Documente Academic

Documente Profesional

Documente Cultură

Complete 32,000 ton/yr Sodium Cyanide Plant

Încărcat de

Frank Mtetwa0 evaluări0% au considerat acest document util (0 voturi)

298 vizualizări9 paginiThe document describes a 32,000 ton/yr sodium cyanide plant that produces high quality sodium cyanide liquor. The plant converts natural gas, ammonia, and air into hydrogen cyanide using a catalyst. The hydrogen cyanide is then reacted with sodium hydroxide to produce sodium cyanide liquor. The liquor is purified through processes like liming and filtration to remove impurities. The plant can produce 32,600 tonnes per year of sodium cyanide liquor in different grades for storage and export.

Descriere originală:

gold process

Titlu original

NaCN Process Description

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThe document describes a 32,000 ton/yr sodium cyanide plant that produces high quality sodium cyanide liquor. The plant converts natural gas, ammonia, and air into hydrogen cyanide using a catalyst. The hydrogen cyanide is then reacted with sodium hydroxide to produce sodium cyanide liquor. The liquor is purified through processes like liming and filtration to remove impurities. The plant can produce 32,600 tonnes per year of sodium cyanide liquor in different grades for storage and export.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

298 vizualizări9 paginiComplete 32,000 ton/yr Sodium Cyanide Plant

Încărcat de

Frank MtetwaThe document describes a 32,000 ton/yr sodium cyanide plant that produces high quality sodium cyanide liquor. The plant converts natural gas, ammonia, and air into hydrogen cyanide using a catalyst. The hydrogen cyanide is then reacted with sodium hydroxide to produce sodium cyanide liquor. The liquor is purified through processes like liming and filtration to remove impurities. The plant can produce 32,600 tonnes per year of sodium cyanide liquor in different grades for storage and export.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 9

Complete 32,000 ton/yr Sodium Cyanide (NaCN) Plant

with Super High Quality Liquor production

The Sodium Cyanide (NaCN) plant produces HCN Irom methane, ammonia and air. The HCN

is then reacted with caustic soda (50 NaOH) to produce a sodium cyanide liquor oI

approximately 30 - 32 NaCN. The liquor is puriIied and diluted to 30 Ior sale.

The plant is capable oI producing approximately 18,000 tonnes per annum oI HCN which is

converted directly to 32,600 tonnes per annum oI NaCN.

Process Chemistry

In the HCN converter stage a gaseous mixture oI ammonia, natural gas and air is passed over

the noble metal catalyst where the ammonia and natural gas react exothermically to Iorm HCN:

NH

3

CH

4

! HCN 3H

2

Approximately 60 65 oI the reagent gasses react as above. OI the remaining ammonia,

approximately 50 passes through unreacted and the other 50 breaks down to nitrogen and

hydrogen.

Virtually all oI the natural gas not converted to HCN is partially or completely combusted in

air to produce CO

2

, H

2

O and CO. All unreacted gasses, along with the side reaction products,

are sent to the main plant stack Ior Ilaring.

The HCN is removed Irom the gas stream by passing through NaCN liquor containing excess

NaOH. Some CO

2

is absorbed at this stage producing sodium carbonate (Na

2

CO

3

).

HCN NaOH ! NaCN H

2

0

C0

2

2NaOH ! Na

2

C0

3

H

2

0

At this point in the process some oI the unlimed NaCN liquor is Ied to the No.2,3 and 4 Stock

Tanks, this is known as standard grade liquor.

The liming process is used to convert soluble Na

2

CO

3

to insoluble calcium carbonate (CaCO

3

).

This is removed by Iiltration.

Na

2

CO

3

Ca(OH)

2

! CaCO

3

2NaOH

The Iiltered liquor is known a high quality liquor. A higher grade oI sodium cyanide known as

Super High Quality Liquor (SHQL) is also produced in the sodium cyanide plant by reacting

liquid HCN Irom HCN6 with 50 sodium hydroxide solution.

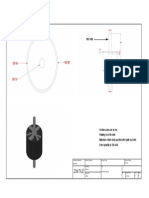

Process Flow Diagram

A simpliIied Ilow diagram oI the NaCN plant is shown in Iig 2.3.1.

Process Inputs

Natural Gas

Natural gas is supplied to the NaCN plant by pipeline Irom site distribution system.

Hvdrocvanic Acid (HCN)

HCN used Ior Super High Quality Liquor production is manuIactured in the HCN6 plant. It is

imported to the NaCN plant by pipeline to the evaporator section via the ACH3 plant.

Note: The manuIacture, import and central storage oI HCN is covered in the HCN6 document

which Iorms part oI this application.

Ammonia

Gaseous ammonia is imported by pipeline.

50 NaOH Solution

Caustic Soda is delivered by road tanker and is stored on the NaCN Plant.

Sodium Hvpochlorite Solution

Sodium hypochlorite is delivered by road tanker and stored to the South side oI the NaCN

plant.

