Documente Academic

Documente Profesional

Documente Cultură

Pin Brazing - DN80 Ph.1

Încărcat de

Marcelo Guerra0 evaluări0% au considerat acest document util (0 voturi)

239 vizualizări14 paginiTitlu original

Pin Brazing - DN80 Ph.1.xls

Drepturi de autor

© © All Rights Reserved

Formate disponibile

XLS, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLS, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

239 vizualizări14 paginiPin Brazing - DN80 Ph.1

Încărcat de

Marcelo GuerraDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLS, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 14

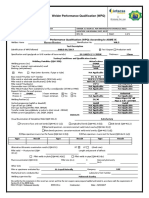

Connection areas cleaned to bright metal.

Minimum pipe wall thickness not compromised.

Connection point minimum of :

150mm from other pin braze connection(s).

200mm from welded pad connection(s)

150mm from any weld.

Correct size stud and cable lug used(both proprietary Pin Braze item)

Cable lug securely crimped to lug

Visual examination of pin brazing connection

Hammer test of connection

Pull test of connection

Pipe/Hydrant to potential(-mV wrt Cu/CuSO4 reference electrode)

Holiday testing(test voltage 5KV/mm) satisfactory

Stress relief loop in the cable provided

Test Instrument :

Form No.:T-4.109.922-001

Test Facility ID : 1CP400F01

Location : DN80 CW PIPE LINE (Phase 1)

Cable No. : 5100070EP1

Company

Name

Check/Test

Date

Cable-to-pipe connection encapsulated and sealed with suitable

coating repair/insulation material

Cable routed to the designated test facility location without

physical damages and correctly identified

Pearl GTL Project Liquid Processing Unit (C5)

Installation Inspection and Test

(Pin Brazing Cable-to-Pipe Connection)

Date :

Sheet No. :

Approved By: Witnessed By:

E-T4109922-

Signature

Check/Test Result

Completed By:

Remarks :

Connection areas cleaned to bright metal.

Minimum pipe wall thickness not compromised.

Connection point minimum of :

150mm from other pin braze connection(s).

200mm from welded pad connection(s)

150mm from any weld.

Correct size stud and cable lug used(both proprietary Pin Braze item)

Cable lug securely crimped to lug

Visual examination of pin brazing connection

Hammer test of connection

Pull test of connection

Pipe/Hydrant to potential(-mV wrt Cu/CuSO4 reference electrode)

Holiday testing(test voltage 5KV/mm) satisfactory

Stress relief loop in the cable provided

Test Instrument :

Form No.:T-4.109.922-001

E-T4109922-

Signature

Check/Test Result

Completed By:

Remarks :

Sheet No. :

Approved By: Witnessed By:

Check/Test

Date

Cable-to-pipe connection encapsulated and sealed with suitable

coating repair/insulation material

Cable routed to the designated test facility location without

physical damages and correctly identified

Pearl GTL Project Liquid Processing Unit (C5)

Installation Inspection and Test

(Pin Brazing Cable-to-Pipe Connection)

Date : Test Facility ID : 1CP400F01

Location : DN80 CW PIPE LINE (Phase 1)

Cable No. : 5100071EP1

Company

Name

Connection areas cleaned to bright metal.

Minimum pipe wall thickness not compromised.

Connection point minimum of :

150mm from other pin braze connection(s).

200mm from welded pad connection(s)

150mm from any weld.

Correct size stud and cable lug used(both proprietary Pin Braze item)

Cable lug securely crimped to lug

Visual examination of pin brazing connection

Hammer test of connection

Pull test of connection

Pipe/Hydrant to potential(-mV wrt Cu/CuSO4 reference electrode)

Holiday testing(test voltage 5KV/mm) satisfactory

Stress relief loop in the cable provided

Test Instrument :

Form No.:T-4.109.922-001

E-T4109922-

Signature

Check/Test Result

Completed By:

Remarks :

Sheet No. :

Approved By: Witnessed By:

Check/Test

Date

Cable-to-pipe connection encapsulated and sealed with suitable

coating repair/insulation material

Cable routed to the designated test facility location without

physical damages and correctly identified

Pearl GTL Project Liquid Processing Unit (C5)

Installation Inspection and Test

(Pin Brazing Cable-to-Pipe Connection)

Date : Test Facility ID : 51CPSTP020

Location : DN80 CW PIPE LINE (Phase 1)

Cable No. : 5100103EC1

Company

Name

Connection areas cleaned to bright metal.

