Documente Academic

Documente Profesional

Documente Cultură

Reliability Engineer Brochure

Încărcat de

Devendra Bangar0 evaluări0% au considerat acest document util (0 voturi)

524 vizualizări5 paginiReliability Engineer Brochure

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentReliability Engineer Brochure

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

524 vizualizări5 paginiReliability Engineer Brochure

Încărcat de

Devendra BangarReliability Engineer Brochure

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 5

Institute of Quality and Reliability R-05 CRE Dec 2009 Page 1 of 5

Certified Reliability Engineer

(Duration: 5 Days)

Introduction:

Assuring Reliability of new products is a major challenge for senior management of most

organizations. This Reliability Engineering workshop is designed to provide in-depth

understanding of Reliability Engineering Basics, Life Data Analysis, Reliability in Design,

Reliability Testing, Maintainability and Availability and various Statistical Techniques. For more

details, see agenda of the workshop on page 2.

According to American Society for Quality (ASQ): The Certified Reliability Engineer (CRE) is a

professional who understands the principles of performance evaluation and prediction to improve

product/systems safety, reliability, and maintainability. The CRE Body of Knowledge (BOK) and

applied technologies include, but are not limited to, design review and control; prediction,

estimation, and apportionment methodology; failure mode and effects analysis; the planning,

operation, and analysis of reliability testing and field failures, including mathematical modeling;

understanding human factors in reliability; and the ability to develop and administer reliability

information systems for failure analysis, design, and performance improvement and reliability

program management over the entire product life cycle.

This workshop is designed based on body of knowledge published by ASQ. The course kit

includes a copy of Certified Reliability Engineer Handbook published by ASQ, additional training

material from Institute of Quality and Reliability and a CD with some useful templates and fully

functional trial versions of software. Classroom training is supported with hands on exercises and

tutorials. Participants are expected to bring scientific calculators and laptop computers for

effective learning. Some of the exercises are designed using reliability analysis software and

templates.

Who should attend the training?

The course is most appropriate for engineers and managers involved in

Design and/or Development of New Products

Reliability Testing of Products

Quality Assurance and improvement of current and new products

Warranty Data Analysis

Problem Solving and Quality/Reliability Improvement

Maintenance Engineers

Considering the course contents, it is expected that participants should have basic understanding

of business processes, should be able to use scientific calculators and computers, and should

have knowledge of basic mathematics and science.

About Certification:

On the last day of the workshop, a test of comprehension will be conducted similar to the exam

conducted by American Society for Quality. However there will be 75 multiple-choice questions

and the test duration is two hours certificate of passing will be issued to successful participants.

Participants can reappear for the exam again within six months of the workshop at no additional

fees.

To appear for ASQ certification exam, if participants are a graduate, they must have six years of

on-the-job experience in one or more of the areas of the Certified Reliability Engineer Body of

Knowledge. A minimum of three years of this experience must be in a decision-making position.

Decision-making is defined as the authority to define, execute, or control projects/processes and

to be responsible for the outcome. This may or may not include management or supervisory

positions. For more information about ASQ certification, visit website

http://www.asq.org/certification/reliability-engineer/index.html. Complete ASQ CRE Certification

brochure can be downloaded from http://www.asq.org/pdf/certification/inserts/cre-insert-2009.pdf.

Institute of Quality and Reliability R-05 CRE Dec 2009 Page 2 of 5

Agenda for the Training:

Day Topic Subtopic/details

1 Introduction and expectations of

participants and introduction of Faculty

1 Introduction to Reliability Definitions: Failure, Reliability, MTTF, MTBF, Failure Rate,

Maintainability, Availability etc.

1 Product Life Cycle Bathtub curve, Decreasing Failure Rate (Infant Mortality or

Burn-in period), Constant Failure Rate (Useful life), Increasing

Failure Rate (Wear-out period)

1 Basic Probability and Probability

Distributions in Reliability Engineering

Exponential, Weibull, Normal, Lognormal, Examples and

illustrations

1 Data Collection and Use Types of data, collection methods, data management and use,

Corrective and Preventive Action using failure analysis to find

root cause(s)