Catalvst

The noble metal catalyst bed, Ior the conversion oI natural gas and ammonia to HCN, is

replaced approximately every 6 months.

Lime

Lime (calcium hydroxide) is imported by road tanker and stored on the NaCN plant.

Water

There are several sources oI water used on the NaCN plant:

Demineralised water is used Ior the dilution oI NaCN liquor to the correct strength and to Ieed

the waster heat boiler.

Process Description

Overview (see fig. 2.3.1)

The plant produces HCN by the catalytic conversion oI ammonia and natural gas in an air

stream. The HCN, combined with liquid HCN receipts by pipeline, is reacted with 50 sodium

hydroxide solution to produce sodium cyanide liquor oI approximately 30 NaCN.

Conversion and Waste Heat Recoverv

In the converter, the mixed gases react exothermically to produce HCN (and hydrogen) on a

platinum-rhodium gauze catalyst that operates at a pressure oI 1.3 barg and a temperature oI

950 1050

o

C. Side reactions produce carbon monoxide and carbon dioxide. The hot gases

exit the converter and are used to generate steam at a pressure oI 21.7 barg in a waste heat

boiler. Further cooling occurs with heat exchange with the boiler Ieed water in an economiser.

The process gas, containing about 8 by volume oI HCN and 2 oI unreacted ammonia is

passed to the HCN absorber at a temperature oI at least 100

o

C and a pressure oI about

70mbarg.

HCN Absorption

The HCN produced in the converter is absorbed in the HCN absorber, using 50 NaOH, to

produce NaCN liquor. An excess oI NaOH in the liquor is necessary to prevent localised HCN

polymerisation. The absorption process also produces sodium carbonate (Na

2

CO

3

) by the

reaction oI carbon dioxide by-product with NaOH. The Na

2

CO

3

is removed in the liming and

Iiltration stage. The HCN absorber exit gases, now depleted in HCN, pass to the main plant

stack where they are burnt.

Liming and Filtration

The 30 w/w sodium cyanide liquor made in the HCN absorber contains between 0.6 and

1.15 w/w sodium carbonate. This is removed Irom the liquor by the addition oI 60-175 kg/h

calcium hydroxide (lime). The lime addition rate depends on the liquor rate and on the sodium

carbonate concentration. Calcium carbonate is precipitated and is removed Irom the liquor by

a rotary vacuum Iilter (Rovac). The sodium carbonate level is reduced to between 0.1 and

0.3 w/w. The Iilter cake is washed with water to remove the bulk oI the cyanide liquor beIore

being discharged to the toxic eIIluent treatment section Ior neutralisation.

The vacuum driving Iorce Ior the Rovac is applied to the metaIilter Ieed tank using the Nash

Vacuum pump that exhausts directly to atmosphere. The liquor is then pumped to one oI two

polishing Iilters (metaIilters) in order to reduce colour and remove any Iines that passed

through the Rovac. The sodium cyanide liquor, now substantially Iree oI carbonate, is pumped

to cyanide liquor storage via a cooler to minimise hydrolysis oI the cyanide to Iormate.

Evaporation

No.2 Evaporator, the smaller oI the two at about 60te capacity, is used to produce Super High

Quality liquor, a purer sodium cyanide liquor using liquid HCN imported Irom the ACH3

HCN storage. This is a batch process using a vessel previously used to produce solid sodium

cyanide. Due to the high oIItake oI the recirculation loop on the vessel, it must be Iirst Iilled

with demineralised water and a heel oI caustic to establish a working level. HCN and 50

caustic are then Ied to Iorm sodium cyanide liquor.

Steam is applied to the circulation loop to evaporate water purely to control the level in the

vessel.

Vacuum is applied to the vessel, using steam ejectors, to minimise hydrolysis oI the cyanide to

Iormate and ammonia. The circulation loop must be maintained to ensure correct control over

the HCN/caustic reaction. Loss oI vacuum, caustic Ilow, high level low level or recirculation

Ilow trips the HCN Ieed.

The evaporator overheads (water and a low levels oI HCN) are condensed and Ied straight to

the eIIluent treatment system.

The product liquor is pumped directly to stock tanks in the liquor storage area.

NaCN Liquor Storage

There are 9 storage tanks in this area, each one set aside Ior storage oI a particular grade oI

liquor. The maximum liquor storage capacity is 1615 tonnes. Each storage tank is Iitted with

a level indicator and an independent high level alarm.

Tank No. Contents

2, 3 & 4 These tanks are used to store Standard grade liquor. (unlimed)

5 Used Ior the storage oI limed, low carbonate liquor Ior recycle to

the HCN Absorber

6 & 7 Used Ior super high quality grade liquor storage.

8 & 9 Storage oI high quality liquor. Like evaporator Ieed liquor. This

liquor has been passed through the liming section and contains

less impurities than standard liquor.

Shutdown Tank This tank is kept empty and is used to drop the contents oI either

evaporator iI a leak oI NaCN develops. The tank is sized to take

the Iull contents oI either evaporator.