Minimum pipe wall thickness not compromised.

Connection point minimum of :

150mm from other pin braze connection(s).

200mm from welded pad connection(s)

150mm from any weld.

Correct size stud and cable lug used(both proprietary Pin Braze item)

Cable lug securely crimped to lug

Visual examination of pin brazing connection

Hammer test of connection

Pull test of connection

Pipe/Hydrant to potential(-mV wrt Cu/CuSO4 reference electrode)

Holiday testing(test voltage 5KV/mm) satisfactory

Stress relief loop in the cable provided

Test Instrument :

Form No.:T-4.109.922-001

Test Facility ID : 51CPSTP020

Location : DN80 CW PIPE LINE (Phase 1)

Cable No. : 5100104EC1

Company

Name

Check/Test

Date

Cable-to-pipe connection encapsulated and sealed with suitable

coating repair/insulation material

Cable routed to the designated test facility location without

physical damages and correctly identified

Pearl GTL Project Liquid Processing Unit (C5)

Installation Inspection and Test

(Pin Brazing Cable-to-Pipe Connection)

Date :

Sheet No. :

Approved By: Witnessed By:

E-T4109922-

Signature

Check/Test Result

Completed By:

Remarks :

Connection areas cleaned to bright metal.

Minimum pipe wall thickness not compromised.

Connection point minimum of :

150mm from other pin braze connection(s).

200mm from welded pad connection(s)

150mm from any weld.

Correct size stud and cable lug used(both proprietary Pin Braze item)

Cable lug securely crimped to lug

Visual examination of pin brazing connection

Hammer test of connection

Pull test of connection

Pipe/Hydrant to potential(-mV wrt Cu/CuSO4 reference electrode)

Holiday testing(test voltage 5KV/mm) satisfactory

Stress relief loop in the cable provided

Test Instrument :

Form No.:T-4.109.922-001

Test Facility ID : 51CPSTP020

Location : DN80 CW PIPE LINE (Phase 1)

Cable No. : 5100074EP1

Company

Name

Check/Test

Date

Cable-to-pipe connection encapsulated and sealed with suitable

coating repair/insulation material

Cable routed to the designated test facility location without

physical damages and correctly identified

Pearl GTL Project Liquid Processing Unit (C5)

Installation Inspection and Test

(Pin Brazing Cable-to-Pipe Connection)

Date :

Sheet No. :

Approved By: Witnessed By:

E-T4109922-

Signature

Check/Test Result

Completed By:

Remarks :

Connection areas cleaned to bright metal.

Minimum pipe wall thickness not compromised.

Connection point minimum of :

150mm from other pin braze connection(s).

200mm from welded pad connection(s)

150mm from any weld.

Correct size stud and cable lug used(both proprietary Pin Braze item)

Cable lug securely crimped to lug

Visual examination of pin brazing connection

Hammer test of connection

Pull test of connection

Pipe/Hydrant to potential(-mV wrt Cu/CuSO4 reference electrode)

Holiday testing(test voltage 5KV/mm) satisfactory

Stress relief loop in the cable provided

Test Instrument :

Form No.:T-4.109.922-001

E-T4109922-

Signature

Check/Test Result

Completed By:

Remarks :

Sheet No. :

Approved By: Witnessed By:

Check/Test

Date

Cable-to-pipe connection encapsulated and sealed with suitable

coating repair/insulation material

Cable routed to the designated test facility location without

physical damages and correctly identified

Pearl GTL Project Liquid Processing Unit (C5)

Installation Inspection and Test

(Pin Brazing Cable-to-Pipe Connection)

Date : Test Facility ID : 51CPSTP020

Location : DN80 CW PIPE LINE (Phase 1)

Cable No. : 5100075EP1

Company

Name

Connection areas cleaned to bright metal.

Minimum pipe wall thickness not compromised.

Connection point minimum of :

150mm from other pin braze connection(s).

200mm from welded pad connection(s)

150mm from any weld.