1 Life Data Analysis of Non-repairable

Systems

Complete and Censored Data, Identifying distribution,

Probability Plotting, Estimating Parameters of the distribution,

predicting reliability, Exercises

1 Reliability Modeling and Prediction Reliability Block Diagrams: Series and parallel systems,

combined reliability, redundancy: complete and partial, Physics

of failure mode, failure mechanisms, S-N Curve, Stress

Strength Analysis using distributions, Monte Carlo Simulation,

Markov Models

2 FMEA and FMECA FMEA Basics, Guidelines for Severity, Occurrence and

Detection Ranking, RPN and prioritization for corrective action,

revised rating, FMEA team dynamics, Developing DVP&R,

Small Group Exercise

2 Reliability in Design S-N Curve, Stress Strength Analysis using distributions ,

Tolerance Analysis: Worst Case Analysis, RMS, Use of Monte

Carlo Simulation, Redundancy, Design for X, Derating

2 Human Factors and considerations Relationship between reliability and human factors,

consideration of these factors in designs.

2 Reliability Prediction Assuming equal failure rates and ARINC apportionment

technique,

3 Reliability Testing Reliability Test strategies and planning, Environmental

considerations, Sampling Plans, Success Run Theorem,

Probability Ratio Sequential Testing (PRST), Determination of

sample size for testing, Degradation Testing, Software Testing,

Stress Screening

3 Reliability Growth and FRACAS Duane Model, AMSAA model for reliability growth, Exercise(s),

Failure Reporting and Corrective Action System (FRACAS)

3 Accelerated Life Tests (ALT) Introduction to ALT, Modeling considerations, Arrhenius and

other Models, Step Stress Testing, Illustrations and Exercise(s)

3 Availability and Maintainability Definitions, Maintenance Strategies, Preventive and Corrective

Maintenance, Nondestructive evaluation, (Predictive

Maintenance), Maintenance Time Distributions, Spare Parts

Strategy, Reliability Centered Maintenance (RCM),

4 Inferential Statistics Basic concepts: Null & Alternate Hypotheses, Producer's and

consumer's risks, confidence level, point and interval estimates

Z, t, F, Chi-square etc.

4 Design of Experiments Plan and conduct Full Factorial Experiments, Fractional

Factorials, Taguchi Designs with noise factors (robust design)

5 Warranty Data Analysis Warranty terms and

conditions, uses and limitations of warranty

data.

5 Quiz/Test of comprehension

5 Closing remarks and wrap up Certificate distribution

Note: Agenda shown in indicative and may vary to some extent depending on participants

profiles.

Institute of Quality and Reliability R-05 CRE Dec 2009 Page 3 of 5

Faculty:

Mr. Hemant Urdhwareshe, Master Black Belt and Director Institute of

Quality and Reliability (IQR) is the principal faculty for the program.

He has more than 28 years of experience in Manufacturing, Quality

and Engineering at Cummins India Limited (CIL). As head of Quality,

Reliability and subsequently Engineering functions at CIL, he was

actively involved in driving reliability improvement programs. He has

applied various reliability tools in reducing product failures and solving

complex manufacturing and field problems. He has conducted many in-house training

programmes on Leadership, Quality Engineering and management at CIL and on behalf

of Indian Institution of Production Engineers (IIPE), Pune Section. He has also published

many articles on Six Sigma and quality engineering.

Hemant has conducted many in-house programs in reliability engineering at Tata

Motors, M&M, Behr, Ashok Leyland, Petronas (Malaysia) etc.. he has also conducted

numerous Six Sigma & DFSS Black/Green Belt Programmes for Fleetguard Filters,

TACO, Alfa Laval, Menon Pistons, Mahindray Hinoday, Eaton Techologies and Forbes

Marshall. He has also conducted Six Sigma Green Belt public workshops. He has

trained more than 350 Black and Green Belts.

Hemant is a visiting faculty at Symbiosis Institute of Business Management (SIBM),

Pune for Six Sigma and Business Statistics.

His book Six Sigma for Business Excellence is expected to be published in April 2010

by Pearson Education.

He is:

ASQ Certified Reliability Engineer (2005)

The first ASQ Certified Six Sigma Black Belt in India (2001)

The first ASQ Certified Quality Manager in India (1998)

ASQ Certified Quality Engineer (1996) and

The only person in India with four or more certifications from ASQ

Recipient of Silver Standard 2003 award from Qimpro Foundation

Senior Member of ASQ, Fellow of IIPE and member of National Center for

Quality Management. (NCQM).

Qualified Lead Assessor

Hemant will be supported by other competent faculties.

Course Material:

1. A copy of Certified reliability Engineer Handbook by Donald Benbow and Hugh

Broome published by ASQ (Subject to availability). This will be supplemented

with Comprehensive workshop material and Question Bank from IQR.

