Documente Academic

Documente Profesional

Documente Cultură

Basics of Conveyor Engineering Hardware

Încărcat de

Terence Tan100%(1)100% au considerat acest document util (1 vot)

59 vizualizări17 paginiBasics of Conveyor Engineering Hardware

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentBasics of Conveyor Engineering Hardware

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

59 vizualizări17 paginiBasics of Conveyor Engineering Hardware

Încărcat de

Terence TanBasics of Conveyor Engineering Hardware

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 17

Page 1 of 17

8720 Red Oak Boulevard Suite 201

Charlotte, North Carolina28217-3992

Perspectives on Material Handling Practice

Perspectives on Material Handling Practice Perspectives on Material Handling Practice Perspectives on Material Handling Practice Perspectives on Material Handling Practice

P ap er s i n t he P er sp ect i ves s er i es have ap p ear ed i n conf er ence p r oceed i ngs o f P ap er s i n t he P er sp ect i ves s er i es have ap p ear ed i n conf er ence p r oceed i ngs o f P ap er s i n t he P er sp ect i ves s er i es have ap p ear ed i n conf er ence p r oceed i ngs o f P ap er s i n t he P er sp ect i ves s er i es have ap p ear ed i n conf er ence p r oceed i ngs o f

t he Mat er i al Handl i ng I ns t i t ut e b et ween 1 9 9 2 and t he p r esent . As such t hey t he Mat er i al Handl i ng I ns t i t ut e b et ween 1 9 9 2 and t he p r esent . As such t hey t he Mat er i al Handl i ng I ns t i t ut e b et ween 1 9 9 2 and t he p r esent . As such t hey t he Mat er i al Handl i ng I ns t i t ut e b et ween 1 9 9 2 and t he p r esent . As such t hey

p r ovi d e a p o i nt o f r ef er ence as t o ho w t he i ndus t r y i s chan p r ovi d e a p o i nt o f r ef er ence as t o ho w t he i ndus t r y i s chan p r ovi d e a p o i nt o f r ef er ence as t o ho w t he i ndus t r y i s chan p r ovi d e a p o i nt o f r ef er ence as t o ho w t he i ndus t r y i s changi ng as wel l as i ns i ght gi ng as wel l as i ns i ght gi ng as wel l as i ns i ght gi ng as wel l as i ns i ght

i nt o accep t ed p r act i ce dur i ng t hi s p er i od. I n many cas es t he aut hor s cr edi t ed have i nt o accep t ed p r act i ce dur i ng t hi s p er i od. I n many cas es t he aut hor s cr edi t ed have i nt o accep t ed p r act i ce dur i ng t hi s p er i od. I n many cas es t he aut hor s cr edi t ed have i nt o accep t ed p r act i ce dur i ng t hi s p er i od. I n many cas es t he aut hor s cr edi t ed have

ei t her changed j ob s or ar e no l onger i n t he i ndust r y. S ome co mp ani es as wel l have ei t her changed j ob s or ar e no l onger i n t he i ndust r y. S ome co mp ani es as wel l have ei t her changed j ob s or ar e no l onger i n t he i ndust r y. S ome co mp ani es as wel l have ei t her changed j ob s or ar e no l onger i n t he i ndust r y. S ome co mp ani es as wel l have

b een t he sub j ect of mer ger s or r eor gani zat i o n wi t h a new cor p o r at e b een t he sub j ect of mer ger s or r eor gani zat i o n wi t h a new cor p o r at e b een t he sub j ect of mer ger s or r eor gani zat i o n wi t h a new cor p o r at e b een t he sub j ect of mer ger s or r eor gani zat i o n wi t h a new cor p o r at e i dent i t y. i dent i t y. i dent i t y. i dent i t y.

BASICS OF CONVEYOR ENGINEERING HARDWARE

BY

MIKE COLEMAN

INTERLAKE CONVEYOR SPECIALIST

NA 94 FORUM

ABSTRACT

In the conveyor business there is never a perfect solution, only partial answers to the solution,

and that is the reason for this seminarto familiarize you with the different types of equipment

available, and their application.