From here all grades oI liquor are loaded to road tankers at the NaCN liquor tanker Iilling

depot.

NaCN Liquor Tanker Filling

NaCN liquor is exported as a product in road tankers. Which are Iilled by selecting a tank and

pumping liquor into the top oI the barrel. The total Ilow oI liquor is automatically controlled by

means oI a batchmeter. The area is continuously manned during tanker Iilling operations.

Effluent Treatment

The eIIluent treatment Iacility receives and treats the continuous purges reIerred to in previous

above, and any washings, leaks and spillages which may arise on the NaCN plant and liquor

storage and tanker loading area. Additionally, the Iacility also receives batches oI eIIluent

arising Irom other process areas, these are

! ACH3 and ACH4 cubicle secondary containment sumps

! Purge Irom the HCN still at HCN6, iI too high in HCN to be discharged to BB06

All eIIluent Irom the above areas remote Irom the sodium cyanide plant itselI is pumped

slowly to the eIIluent treatment system. II there is a problem with the eIIluent treatment

system, e.g. due to increased load Irom the sodium cyanide plant, the transIers are stopped

immediately.

The alkaline cyanide eIIluent is treated with 10-15 sodium hypochlorite solution in Iour

stirred vessels in series. The sodium hypochlorite solution reacts with cyanide to Iorm the less

toxic cyanate. The treated eIIluent, containing less than 10 ppm oI cyanide, Ilows to drain

where, aIter mixing with other eIIluents, it is discharged via a consented outIall, BB03, to

Billingham Beck.

The hypochlorite storage consists oI 3 tanks, with a total storage capacity oI 250 tonnes, Iilled

Irom road tankers, Irom which sodium hypochlorite Ilows to the treatment vessels by gravity.

The Ilows are continuously measured, a high Ilow being indicative oI an abnormally high loss

oI cyanide.

II the treatment Iacility is in danger oI being overwhelmed by a sudden large increase in

cyanide load or iI the treatment process Iails to Iunction, then the operator may divert the

eIIluent leaving the Iourth (Iinal sump) into a large (300 m3) secondary containment pit whilst

the problem is being attended to. Later, the contents oI the pit can be pumped back into the

eIIluent treatment system Ior re-treatment. As there are eH analysers in each sump, iI there is a

spillage the operator will have many warnings beIore the eIIluent reaches BB03. The Iirst

sump will have high cyanide and then the second, third and Iinally the Iourth. When this

sequence starts to happen the operator will divert the eIIluent stream to the secondary

containment pit.

The secondary containment pit has suIIicient capacity to contain all oI the liquor released Irom

a catastrophic Iailure oI the largest vessel on the sodium cyanide plant.

Caustic Storage and Dilution.

The 50 w/w sodium hydroxide solution used in the absorber and evaporators on the sodium

cyanide plant is stored in a series oI tanks on the sodium cyanide plant.

The 50 w/w caustic is imported in road tankers and oIIloaded directly into 3 linked tanks

with a 225te capacity. From these tanks the 50 caustic is pumped into a 20te capacity

dilution tank located in the storage area where the caustic is diluted to give a 25 w/w solution

by the addition oI soItened water. This 25 caustic solution is used on the eIIluent treatment

sections oI the Monomer 7 and Monomer 8 complexes.

An operator Irom the sodium cyanide plant is always present during oII-loading operations.

Drainage Svstems

All eIIluent Irom the sodium cyanide plant, liquor storage and tanker loading area passes Iirst

through the eIIluent treatment system beIore being discharged via outIall BBO3. All

additional eIIluent streams which are pumped to the sodium cyanide plant eIIluent treatment

system will also discharge to BBO3

Any eIIluents arising Irom the caustic import depot will be discharged to BBO3 via the

eIIluent treatment system.

Process Outputs

NaCN Liquor

Liquor is exported as 30 NaCN in three Iorms, standard (unlimed), high quality and super

high quality which has a lower concentration oI contaminants.

NaCN Plant Control Philosophy

The NaCN plant is operated on a continuous basis and controlled and monitored Irom a

Distributed Control System (DCS). Minimum operator intervention is required under normal

operation.

Absorption oI HCN into caustic soda is the critical step which determines the eIIiciency oI

HCN recovery and avoids HCN being burnt. Consequently it is essential that the HCN

absorber liquor is always circulating and is always alkaline. The Ilow oI Iresh caustic soda

solution to the Centre oI the tower is ratioed to the converter load. pH control oI the circulating

liquor adjusts the Ilow oI trim caustic to the recirculation line. The recirculation Ilow is set at

200 m3/hr.