2. Many useful templates and data files by IQR

3. Fully functional trial version of useful software for reliability analysis.

Institute of Quality and Reliability R-05 CRE Dec 2009 Page 4 of 5

Course Fees:

Registration with payment on or before 25 January 2010:

1 2 or 3 4 or more

Price Per Participant 17100 16150 15200

Service Tax 1761 1663 1566

Total Payable per participant 18862 17813 16766

1 2 or 3 4 or more

Price Per Participant including tax 474 428 404

Price in US $

Number of Participants

Price in Indian

Rupees

Registration after 25 January 2010:

1 2 or 3 4 or more

Price Per Participant 18000 17000 16000

Service Tax 1854 1751 1648

Total Payable per participant 19855 18751 17648

1 2 or 3 4 or more

Price Per Participant including tax 499 450 425 Price in US $

Number of Participants

Price in Indian

Rupees

Payment:

Registration will be confirmed after payment by DD/Cheque payable at par in

favour of Institute of Quality and Reliability, Pune.

Cancellation Policy:

Registration can be cancelled till 31 January 2010. Fees paid will be refunded

after deducting Rs.2500. Cancellation after this date is not possible.

Registration can be transferred prior to start of the course at no extra cost.

Institute of Quality and Reliability R-05 CRE Dec 2009 Page 5 of 5

About Institute of Quality and Reliability:

Institute of Quality and Reliability (IQR) was established in Nov. 2005, with primary

objective to help Industries for improving their business performance. IQR also supports

individuals aspiring to improve their knowledge and skills in Quality and Reliability. After

28 years of rich industrial experience in the Industry, at Cummins India Ltd. (CIL),

Hemant Urdhwareshe decided to start IQR. So far IQR has trained more than 350 Six

Sigma Black/Green Belts and about 500 individuals in the field of Quality and Reliability.

For registration or more information Contact us:

Institute of Quality and Reliability,

Plot No.39, Shantiban Cooperative Housing Society,

Near Gandhi Bhavan,

Kothrud, Pune 411029.

Phone:91-20-25367952,

Hemant Urdhwareshe: 9822014488 (Send SMS with your name and email id

if call is not answered)

Learning Center is located at Paud Road, Pune.

Email: ioqr@world-class-quality.com

Web site: www.world-class-quality.com

We are proud to be associated with our Customers:

Semco Electric

S-ar putea să vă placă și

- Reliability EngineeringDocument5 paginiReliability Engineeringshivaprasadmvit100% (2)

- Cre Insert PDFDocument4 paginiCre Insert PDFFirdaus TahirÎncă nu există evaluări

- CRE TrainingDocument6 paginiCRE Trainingnack89Încă nu există evaluări

- CRE Exam Prep Course OnlineDocument8 paginiCRE Exam Prep Course OnlineAsadAliÎncă nu există evaluări

- Condition-based maintenance Complete Self-Assessment GuideDe la EverandCondition-based maintenance Complete Self-Assessment GuideÎncă nu există evaluări

- Reliability Centered Maintenance Rcm A Complete Guide - 2020 EditionDe la EverandReliability Centered Maintenance Rcm A Complete Guide - 2020 EditionÎncă nu există evaluări

- Plant Maintenance A Complete Guide - 2020 EditionDe la EverandPlant Maintenance A Complete Guide - 2020 EditionÎncă nu există evaluări

- Maintenance and Reliability Certification Exam GuideDe la EverandMaintenance and Reliability Certification Exam GuideEvaluare: 5 din 5 stele5/5 (2)

- Effective FMEAs: Achieving Safe, Reliable, and Economical Products and Processes using Failure Mode and Effects AnalysisDe la EverandEffective FMEAs: Achieving Safe, Reliable, and Economical Products and Processes using Failure Mode and Effects AnalysisEvaluare: 4 din 5 stele4/5 (1)

- Reliability, Maintainability and Risk: Practical Methods for EngineersDe la EverandReliability, Maintainability and Risk: Practical Methods for EngineersEvaluare: 4.5 din 5 stele4.5/5 (3)

- Basic Reliability Engineering Analysis: Butterworths Basic SeriesDe la EverandBasic Reliability Engineering Analysis: Butterworths Basic SeriesEvaluare: 4 din 5 stele4/5 (4)

- Reliability Assessment: A Guide to Aligning Expectations, Practices, and PerformanceDe la EverandReliability Assessment: A Guide to Aligning Expectations, Practices, and PerformanceÎncă nu există evaluări