Correct size stud and cable lug used(both proprietary Pin Braze item)

Cable lug securely crimped to lug

Visual examination of pin brazing connection

Hammer test of connection

Pull test of connection

Pipe/Hydrant to potential(-mV wrt Cu/CuSO4 reference electrode)

Holiday testing(test voltage 5KV/mm) satisfactory

Stress relief loop in the cable provided

Test Instrument :

Form No.:T-4.109.922-001

Test Facility ID : 51CPSTP021

Location : DN80 CW PIPE LINE (Phase 1)

Cable No. : 5100107EC1

Company

Name

Check/Test

Date

Cable-to-pipe connection encapsulated and sealed with suitable

coating repair/insulation material

Cable routed to the designated test facility location without

physical damages and correctly identified

Pearl GTL Project Liquid Processing Unit (C5)

Installation Inspection and Test

(Pin Brazing Cable-to-Pipe Connection)

Date :

Sheet No. :

Approved By: Witnessed By:

E-T4109922-

Signature

Check/Test Result

Completed By:

Remarks :

Connection areas cleaned to bright metal.

Minimum pipe wall thickness not compromised.

Connection point minimum of :

150mm from other pin braze connection(s).

200mm from welded pad connection(s)

150mm from any weld.

Correct size stud and cable lug used(both proprietary Pin Braze item)

Cable lug securely crimped to lug

Visual examination of pin brazing connection

Hammer test of connection

Pull test of connection

Pipe/Hydrant to potential(-mV wrt Cu/CuSO4 reference electrode)

Holiday testing(test voltage 5KV/mm) satisfactory

Stress relief loop in the cable provided

Test Instrument :

Form No.:T-4.109.922-001

E-T4109922-

Signature

Check/Test Result

Completed By:

Remarks :

Sheet No. :

Approved By: Witnessed By:

Check/Test

Date

Cable-to-pipe connection encapsulated and sealed with suitable

coating repair/insulation material

Cable routed to the designated test facility location without

physical damages and correctly identified

Pearl GTL Project Liquid Processing Unit (C5)

Installation Inspection and Test

(Pin Brazing Cable-to-Pipe Connection)

Date : Test Facility ID : 51CPSTP021

Location : DN80 CW PIPE LINE (Phase 1)

Cable No. : 5100077EP1

Company

Name

Connection areas cleaned to bright metal.

Minimum pipe wall thickness not compromised.

Connection point minimum of :

150mm from other pin braze connection(s).

200mm from welded pad connection(s)

150mm from any weld.

Correct size stud and cable lug used(both proprietary Pin Braze item)

Cable lug securely crimped to lug

Visual examination of pin brazing connection

Hammer test of connection

Pull test of connection

Pipe/Hydrant to potential(-mV wrt Cu/CuSO4 reference electrode)

Holiday testing(test voltage 5KV/mm) satisfactory

Stress relief loop in the cable provided

Test Instrument :

Form No.:T-4.109.922-001

E-T4109922-

Signature

Check/Test Result

Completed By:

Remarks :

Sheet No. :

Approved By: Witnessed By:

Check/Test

Date

Cable-to-pipe connection encapsulated and sealed with suitable

coating repair/insulation material

Cable routed to the designated test facility location without

physical damages and correctly identified

Pearl GTL Project Liquid Processing Unit (C5)

Installation Inspection and Test

(Pin Brazing Cable-to-Pipe Connection)

Date : Test Facility ID : 51CPSTP022

Location : DN80 CW PIPE LINE (Phase 1)

Cable No. : 5100110EC1

Company

Name

Connection areas cleaned to bright metal.

Minimum pipe wall thickness not compromised.

Connection point minimum of :

150mm from other pin braze connection(s).

200mm from welded pad connection(s)

150mm from any weld.

Correct size stud and cable lug used(both proprietary Pin Braze item)

Cable lug securely crimped to lug

Visual examination of pin brazing connection

Hammer test of connection

Pull test of connection

Pipe/Hydrant to potential(-mV wrt Cu/CuSO4 reference electrode)

Holiday testing(test voltage 5KV/mm) satisfactory

Stress relief loop in the cable provided

Test Instrument :

Form No.:T-4.109.922-001

Test Facility ID : 51CPSTP022

Location : DN80 CW PIPE LINE (Phase 1)

Cable No. : 5100078EP1

Company

Name

Check/Test

Date

Cable-to-pipe connection encapsulated and sealed with suitable

coating repair/insulation material

Cable routed to the designated test facility location without

physical damages and correctly identified

Pearl GTL Project Liquid Processing Unit (C5)

Installation Inspection and Test

(Pin Brazing Cable-to-Pipe Connection)

Date :

Sheet No. :

Approved By: Witnessed By:

E-T4109922-

Signature

Check/Test Result

Completed By:

Remarks :

Connection areas cleaned to bright metal.

