=

V

m

in

+

V

o

f

f

+

V

n

o

m

)

=

m

3

S

E

L

E

C

T

I

O

N

T

A

N

K

C

A

P

A

C

I

T

Y

C

O

N

C

L

U

T

I

O

N

T

A

N

K

D

I

M

E

N

S

I

O

N

S

E

L

E

C

T

I

O

N

V

m

a

x

V

t

a

n

k

S

e

l

e

c

t

e

d

T

a

n

k

C

a

p

a

c

i

t

y

(

V

t

a

n

k

)

=

k

L

i

t

e

r

S

e

l

e

c

t

e

d

N

o

m

i

n

a

l

T

a

n

k

D

i

a

m

e

t

e

r

(

D

)

=

m

M

a

x

i

m

u

m

F

l

u

i

d

H

i

g

h

t

f

o

r

o

p

e

r

a

t

i

o

n

(

H

m

a

x

)

=

m

S

e

l

e

c

t

e

d

C

o

u

r

s

e

Q

u

a

n

t

i

t

y

(

n

)

=

N

o

s

S

e

l

e

c

t

e

d

H

i

g

h

t

o

f

T

a

n

k

(

H

)

=

m

M

i

n

i

m

u

m

L

i

q

u

i

d

L

e

v

e

l

=

m

D

i

f

f

e

r

e

n

c

e

L

e

v

e

l

b

e

t

w

e

e

n

N

o

r

m

a

l

F

i

l

l

i

n

g

t

o

=

m

D

e

s

i

g

n

L

e

v

e

l

E

n

g

i

n

e

e

r

:

T

j

o

P

r

o

c

e

s

s

&

P

i

p

i

n

g

S

p

e

c

i

f

i

c

a

t

i

o

n

I

N

P

U

T

O

U

T

P

U

T

3

7

.

0

7

2

5

3

8

5

1

7

1

2

.

6

0

0

.

3

3

0

0

0

1

0

5

.

0

7

7

8

.

8

0

3

0

0

0

6

.

0

9

6

M

I

A

N

G

B

E

S

A

R

C

O

A

L

T

E

R

M

I

N

A

L

C

A

L

C

U

L

A

T

I

O

N

F

O

R

S

T

O

R

A

G

E

T

A

N

K

R

e

f

e

r

e

n

c

e

s

p

e

c

.

:

D

o

c

.

N

o

.

:

J

o

b

.

N

o

.

:

R

e

v

.

N

o

.

:

D

a

t

e

:

1

.

8

2

8

3

2

0

6

1

8

.

3

6

4

7

6

-

-

-

-

0

.

4

4

m

m

m

m

A

P

I

S

t

a

n

d

a

r

d

6

5

0

,

T

a

b

l

e

A

-

1

a

(

S

I

)

T

y

p

i

c

a

l

s

i

z

e

a

n

d

c

o

r

r

e

s

p

o

n

d

i

n

g

N

o

r

m

a

l

c

a

p

a

c

i

t

y

(

m

3

)

f

o

r

t

a

n

k

w

i

t

h

1

8

0

0

-

m

m

c

o

u

r

s

e

s

1

6

.

2

1

8

m

m

3

m

m

m

m

3

1

8

3

.

8

7

,

t

h

u

s

s

e

l

e

c

t

e

d

d

i

a

m

e

t

e

r

a

n

d

h

i

g

h

t

o

f

t

a

n

k

i

s

a

c

c

e

p

t

a

b

l

e

7

.

5

4

4

.

2

1

5

9

2

3

9

3

1

8

-

-

6

1

8

.

3

1

0

2

1

5

3

2

0

4

2

5

4

3

0

5

4

.

5

1

5

.

9

5

7

8

6

1

1

5

1

4

3

1

7

2

-

-

3

9

8

4

7

7

5

5

7

6

3

6

7

1

6

7

9

5

3

5

6

4

0

7

-

-

1

2

1

1

3

4

0

7

6

1

1

8

1

4

1

0

3

1

1

1

4

5

1

0

.

5

8

6

.

6

3

1

2

4

6

8

6

2

3

7

7

9

9

3

5

9

6

3

.

6

2

2

9

3

4

4

4

5

8

5

7

3

6

8

7

8

0

2

9

1

6

1

0

1

8

1

2

2

1

1

4

2

5

1

6

2

9

1

8

3

2

2

0

3

6

1

0

9

1

1

2

4

7

1

4

0

3

1

5

5

9

1

8

.

2

8

8

2

5

4

9

1

6

1

3

7

4

1

8

3

2

2

3

1

9

2

5

7

6

1

5

1

7

7

6

3

6

9

5

4

1

2

7

2

1

5

9

0

1

9

0

9

1

3

.

5

1

4

3

5

1

5

7

7

3

1

0

3

1

1

2

8

8

1

5

4

6

1

8

0

4

2

0

6

1

2

2

9

0

2

7

4

8

3

2

0

6

3

6

6

4

4

1

2

2

4

5

8

0

2

2

2

7

2

5

4

5

2

8

6

3

3

1

8

1

5

0

8

9

D

=

1

8

2

4

4

5

2

1

6

2

9

2

4

4

3

3

2

5

7

4

0

7

2

4

8

8

6

2

1

3

4

6

1

2

4

7

1

8

7

0

2

4

9

4

3

1

1

7

3

7

4

1

4

3

6

4

4

9

8

8

6

6

9

0

D

=

2

2

-

5

7

0

0

5

4

7

4

D

=

2

0

-

2

7

5

7

3

2

0

6

1

3

0

9

2

4

1

2

2

-

-

3

6

1

0

1

8

3

6

6

4

5

4

9

7

7

3

2

9

9

1

6

1

D

=

3

0

3

0

7

0

7

2

5

4

5

3

8

1

7

5

0

8

9

6

3

6

2

7

6

3

4

D

=

2

6

-

-

-

-

-

-

-

4

2

1

3

8

5

4

9

8

8

7

4

8

1

9

9

7

5

-

-

-

-

5

4

2

2

9

0

8

2

4

5

1

2

3

6

7

D

=

4

6

-

-

4

8

1

8

1

0

6

5

1

4

9

7

7

2

1

1

9

6

6

-

-

-

-

3

.

6

5

.

4

7

.

2

9

1

0

.

8

1

2

.

6

1

4

.

4

6

6

3

4

2

1

1

2

3

1

6

1

6

3

0

3

-

-

-

-

-

-

-

D

=

3

6

-

-

-

5

1

5

3

6

1

8

4

T

a

n

k

H

e

i

g

h

t

(

m

)

/

N

u

m

b

e

r

o

f

C

o

u

r

s

e

i

n

c

o

m

p

l

e

t

e

d

t

a

n

k

R

e

m

a

r

k

6

0

2

8

2

8

1

0

1

7

8

1

5

2

6

8

-

-

-

5

6

7

8

9

1

0

C

a

p

a

c

i

t

y

p

e

r

m

o

f

h

e

i

g

h

t

T

a

n

k

D

i

a

m

e

t

e

r

2

3

m

-

-

-

-

-

-

A

P

I

S

t

a

n

d

a

r

d

6

5

0

,

T

a

b

l

e

A

-

1

b

(

U

C

S

)

T

y

p

i

c

a

l

s

i

z

e

a

n

d

c

o

r

r

e

s

p

o

n

d

i

n

g

N

o

r

m

a

l

c

a

p

a

c

i

t

y

(

b

a

r

r

e

l

s

)

f

o

r

t

a

n

k

w

i

t

h

7

2

-

i

n

c

o

u

r

s

e

s

T

a

n

k

D

i

a

m

e

t

e

r

C

a

p

a

c

i

t

y

p

e

r

f

t

o

f

h

e

i

g

h

t

T

a

n

k

H

e

i

g

h

t

(

m

)

/

N

u

m

b

e

r

o

f

C

o

u

r

s

e

i

n

c

o

m

p

l

e

t

e

d

t

a

n

k

R

e

m

a

r

k

1

2

1

8

2

4

3

0

3

6

4

2

4

8

5

4

6

0

2

3

4

5

6

7

8

9

1

0

f

t

b

a

r

r

e

l

s

f

t

f

t

f

t

f

t

f

t

f

t

f

t

f

t

f

t

1

0

1

4

1

7

0

2

5

0

3

3

5

1

5

3

1

.

5

3

8

0

5

6

5

7

5

5

9

4

5

1

1

3

0

-

-

4

2

0

5

0

5

-

-

-

-

-

-

2

0

5

6

6

7

0

1

0

1

0

1

3

4

0

1

6

8

0

2

0

1

0

2

3

5

0

2

6

9

0

-

-

2

5

8

7

.