- Predictive Maintenance A Complete Guide - 2021 EditionDe la EverandPredictive Maintenance A Complete Guide - 2021 EditionÎncă nu există evaluări

- Reliability, Maintainability and Risk: Practical Methods for Engineers including Reliability Centred Maintenance and Safety-Related SystemsDe la EverandReliability, Maintainability and Risk: Practical Methods for Engineers including Reliability Centred Maintenance and Safety-Related SystemsEvaluare: 4.5 din 5 stele4.5/5 (5)

- Workbook to Accompany Maintenance & Reliability Best PracticesDe la EverandWorkbook to Accompany Maintenance & Reliability Best PracticesEvaluare: 3.5 din 5 stele3.5/5 (3)

- CMMS computerized maintenance management system The Ultimate Step-By-Step GuideDe la EverandCMMS computerized maintenance management system The Ultimate Step-By-Step GuideÎncă nu există evaluări

- Mechanical ReliabilityDocument3 paginiMechanical ReliabilityAndre MarsÎncă nu există evaluări

- Reliability Centered Maintenance Rcm A Complete Guide - 2019 EditionDe la EverandReliability Centered Maintenance Rcm A Complete Guide - 2019 EditionÎncă nu există evaluări

- FMEA konkret: Preventive risk analysis concretely with FMEA plus. The series of successful developers, trainers and presenters.De la EverandFMEA konkret: Preventive risk analysis concretely with FMEA plus. The series of successful developers, trainers and presenters.Încă nu există evaluări

- Automotive Safety Integrity Level A Complete Guide - 2020 EditionDe la EverandAutomotive Safety Integrity Level A Complete Guide - 2020 EditionÎncă nu există evaluări

- Reliability Calculations: What, Why, When & How Do We Benefit From Them?Document16 paginiReliability Calculations: What, Why, When & How Do We Benefit From Them?b_shadid8399100% (1)

- Predictive Maintenance Plan A Complete Guide - 2020 EditionDe la EverandPredictive Maintenance Plan A Complete Guide - 2020 EditionÎncă nu există evaluări

- Benchmarking Best Practices in Maintenance ManagementDe la EverandBenchmarking Best Practices in Maintenance ManagementÎncă nu există evaluări

- The Death of Reliability: Is it Too Late to Resurrect the Last, True Competitive Advantage?De la EverandThe Death of Reliability: Is it Too Late to Resurrect the Last, True Competitive Advantage?Încă nu există evaluări

- Failure Mode Effects and Criticality Analysis A Clear and Concise ReferenceDe la EverandFailure Mode Effects and Criticality Analysis A Clear and Concise ReferenceÎncă nu există evaluări

- Managing Risk and Reliability of Process PlantsDe la EverandManaging Risk and Reliability of Process PlantsEvaluare: 5 din 5 stele5/5 (5)

- Benchmarking Best Practices for Maintenance, Reliability and Asset ManagementDe la EverandBenchmarking Best Practices for Maintenance, Reliability and Asset ManagementÎncă nu există evaluări

- Software Validation A Complete Guide - 2020 EditionDe la EverandSoftware Validation A Complete Guide - 2020 EditionÎncă nu există evaluări

- RCM3: Risk-Based Reliability Centered MaintenanceDe la EverandRCM3: Risk-Based Reliability Centered MaintenanceEvaluare: 1 din 5 stele1/5 (1)

- The ASQ Pocket Guide to Failure Mode and Effect Analysis (FMEA)De la EverandThe ASQ Pocket Guide to Failure Mode and Effect Analysis (FMEA)Încă nu există evaluări

- Preventive Maintenance A Complete Guide - 2019 EditionDe la EverandPreventive Maintenance A Complete Guide - 2019 EditionÎncă nu există evaluări

- The RCM Solution: A Practical Guide to Starting and Maintaining a Successful RCM ProgramDe la EverandThe RCM Solution: A Practical Guide to Starting and Maintaining a Successful RCM ProgramEvaluare: 5 din 5 stele5/5 (1)

- Engineering Maintainability:: How to Design for Reliability and Easy MaintenanceDe la EverandEngineering Maintainability:: How to Design for Reliability and Easy MaintenanceEvaluare: 1 din 5 stele1/5 (1)