Minimum pipe wall thickness not compromised.

Connection point minimum of :

150mm from other pin braze connection(s).

200mm from welded pad connection(s)

150mm from any weld.

Correct size stud and cable lug used(both proprietary Pin Braze item)

Cable lug securely crimped to lug

Visual examination of pin brazing connection

Hammer test of connection

Pull test of connection

Pipe/Hydrant to potential(-mV wrt Cu/CuSO4 reference electrode)

Holiday testing(test voltage 5KV/mm) satisfactory

Stress relief loop in the cable provided

Test Instrument :

Form No.:T-4.109.922-001

Test Facility ID : 51CPSTP023

Location : DN80 CW PIPE LINE (Phase 1)

Cable No. : 5100113EC1

Company

Name

Check/Test

Date

Cable-to-pipe connection encapsulated and sealed with suitable

coating repair/insulation material

Cable routed to the designated test facility location without

physical damages and correctly identified

Pearl GTL Project Liquid Processing Unit (C5)

Installation Inspection and Test

(Pin Brazing Cable-to-Pipe Connection)

Date :

Sheet No. :

Approved By: Witnessed By:

E-T4109922-

Signature

Check/Test Result

Completed By:

Remarks :

Connection areas cleaned to bright metal.

Minimum pipe wall thickness not compromised.

Connection point minimum of :

150mm from other pin braze connection(s).

200mm from welded pad connection(s)

150mm from any weld.

Correct size stud and cable lug used(both proprietary Pin Braze item)

Cable lug securely crimped to lug

Visual examination of pin brazing connection

Hammer test of connection

Pull test of connection

Pipe/Hydrant to potential(-mV wrt Cu/CuSO4 reference electrode)

Holiday testing(test voltage 5KV/mm) satisfactory

Stress relief loop in the cable provided

Test Instrument :

Form No.:T-4.109.922-001

E-T4109922-

Signature

Check/Test Result

Completed By:

Remarks :

Sheet No. :

Approved By: Witnessed By:

Check/Test

Date

Cable-to-pipe connection encapsulated and sealed with suitable

coating repair/insulation material

Cable routed to the designated test facility location without

physical damages and correctly identified

Pearl GTL Project Liquid Processing Unit (C5)

Installation Inspection and Test

(Pin Brazing Cable-to-Pipe Connection)

Date : Test Facility ID : 51CPSTP023

Location : DN80 CW PIPE LINE (Phase 1)

Cable No. : 5100114EC1

Company

Name

Connection areas cleaned to bright metal.

Minimum pipe wall thickness not compromised.

Connection point minimum of :

150mm from other pin braze connection(s).

200mm from welded pad connection(s)

150mm from any weld.

Correct size stud and cable lug used(both proprietary Pin Braze item)

Cable lug securely crimped to lug

Visual examination of pin brazing connection

Hammer test of connection

Pull test of connection

Pipe/Hydrant to potential(-mV wrt Cu/CuSO4 reference electrode)

Holiday testing(test voltage 5KV/mm) satisfactory

Stress relief loop in the cable provided

Test Instrument :

Form No.:T-4.109.922-001

E-T4109922-

Signature

Check/Test Result

Completed By:

Remarks :

Sheet No. :

Approved By: Witnessed By:

Check/Test

Date

Cable-to-pipe connection encapsulated and sealed with suitable

coating repair/insulation material

Cable routed to the designated test facility location without

physical damages and correctly identified

Pearl GTL Project Liquid Processing Unit (C5)

Installation Inspection and Test

(Pin Brazing Cable-to-Pipe Connection)

Date : Test Facility ID : 51CPSTP023

Location : DN80 CW PIPE LINE (Phase 1)

Cable No. : 5100079EP1

Company

Name

Connection areas cleaned to bright metal.

Minimum pipe wall thickness not compromised.

Connection point minimum of :

150mm from other pin braze connection(s).