4

1

0

5

0

1

5

7

0

2

1

0

0

3

0

1

2

6

1

5

1

0

2

2

7

0

3

0

2

0

3

7

8

0

4

5

3

0

5

2

9

0

6

0

4

0

2

6

2

0

3

1

5

0

3

6

7

0

4

2

0

0

4

7

2

0

5

2

5

0

6

8

0

0

7

5

5

0

9

2

5

0

1

0

2

8

0

4

0

2

2

4

2

6

9

0

4

0

3

0

5

3

7

0

6

7

1

0

8

0

6

0

9

4

0

0

1

0

7

4

0

1

2

1

0

0

1

3

4

3

0

3

5

1

7

1

2

0

6

0

3

0

8

0

4

1

1

0

5

1

4

0

6

1

7

0

7

2

0

0

8

2

3

0

1

5

3

0

0

1

7

0

0

0

5

0

3

5

0

4

2

0

0

6

3

0

0

8

4

0

0

1

0

5

0

0

1

2

6

0

0

1

4

7

0

0

1

6

8

0

0

1

8

9

0

0

2

1

0

0

0

4

5

2

8

3

3

4

0

0

5

1

0

0

6

8

0

0

8

5

0

0

1

0

2

0

0

1

1

9

0

0

1

3

6

0

0

6

0

5

0

4

6

0

4

0

9

0

6

0

1

2

1

0

0

7

0

6

8

5

8

2

3

0

1

2

3

4

0

1

6

4

5

0

2

0

5

8

0

2

4

7

0

0

2

8

8

0

0

3

2

9

3

0

1

5

1

1

0

1

8

1

3

0

2

1

1

5

0

2

4

1

9

0

3

7

2

2

0

2

8

2

6

0

3

0

9

7

0

D

=

5

8

D

=

6

4

-

9

0

1

1

3

3

1

3

6

0

0

2

0

4

0

0

2

7

7

2

0

3

4

0

3

0

4

0

8

2

0

4

0

5

1

0

D

=

7

3

-

8

0

8

9

5

1

0

7

4

0

1

6

1

2

0

2

1

5

0

0

2

6

8

8

0

3

2

2

6

0

3

7

6

0

0

3

5

8

1

0

-

-

1

2

0

2

0

1

4

2

4

1

9

0

3

6

2

9

0

4

8

3

8

0

5

8

4

8

0

D

=

9

8

-

-

-

-

1

0

0

1

3

9

9

1

6

8

0

0

2

5

2

0

0

3

3

6

0

0

4

2

0

0

0

4

8

4

0

0

D

=

8

3

-

1

4

0

2

7

4

2

3

2

9

3

0

4

9

3

5

0

6

5

8

6

0

1

6

0

3

5

8

1

4

3

0

0

0

6

4

5

1

0

7

4

6

0

0

-

-

-

-

D

=

1

1

8

-

-

-

-

-

-

-

2

0

0

5

5

9

5

6

7

2

0

0

1

0

0

8

0

0

-

-

-

1

8

0

4

5

3

2

5

4

4

3

0

8

1

6

5

0

D

=

1

4

9

-

-

-

-

D

=

6

2

D

=

2

0

2

1

2

.

1

2

2

2

0

6

7

7

0

8

1

3

1

0

1

0

2

8

3

0

-

-

-

-

-

-

-

-

-

-

-

-

-

ROOF DATA TOP STIFFENER

Roof Plate Material = ASTM A-36 Stiffener Material = ASTM A-36

SMYS Roof of Tank Material (F

yr

) = MPa SMYS Stiffener Material (F) = Mpa

Allowable Design Strees (F) = MPa Compression Ring Detail = API-650 Fig F-2, Detail a

Density (U) = kg/m

3

Lenght of Angle Leg Parallel to the shell = mm

Roof Corrosion Allowance (CA) = mm Distance from top of shell to angle = mm

Design Pressure at Top of Tank (P

i

) = kPa Comp. Ring Joint Efficiency =

Design Vacuum at Top of Tank = kPa Stiffener Size = x x 7

Operating ratio (Oerating/Design Pressure) = Stiffener Area = mm

2

Live Load (Lr) = kg/m

2

Modulus of Section = mm3

Ground Snow Load (S) = kg/m

2

Additional Dead Load = kg/m

2

Roof Insulation thickness = mm

Roof Insulation Density = kg/m

3

Nominal Tank Diameter (D) = m

ROOF CONSTRUCTION

Roof type of tank =

Slope Roof = 1 / 12 or

Roof Plate Weld Type = Lap-Welded

Selected Roof Thickness = mm

DESIGN THICKNESS OF ROOF DESIGN THICKNESS OF ROOF (CONT'd)

(Ref. Paragraph 5.10.4.1, API 650-Supported Cone Roof) ACTUAL PARTICIPATING AREA OF ROOF TO SHELL JUNCTURE

Supporting cone roofs shall conform to the following requirements : Nominal Roof Thickness (t

r

= t-CA) = mm

9.5 q 37 degree ( slope ) Nominal Shell Thickness (t

s

= t-CA) = mm

( Slope of the cone elements to the horizontal shall be m per m)

Plate Weight , assumsing 1/2" roof plate = kg/m

2

Added Dead Load = kg/m

2

R

c = = m

Minimum Roof Live Load (L

r

) = kg/m

2

From API-650 Figure F-2

Specific Snow Load (S) = kg/m

2

W

c = 0.6 (R

c

t

s

)

0.5

= mm

Specified external pressure (P

e

) = kPa From API-650 Figure F-2

= kg/m

2

W

h = MIN (0.3(R

2

t

r

)

0.5

, 300)

Dead Load (D

L

) = Insulation + Plate Weight + Added Dead Load = MIN ( , 300)

= x + + = mm

= kg/m

2

Unstiffenesed length of angle bar (L

e

)

ROOF LOAD PER API-650 APPENDIX R L

e = 250t/Fy

0.5

= mm

Load combination (L

1

) Effective Stiffener Area (A

a

) = Stiffener area - unstiffened area

L

1 = DL + MAX (S,Lr)+0.4*Pe = - 0

= + + = mm

2

= kg/m

2

Contributing Area due to shell plate

Load combination (L

2

) A

shell = W

c

* t

s = x 4 = mm

2

L

2 = DL + Pe +0.4*MAX (S,Lr) Contributing Area due to Roof plate

= + + MAX (0,100) A

roof = W

h

* t

r = x 5 = mm

2

= kg/m

2

Actual part. Area of roof to shell juncture (per API 650) (A)

Balance roof design Load (T) A = A

a

+ A

shell

+ A

roof

T = MAX (L

1

,L

2

) = + +

= MAX (259.13,260.35) = mm

2

= kg/m

2

SUMMERY OF ROOF WEIGHT

= kPa

DESIGN THICKNESS AT DESIGN CONDITION FOR SELF-SUPPORTED CONE ROOF

Minimum Slope Roof for Self-Supported Cone roof = or q

4.8 x sin T x 2.2

4.8 x sin x 2.2 Weight of New Roof plates

= mm W

rnt = density x t x PI/4 x (D-t

shell

)^2 / cos T

Nominal roof thickness base on API 5.10.5.1 = x x PI/4 x ( - ) /cos

Minimum roof thickness (t

rmin

) = mm ( exclude CA) = kg

Maximum roof thickness (t

rmax

) = mm ( include CA) Weight of Corroded Roof plates

Self-Supported roof type evaluation W

rct = density x t x PI/4 x (D-t

shell

)^2 / cos T

Because t

r t

rmin & t

r

+ CA > t

rmax = x x PI/4 x ( - ) /cos

= kg

7865 0.006

6 5 12431.90 10359.92

4.76

10359.9

12431.9

7865 0.005 18.29 0.005

Corroded New

Weight

kg kg mm

t Calculated

inc. CA

mm

Description No.

t Selected

exc. CA exc. CA inc. CA

mm mm

18.29 0.005 4.76

931.0 459

1 Roof 6 5

1113

2503.0

222.6 1113

110.68

931.00

931.00

114.7

931

70 70

5

4

114.7

8430

= 110.1 m

D/2 9.14

=

9.144

Sin 4.76

459

=

D/2

Sin T

222.6

222.60

24.96

2.55

5

12.5

, thus self- supported cone roof can not be constructed

=

260.35

260.35

1/6 9.46

D x T

= Nominal roof thickness (t

r

)

102 0.4*

259.13

118.3 102.04 0.4*

Reference spec.: Process & Piping Specification Engineer : Tjo

INPUT

250

160

1

7865

MIANG BESAR COAL TERMINAL

CALCULATION FOR STORAGE TANK

Doc. No. :

Job. No. :

Rev. No. :

Date :