GATHER FACTS

Certain questions must first be answered before you can even begin to conceptualize that

conveyor system. An overall objective must first be set, and a basic understanding of the type of

system is important. A few examples of the type of systems are warehousing,

receiving,

packaging, shipping, production (both flexible, and progressive). It is also important to consider

the size, shape, and age of the building, and possible future expansions. Environmental

conditions must also be taken into account like temperature, and humidity.

Additional information should include, sales forecasts, combined with production capabilities,

keeping in mind the need for flexibility since manufacturing is ever changing in this world

economy.

But the most important thing to remember when considering a conveyor system is the KISS

principle, for often times we get carried away with the equipment options, and before you know

it, we have lost the true objective of the system, with over design, and expensive features. Future

Page 2 of 17

8720 Red Oak Boulevard Suite 201

Charlotte, North Carolina28217-3992

Perspectives on Material Handling Practice

considerations must also be taken into account early on, so your system must be adaptable, and

flexible for a phase-in expansion.

Once you have an overall picture, or sequence of operations, then specific questions must be

asked. Load Characteristics are vital, and include the size, shape, weight, and material to be

conveyed. The footprint is important for it is what the conveyor will see, and will help determine

the best type of equipment to use. Rate of flow is important for it will determine the speed that

the conveyor needs to run, and product orientation if you are interfacing with automated

equipment, and or need to incorporate accumulation of products.

Now that you have a general layout, combined with the specific information of your system, you

can begin to specify the type of equipment required.

EQUIPMENT APPLICATION

There are multiple functions for each type of conveyor. It is now a question of applying the best-

suited equipment, while staying within your budget.

GRAVITY

Gravity conveyor is your least expensive equipment, and is suitable for most manual

applications. It is often used to pass orders from picking zones, or for staging material to

shipping, packaging, or inspection. Since it is non-powered, it is safe and easy to work with. If

the conveyor is to be pitched, it is important to know the weight of the product, for a heavy

carton will build up more momentum than a lighter carton.

It is also important to know how the conveyor is being loaded, for there is a wide range of

capacities. Hand loading applications would require a lighter gage material than fork truck

loading due to less shock. Also take into account the side frames for a structural member may be

needed to resist impact.

POWERED CONVEYOR

There are many types, and styles, but they all have one objective, and that is to move the product

from one point to another as efficiently as possible. From the application chart, you can see that

belt conveyors have a broad range of usage. They are the least expensive type of powered

conveyor due to the limited number of bearings required. Horizontal belts can handle most

product shapes, and weights. There are two types, a slider bed, and a roller bed. A slider bed is a

steel sheet that the belt rides over and a roller bed is just as the name implies.

A slider bed is most often used for small lightweight products, where a roller bed is used for

heavier products with longer runs. Belt pull is the limiting factor, and should be determined by

your conveyor supplier.

An incline/decline belt conveyor is used to move product from one elevation to another. A ruff

top belt is usually supplied, which grips the product, and prevents it from freewheeling or

sliding. It is important to know the maximum incline angle to prevent product tumbling.

Page 3 of 17

8720 Red Oak Boulevard Suite 201

Charlotte, North Carolina28217-3992

Perspectives on Material Handling Practice

LIVE ROLLER CONVEYOR

Live Roller conveyor is the next conveyor of choice, and covers a wide range of application. It is

used mostly in areas where product accumulation or staging is important. Live Roller conveyor

comes in many styles. They are, belt driven, cable drive, and shaft driven. Each has it's own

advantages, and disadvantages, in regards to usage and flexibility.

Belt driven live roller (BDLR) is where the carrying rollers (rollers holding the product) are

powered by a belt. This belt is wedged between the carrying rollers and the pressure rollers. The

pressure rollers can be adjusted up or down to increase or decrease the driving force. Another set

of rollers is required for this conveyor but is not shown, and that is the return rollers used to

return the belt to its starting position. Most BDLRs are used for medium to heavy-duty

application, where significant driving force is required, such as through merges, divert arms, and

pallet handling applications.

A shaft driven live roller (Lines shaft) is the carrying rollers are individually powered by an

elastomeric belt, which is driven off a main shaft. This type of conveyor is used mostly in light to

medium duty applications, and lends itself to multiple accessories powered by a single drive.