II either the absorber circulation pump or caustic Ieed pump Iails, an alarm is generated and the

operator shuts the plant down immediately. II there is any delay in this action, the liquor inside

the vessel will turn black within 3 minutes Irom HCN polymerisation and the gases Irom he

converter will be burnt in the stack. A runaway HCN reaction could not occur as the solubility

oI HCN in aqueous solutions containing ammonia is very low (1 W/W) and the water

would remove the heat oI reaction. ThereIore, the loss oI caustic supply to the HCN Absorber

is considered to be a product quality issue and not a saIety issue.

Ancillaries

HCN Pipeline and Plant Cubicles

The HCN pipeline enables liquid HCN to be transIerred Irom HCN storage at the ACH3 plant,

directly into the evaporation section Ior use in SHQL production. There is no HCN storage on

the NaCN plant. All Ilanges, joints, valves, etc. in this pipeline are located in HCN cubicles.

On shutdown, the pipework local to the evaporators is washed out by an automatic washing

system sequence using hot water. The hot water Ilushes the HCN Ilow control system through

to the evaporators. II the shutdown is prolonged then the entire pipeline Irom ACH3 to the

evaporators is Ilushed through.

An HCN cubicle comprises oI an enclosure whose purpose is to conIine any conceivable

spillage or leak. Any volatile material spilled or otherwise released within a cubicle is

extracted by a Ian and discharged via a stack at height where its release into the atmosphere is

designed to avoid a signiIicant hazard to individuals, either inside or outside the site

boundaries.

The cubicle vent Ian is operated continuously and it is treated as local exhaust ventilation in

terms oI operational checks. The cubicle vent stacks are continuously monitored Ior the

presence oI HCN. The cubicles are provided with sumps to contain any liquid spillages.

Decontamination Area

The courtyard oI the NaCN plant is used Ior decontaminating all materials/equipment that

leaves the works. All washings drain to the eIIluent treatment section.

2.3.1 Control of Point Source emissions to Air

To ensure that the emissions to air remain insigniIicant, besides applying the BAT Ior

Management Techniques, the Iollowing are speciIic to the plant:

1. The major emissions to air are to the plant stack, which is lit continuously to burn any

ammonia or HCN that may slip through the conversion and absorption process. The plant

Ilare has been demonstrated to have a combustion eIIiciency oI 99.17. II the Ilare cannot

be lit within an hour the plant is shutdown.

2. Monitoring and control oI various temperatures in the main process equipment helps

minimise emissions, by ensuring the process operates eIIiciently. Key process eIIiciency

measurements are continually monitored.

3. Two cooling water condensers minimise discharges via the evaporator ejector vent.

4. The Ilanges and valves Ior the HCN pipeline are contained within ventilated cubicles

which discharge via vents at height, which reduces the ground level concentration oI

components. The cubicle vents are constantly monitored Ior HCN and have high

concentration alarms and trips.

2.3.2 Abatement of Point Source emissions to surface water and sewer

All liquid Ilows and the slurry Irom the Iiltration section oI the plant are channelled to the

cyanide eIIluent treatment section via a series oI drains and gulleys on each Iloor oI the plant.

Any cyanide present is destroyed by reaction with sodium hypochlorite to produce sodium

cyanate, in Iour stirred treatment pits in series.

The addition oI sodium hypochlorite to each sump is automatically controlled using an

analyser that measures the extent oI the cyanide destruction reaction by means oI eH

measurement oI the redox potential.

Emissions reaching the drain then Ilow to BB03 outIall. The Plant operation complies with its

permit to operate, and there are no emissions to public sewers. BB03 is the outIall route Ior the

cyanide eIIluent treatment plant as well as stormwater run-oII Irom site roads, the site

laboratories and the site restaurant. In addition scour water` is added to ensure that there is

suIIicient velocity in the drain to ensure that the suspended solids do not settle out, which

could ultimately lead to blockages. When the plant is not operational the scour water` is

isolated.

II the treatment Iacility is in danger oI being overwhelmed by a sudden large increase in

cyanide load or iI the treatment process Iails to Iunction the operator can divert the eIIluent.

The Ilow leaving the Iourth (and Iinal) sump can be directed into a large (300 m

3

) secondary

containment pit, whilst the problem is rectiIied. The contents oI the pit can then be pumped

back into the eIIluent treatment system.

1.

2.

The eIIluent is diverted by means oI a large valve, remotely operated Irom the sodium cyanide

control room, which when closed blocks the drain. The eIIluent then overIlows via a weir into

the secondary containment pit. It takes three minutes Ior the diversion valve to move Irom Iully

open to the Iully closed position. II the diversion valve Iails to close, identiIied Irom the valve

position indicator in the control room, the operator is required to operate the valve manually.

The operation oI this valve is tested on a regular basis by the plant operating team.

The secondary containment pit has suIIicient capacity to contain all the liquor released Irom

the catastrophic Iailure oI the largest vessel on the sodium cyanide plant. Continuous

monitoring oI the outIall Ior consented analytes and alarm values at warning limits ensures that

the diversion valve is closed soon enough to prevent consents being breached.