200mm from welded pad connection(s)

150mm from any weld.

Correct size stud and cable lug used(both proprietary Pin Braze item)

Cable lug securely crimped to lug

Visual examination of pin brazing connection

Hammer test of connection

Pull test of connection

Pipe/Hydrant to potential(-mV wrt Cu/CuSO4 reference electrode)

Holiday testing(test voltage 5KV/mm) satisfactory

Stress relief loop in the cable provided

Test Instrument :

Form No.:T-4.109.922-001

Test Facility ID : 51CPSTP023

Location : DN80 CW PIPE LINE (Phase 1)

Cable No. : 5100080EP1

Company

Name

Check/Test

Date

Cable-to-pipe connection encapsulated and sealed with suitable

coating repair/insulation material

Cable routed to the designated test facility location without

physical damages and correctly identified

Pearl GTL Project Liquid Processing Unit (C5)

Installation Inspection and Test

(Pin Brazing Cable-to-Pipe Connection)

Date :

Sheet No. :

Approved By: Witnessed By:

E-T4109922-

Signature

Check/Test Result

Completed By:

Remarks :

S-ar putea să vă placă și

- Electric ITP'sDocument23 paginiElectric ITP'sUtku Can Kılıç100% (3)

- Atlas of Stress-Strain CurvesDocument808 paginiAtlas of Stress-Strain Curvesankitsarvaiya100% (3)

- F120 - F160 Peco ManualDocument44 paginiF120 - F160 Peco ManualBernie WireÎncă nu există evaluări

- BS en 1090-2:2008+a1:2011Document1 paginăBS en 1090-2:2008+a1:2011234ahmed50% (2)

- Sfa-5 10Document23 paginiSfa-5 10Allen RosonÎncă nu există evaluări

- NDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023Document16 paginiNDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023SANJEEV YADAVÎncă nu există evaluări

- ASTM A370 - 97a PDFDocument53 paginiASTM A370 - 97a PDFbaolengocÎncă nu există evaluări

- Easa Ar100 2006 PDFDocument33 paginiEasa Ar100 2006 PDFChecho Buenaventura100% (1)

- 01 Operator Manual - StirLIN-2 - J0847 - ENDocument54 pagini01 Operator Manual - StirLIN-2 - J0847 - ENA TurkiÎncă nu există evaluări

- Cranfield University Entry For IWE PDFDocument2 paginiCranfield University Entry For IWE PDFbharani dharanÎncă nu există evaluări

- 171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQDocument4 pagini171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- E 543 - 04 - Rtu0mw - PDFDocument11 paginiE 543 - 04 - Rtu0mw - PDFUpul Eranda AbeyrathnaÎncă nu există evaluări

- Appendix 4 Rounded Indications Charts Acceptance Standard For Radiographically Determined Rounded Indications in WeldsDocument8 paginiAppendix 4 Rounded Indications Charts Acceptance Standard For Radiographically Determined Rounded Indications in WeldsStephen RajÎncă nu există evaluări

- Ultrasonic Testing of ConcreteDocument4 paginiUltrasonic Testing of ConcreteAshrafÎncă nu există evaluări

- Hardness Conversion TableDocument5 paginiHardness Conversion TablejaswanthÎncă nu există evaluări

- AS 1627.1-2003 Metal Finishing - Preparation and PretreatmenDocument21 paginiAS 1627.1-2003 Metal Finishing - Preparation and PretreatmenDang Thanh TuanÎncă nu există evaluări

- Is 11166 PDFDocument13 paginiIs 11166 PDFAnonymous NRlowQUcn100% (1)

- As 2207-2007 Non-Destructive Testing - Ultrasonic Testing of Fusion Welded Joints in Carbon and Low Alloy SteDocument7 paginiAs 2207-2007 Non-Destructive Testing - Ultrasonic Testing of Fusion Welded Joints in Carbon and Low Alloy SteSAI Global - APAC0% (2)

- Nondestructive Testing - Wikipedia PDFDocument12 paginiNondestructive Testing - Wikipedia PDFVysakh VasudevanÎncă nu există evaluări

- ASMe Sec2 PartcDocument53 paginiASMe Sec2 PartcSARSAN NDTÎncă nu există evaluări