1

0

0.4

250

0.85

20

118.313

118.3 MAX (0,100)

100

0

1

102.04

98.3

20

0 0 98.3

R

2

100

0

20

0

0

1/6 3/4

Structurally Supported Conical Roof

4.76

OUTPUT

6

18.29

x 18.29 2.55

9.46

Reference spec.: Process & Piping Specification Engineer : Tjo

MIANG BESAR COAL TERMINAL

CALCULATION FOR STORAGE TANK

Doc. No. :

Job. No. :

Rev. No. :

Date :

EVALUATION OF ROOF TO THE SHELL JOINT WITH APPENDIX F

Design Internal Pressure (P

i

) = kPa = kg/m

2

Roof plate Weight (corroded) (W

rct

) = kg

Roof Structure Weight (W

f

) = kg

Shell Weight (corroded )(W

sct

) = kg

UPLIFT FOR DESIGN PRESSURE (Fu)

Fu = P

i

x PI x D

2

/4 = x PI x

2

/4 = kg

EVALUASION 1 (UPLIFT CASE PER API 650 1.1.1)

Total Weight Resisting uplift

Fr = W

rct = kg

Because Fu > Fr ,then see evaluation 2 result

EVALUASION 2 (UPLIFT CASE PER API 650 F.1.2)

Total Weight Resisting uplift

Fr = W

rct

+ W

f

+W

sct = + +

=

Because Fu Fr

MINIMUM PARTICIPATING AREA PER API 650 F.5.1

SMYS Roof of Tank Material (F

yr

) = MPa

SMYS Shell of Tank Material (F

ys

) = MPa

SMYS Stiffener Material (F

yf

) = MPa

F

y = MIN ( F

yr

, F

ys

, F

yf

)

= MIN ( , , )

= MPa

Minimum Participating Area per API 650 F.5.1 (A

min

)

2

( 1 /

2

)

x tan ( )

= mm

2

Actual part. Area of roof to shell juncture (per API 650) (A) Evaluation

Because A A

min

,

FRANGIBLE ROOF DESIGN PER API 650 5.10.2.6.a.5

Shell Weight (corroded )(W

sct

) = kg = N

Roof Structure Weight (W

f

) = kg = N

SMYS Shell of Tank Material (F

ys

) = MPa =

Maximum Participating area for frengible joint (A

fr

)

2*PI* * tan

Actual part. Area of roof to shell juncture (per API 650) (A) Evaluation

Because A < A

fr

315604.69

180031.21

18.29

250

Lowest Minimum specified Yield Strenght material in juction (F

y

)

250 250 250

250

A

min =

1

10359.92

18370.53

32204.56

102

102 18.29 26803.8

10359.92

10359.92 18370.5 32204.56

60935.01

Design max. internal pressure as per F.1 through F.6

250

250

A

fr =

W

sct

+ W

f

2*PI*Fy*tan T

250

32204.56

=

250 4.76

495635.90

250 4.76

200D

2

(P

i

-0.00127D

LR

/D

2

)

F

y

tan T

thus Actual part. Area of roof to shell jucture is acceptable

18370.53

1972.91

- 0.00127 x

thus Actual part. Area of roof to shell jucture is acceptable

= 3786.38 mm2

=

200 x 18.29 101527.2

GENERAL DATA GIRDER DATA

Roof Type = Girder Material = ASTM A-36

AlloAllowable Design Strees (Sd) = Mpa

Roof Plate Material = ASTM A-36 Numbers of intermediate girder ring = Nos

SMYS Roof of Tank Material (F

y

) = MPa Intermedier Girder Ring

Allowable Design Strees (S

d

) = MPa

Density (U) = kg/m

3

Roof Corrosion Allowance (CA) = mm

Design Pressure at Top of Tank (Pe) = kPa

Design Vacuum at Top of Tank = kPa

Operating ratio (Operating/Design Pressure) =

Live Load (Lr) = kg/m

2

Ground Snow Load (S) = kg/m

2

Girder Selection

Additional Dead Load = kg/m

2

Roof Insulation thickness = mm

Roof Insulation Density = kg/m

3

Nominal Tank Diameter (D) = m

Slope Roof = 1 / 12 or

RAFTER DATA COLUMN DATA

Rafter Material = ASTM A-36 Column Material = ASTM A-36

Allowable Design Strees (Sd) = Mpa Allowable Design Strees (Sd) = Mpa

Rafter Selection Modulus of Elasticity ( E ) = Gpa

Column Selection

RAFTER DESIGN

Nominal Roof Thickness = mm MAXIMUM RAFTER SPACING PER API 650 5.10.4.4

Roof Plate Weight = kg/m

2

Maximum Rafter Spacing (b)

Added Dead Load = kg/m

2

b = ( t - c ) * sqrt (1.5 * Fy / T)

Minimum Roof Live Load (L

r

) = kg/m

2

= ( 6 - 1 )* sqrt (1.5 * / )

Specific Snow Load (S) = kg/m

2

= mm

Specified external pressure (P

e

) = kPa SPACING OF RAFTERS

= kg/m

2

<FOR OUTER SHELL RING>

Dead Load (D

L

) = Insulation + Plate Weight + Added Dead Load Ring Radius ( R ) = m

= x + + b = mm since b > mm , then b = mm

= kg/m

2

Minimum numbers of Rafter (N_min)

N_min = 2*PI*R/b = 2 *PI* /

= Nos

ROOF LOAD PER API-650 APPENDIX R N_min must be a multiple of 16 , therefore N_min = Nos

Load combination (L

1

) Actual Numbers of Rafter = Nos

L

1 = DL + MAX (S,L

r

)+0.4*Pe Minimum roof thickness based on actual rafter spacing (t-calc)

= + + b = mm

= kg/m

2

t-calc = b/ SQRT (1.5*F

y

/T) + CA

Load combination (L

2

) = / SQRT(1.5 * / ) +

L

2 = DL + Pe +0.4*MAX (S,Lr) = mm

= + + MAX (0,100) Maximum Roof Load based on actual rafter spacing (Rload_Max)

= kg/m

2

RLoad_Max = 1.5*F

y

*((t-CA )/b)^2

Balance roof design Load (T) = 1.5 * *(( 6 - 1 )/ )^2

T = MAX (L

1

,L

2

) = kPA

= MAX (167.19,107.19) = kg/m

2

= kg/m

2

Let Max T

1 = RLoad_Max

= kPa Vacuum Limited by actual rafter spacing (P_ext_1)

P_ext_1 = -(MaxT1-DL-0.4*MAX(Snow_Load;Lr))

= - ( - - 0.4 * Max ( 0 , )

= kg/m

2

= kPa

Pa_rafter_4 = P_ext_1

= kg/m

2

= kPa

200

2.50E+08 1795

167.19

1.64

297.03

297.0 67.19 100

-190 -1.86

-190 -1.86

2100 2100

9.14

9140 2100

1.64

2392.03

2.50E+05

27.35

27.35

1794.63

1795 2.50E+05 1.64 1

107.19

0

20

0

160

2392

0

18.288

OUTPUT

0 0 47.2 20

100

0

0

47.2

20

43

160

67.19 0.00 0.4*

67.19

67.19 MAX (0,100) 0.4* 0.0

167.19

Shell C 75x40x5 20080 0.0292 6.92

#3 C 75x40x5 20080 0.0292 6.92

#2 C 75x40x5

Center 200mm 40sch 40 Pipe 27562 0.1095

5303.01

5303.01

#2 200mm 40sch 40 Pipe 27562 0.1095

0.00

160 Structurally Supported Conical Roof

6

9.14 0 32

4.57 16 16

6.86 16 32

#2 C 75x40x5 20080 0.0292

Ring Name Type of Girder

Z R Weight

43

#3 200mm 40sch 40 Pipe 27562 0.1095 43

20080 0.0292 6.92

m

2

#1 C 75x40x5 20080 0.0292 6.92

Ring Name Type of Rafter

Z R Weight

mm

3

Area

Area

mm

3

m kg/m m

2

4.75

32

#3 C 100x50x5 37600 0.0292 6.92

5303.01

Area

mm

3

2.91

6.92

#1 C 75x40x5 20080 0.0292 6.92

m kg/m mm

2

#1 200mm 40sch 40 Pipe 27562 0.1095 43

Ring Name Type of Column

Z R Weight

5303.01

3

#3

Shell

1

0

0.4

100

160

7865

1 8

Ring Name

#1

#2

Ring Radius

Number of Girder Number of Rafter

m

2.29 8

250

INPUT

Date :

Reference spec.: Process & Piping Specification Engineer : Tjo

MIANG BESAR COAL TERMINAL

CALCULATION FOR STORAGE TANK

Doc. No. :

Job. No. :

Rev. No. :

4.76

m kg/m

Date :