Improvement programme

To ensure that the emissions to water remain insigniIicant, besides applying the BAT Ior

Management Techniques, the Iollowing are speciIic to the plant

All storage tanks are located within bunds. The tanks are equipped with high level

alarms and independent high level trips which stop the Ieed into the tanks.

HCN liquor is not stored on the NaCN Plant but is imported as required Irom the HCN

Plants.

2.3.5 Odour Control

Ammonia, Nitrogen Dioxide and Chlorine are the components released Irom the process that

have the potential risk oI an odour emission. Ammonia and NO2 are released Irom the main

plant stack which beneIits Irom height and temperature to aid dispersion. Ammonia and

Chlorine are present in other intermittent process vents and in the storage tanks where they are

present in extremely low concentrations when compared with the odour threshold value. As the

compounds are part oI a mixture the actual emission concentration should be converted to

odour units. This would require the emission to be captured and tested by an odour panel

however as the odour risk is believed to be low this characterisation is believed to be

unnecessary. The measures taken to limit the releases are described in section 2.3.1.

S-ar putea să vă placă și

- Introduction To Chemical Reactions and Equations: John Paul A. Reponte General Chemistry 1 STEM - Grade 11Document20 paginiIntroduction To Chemical Reactions and Equations: John Paul A. Reponte General Chemistry 1 STEM - Grade 11Hillary MarieÎncă nu există evaluări

- Anic Chemistry ReviewDocument59 paginiAnic Chemistry ReviewEnrica GaÎncă nu există evaluări

- Study Material on Concentration of Ores and Extraction of MetalsDocument15 paginiStudy Material on Concentration of Ores and Extraction of MetalsitishaÎncă nu există evaluări

- The Synthesis of Organic CompoundsDocument96 paginiThe Synthesis of Organic CompoundsDoroteo Jose StationÎncă nu există evaluări

- MSM Cut Detection GuideDocument11 paginiMSM Cut Detection Guidebillzebub2-30% (1)

- How To Make Nitrogen FertilizerDocument12 paginiHow To Make Nitrogen FertilizerAndrea KakuruÎncă nu există evaluări

- Factors of Active Citizenship EducationDocument2 paginiFactors of Active Citizenship EducationmauïÎncă nu există evaluări

- Liquid Dishwashing SoapDocument6 paginiLiquid Dishwashing Soapranjeet kumar100% (1)

- Liquid Dishwashing SoapDocument6 paginiLiquid Dishwashing Soapranjeet kumar100% (1)

- R&S ARGUS Monitoring Software GuideDocument54 paginiR&S ARGUS Monitoring Software GuideVio ViorelÎncă nu există evaluări

- Pre-Med Organic & Physical Chemistry GuideDocument22 paginiPre-Med Organic & Physical Chemistry GuideNeayzahn AcesSkaÎncă nu există evaluări

- Salvia Divinorum Extractions Using Chilled Acetone PDFDocument13 paginiSalvia Divinorum Extractions Using Chilled Acetone PDFChristoph EderÎncă nu există evaluări

- HofmannDocument12 paginiHofmannDavidek VeverkaÎncă nu există evaluări

- How To Make DIY Activated Charcoal For Prepping and SurvivalDocument35 paginiHow To Make DIY Activated Charcoal For Prepping and SurvivalIsrael SalubiÎncă nu există evaluări

- AcidDocument12 paginiAcidpacman10112Încă nu există evaluări

- Cyano Compounds Article with Color FiguresDocument38 paginiCyano Compounds Article with Color FiguresRasoulÎncă nu există evaluări

- Chemistry Vol.2 Figures Class 12Document60 paginiChemistry Vol.2 Figures Class 12Sasidaran SasiÎncă nu există evaluări

- Detection and Localization of Wireless Jammer Using XBee ModuleDocument3 paginiDetection and Localization of Wireless Jammer Using XBee ModuleEditor IJRITCCÎncă nu există evaluări

- Arclightshroom's 4 Aco DMT WorkDocument6 paginiArclightshroom's 4 Aco DMT Workj.pedrogomes84Încă nu există evaluări

- Mine SynthesisDocument3 paginiMine SynthesisriskobinskoÎncă nu există evaluări

- Job Order Costing: Patrick Louie E. Reyes, CTT, Micb, Rca, CpaDocument45 paginiJob Order Costing: Patrick Louie E. Reyes, CTT, Micb, Rca, CpaClaudette Clemente100% (1)

- Embryology-Nervous System DevelopmentDocument157 paginiEmbryology-Nervous System DevelopmentGheavita Chandra DewiÎncă nu există evaluări

- EXP.2 Enzyme Extraction From BacteriaDocument3 paginiEXP.2 Enzyme Extraction From BacteriaLinhNguyeÎncă nu există evaluări

- New Magicks For A New Age: Bibliography Book 2Document123 paginiNew Magicks For A New Age: Bibliography Book 2Polaris93Încă nu există evaluări

- 8A Vimshottari LogevityDocument5 pagini8A Vimshottari Logevityanon-76832Încă nu există evaluări