Cable driven live roller is similar to lineshaft, except the carrying rollers are powered by a steel

cable that are able to snake around through the curves, and straight sections. It is also a light to

medium duty conveyor.

Live roller conveyors lend themselves better for accumulation applications both zero pressure,

and minimum pressure because the power source can be dropped out of a zone, or adjusted to

limit the amount of driving force required to move the product while at the same time maintain

product flow throughout.

CHAIN DRIVEN LIVE ROLLER CONVEYOR

Chain Driven Live Roller (CDLR) is used for heavy-duty applications, and comes in both

transport and accumulation models. Like any powered roller conveyor the footprint is important

to provide smooth roller to roller flow, so if the pallet has bottom slats, it is a good idea to have

them running length wise or perpendicular to the rollers.

This type of conveyor is powered by a series of chains that is connected progressively to each

roller, or by a single chain that runs the length of the conveyor. The progressive roller to roller

requires two sprockets welded to each roller, where a single chain only requires one sprocket.

Each has its application, but the heavier the load the more chain pull is required which would

dictate one over the other.

Due to the heavy loads being transported, a fork truck is often required, consequently, a

structural frame and heavy gage roller is often required to withstand the abuse factor. Also, a toe

in or toe out frame configuration may be needed to mount the rollers high opposite the chain

guard to allow ease of loading and unloading. Roller capacity can run as high as 1200 lbs each so

we are talking heavy stuff here.

Page 4 of 17

8720 Red Oak Boulevard Suite 201

Charlotte, North Carolina28217-3992

Perspectives on Material Handling Practice

SUMMARY

This paper should provide a better understanding of the type of equipment available and the

primary application. As you have noticed, different types of equipment can be used for the same

application; but remember the future and this ever changing world market, for your system today

needs to be flexible, changeable and simple. It is a major investment that you should not

outgrow.

EXHIBITS

Gravity Conveyor

Gravity roller conveyors provide one of the most versatile and economical means of moving

portable applications. Gravity conveyors can quickly move large quantities of items in virtually

any direction with a minimum of effort and expense. Gravity conveyors move product in two

ways: on a pitch, utilizing the natural flow of gravity or on a level line where conveyance of the

item in accomplished by pushing.

Gravity, or non-powered roller conveyors, is ideal for moving most unit loads that have a firm,

flat bottom surface. They can be used in both permanent and portable applications. To select the

proper equipment for the required application, the following steps must be considered.

1. Load Characteristics

2. Conditions and Bearing Selection

3. Roller Center Spacing

4. Roller Capacity

5. Width and Settings

6. Frame Requirement

7. Support Capacity

8. Conveyor Pitch

9. Support Heights and Quantities

Load Characteristics

The single most important consideration to insure your system reliability is known as the

footprint, which is the bottom surface of the load that is to be conveyed. The load bottom must

be firm and free of projections, which could prevent smooth travel over rollers. A slipsheet

could provide the necessary rigidity. If at this step, all load characteristics are not favorable, do

not proceed. Consider a power conveyor.

Page 5 of 17

8720 Red Oak Boulevard Suite 201

Charlotte, North Carolina28217-3992

Perspectives on Material Handling Practice

Conditions and Bearing Selection

Bearings

OPEN DRY BEARING

Open dry bearings offer the least resistance to turning of all bearing types. They are constructed

with an outer shield, which is fixed to the stationary inner race of the bearing and does not touch

any rotating part. Manufactured with a light oil lubricant, the open dry bearing gives satisfactory

results in most normally clean, dry, indoor applications.

Page 6 of 17

8720 Red Oak Boulevard Suite 201

Charlotte, North Carolina28217-3992

Perspectives on Material Handling Practice

DUST PROTECTED BEARINGS

Dust protected bearings, non-lubricated, have the same easy rolling action as a plain bearing

because the dust shield is a non-contact type seal. The shield, which is fit to the stationary inner

race does not touch any rotating parts of the bearing. In a reasonably moisture free environment,

excellent results are achieved with absolutely no lubrication.

FACTORY LUBRICATED BEARINGS

The lubricated bearings are similar in construction to the dust protected incorporating the same

dust shield arrangement with an additional rear grease seal.