- Reliability Analysis of Dynamic Systems: Efficient Probabilistic Methods and Aerospace ApplicationsDe la EverandReliability Analysis of Dynamic Systems: Efficient Probabilistic Methods and Aerospace ApplicationsÎncă nu există evaluări

- What Should A Reliability Engineer RE Actually Do and Know Bennie Oosthuizen and Arnold Botha PDFDocument25 paginiWhat Should A Reliability Engineer RE Actually Do and Know Bennie Oosthuizen and Arnold Botha PDFgersonmorais100% (1)

- List of Reliability StandardsDocument7 paginiList of Reliability Standardsmzai2003Încă nu există evaluări

- Introduction to Mechatronics and Measurement SystemsDocument1 paginăIntroduction to Mechatronics and Measurement SystemsDevendra BangarÎncă nu există evaluări

- Partial Stoke TestingDocument13 paginiPartial Stoke TestingDevendra BangarÎncă nu există evaluări

- TiN Coating Best for Valves in Severe ApplicationsDocument1.635 paginiTiN Coating Best for Valves in Severe ApplicationsDevendra BangarÎncă nu există evaluări

- Valve AttributesDocument4 paginiValve AttributesDevendra BangarÎncă nu există evaluări

- Waste 1 AXAXDocument880 paginiWaste 1 AXAXDevendra BangarÎncă nu există evaluări

- SdadgDocument13 paginiSdadgDevendra BangarÎncă nu există evaluări

- Matrix Material SelectionDocument3 paginiMatrix Material SelectionDevendra BangarÎncă nu există evaluări

- Chapter4 Allowable StresseDocument26 paginiChapter4 Allowable StresseDevendra BangarÎncă nu există evaluări

- Partial Stoke TestingDocument13 paginiPartial Stoke TestingDevendra BangarÎncă nu există evaluări

- Waste ZZXZDocument1.719 paginiWaste ZZXZDevendra BangarÎncă nu există evaluări

- Waste ZZXASDocument1.854 paginiWaste ZZXASDevendra BangarÎncă nu există evaluări

- Waste 10Document479 paginiWaste 10Devendra BangarÎncă nu există evaluări

- Waste 1 ASCQ2Document1.584 paginiWaste 1 ASCQ2Devendra BangarÎncă nu există evaluări

- Worthless 1 ADocument154 paginiWorthless 1 ADevendra BangarÎncă nu există evaluări

- packing length formula and installation guideDocument2 paginipacking length formula and installation guideDevendra BangarÎncă nu există evaluări

- Worthless 99999Document47 paginiWorthless 99999Devendra BangarÎncă nu există evaluări

- Packing 111Document45 paginiPacking 111Devendra BangarÎncă nu există evaluări

- Worthless 99Document43 paginiWorthless 99Devendra BangarÎncă nu există evaluări

- Worthless 1Document285 paginiWorthless 1Devendra BangarÎncă nu există evaluări

- Waste 4Document47 paginiWaste 4Devendra BangarÎncă nu există evaluări

- Fire Safe Nickel Aluminium Bronze ValvesDocument51 paginiFire Safe Nickel Aluminium Bronze ValvesDevendra BangarÎncă nu există evaluări

- Nothing 2Document7 paginiNothing 2Devendra BangarÎncă nu există evaluări

- Waste 10Document424 paginiWaste 10Devendra BangarÎncă nu există evaluări

- Fire-Safe Triple Offset Butterfly ValveDocument22 paginiFire-Safe Triple Offset Butterfly ValveDevendra BangarÎncă nu există evaluări

- HOON TobvDocument16 paginiHOON TobvDevendra BangarÎncă nu există evaluări

- Waste 4Document45 paginiWaste 4Devendra BangarÎncă nu există evaluări

- The Cryogenic Valve: Why Use Triple Offset Technology?Document40 paginiThe Cryogenic Valve: Why Use Triple Offset Technology?Devendra BangarÎncă nu există evaluări

- Valve Vala NewsDocument2 paginiValve Vala NewsDevendra BangarÎncă nu există evaluări

- Hobbs Tobv NewsDocument9 paginiHobbs Tobv NewsDevendra BangarÎncă nu există evaluări

- ICT 34 Data Structures and Analysis of AlgorithmDocument9 paginiICT 34 Data Structures and Analysis of AlgorithmKimondo KingÎncă nu există evaluări

- Digital Circuits and Logic Design Lecture OverviewDocument42 paginiDigital Circuits and Logic Design Lecture Overviewramanaidu1Încă nu există evaluări