- Richard Young and Richard A. Glennon - Cocaine-Stimulus Generalization To Two New Designer Drugs: Methcathinone and 4-MethylaminorexDocument3 paginiRichard Young and Richard A. Glennon - Cocaine-Stimulus Generalization To Two New Designer Drugs: Methcathinone and 4-MethylaminorexFedrmÎncă nu există evaluări

- The Basement Chemistry of GoldDocument48 paginiThe Basement Chemistry of GoldPredrag MladenovicÎncă nu există evaluări

- Marshall Stability Test AnalysisDocument5 paginiMarshall Stability Test AnalysisZick Zickry50% (2)

- Acids and AlkalisDocument33 paginiAcids and AlkalisLubna ErumÎncă nu există evaluări

- Trash To Treasure.: Food Living Outside Play Technology WorkshopDocument10 paginiTrash To Treasure.: Food Living Outside Play Technology Workshopx spaceÎncă nu există evaluări

- Ethyl Acetate SynthesisDocument1 paginăEthyl Acetate SynthesisJi ChemÎncă nu există evaluări

- NaCN Process Description PDFDocument9 paginiNaCN Process Description PDFEncepMuhammadIlyasÎncă nu există evaluări

- Analysis Sildenafil Citrate Dapoxetin HPLC UVDocument52 paginiAnalysis Sildenafil Citrate Dapoxetin HPLC UVUnor Known100% (1)

- Organic Chem Lab FDocument33 paginiOrganic Chem Lab FRanjith Kumar mÎncă nu există evaluări

- Propagation With Ultra Sonic FogDocument4 paginiPropagation With Ultra Sonic FogAlexandru BanicaÎncă nu există evaluări

- Aniline Process DescriptionDocument13 paginiAniline Process Descriptionkeyur1109100% (3)

- Thermite and IceDocument3 paginiThermite and IceAlissa GayÎncă nu există evaluări

- History of Microfinance in NigeriaDocument9 paginiHistory of Microfinance in Nigeriahardmanperson100% (1)

- Audi Q5: First Generation (Typ 8R 2008-2017)Document19 paginiAudi Q5: First Generation (Typ 8R 2008-2017)roberto100% (1)

- Materials: Calculation of Cement Composition Using A New Model Compared To The Bogue ModelDocument20 paginiMaterials: Calculation of Cement Composition Using A New Model Compared To The Bogue ModelFrank MtetwaÎncă nu există evaluări

- Prac Res Q2 Module 1Document14 paginiPrac Res Q2 Module 1oea aoueoÎncă nu există evaluări

- NHTDocument6 paginiNHTPadarthi Venkateswarlu50% (2)

- 4 Influencing Factors of Learners Career Choice Parents Choice Vs Personal DescisionDocument24 pagini4 Influencing Factors of Learners Career Choice Parents Choice Vs Personal Descisionmatteo mamaloÎncă nu există evaluări

- Chlor AlkaliDocument4 paginiChlor AlkaliYusof SundangÎncă nu există evaluări

- Ignore This StuffDocument92 paginiIgnore This StuffNiharika GottipatiÎncă nu există evaluări

- Chemistry Notes For Class 12 Chapter 6 General Principles and Processes of Isolation of ElementsDocument13 paginiChemistry Notes For Class 12 Chapter 6 General Principles and Processes of Isolation of ElementsPrajapat RockÎncă nu există evaluări

- Equipment Design HW01Document4 paginiEquipment Design HW01Grin NikiforovÎncă nu există evaluări

- Fake Slots: Problem and SolutionDocument7 paginiFake Slots: Problem and SolutionKelly DueÎncă nu există evaluări

- chemistry-technical-document-CHTD 500 v1 Revo 07jul2016 PDFDocument27 paginichemistry-technical-document-CHTD 500 v1 Revo 07jul2016 PDFMoni Becerra WongÎncă nu există evaluări

- Soxhlet Extraction: By-Shewarega HabtamuDocument12 paginiSoxhlet Extraction: By-Shewarega HabtamuAbdisa GemechuÎncă nu există evaluări

- LSD ChemistryDocument15 paginiLSD ChemistryJose Rafael Cerda CespedesÎncă nu există evaluări

- Synthetic Approaches To The 2002-2007 New DrugsDocument120 paginiSynthetic Approaches To The 2002-2007 New DrugsBen ZoeÎncă nu există evaluări

- Flaming Snowball Instruction & QuestionsDocument7 paginiFlaming Snowball Instruction & QuestionsJohn CenaÎncă nu există evaluări

- Causes, Types and Treatment of CoughDocument6 paginiCauses, Types and Treatment of Coughiqra sarwar100% (1)

- Chlorine Element FactsDocument2 paginiChlorine Element FactsElla May Prado100% (1)

- DIY Liquid Nitrogen Generator Using CryocoolerDocument2 paginiDIY Liquid Nitrogen Generator Using CryocoolerYasir AliÎncă nu există evaluări