The factory-lubricated bearings are recommended for all powered roller applications, both for

live roller and belt conveyor applications. Caution should be used in applying this construction in

areas where excessive grit or dust exists, as there are no means provided for regreasing these

bearings as there are with pressure-lubricated construction.

PRESSURE LUBRICATED BEARINGS

The pressure-lubricated bearings are similar in construction to the factory-lubricated bearings:

however, requiring in application the necessity of drilling the hex axle for grease fittings for

delivery of grease to internal parts of the bearing. Grease delivered under pressure to the interior

of the bearings forces out old grease, thereby producing a new effective seal. The advantages of

the re-greasable feature are obvious when considering application in extremely dirty

environments.

Determine Roller Center Spacing

A MINIMUM OF THREE ROLLERS MUST SUPPORT THE SMALLEST UNIT LOAD.

Divide the minimum package length you anticipate conveying in your system by three (or the

number of rollers needed) to arrive at the roller center-to-center distance. Choose a roller section

with roller centers the same or less than this figure.

Page 7 of 17

8720 Red Oak Boulevard Suite 201

Charlotte, North Carolina28217-3992

Perspectives on Material Handling Practice

Determine Roller Capacity

Roller capacity is determined by dividing the weight of the heaviest load by the minimum

number of rollers that will carry the load at any single moment.

Determine Width & Settings Straight Sections

STRAIGHT SECTIONS

If your application consists only of straight conveyor sections, the recommended conveyor width

is: Conveyor Width = Package Width + 2 inches

Page 8 of 17

8720 Red Oak Boulevard Suite 201

Charlotte, North Carolina28217-3992

Perspectives on Material Handling Practice

Determine Frame Requirement

To extend the life of the conveyor or to avoid damage from overloading, it is best to be on the

safe side in calculating frame capacity. Allow for extra loading. In many cases conveyors are

subjected to greater abuse and loads than they were intended for. Frame requirements should be

carefully calculated. Locating supports on closer centers is one way to increase frame capacities.

In doing this, compare the cost of an increased frame to the number of extra supports to see

which method is most economically feasible. When figuring capacities, include the weight of the

conveyor section and be sure to check the capacities of each type of frame against the total load.

FORMULA:

Live Load: Multiply Number of Loads in 10-0 Long Section x Weight of Each Load

+

Dead Load: Multiply Number of Rollers in 10-0 Long Section x Weight on Each Roller

= Total Load

Page 9 of 17

8720 Red Oak Boulevard Suite 201

Charlotte, North Carolina28217-3992

Perspectives on Material Handling Practice

DETERMINE SUPPORT CAPACITY: The supports to be selected must have a load carrying

capacity equal to or greater than the maximum loading condition and weight of section itself.

Page 10 of 17

8720 Red Oak Boulevard Suite 201

Charlotte, North Carolina28217-3992

Perspectives on Material Handling Practice

Page 11 of 17

8720 Red Oak Boulevard Suite 201

Charlotte, North Carolina28217-3992

Perspectives on Material Handling Practice

Powered Conveyor

Belt Conveyors Types and Applications

Being the most versatile of power conveyor, belt conveyors are the most frequently used. One

reason for the versatility is the work surface belt, which can handle loads of almost any shape

and over a moving platform for process or production work. Belt conveyors are also one of the

least expensive power conveyors.

Slider Bed

The belt slides over a continuous metal bed, which is attached between the tops of the conveyor

channel frames. Because support for the entire belt surface is provided, the belt friction (30%

friction coefficient) is increased, thus limiting loads to 52 lbs. per sq. ft. or less. Operation is

quiet and the bed offers a no-sag, no bump surface.

Slider bed conveyors are excellent for production work where small parts of varying sizes and

shapes must be carried or assembled. The surface remains constantly flat.

Page 12 of 17

8720 Red Oak Boulevard Suite 201

Charlotte, North Carolina28217-3992

Perspectives on Material Handling Practice

Roller Bed

The belt rolls over rollers rather than a metal bed. Friction is greatly reduced thus smaller motors

and drives can be used. For light loads, one roller is sufficient under each load but for heavier

loads and inclines, two or more rollers should be used. (See your conveyor supplier for specific

roller capacities.)

Inclines and Declines

When elevation must be changed, incline or decline belt conveyors are used at a maximum 300

angle.