Reference spec.: Process & Piping Specification Engineer : Tjo

MIANG BESAR COAL TERMINAL

CALCULATION FOR STORAGE TANK

Doc. No. :

Job. No. :

Rev. No. :

RAFTER DESIGN (CONT'd)

SPACING OF RAFTERS (CONT'd)

< FOR GIRDER RING OUTER RADIUS = m> < FOR GIRDER RING OUTER RADIUS = m>

Numbers of Girder (N) = 16 Numbers of Girder (N) = 8

Ring Radius ( R ) = m Ring Radius ( R ) = m

b = mm since b > mm , then b = mm b = mm since b > mm , then b = mm

Minimum numbers of Rafter (N_min) Minimum numbers of Rafter (N_min)

N_min = 2*PI*R/b = 2 *PI* / N_min = 2*PI*R/b = 2 *PI* /

= Nos = Nos

N_min must be a multiple of 16 , therefore N_min = Nos N_min must be a multiple of 8 , therefore N_min = Nos

Actual Numbers of Rafter = Nos Actual Numbers of Rafter = Nos

Minimum roof thickness based on actual rafter spacing (t-calc) Minimum roof thickness based on actual rafter spacing (t-calc)

b = mm b = mm

t-calc = b/ SQRT (1.5*Fy/T) + CA t-calc = b/ SQRT (1.5*Fy/T) + CA

= /SQRT(1.5* / ) + = /SQRT(1.5* / ) +

= mm = mm

Maximum Roof Load based on actual rafter spacing (Rload_Max) Maximum Roof Load based on actual rafter spacing (Rload_Max)

RLoad_Max = 1.5*F

y

*((t-CA )/b)^2 RLoad_Max = 1.5*F

y

*((t-CA )/b)^2

= 1.5 * *(( 6 - 1 )/ )^2 = 1.5 * *(( 6 - 1 )/ )^2

= kPA = kPA

= kg/m

2

= kg/m

2

Let Max T

1 = RLoad_Max Let Max T

1 = RLoad_Max

Vacuum Limited by actual rafter spacing (P_ext_1) Vacuum Limited by actual rafter spacing (P_ext_1)

P_ext_1 = -(MaxT1-DL-0.4*MAX(Snow_Load;Lr)) P_ext_1 = -(MaxT1-DL-0.4*MAX(Snow_Load;Lr))

= - ( - - 0.4 * Max ( 0 , ) = - ( - - 0.4 * Max ( 0 , )

= kg/m

2

= kPa = kg/m

2

= kPa

Pa_rafter_3 = P_ext_1 Pa_rafter_1 = P_ext_1

= kg/m

2

= kPa = kg/m

2

= kPa

< FOR GIRDER RING OUTER RADIUS = m> TYPE OF RAFTERS

Numbers of Girder (N) = 16 < SPAN TO SHELL >

Ring Radius ( R ) = m Maximum Rafter Span = mm

b = mm since b > mm , then b = mm Average Rafter Spacing on inner Girders = mm

Minimum numbers of Rafter (N_min) Average Rafter Spacing on Shell = mm

N_min = 2*PI*R/b = 2 *PI* / Average plate Width = mm

= Nos Maximum Bending Moment (Mmax)

N_min must be a multiple of 16 , therefore N_min = Nos Mmax = W*l^2/8

Actual Numbers of Rafter = Nos Where

Minimum roof thickness based on actual rafter spacing (t-calc) w = Uniform Load from Plate + Uniform Load from Rafter

b = mm = * +

t-calc = b/ SQRT (1.5*Fy/T) + CA = N/m

= /SQRT(1.5* / ) + l = m

= mm Mmax = * ^2 /8

Maximum Roof Load based on actual rafter spacing (Rload_Max) = N.m

RLoad_Max = 1.5*F

y

*((t-CA )/b)^2 Section of Modulus Required (Z_req'd)

= 1.5 * *(( 6 - 1 )/ )^2 Z_req'd = Mmax / Allowable design stress

= kPA = /

= kg/m

2

= m

3

= mm

3

Let Max T

1 = RLoad_Max Actual Z = mm

3

,using = C 75x40x5

Vacuum Limited by actual rafter spacing (P_ext_1) Maximum stress allowed for each rafter in ring shell

P_ext_1 = -(MaxT1-DL-0.4*MAX(Snow_Load;Lr)) W_max = Z*Sd*8/l^2

= - ( - - 0.4 * Max ( 0 , ) = * * 8 / ^2

= kg/m

2

= kPa = N/ m'

Pa_rafter_2 = P_ext_1 Maximum Load Allowed for each rafter in ring shell (Max_P)

= kg/m

2

= kPa Max_P = (Wmax-Wrafter)/Average plate width

= ( - 68 ) /

= N/m2 = kPa

Vacuum limited by rafter type (P_ext_2)

Let Max_T1 = Kg/m

2

P_ext_2 = -2.5 *(MaxT1-DL-MAX(Snow_Load, Lr))

= -2.5*( - - Max ( 0 , )

= kg/m

2

= kPa

Pa2_rafter_4 = Max(P_ext_1,P_ext_2)

= kPA

2.50E+08 1346

2.50E+08 1795

2.50E+08 1799

100

-286 -2.8

281.56

281.6 67.19

-1.86

4400.70

4.40E+03 1.57

2759.26 2.759

3.6E-06 3623.05

20080

2.01E-05 1.60E+08 2.42

794.02

2.42

794.02 2.42

579.69

579.69 1.6E+08

-189 -1.85

1346

1795

2417

1570

462.5 1.57 67.82

4.76

2.90

295.73

295.7 67.19 100

-189 -1.85

2100

6.852

6.852

8

1798.56

1799 2.50E+05 1.64 1

297.03

297.0 67.19 100

-190 -1.86

-190 -1.86

6.855

4.57

4.57

3.81

5.17

528.04

528.0 67.19 100

-421 -4.12

6855 2100

20.51

1794.63

1795 2.50E+05 1.64 1

4.75

2.91

2392 2100 2100

4570 2100

13.67

13.67

16

-421 -4.12

20.51

32

1345.98

1346 2.50E+05 1.64 1

2290

6.855

2392 2100 2100

2.29

2.29

2392 2100 2100

Date :

Reference spec.: Process & Piping Specification Engineer : Tjo

MIANG BESAR COAL TERMINAL

CALCULATION FOR STORAGE TANK

Doc. No. :

Job. No. :

Rev. No. :

RAFTER DESIGN (CONT'd)

TYPE OF RAFTERS TYPE OF RAFTERS

< SPAN TO GIRDER RING OUTER RADIUS m> < SPAN TO GIRDER RING OUTER RADIUS m>

Maximum Rafter Span = mm Maximum Rafter Span = mm

Average Rafter Spacing on inner Girders = mm Average Rafter Spacing on inner Girders = mm

Average Rafter Spacing on Outter Girders = mm Average Rafter Spacing on Outter Girders = mm

Average plate Width = mm Average plate Width = mm

Maximum Bending Moment (Mmax) Maximum Bending Moment (Mmax)

Mmax = w*l^2/8 Mmax = w*l^2/8

Where Where

w = Uniform Load from Plate + Uniform Load from Rafter w = Uniform Load from Plate + Uniform Load from Rafter

= * + = * +

= N/m' = N/m'

l = m l = m

Mmax = * ^2 /8 Mmax = * ^2 /8

= N.m = N.m

Section of Modulus Required (Z_req'd) Section of Modulus Required (Z_req'd)

Z_req'd = Mmax / Allowable design stress Z_req'd = Mmax / Allowable design stress

= / = /

= m

3

= mm

3

= m

3

= mm

3

Actual Z = mm

3

,using = C 75x40x5 Actual Z = mm

3

,using = C 75x40x5

Maximum stress allowed for each rafter in ring shell Maximum stress allowed for each rafter in ring shell

w_max = Z*Sd*8/l^2 w_max = Z*Sd*8/l^2

= * * 8 / ^2 = * * 8 / ^2

= N/ m' = N/ m'

Maximum Load Allowed for each rafter in ring shell (Max_P) Maximum Load Allowed for each rafter in ring shell (Max_P)

Max_P = (wmax-wrafter)/Average plate width Max_P = (Wmax-Wrafter)/Average plate width

= ( - 68 ) / = ( - 68 ) /

= N/m2 = kPa = N/m2 = kPa

Vacuum limited by rafter type (P_ext_2) Vacuum limited by rafter type (P_ext_2)

Let Max_T1 = kg/m

2

Let Max_T1 = kg/m

2

P_ext_2 = (MaxT1-DL-0.4*MAX(Snow_Load, Lr)) P_ext_2 = (MaxT1-DL-0.4*MAX(Snow_Load, Lr))