- Beginners Recipe PDFDocument5 paginiBeginners Recipe PDFLiviuÎncă nu există evaluări

- Poisonous Plants: An Overview of Toxic Principles and SpeciesDocument48 paginiPoisonous Plants: An Overview of Toxic Principles and Species53-Deepankar SutradharÎncă nu există evaluări

- Nitric Acid Semester 2Document11 paginiNitric Acid Semester 2Aditya M GuptaÎncă nu există evaluări

- One Pot SynthesisDocument7 paginiOne Pot SynthesisvirparaÎncă nu există evaluări

- The Reaction Between Sulfur and Calcium Hydroxide PDFDocument4 paginiThe Reaction Between Sulfur and Calcium Hydroxide PDFJavier Aviles100% (1)

- Mushroom Cultivation Guide and SO1Document25 paginiMushroom Cultivation Guide and SO1DanielÎncă nu există evaluări

- Psyc1022 Topic 1Document8 paginiPsyc1022 Topic 1PatriciaÎncă nu există evaluări

- Cyanide PoisoningDocument23 paginiCyanide PoisoningKeisha ReccionÎncă nu există evaluări

- CocaineDocument2 paginiCocaineapi-343584104Încă nu există evaluări

- Fentanyl - 800mcg - Short ReportDocument17 paginiFentanyl - 800mcg - Short ReportLÑcamoaÎncă nu există evaluări

- List 20150331 PDFDocument131 paginiList 20150331 PDFHuesniÎncă nu există evaluări

- Ergot Genus Claviceps PDFDocument2 paginiErgot Genus Claviceps PDFBrandonÎncă nu există evaluări

- Sodium Cyanide Production by Andrussow Process of Ammonia and MethaneDocument3 paginiSodium Cyanide Production by Andrussow Process of Ammonia and MethaneAdel Ybañez-OdesteÎncă nu există evaluări

- Product Description (KNO3)Document2 paginiProduct Description (KNO3)Vanjared OcampoÎncă nu există evaluări

- CALSIA Info SheetDocument2 paginiCALSIA Info SheetFrank MtetwaÎncă nu există evaluări

- Radiation Applications FormsDocument4 paginiRadiation Applications FormsFrank MtetwaÎncă nu există evaluări

- Relation between physical and mechanical properties of concrete paving blocksDocument10 paginiRelation between physical and mechanical properties of concrete paving blocksFrank MtetwaÎncă nu există evaluări

- Radiation Protection Programme (RPP)Document36 paginiRadiation Protection Programme (RPP)Frank MtetwaÎncă nu există evaluări

- ZW - Radiation Protection ActDocument12 paginiZW - Radiation Protection ActFrank MtetwaÎncă nu există evaluări

- World Happiness RankingsDocument12 paginiWorld Happiness RankingsFrank MtetwaÎncă nu există evaluări

- S. I. 281 of 2020 Radiation Protection Safety and Security of Radiation SourcesDocument4 paginiS. I. 281 of 2020 Radiation Protection Safety and Security of Radiation SourcesFrank MtetwaÎncă nu există evaluări

- Guide For Completing Application For X-Ray FacilitiesDocument9 paginiGuide For Completing Application For X-Ray FacilitiesFrank MtetwaÎncă nu există evaluări

- Raw Materials PricelistDocument4 paginiRaw Materials PricelistFrank MtetwaÎncă nu există evaluări

- CALSIA Become An AgentDocument2 paginiCALSIA Become An AgentFrank MtetwaÎncă nu există evaluări

- BP Rubber Mounting Small-Layout1Document1 paginăBP Rubber Mounting Small-Layout1Frank MtetwaÎncă nu există evaluări

- BP Rubber Mounting-Layout2Document1 paginăBP Rubber Mounting-Layout2Frank MtetwaÎncă nu există evaluări

- BP Rubber Mounting-Layout1Document1 paginăBP Rubber Mounting-Layout1Frank MtetwaÎncă nu există evaluări

- Title: Sub Title It Is Possible To Feed The World by Small & Big Farmers by Hard WorkDocument4 paginiTitle: Sub Title It Is Possible To Feed The World by Small & Big Farmers by Hard WorkFrank MtetwaÎncă nu există evaluări

- Description Unit of MeasureDocument2 paginiDescription Unit of MeasureFrank MtetwaÎncă nu există evaluări

- Saponification Work BookDocument11 paginiSaponification Work BookFrank MtetwaÎncă nu există evaluări

- Introduction To Deep LearningDocument12 paginiIntroduction To Deep LearningFrank MtetwaÎncă nu există evaluări

- Raw M PricesDocument3 paginiRaw M PricesFrank MtetwaÎncă nu există evaluări

- Basic Fitting and Machining SchemeDocument1 paginăBasic Fitting and Machining SchemeFrank MtetwaÎncă nu există evaluări