This rule can only be used for evenly weighted loads! A vertical line dropped from the exact

center of the load (center of gravity) should fall within the center one third of the bottom of the

load. Outside of this area the load would be unstable. If the weight within the carton is off center

or unevenly distributed, do not use this rule! Testing may be necessary to determine the center of

gravity and exact incline.

Example: A package is 28L x 20H x 12W

X = L/H

X = 28/20 = 1.4 Maximum incline angle = 25 degrees

Page 13 of 17

8720 Red Oak Boulevard Suite 201

Charlotte, North Carolina28217-3992

Perspectives on Material Handling Practice

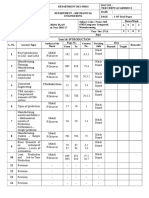

Handy Incline Table

This chart is also to be used only with evenly weighted loads. Divide carton length by carton

height to find: X = L/H

On the table, the degree of include next to your value of X will be the maximum incline

guideline you should use.

Page 14 of 17

8720 Red Oak Boulevard Suite 201

Charlotte, North Carolina28217-3992

Perspectives on Material Handling Practice

Page 15 of 17

8720 Red Oak Boulevard Suite 201

Charlotte, North Carolina28217-3992

Perspectives on Material Handling Practice

Page 16 of 17

8720 Red Oak Boulevard Suite 201

Charlotte, North Carolina28217-3992

Perspectives on Material Handling Practice

Page 17 of 17

8720 Red Oak Boulevard Suite 201

Charlotte, North Carolina28217-3992

Perspectives on Material Handling Practice

Belt Driven Live Roller Curves

Belt driven curves are used with live roller conveyor. However, their use does have some

limitations, such as it can be used for transportation only and cannot accumulate. Pressure rollers

are not used in curves. In their place, sheaves along the inner frame (smaller radii) are used to

guide a V-Belt and apply belt pressure to the carrying rollers. The carrying rolls thru the curve

are tapered to keep loads properly aligned. There is a maximum 400 lb. limit of distributed load

per curve. Powered curves generally operate faster than straight conveyors to keep loads

separated and from bumping each other.

CHAIN DRIVEN LIVE ROLLER CONVEYOR

Chain driven live roller conveyors utilize a roller bed for the carrying space. They provide

controlled movement of a great variety of commodities from the lightest to the heaviest loads.

Unit loads travel directly on the roller surface.

The positive drive afforded by chain on sprockets makes chain driven live roller conveyor the

choice for heavy loads (pallets. etc.) and for conveyors used in applications where heat, dirt, oil,

grease or other contaminants may cause belt damage. Two sprockets are welded to each roller

and individual loops of chain connect rollers in a staggered pattern. The driving chain or chains

are at one end of the rollers and are shielded or guarded. This driving arrangement is desirable

for heavy loads and for applications, which require frequent stopping or reversing.

The path is usually level, but can be slightly inclined or declined, limited by the coefficient of

friction between the rollers and the load. Because the drive is positive, there is no slippage: all

rollers turn at the same speed. Both straight sections and curves are available.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Heat Transfer Equipment Agitated VesselDocument70 paginiHeat Transfer Equipment Agitated VesselTerence TanÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Heat Transfer in Agitated VesselsDocument33 paginiHeat Transfer in Agitated VesselsGanesh.Mahendra100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- TechPage Gravity RollerDocument1 paginăTechPage Gravity RollerTerence TanÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Conventional JacketsDocument4 paginiConventional JacketsTerence TanÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Technical ManualDocument50 paginiTechnical ManualTerence TanÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- HVAC Cooling Load Procedure Guideline Lo0Document62 paginiHVAC Cooling Load Procedure Guideline Lo0api-385802594% (36)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- 5595 E2 VP MD 001 014 - Hydro - Test Procedure REV 0Document9 pagini5595 E2 VP MD 001 014 - Hydro - Test Procedure REV 0Terence TanÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Mitsubishi Melsec PLC Ladder Logic ApplicationDocument215 paginiMitsubishi Melsec PLC Ladder Logic ApplicationAmon AmarthÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A PID Controller For Real-Time DC Motor Speed Control Using The C505C Micro ControllerDocument6 paginiA PID Controller For Real-Time DC Motor Speed Control Using The C505C Micro Controllerbhargav103Încă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Bednar - Pressure Vessel Design HandbookDocument230 paginiBednar - Pressure Vessel Design HandbookceballosingÎncă nu există evaluări