= -( - - Max ( 0 , ) = -( - - Max ( 0 , )

= kg/m

2

= kPa = kg/m

2

= kPa

Pa2_rafter_3 = Max(P_ext_1,P_ext_2) Pa2_rafter_1 = Max(P_ext_1,P_ext_2)

= kPa = kPa

< SPAN TO GIRDER RING OUTER RADIUS m> RAFTERS WEIGHT SUMMARY

Maximum Rafter Span = mm

Average Rafter Spacing on inner Girders = mm

Average Rafter Spacing on Outter Girders = mm

Average plate Width = mm

Maximum Bending Moment (Mmax)

Mmax = w*l^2/8

Where

w = Uniform Load from Plate + Uniform Load from Rafter

= * +

= N/m'

l = m

Mmax = * ^2 /8

= N.m

Section of Modulus Required (Z_req'd)

Z_req'd = Mmax / Allowable design stress

= /

= m

3

= mm

3

Actual Z = mm

3

,using C 75x40x5

Maximum stress allowed for each rafter in ring shell

W_max = Z*Sd*8/l^2

= * * 8 / ^2

= N/ m'

Maximum Load Allowed for each rafter in ring shell (Max_P)

Max_P = (Wmax-Wrafter)/Average plate width

= ( - 68 ) /

= N/m

2

= kPa

Vacuum limited by rafter type (P_ext_2)

Let Max_T1 = kg/m

2

P_ext_2 = (MaxT1-DL-0.4*MAX(Snow_Load, Lr))

= -( - - Max ( 0 , )

= kg/m

2

= kPa

Pa2_rafter_2 = Max(P_ext_1,P_ext_2)

= kPa

TOTAL 993.73

198.70

3 RING #3 6.920 32 1345.98 298.05

4 SHELL RING 6.920 32 1794.63 397.40

Weight

kg/m Nos mm kg

1 RING #1 6.920 8 1798.56 99.57

-1.85

430.7

1.15

4221.3 4.221

430.74

67.19

2.29

4.90E+03

4.90E+03

1347

100

No. Description

Weight /

Lenght

Quantity Lenght

2 RING #2 6.920 16 1794.63

100

-324 -3.17

-2.57

2290

0

2290

1145

462.5 1.145 67.82

597.33

2.29

597.33 2.29

391.56

391.56 1.6E+08

2.4E-06 2447.25

20080

2E-05 1.60E+08

4.94E+03 1.35

3620.36 3.62

369.4

369.4 67.19 100

-262 -2.57

448.84 1.6E+08

2.8E-06 2805.24

20080

2E-05 1.60E+08 2.28

4.94E+03

462.5 1.347 67.82

690.73

2.28

690.73 2.28

448.84

-334 -3.28

-3.28

441.7

4.57

2280

899.3

1795

4.92E+03

4.92E+03 1.12

4328.33 4.328

441.7

67.19

382.80

382.80 1.6E+08

2.4E-06 2392.52

20080

2E-05 1.60E+08 2.29

462.5 1.122 67.82

586.54

2.29

586.54 2.29

2.29

897.3

1346

1122

6.855

2285

Date :

Reference spec.: Process & Piping Specification Engineer : Tjo

MIANG BESAR COAL TERMINAL

CALCULATION FOR STORAGE TANK

Doc. No. :

Job. No. :

Rev. No. :

GIRDER DESIGN

< AT GIRDER RING OUTER RADIUS m> < AT GIRDER RING OUTER RADIUS m>

Number of Girders = 16 Number of Girders = 16

Girder Length (l) = Girder Length (l) =

Load due to inner rafters and roof (Wi) Load due to inner rafters and roof (Wi)

Wi = (Rafter_Load_Inner) (Rafter_Span) (NumberRaft/Numbergird) Wi = (Rafter_Load_Inner) (Rafter_Span) (NumberRaft/Numbergird)

= * * 2 = * * 1

= N = N

Load due to outer rafters and roof (Wo) Load due to outer rafters and roof (Wo)

Wo = (Rafter_Load_Outer) (Rafter_Span) (NumberRaft/Numbergird) Wo = (Rafter_Load_Outer) (Rafter_Span) (NumberRaft/Numbergird)

= * * 2 = * * 2

= N = N

W1 = (Wi + Wo)/L_gird W1 = (Wi + Wo)/L_gird

= ( + ) / = ( + ) /

= N/m' = N/m

Total Load including Weight of Girder (w) Total Load including Weight of Girder (w)

w = + w = +

= N/m' = N/m

Maximum Bending Moment (Mmax) Maximum Bending Moment (Mmax)

Mmax = w*l^2/8 Mmax = w*l^2/8

Mmax = * ^2 /8 Mmax = * ^2 /8

= N.m = N.m

Section of Modulus Required (Z_req'd) Section of Modulus Required (Z_req'd)

Z_req'd = Mmax / Allowable design stress Z_req'd = Mmax / Allowable design stress

= / = /

= m

3

= mm

3

= m

3

= mm

3

Actual Z = mm

3

,using C 100x50x5 Actual Z = mm

3

,using C 75x40x5

Maximum stress allowed for each Girder in ring shell Maximum stress allowed for each Girder in ring shell

w_max = Z*Sd*8/l^2 w_max = Z*Sd*8/l^2

= * * 8 / ^2 = * * 8 / ^2

= N/ m' = N/ m'

Let_C1 = (RafterSpan) (NumRaft_inner/NumGird) Let_C1 = (RafterSpan) (NumRaft_inner/NumGird)

= * = *

= m = m

Let_C2 = (RafterSpan) (NumRaft_outer/NumGird) Let_C2 = (RafterSpan) (NumRaft_outer/NumGird)

= * = *

= m = m

Maximum Load allowed for each girder in ring 3 (F_Max) Maximum Load allowed for each girder in ring 2 (F_Max)

F_Max = w_max *GirdLengt F_Max = w_max *GirdLengt

= * = *

= N = N

Back calculate Max_P from F_Max, using Back calculate Max_P from F_Max, using

F_Max = (Max_P*RafterSpacing_Inner)+RWgt_Inner)*C1 F_Max = (Max_P*RafterSpacing_Inner)+RWgt_Inner)*C1

(Max_P*RafterSpacing_Inner)+RWgt_Outer)*C (Max_P*RafterSpacing_Inner)+RWgt_Outer)*C

Solving for Max_P Solving for Max_P

RafterSpacing_Inner*C1 + RafterSpacing_Outter*C2 RafterSpacing_Inner*C1+RafterSpacing_Outter*C2

- ( * )-( * ) - ( * )-( * )

* + * * + *

= Pa = Pa

Let Max_T1 = Max_P = kg/m

2

Let Max_T1 = Max_P = kg/m

2

Vacuum limited by girder type (P_ext_4) Vacuum limited by girder type (P_ext_4)

P_ext_4 = -2.5 * (MaxT1 - DL - MAX(Snow_Load, Lr)) P_ext_4 = -2.5 * (MaxT1 - DL - MAX(Snow_Load, Lr))

= -2.5*( - - Max ( 0 , ) = -2.5*( - - Max ( 0 , )

= kg/m

2

= kPa = kg/m

2

= kPa

1193.22

1193.22 67.816

1261.04

1261.04 1.78

501.19

501.19 1.6E+08

2

2.29

1.783

690.73 1.14

787.435

586.54 1.143

1340.23

787.44 1340.23 1.783

6.855 4.57

1179.42

1179.42 67.816

1247.23

2.675

586.54 1.14

1340.23

794.02 1.14

1814.34

1340.23 1814.34

3.8E-05 1.60E+08 2.67

6.73E+03

1247.23 2.67

1115.33

1115.33 1.6E+08

7E-06 6970.82

37600

1.1425 2

2.29

1.1425 2

2.29

6727.47 2.67

17993.87

= Max_P

(F_Max - RWgt_Inner*C1 - RWgt_Outer*C2)

Max_P =

17993.87 67.82 2.29 67.82 2.29

1.12 2.29 1.57 2.29

=

17684

6.15

2874.92

293.4 67.19 100

-315 -3.09

293.4

8.08E+03 1.78

14414.24

Max_P =

(F_Max-RWgt_Inner*C1-RWgt_Outer*C2)

3.1E-06 3132.44

20080

2E-05 1.60E+08 1.78

8.08E+03

1.14 1

353.1

353.1 67.19 100

-465 -4.55

Max_P =

14414.24 67.82 1.14 67.82 2.29

1.35 1.14 1.12 2.29

=

14182

4.09849

3460.29

1.14

1.1425

2.675

Date :

Reference spec.: Process & Piping Specification Engineer : Tjo

MIANG BESAR COAL TERMINAL

CALCULATION FOR STORAGE TANK

Doc. No. :