- Report of Accident: Zimbabwe Factories and Works Act (Chapter 14:08)Document2 paginiReport of Accident: Zimbabwe Factories and Works Act (Chapter 14:08)Frank Mtetwa100% (2)

- Product Costs TemplateDocument2 paginiProduct Costs TemplateFrank MtetwaÎncă nu există evaluări

- Claims Statement SummaryDocument1 paginăClaims Statement SummaryFrank MtetwaÎncă nu există evaluări

- Demolition Waste Management PlanningDocument11 paginiDemolition Waste Management PlanningFrank MtetwaÎncă nu există evaluări

- Cement and Aggregate Inspection RecordsDocument90 paginiCement and Aggregate Inspection RecordsFrank MtetwaÎncă nu există evaluări

- Extraction of Pyrethrins from Chrysanthemum Flowers for BiopesticideDocument3 paginiExtraction of Pyrethrins from Chrysanthemum Flowers for BiopesticideFrank MtetwaÎncă nu există evaluări

- 2019 Tax TablesDocument1 pagină2019 Tax TablesGodfrey JokonyaÎncă nu există evaluări

- Dates & Deadlines 2019-2020: Events FALL 2019 WINTER 2020 SPRING 2020Document1 paginăDates & Deadlines 2019-2020: Events FALL 2019 WINTER 2020 SPRING 2020Frank MtetwaÎncă nu există evaluări

- Iphoneos 31Document159 paginiIphoneos 31Ivan VeBoÎncă nu există evaluări

- Bengali (Code No - 005) COURSE Structure Class - Ix (2020 - 21Document11 paginiBengali (Code No - 005) COURSE Structure Class - Ix (2020 - 21Břîšťỹ ÃhmęđÎncă nu există evaluări

- Inventory ControlDocument26 paginiInventory ControlhajarawÎncă nu există evaluări

- Statistical Quality Control, 7th Edition by Douglas C. Montgomery. 1Document76 paginiStatistical Quality Control, 7th Edition by Douglas C. Montgomery. 1omerfaruk200141Încă nu există evaluări

- (123doc) - Chapter-24Document6 pagini(123doc) - Chapter-24Pháp NguyễnÎncă nu există evaluări

- Paper 4 (A) (I) IGCSE Biology (Time - 30 Mins)Document12 paginiPaper 4 (A) (I) IGCSE Biology (Time - 30 Mins)Hisham AlEnaiziÎncă nu există evaluări

- Case Study IndieDocument6 paginiCase Study IndieDaniel YohannesÎncă nu există evaluări

- Computer Networks Transmission Media: Dr. Mohammad AdlyDocument14 paginiComputer Networks Transmission Media: Dr. Mohammad AdlyRichthofen Flies Bf109Încă nu există evaluări

- Critical Methodology Analysis: 360' Degree Feedback: Its Role in Employee DevelopmentDocument3 paginiCritical Methodology Analysis: 360' Degree Feedback: Its Role in Employee DevelopmentJatin KaushikÎncă nu există evaluări

- Basic Features of The Microcredit Regulatory Authority Act, 2006Document10 paginiBasic Features of The Microcredit Regulatory Authority Act, 2006Asif Hasan DhimanÎncă nu există evaluări

- MCQ Ch16solDocument4 paginiMCQ Ch16solandiswahlongwa870Încă nu există evaluări

- AtlasConcorde NashDocument35 paginiAtlasConcorde NashMadalinaÎncă nu există evaluări

- Prlude No BWV in C MinorDocument3 paginiPrlude No BWV in C MinorFrédéric LemaireÎncă nu există evaluări

- Methods to estimate stakeholder views of sustainabilityDocument7 paginiMethods to estimate stakeholder views of sustainabilityAlireza FatemiÎncă nu există evaluări

- Dance Appreciation and CompositionDocument1 paginăDance Appreciation and CompositionFretz Ael100% (1)

- Rapport DharaviDocument23 paginiRapport DharaviUrbanistes du MondeÎncă nu există evaluări

- ALXSignature0230 0178aDocument3 paginiALXSignature0230 0178aAlex MocanuÎncă nu există evaluări

- Flowmon Ads Enterprise Userguide enDocument82 paginiFlowmon Ads Enterprise Userguide ennagasatoÎncă nu există evaluări

- Corporate Governance, Corporate Profitability Toward Corporate Social Responsibility Disclosure and Corporate Value (Comparative Study in Indonesia, China and India Stock Exchange in 2013-2016) .Document18 paginiCorporate Governance, Corporate Profitability Toward Corporate Social Responsibility Disclosure and Corporate Value (Comparative Study in Indonesia, China and India Stock Exchange in 2013-2016) .Lia asnamÎncă nu există evaluări

- Lab StoryDocument21 paginiLab StoryAbdul QadirÎncă nu există evaluări

- Srimanta Sankaradeva Universityof Health SciencesDocument3 paginiSrimanta Sankaradeva Universityof Health SciencesTemple RunÎncă nu există evaluări