- 10 1 1 126 6871Document8 pagini10 1 1 126 6871Terence TanÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Internal-Business-Process PerspectiveDocument6 paginiInternal-Business-Process PerspectiveMUTIA ADELIA MURKIÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- 3.stress ReliefDocument2 pagini3.stress ReliefRajeevSangamÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Pickling Process: Continuous OperationDocument2 paginiThe Pickling Process: Continuous Operationm daneshpourÎncă nu există evaluări

- Schiffstechnik Eng 2007Document16 paginiSchiffstechnik Eng 2007Ardhan FauzanÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Myra Enterprises - IntroductionDocument3 paginiMyra Enterprises - IntroductiongcadvisersÎncă nu există evaluări

- ESAB Electrodes User ManualDocument44 paginiESAB Electrodes User ManualF. Alijani100% (1)

- 3mtm Scotchcasttm Polyolefin Fiber Product DataDocument3 pagini3mtm Scotchcasttm Polyolefin Fiber Product Datajack21abÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Cim New Lesson PlanDocument6 paginiCim New Lesson Planjamunaa83Încă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- List of Technical Short Course - SBTEDocument3 paginiList of Technical Short Course - SBTEArsalan A. RajputÎncă nu există evaluări

- Designing A Container Terminal YardDocument108 paginiDesigning A Container Terminal Yardlim kang hai100% (5)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Deuterium Lamps PdfpricelistDocument16 paginiDeuterium Lamps PdfpricelistAnggun Teh PamegetÎncă nu există evaluări

- Final Project ReportDocument83 paginiFinal Project ReportMohit SrivastavaÎncă nu există evaluări

- Total Quality Management: January 2017Document11 paginiTotal Quality Management: January 2017Arun Nalamara100% (1)

- Cem II - A-V 42,5r (En)Document2 paginiCem II - A-V 42,5r (En)danbelaÎncă nu există evaluări

- Challenges Facing The Indian Manufacturing SectorDocument9 paginiChallenges Facing The Indian Manufacturing SectorThakur KhoraÎncă nu există evaluări

- Specifications (San Carlos Heights)Document10 paginiSpecifications (San Carlos Heights)Bryan Soriano PascualÎncă nu există evaluări

- ch07 AIS TEST BANKDocument8 paginich07 AIS TEST BANKmcdo friesÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Ncma Tek 10-03Document4 paginiNcma Tek 10-03Jeff HedmanÎncă nu există evaluări

- AssignmentDocument9 paginiAssignmentJuliene HindsÎncă nu există evaluări

- Performance Based Routine Maintenance For Lot 1 Roads Buruburu-Makadara AreaDocument8 paginiPerformance Based Routine Maintenance For Lot 1 Roads Buruburu-Makadara AreaBernie QuepÎncă nu există evaluări

- Am250 GleasonDocument4 paginiAm250 GleasonErhan GencÎncă nu există evaluări

- Hirschmann NEW 9000K CatalogDocument24 paginiHirschmann NEW 9000K CatalogAllan Nalla100% (1)

- Chapter 11 (Foundry Modernization and Mechanization) 2003Document10 paginiChapter 11 (Foundry Modernization and Mechanization) 2003gere33% (3)

- GATE RCC & Steel Structures BookDocument12 paginiGATE RCC & Steel Structures BookMims120% (1)

- ME-07 .Francisco P.G.Document12 paginiME-07 .Francisco P.G.nguyenÎncă nu există evaluări

- Oprational Management (10me81)Document102 paginiOprational Management (10me81)Anu RagÎncă nu există evaluări

- Annex - 3 - 108695Document8 paginiAnnex - 3 - 108695Anaruzzaman SheikhÎncă nu există evaluări

- CGL Multistage PumpsDocument8 paginiCGL Multistage PumpsSaravanan ManiÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- IME Time TableDocument1 paginăIME Time Tableksat85Încă nu există evaluări

- Composites RevisedDocument109 paginiComposites RevisedWashington Masaquiza100% (1)