- MySQL Triggers GuideDocument21 paginiMySQL Triggers Guidesatya prakash singhÎncă nu există evaluări

- p328.07x - Vogue Wireless Charging Speaker 2Document28 paginip328.07x - Vogue Wireless Charging Speaker 2Georgie SÎncă nu există evaluări

- Ns-Jsra: Risk Type: Risk TypeDocument6 paginiNs-Jsra: Risk Type: Risk TypeMarco MotaÎncă nu există evaluări

- Chapter 1 - IntroductionDocument29 paginiChapter 1 - Introductionsibhat mequanintÎncă nu există evaluări

- Project ChiptopDocument39 paginiProject ChiptopNikita Patel086Încă nu există evaluări

- Bus Bar and LBB Protection PDFDocument33 paginiBus Bar and LBB Protection PDFAlind Dubey100% (5)

- It SecurityDocument285 paginiIt SecuritySUSOVAN GARAIÎncă nu există evaluări

- Toughpad Fz-G1 Atex: Atex A Zone 2 Certified Fully Rugged Windows 10 Pro TabletDocument2 paginiToughpad Fz-G1 Atex: Atex A Zone 2 Certified Fully Rugged Windows 10 Pro TabletTop5 In VietnamÎncă nu există evaluări

- 75 GPD RO Membrane SelectionDocument2 pagini75 GPD RO Membrane SelectionKesavan RÎncă nu există evaluări

- Cryptography and Network Security: Third Edition by William Stallings Lecture Slides by Lawrie BrownDocument26 paginiCryptography and Network Security: Third Edition by William Stallings Lecture Slides by Lawrie BrownHabhaile AsfawÎncă nu există evaluări

- Project Report on Just-In-Time Manufacturing SystemDocument70 paginiProject Report on Just-In-Time Manufacturing SystemKrishna Sharma100% (1)

- If A Pedestrian Is Hit and Lands On The Front of The Car, The Airbag InflatesDocument1 paginăIf A Pedestrian Is Hit and Lands On The Front of The Car, The Airbag InflatesYu SunÎncă nu există evaluări

- CJ - CP 300 IM 10052125-AC EnglishDocument26 paginiCJ - CP 300 IM 10052125-AC EnglishFarissa ACHIROU ALASSANEÎncă nu există evaluări

- Python Library ReferenceDocument92 paginiPython Library ReferenceaawaakÎncă nu există evaluări

- What Is Amplitude ModulationDocument15 paginiWhat Is Amplitude ModulationRachhan Khorn100% (1)

- YOGENDocument1 paginăYOGENYogendranÎncă nu există evaluări

- 0152 - Interational Confrence On 1200kV National Test StationDocument346 pagini0152 - Interational Confrence On 1200kV National Test StationsreejitvpÎncă nu există evaluări

- ECE 124 Week 7 ReviewDocument55 paginiECE 124 Week 7 Reviewjahnavi thotaÎncă nu există evaluări

- Tidud62 PDFDocument30 paginiTidud62 PDFAnonymous OFwyjaMyÎncă nu există evaluări

- L OCALdb EXTRACTDocument37 paginiL OCALdb EXTRACTMohiuddin BabanbhaiÎncă nu există evaluări

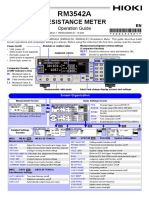

- Resistance Meter: Operation GuideDocument2 paginiResistance Meter: Operation GuideEko SutjiptoÎncă nu există evaluări

- Qas 125-150 Vod (LS)Document2 paginiQas 125-150 Vod (LS)Sico LabenÎncă nu există evaluări

- The Ages of Globalization Geography Technology and Institutions by Jeffrey D. SachsDocument316 paginiThe Ages of Globalization Geography Technology and Institutions by Jeffrey D. SachsJesus Rubio50% (2)

- EE021 - Sub-Station Earth Grid DesignDocument4 paginiEE021 - Sub-Station Earth Grid DesignbhavikÎncă nu există evaluări

- MDS Report for PTFE TubeDocument3 paginiMDS Report for PTFE TubeyatheendravarmaÎncă nu există evaluări

- Datasheet IC 3771 PDFDocument20 paginiDatasheet IC 3771 PDFekodianirawanto100% (1)

- Selenium Suresh V004Document139 paginiSelenium Suresh V004tester mahesh25Încă nu există evaluări

- A7800 PDFDocument9 paginiA7800 PDFkarkonÎncă nu există evaluări