- Certified Piping and Mechanical Quality Control (QC) InspectorDocument10 paginiCertified Piping and Mechanical Quality Control (QC) InspectorWilson NjangeÎncă nu există evaluări

- Iso 898 2 2012 en PDFDocument11 paginiIso 898 2 2012 en PDFPablo BritoÎncă nu există evaluări

- GB-T 232-2010 Metallic Materials-Bend TestDocument14 paginiGB-T 232-2010 Metallic Materials-Bend TestH. Camer E.Încă nu există evaluări

- Acceptance Criteria Asme B31.3 PDFDocument1 paginăAcceptance Criteria Asme B31.3 PDFAhmad Rizki100% (1)

- Bauteilspezifische Angaben Für Rohrleitungen: Ausgabe/Edition 1999-06Document19 paginiBauteilspezifische Angaben Für Rohrleitungen: Ausgabe/Edition 1999-06EdAlm100% (1)

- Asme Section Ix InterpretationsDocument72 paginiAsme Section Ix InterpretationsEmmanuelÎncă nu există evaluări

- ASME VIII-2-Service Restrictions, Joint Efficiencies, RadiographyDocument34 paginiASME VIII-2-Service Restrictions, Joint Efficiencies, RadiographyMohammed AnshafÎncă nu există evaluări

- Procedure For Radiographic Profile Thickness MeasurementDocument7 paginiProcedure For Radiographic Profile Thickness MeasurementSergey KichenkoÎncă nu există evaluări

- OCS Prel WPS 007Document2 paginiOCS Prel WPS 007vinothÎncă nu există evaluări

- Pull Off Test Report RefinaryDocument3 paginiPull Off Test Report RefinaryZaid Raslan AyoubÎncă nu există evaluări

- BS 2901-1 Specification For Filler RodDocument11 paginiBS 2901-1 Specification For Filler Rodaidroos1985Încă nu există evaluări

- Electrode Issue SlipDocument1 paginăElectrode Issue SlipHasan ShahriarÎncă nu există evaluări

- MTC Er70s 2Document1 paginăMTC Er70s 2Mirza BaigÎncă nu există evaluări

- G10 PDFDocument3 paginiG10 PDFSameer Sa100% (1)

- Ankur Kakroo: Engineering Manager - WebDocument3 paginiAnkur Kakroo: Engineering Manager - WebShreyaÎncă nu există evaluări

- Hardness App GuideDocument21 paginiHardness App GuideAbd Rahman AliasÎncă nu există evaluări

- Welder Performance Qualification (WPQ) According To ASME IX Hassan HussienDocument1 paginăWelder Performance Qualification (WPQ) According To ASME IX Hassan HussienMahmoud shawkyÎncă nu există evaluări

- Asmeviii Uw EDocument196 paginiAsmeviii Uw ETâm NgôÎncă nu există evaluări

- Tube To Tubesheet WeldsDocument1 paginăTube To Tubesheet Weldsramzi5ben5ahmedÎncă nu există evaluări

- Norma CWB Cambios en W47.1-2009Document6 paginiNorma CWB Cambios en W47.1-2009Jose ManuelÎncă nu există evaluări

- JIS G3452 PipeDocument0 paginiJIS G3452 PipefaridyeniÎncă nu există evaluări

- GE Mentor EM Weld BrochureDocument6 paginiGE Mentor EM Weld BrochuredimachampionÎncă nu există evaluări

- Effect of Sugaring On SS JointsDocument50 paginiEffect of Sugaring On SS Jointsrith100% (1)

- Equotip ASTM Standards For Leeb Testing E 2010.04.23Document2 paginiEquotip ASTM Standards For Leeb Testing E 2010.04.23Pablo Echaure AriñoÎncă nu există evaluări

- WPS P5A Group Any To P5A Group Any GTAW FCAW Manual Semi AutomaticDocument2 paginiWPS P5A Group Any To P5A Group Any GTAW FCAW Manual Semi AutomaticAlex MendozaÎncă nu există evaluări

- JIS Z 2320-1-2007 Non-Destructive Testing - Magnetic Particle Testing - Part 1 General Principles-6 PDFDocument31 paginiJIS Z 2320-1-2007 Non-Destructive Testing - Magnetic Particle Testing - Part 1 General Principles-6 PDFNguyễn Hữu BằngÎncă nu există evaluări