Job. No. :

Rev. No. :

GIRDER DESIGN

< AT GIRDER RING OUTER RADIUS m> GIRDER WEIGHT SUMMARY

Number of Girders = 8

Girder Length (l) =

Load due to inner rafters and roof (Wi)

Wi = (Rafter_Load_Inner) (Rafter_Span) (NumberRaft/Numbergird)

= * * 1

= N

Load due to outer rafters and roof (Wo)

Wo = (Rafter_Load_Outer) (Rafter_Span) (NumberRaft/Numbergird)

= * * 2

= N

W1 = (Wi + Wo)/L_gird

= ( + ) /

= N/m'

Total Load including Weight of Girder (w)

w = +

= N/m

Maximum Bending Moment (Mmax)

Mmax = w*l^2/8

Mmax = * ^2 /8

= N.m

Section of Modulus Required (Z_req'd)

Z_req'd = Mmax / Allowable design stress

= /

= m

3

= mm

3

Actual Z = mm

3

,using = C 75x40x5

Maximum stress allowed for each Girder in ring shell

w_max = Z*Sd*8/l^2

= * * 8 / ^2

= N/ m'

Let_C1 = (RafterSpan) (NumRaft_inner/NumGird)

= *

= m

Let_C2 = (RafterSpan) (NumRaft_outer/NumGird)

= *

= m

Maximum Load allowed for each girder in ring 1 (F_Max)

F_Max = w_max *GirdLengt

= *

= N

Back calculate Max_P from F_Max, using

F_Max = (Max_P*RafterSpacing_Inner)+RWgt_Inner)*C1

(Max_P*RafterSpacing_Inner)+RWgt_Outer)*C2

Solving for Max_P

RafterSpacing_Inner*C1+RafterSpacing_Outter*C2

- ( * )-( * )

* + *

= Pa

Let Max_T1 = Max_P = Kg/m

2

Vacuum limited by girder type (P_ext_4)

P_ext_4 = -2.5 *(MaxT1-DL-MAX(Snow_Load, Lr))

= -2.5*( - - Max ( 0 , )

= kg/m

2

= kPa

TOTAL

No. Description

Weight /

Lenght

Quantity Lenght Weight

kg/m Nos m kg

1 RING #1 6.920 8 1.75 97.03

2 RING #2 6.920 16 1.78 197.43

3 RING #3 6.920 16 2.67 296.14

590.60

597.33 1.145

683.949

690.73 1.14

1574.87

683.949 1574.87 1.753

1288.77

1288.77 67.816

1356.59

1356.59 1.75

520.92

520.92 1.6E+08

3.3E-06 3255.73

20080

2E-05 1.60E+08 1.75

8.37E+03

1.145 1

1.15

1.14 2

2.28

8.37E+03 1.75

14664.54

Max_P =

(F_Max-RWgt_Inner*C1-RWgt_Outer*C2)

Max_P =

14664.54 67.82 1.15 67.82 2.28

1.145 1.15 1.347 2.28

=

14432.3

4.38209

3293.47

336.1

336.1 67.19

-422 -4.14

100

2.29

1.753

Date :

Reference spec.: Process & Piping Specification Engineer : Tjo

MIANG BESAR COAL TERMINAL

CALCULATION FOR STORAGE TANK

Doc. No. :

Job. No. :

Rev. No. :

COLUMN DESIGN

< AT GIRDER RING OUTER RADIUS m> < AT GIRDER RING OUTER RADIUS m>

Number of Column = 16 Number of Column = 8

Column Length (l) = Column Length (l) =

Radius Gyration ( r ) Radius Gyration ( r )

if l/r must be less than 180, then if l/r must be less than 180, then

r_req'd = l/180 = / 180 = m r_req'd = l/180 = / 180 = m

Actual_r = m , using = 200mm 40sch 40 Pipe Actual_r = m , using = 200mm 40sch 40 Pipe

Total Roof Load Supported by each column (P) Total Roof Load Supported by each column (P)

P = x P = x

= N = N

Allowable Compressive Stress per API 650 5.10.3.4 (Fa) Allowable Compressive Stress per API 650 5.10.3.4 (Fa)

R = l/r = (Actual) R = l/r = (Actual)

Column Selenderness ratio (Cc) Column Selenderness ratio (Cc)

Cc = SQRT (2 PI ^2 E /Fy) Cc = SQRT (2 PI ^2 E /Fy)

= SQRT (2*PI^2* / ) = SQRT (2*PI^2* / )

= =

Factor of Safety (FS) Factor of Safety (FS)

FS = 5/4 + (3 * R /8 * CC)-(R^3 / 8*CC^3) FS = 5/4 + (3 * R /8 * CC)-(R^3 / 8*CC^3)

= 5/4 + ( 3* / (8 * )) - ( ^3 / ( 8* ^3) = 5/4 + ( 3* / (8 * )) - ( ^3 / ( 8* ^3)

= =

Since R <= Since R <=

Using AISC Specification Formulas Section E2 Using AISC Specification Formulas Section E2

Let_K = 1 Let_K = 1

Fa = ((1 - R^2/(2*Cc^2))*Fy/FS Fa = ((1 - R^2/(2*Cc^2))*Fy/FS

= ( 1 - ^2 / ( 2 * ^2))* / = ( 1 - ^2 / ( 2 * ^2))* /

= Pa = Pa

= kPa = kPa

Fa is not modified since design temp <= 93qC (API-650 M.3.5 N.A) Fa is not modified since design temp <= 93qC (API-650 M.3.5 N.A)

Fa = x 1 Fa = x 1

A_reqd = P /Fa A_reqd = P /Fa

= ( / ) = ( / )

= m

2

= m

2

= mm

2

= mm

2

A_act = mm2 A_act = mm2

Actual Induced Stress for the column ( F ) Actual Induced Stress for the column ( F )

F = / F = /

= Pa = Pa

= MPa = MPa

Max. Weight Allowed for each coloumn (W_max) Max. Weight Allowed for each coloumn (W_max)

W_Max = - W_Max = -

= Kg = Kg

Max. Load Allowed for each column (Max_P)) Max. Load Allowed for each column (Max_P))

RafterSpacing_Inner*C1 + RafterSpacing_Outter*C2 RafterSpacing_Inner*C1 + RafterSpacing_Outter*C2

- ( * )-( * ) - ( * )-( * )

* + * * + *

= Pa = Pa

Let Max_T1 = Max_P = Kg/m

2

Let Max_T1 = Max_P = Kg/m

2

P_ext_2 = (MaxT1-DL-0.4*MAX(Snow_Load, Lr)) P_ext_2 = (MaxT1-DL-0.4*MAX(Snow_Load, Lr))

= -( - - Max ( 0 , ) = -( - - Max ( 0 , )

= kg/m

2

= kPa = kg/m

2

= kPa

1645451

0.0053

1.65

6E+07

63263.6

63263.6

8725.84 6E+07

0.00014

137.928

8725.84

5303

1.498

116.8 125.7

120

116.8 125.7 2E+08 1.498

2.00E+11

125.66

3E+08

116.81 125.7

116.8

0.11

1247 2.67

3335.96

9E+07

92578.4

92578.4

7718.72

67.19

6.855

12.79

12.79 0.071

4.57

12.98

12.98 0.072

0.11

1261 1.783

2248.59

118.5

3E+08

125.66

118.55 125.7 118.5 125.7

1.499

120

118.5 125.7 3E+08 1.499

2.00E+11

9E+07

8.3E-05

83.3749

5303

7718.72 0.0053

1455535

1.46

8003.15

816.6

816.6 67.19

50096.36 558.176

49538.18

=

49228.3

6.15

=

33373.5

6.15

5425.60

553.6

553.6

34233.40 549.988

33683.41

Max_P =

(F_Max - RWgt_Inner*C1 - RWgt_Outer*C2)

Max_P =

33683.41 67.82 2.29 67.82 2.29

1.12 2.29 1.57 2.29

Max_P =

(F_Max - RWgt_Inner*C1 - RWgt_Outer*C2)

Max_P =

49538.18 67.82 2.29 67.82 2.29

1.12 2.29 1.57 2.29

100

-709 -6.95

100

-446 -4.38

Date :

Reference spec.: Process & Piping Specification Engineer : Tjo

MIANG BESAR COAL TERMINAL

CALCULATION FOR STORAGE TANK

Doc. No. :

Job. No. :

Rev. No. :

COLUMN DESIGN (CONT'd)

< AT GIRDER RING OUTER RADIUS m> < AT GIRDER RING OUTER RADIUS m>

Number of Column = 8 Number of Column = 1

Column Length (l) = Column Length (l) =

Radius Gyration ( r ) Radius Gyration ( r )

if l/r must be less than 180, then if l/r must be less than 180, then

r_req'd = l/180 = / 180 = m r_req'd = l/180 = / 180 = m

Actual_r = m , using = 200mm 40sch 40 Pipe Actual_r = m , using = 200mm 40sch 40 Pipe

Total Roof Load Supported by each column (P) Total Roof Load Supported by each column (P)

P = x P = x

= N = N

Allowable Compressive Stress per API 650 5.10.3.4 (Fa) Allowable Compressive Stress per API 650 5.10.3.4 (Fa)

R = l/r = (Actual) R = l/r = (Actual)

Column Selenderness ratio (Cc) Column Selenderness ratio (Cc)

Cc = SQRT (2 PI ^2 E /Fy) Cc = SQRT (2 PI ^2 E /Fy)

= SQRT (2*PI^2* / ) = SQRT (2*PI^2* / )

= =

Factor of Safety (FS) Factor of Safety (FS)

FS = 5/4 + (3 * R /8 * CC)-(R^3 / 8*CC^3) FS = 5/4 + (3 * R /8 * CC)-(R^3 / 8*CC^3)

= 5/4 + ( 3* / (8 * )) - ( ^3 / ( 8* ^3) = 5/4 + ( 3* / (8 * )) - ( ^3 / ( 8* ^3)

= =

Since R <= Since R <=

Using AISC Specification Formulas Section E2 Using AISC Specification Formulas Section E2

Let_K = 1 Let_K = 1

Fa = ((1 - R^2/(2*Cc^2))*Fy/FS Fa = ((1 - R^2/(2*Cc^2))*Fy/FS

= ( 1 - ^2 / ( 2 * ^2))* / = ( 1 - ^2 / ( 2 * ^2))* /

= Pa = Pa

= kPa = kPa

Fa is not modified since design temp <= 93qC (API-650 M.3.5 N.A) Fa is not modified since design temp <= 93qC (API-650 M.3.5 N.A)

Fa = x 1 Fa = x 1

A_reqd = P /Fa A_reqd = P /Fa

= ( / ) = ( / )

= m

2

= m

2

= mm

2

= mm

2

A_act = mm2 A_act = mm2

Actual Induced Stress for the column ( F ) Actual Induced Stress for the column ( F )

F = / F = /

= Pa = Pa

= MPa = MPa

Max. Weight Allowed for each coloumn (W_max) Max. Weight Allowed for each coloumn (W_max)

W_Max = - W_Max = -

= Kg = Kg

Max. Load Allowed for each column (Max_P)) Max. Load Allowed for each column (Max_P))

RafterSpacing_Inner*C1 + RafterSpacing_Outter*C2 RafterSpacing_Inner*C1 + RafterSpacing_Outter*C2

- ( * )-( * ) - ( * )-( * )

* + * * + *

= Pa = Pa

Let Max_T1 = Max_P = Kg/m

2

Let Max_T1 = Max_P = Kg/m

2

P_ext_2 = (MaxT1-DL-0.4*MAX(Snow_Load, Lr)) P_ext_2 = (MaxT1-DL-0.4*MAX(Snow_Load, Lr))

= -( - - Max ( 0 , ) = -( - - Max ( 0 , )

= kg/m

2

= kPa = kg/m

2

= kPa

COLUMN WEIGHT SUMMARY

18370.53 TOTAL

3 RING #3 43.0 16 12.79 8799.81

1 CENTER 43.0 1 13.36 574.55

1 RING #1 43.0 8 13.17 4530.77

2 RING #2 43.0 8 12.98 4465.41

No. Description

Weight /

Lenght

Quantity Lenght Weight

kg/m Nos m kg

0

13.36

13.36 0.074

0.11

597.3 1.145

683.949

122

2.00E+11 3E+08

125.66

122.02 125.7 122 125.7

1.500

120

122 125.7 3E+08 1.500

1190750

1.19

9E+07

88108.6

88108.6

6314.55 9E+07

7.2E-05

71.6679

5303

6314.55 0.0053

90359.6

90359.6

2377.68 9E+07

2.6E-05

26.3135

5303

2377.68 0.0053

9E+07

2.29

13.17

13.17 0.073

0.11

1.75 1356.6

2377.68

120.3

2.00E+11 3E+08

125.66

120.28 125.7 120.3 125.7

1.499

120

48895.67 566.346

48329.33

Max_P =

(F_Max - RWgt_Inner*C1 - RWgt_Outer*C2)

47677.60 574.552

47103.05

Max_P =

(F_Max - RWgt_Inner*C1 - RWgt_Outer*C2)

448364

0.45

120.3 125.7 3E+08 1.499

Max_P =

48329.33 67.82 2.29 67.82 2.29

1.12 2.29 1.57 2.29

=

48019.4

6.15

7806.62

796.6

796.6 67.19 100

-689 -6.76

Max_P =

47103.05 67.82 2.29 67.82 2.29

1.12 2.29 1.57 2.29

=

46793.1

6.15

7607.27

776.3

776.3 67.19 100

-669 -6.56

SHELL DATA SHELL STIFFENER

Design Method = 1-Foot Method Stiffener Material = ASTM A-36

Shell Plate Material = ASTM A-36 Number of Stiffener = 0

SMYS Shell of Tank Material (F

ys

) = MPa API 650 stiffening-ring type = -

Allowable Design Strees (S

d

) = MPa Stiffener Size = -

Allowable Test Stress (S

t

) = MPa Stiffener Area = -

Density (U) = kg/m

3

Shell Corrosion Allowance (CA) = mm

Shell Joint Type = Butt Weld

Joint Efficiency =

Design Pressure at Top of Tank (Pe) = kPa

Maximum Liquid Level = m

Minimum Liquid Level = m

Roof Insulation thickness = mm

Roof Insulation Density = kg/m

3

DATA

Nominal Tank Diameter (D) = m Water Density (at Temp = 10 C ) ( U) = kg/m

3

Per API 650 Appendix (example A or J) = None Grafity (g) = m/s

2

DESIGN THICKNESS OF SHELL DESIGN THICKNESS OF SHELL (CONT'd)

EVALUATION TO VARIABLE-DESIGN-POINT METHOD WITH API 5.6.4.1 SUMMERY OF SHELL THICKNESS AND WEIGHT

Nominal Tank Diameter (D) = m

Bottom-course corroded shell thickness (t) = mm

Maximum Liquid Level = m

VDP Criteria (per API 650 5.6.4.1)

L = (500xDxt)^0.5 = ( 500 x x )^0.5

= m

L/H 1000/6

1000/6 ----->>>

THICKNESS OF SHELL COURSE #1 THICKNESS OF SHELL COURSE #2

Shell Plate Material = ASTM A-36 Shell Plate Material = ASTM A-36

Corrosion Allowance (CA) = Corrosion Allowance (CA) =

Joint Efficiency ( E) = Joint Efficiency ( E) =

Allowable Design Strees (S

d

) = MPa Allowable Design Strees (S

d

) = MPa

Allowable Test Stress (S

t

) = MPa Allowable Test Stress (S

t

) = MPa

DESIGN CONDITION DESIGN CONDITION

Design specific grafity of the liquid to be store = (per API 650) Design specific grafity of the liquid to be store = (per API 650)

< Design Condition G = > < Design Condition G = >

Effective Liquid head at design Pressure (H') Effective Liquid head at design Pressure (H')

H' = H + 1000P

e

/UgG H' = H + 1000P

e

/UgG

= + 1 / ( x x ) = + 1 / ( x x )

= m = m

Thickness of Shell Thickness of Shell

x x ( - 0.3) x x x ( - 0.3) x

x x

= mm = mm

HYDROSTATIC TEST CONDITION HYDROSTATIC TEST CONDITION

< Design Condition G = 1 > < Design Condition G = 1 >

= + 1 / ( x x ) = + 1 / ( x x )

= m = m

Thickness of Shell Thickness of Shell

x x ( - 0.3) x 1 x x ( - 0.3) x 1

x x

= mm = mm

2

0.85

160

171

2

0.835

7.351

0.835

=

t

calc

=

=

4.9 18.29

12.24

t

calc

=

=

4.9

0.85

6.224

0.85

18.29 10.40

12.24 18.29 10.42

1.000

10.40

t

calc

=

4.9D(H'-0.3)*G

(St*E)

7.565

10.29 1000 * 998 9.8

160

171

0.835

0.835

10.29 1000 * 998 9.8 0.835

10.42

8.571

160 0.85

+

CA

0.835

=

4.9

171

160

4.9 18.29 12.22

1.000

12.22

4.9D(H'-0.3)*G

(St*E)

12.12 1000 * 998 9.8

171 0.85

4.9D(H'-0.3)*G

(Sd*E)

+

t Selected Weight

inc. CA exc. CA New Corroded

2

5 5779.93 5779.93

4.00 6 4 4954.50 3303.36

0.85

4128.98

5.57

7

12.12 1000 *

0.835

+ 2

Because L/H 1000/6, then Variable-Design-Point Method can be used

5779.93

No. Description

t Calculated

inc. CA exc. CA

mm mm

8

0.253

12.12

0.021 TRUE

3 Course #3 6.56 4.56 7 5 5779.93

998 9.8 0.835

t

calc

=

4.9D(H'-0.3)*G

+ CA

(Sd*E)

18.288

18.29

7

18.29

OUTPUT DATA

998

9.8

mm mm kg kg

1 Course #1 8.57 6.57 9 7 7430.53

6 6605.28 4954.50 2 Course #2 7.57

INPUT DATA

0.4

10

12.12

0.3

1

Reference spec.: Process & Piping Specification Engineer : Tjo

250

160

7865

2

0.85

171

MIANG BESAR COAL TERMINAL

CALCULATION FOR STORAGE TANK

Doc. No. :

Job. No. :

Rev. No. :

Date :

5 Course #5 6.00 4.00 6 4 4954.50 4954.50

4 Course #4 6.00 4.00

7 Course #7 6.00 4.00 6 4 4954.50 3303.36

6 Course #6 6.00

40459.17 32204.56 TOTAL

0.007

Reference spec.: Process & Piping Specification Engineer : Tjo

MIANG BESAR COAL TERMINAL

CALCULATION FOR STORAGE TANK

Doc. No. :

Job. No. :

Rev. No. :

Date :

DESIGN THICKNESS OF SHELL DESIGN THICKNESS OF SHELL (CONT'd)

THICKNESS OF SHELL COURSE #3 THICKNESS OF SHELL COURSE #5

Shell Plate Material = ASTM A-36 Shell Plate Material = ASTM A-36

Corrosion Allowance (CA) = Corrosion Allowance (CA) =

Joint Efficiency ( E) = Joint Efficiency ( E) =

Allowable Design Strees (S

d

) = MPa Allowable Design Strees (S

d

) = MPa

Allowable Test Stress (S

t

) = MPa Allowable Test Stress (S

t

) = MPa

DESIGN CONDITION DESIGN CONDITION

Design specific grafity of the liquid to be store = (per API 650) Design specific grafity of the liquid to be store = (per API 650)

< Design Condition G = > < Design Condition G = >

Effective Liquid head at design Pressure (H') Effective Liquid head at design Pressure (H')

H' = H + 1000P

e

/UgG H' = H + 1000P

e

/UgG

= + 1 / ( x x ) = + 1 / ( x x )

= m = m

Thickness of Shell Thickness of Shell

x x ( - 0.3) x x x ( - 0.3) x

x x

= mm = mm

HYDROSTATIC TEST CONDITION HYDROSTATIC TEST CONDITION

< Design Condition G = 1 > < Design Condition G = 1 >

= + 1 / ( x x ) = + 1 / ( x x )

= m = m

Thickness of Shell Thickness of Shell

x x ( - 0.3) x 1 x x ( - 0.3) x 1

x x

= mm = mm

THICKNESS OF SHELL COURSE #4 THICKNESS OF SHELL COURSE #6

Shell Plate Material = ASTM A-36 Shell Plate Material = ASTM A-36

Corrosion Allowance (CA) = Corrosion Allowance (CA) =

Joint Efficiency ( E) = Joint Efficiency ( E) =

Allowable Design Strees (S

d

) = MPa Allowable Design Strees (S

d

) = MPa

Allowable Test Stress (S

t

) = MPa Allowable Test Stress (S

t

) = MPa

DESIGN CONDITION DESIGN CONDITION

Design specific grafity of the liquid to be store = (per API 650) Design specific grafity of the liquid to be store = (per API 650)

< Design Condition G = > < Design Condition G = >

Effective Liquid head at design Pressure (H') Effective Liquid head at design Pressure (H')

H' = H + 1000P

e

/UgG H' = H + 1000P

e

/UgG

= + 1 / ( x x ) = + 1 / ( x x )

= m = m

Thickness of Shell Thickness of Shell

x x ( - 0.3) x x x ( - 0.3) x

x x

= mm = mm

HYDROSTATIC TEST CONDITION HYDROSTATIC TEST CONDITION

< Design Condition G = 1 > < Design Condition G = 1 >

= + 1 / ( x x ) = + 1 / ( x x )

= m = m

Thickness of Shell Thickness of Shell

x x ( - 0.3) x 1 x x ( - 0.3) x 1

x x

= mm = mm

(St*E)

160

4.93

0.835

0.835

+ 2

0.835

+

4.9 18.29 3.10

0.835

3.10

t

calc

=

4.9D(H'-0.3)*G

+ CA

(Sd*E)

0.835

2.98 1000 * 998 9.8

2

=

4.9 18.29 3.08

171 0.85

1.000

3.08

t

calc

=

4.9D(H'-0.3)*G

0.85

3.542

2.98 1000 * 998 9.8

=

2

0.85

160

171

0.835

0.835

4.81 1000 * 998 9.8 0.835

1.716 3.970

2

0.85

160

171

0.835

4.91

171 0.85

2.843

4.91

t

calc

=

4.9D(H'-0.3)*G

(St*E)

=

4.9 18.29

4.81 1000 * 998 9.8 1.000

160 0.85

4.548

CA

(Sd*E)

=

4.9 18.29 4.93

t

calc

=

4.9D(H'-0.3)*G

+

0.835

+ 2

160 0.85

5.554

=

4.9 18.29 6.74

171 0.85

=

4.9 18.29 6.76

1.000

6.74

t

calc

=

4.9D(H'-0.3)*G

(St*E)

6.64 1000 * 998 9.8

6.76

t

calc

=

4.9D(H'-0.3)*G

+ CA

(Sd*E)

0.835

0.835

6.64 1000 * 998 9.8 0.835

5.097

2

0.85

160

171

=

4.9 18.29 8.57

171 0.85

1.000

8.57

t

calc

=

4.9D(H'-0.3)*G

(St*E)

160 0.85

6.560

8.46 1000 * 998 9.8

=

4.9 18.29 8.59 0.835

+ 2

8.59

t

calc

=

4.9D(H'-0.3)*G

+ CA

(Sd*E)

0.835

8.46 1000 * 998 9.8

2

0.85

160

171

0.835

Reference spec.: Process & Piping Specification Engineer : Tjo

MIANG BESAR COAL TERMINAL

CALCULATION FOR STORAGE TANK

Doc. No. :

Job. No. :

Rev. No. :

Date :

DESIGN THICKNESS OF SHELL DESIGN THICKNESS OF SHELL (CONT'd)

THICKNESS OF SHELL COURSE #7 SHELL COURSE #3 SUMMARY

Shell Plate Material = ASTM A-36 Widht of Shell plate = m

Corrosion Allowance (CA) = t-calc = MAX (t-calc_650,t.seismic)

Joint Efficiency ( E) = = MAX ( , )

Allowable Design Strees (S

d

) = MPa = mm

Allowable Test Stress (S

t

) = MPa t.required = MAX(t.design, t.test, t.min650)

DESIGN CONDITION = MAX ( , , 6 )

Design specific grafity of the liquid to be store = (per API 650) = mm

< Design Condition G = > t.actual = mm

Effective Liquid head at design Pressure (H') Weight = Density*PI*(D-t)*Widht*t

H' = H + 1000P

e

/UgG = x PI x( - ) * *

= + 1 / ( x x ) = kg (NEW)

= m Weight = Density*PI*(D-t)*Widht*t

Thickness of Shell = x PI x( - ) * *

= kg (CORRODED)

x x ( - 0.3) x SHELL COURSE #4 SUMMARY

x Widht of Shell plate = m

= mm t-calc = MAX (t-calc_650,t.seismic)

HYDROSTATIC TEST CONDITION = MAX ( , )

< Design Condition G = 1 > = mm

= + 1 / ( x x ) t.required = MAX(t.design, t.test, t.min650)

= m = MAX ( , , 6 )

Thickness of Shell = mm

t.actual = mm

Weight = Density*PI*(D-t)*Widht*t

x x ( - 0.3) x 1 = x PI x( - ) * *

x = kg (NEW)

= mm Weight = Density*PI*(D-t)*Widht*t

= x PI x( - ) * *

= kg (CORRODED)

SHELL COURSE #1 SUMMARY SHELL COURSE #5 SUMMARY

Widht of Shell plate = m Widht of Shell plate = m

t-calc = MAX (t-calc_650,t.seismic) t-calc = MAX (t-calc_650,t.seismic)

= MAX ( , ) = MAX ( , )