- Public-: Rev. D E English 03 / 2014Document33 paginiPublic-: Rev. D E English 03 / 2014xaviereduardoÎncă nu există evaluări

- Preheat RequirementsDocument3 paginiPreheat RequirementsVJG369Încă nu există evaluări

- TLV - Electro-Pneumatic Control Valve For Steam PDFDocument2 paginiTLV - Electro-Pneumatic Control Valve For Steam PDFsirballesterosÎncă nu există evaluări

- CV - Project ManagerDocument2 paginiCV - Project ManagerDARA SINGHÎncă nu există evaluări

- As 1984-1977 Vernier Callipers (Metric Series)Document7 paginiAs 1984-1977 Vernier Callipers (Metric Series)SAI Global - APACÎncă nu există evaluări

- BS 6072 - MPI Flaw Detection PDFDocument35 paginiBS 6072 - MPI Flaw Detection PDFShrikant UtekarÎncă nu există evaluări

- SB 548Document5 paginiSB 548Edson Julio S RÎncă nu există evaluări

- Test Pack ProcedureDocument10 paginiTest Pack ProcedureDaengkulle Firmansyah PuteraÎncă nu există evaluări

- As 2205.3.1-2003 Methods For Destructive Testing of Welds in Metal - Transverse Guided Bend TestDocument2 paginiAs 2205.3.1-2003 Methods For Destructive Testing of Welds in Metal - Transverse Guided Bend TestSAI Global - APACÎncă nu există evaluări

- Welder and Welding Operator Performance Qualification RecordDocument1 paginăWelder and Welding Operator Performance Qualification RecordAsif HameedÎncă nu există evaluări

- HMC Spec 001 - Welding and Fabrication of Structural SteelDocument29 paginiHMC Spec 001 - Welding and Fabrication of Structural SteelJohnnyÎncă nu există evaluări

- BS en 10204Document14 paginiBS en 10204Kalyan Chakravathi A G100% (1)

- Dep 30.10.60.32 - Welding of Metals, Based On Iso StandardsDocument76 paginiDep 30.10.60.32 - Welding of Metals, Based On Iso StandardsPablo PazÎncă nu există evaluări

- CBT Questions: (2) Peel TestDocument18 paginiCBT Questions: (2) Peel TestMOHAMEDÎncă nu există evaluări

- Duplex Welding GuidelinesDocument13 paginiDuplex Welding GuidelinesadelÎncă nu există evaluări

- ISO Kardemir - 2023Document1 paginăISO Kardemir - 2023Athul T.NÎncă nu există evaluări

- E9018 G Welding ElectrodeDocument1 paginăE9018 G Welding ElectrodeSai PrasathÎncă nu există evaluări

- Field Quality Plan of EHV Power CablesDocument10 paginiField Quality Plan of EHV Power CablesMohammed TauseefÎncă nu există evaluări

- Solar FuelDocument10 paginiSolar FuelMarcelo GuerraÎncă nu există evaluări

- Efficient Optimization of BOF-dedusting: October 2014Document12 paginiEfficient Optimization of BOF-dedusting: October 2014Marcelo GuerraÎncă nu există evaluări

- Schroeder Calculation of Flammability LimitsDocument17 paginiSchroeder Calculation of Flammability LimitsAlexandre Hugen0% (1)

- Pub 98 Joining of Cu and Cu Alloys PDFDocument64 paginiPub 98 Joining of Cu and Cu Alloys PDFsaravananÎncă nu există evaluări

- Effect of Melt Temperature Cleanout Cycle Continuous Casting Direction Horizontal Vertical and Super Cooler SizeDocument20 paginiEffect of Melt Temperature Cleanout Cycle Continuous Casting Direction Horizontal Vertical and Super Cooler SizeMarcelo GuerraÎncă nu există evaluări

- Optimizing The Parameters of TIG-MIGMAG Hybrid Welding On The Geometry of Bead Welding Using The Taguchi MethodDocument17 paginiOptimizing The Parameters of TIG-MIGMAG Hybrid Welding On The Geometry of Bead Welding Using The Taguchi MethodKaushik SenguptaÎncă nu există evaluări

- Guía de Ingeniería EclipseDocument121 paginiGuía de Ingeniería Eclipsegiovanny1136Încă nu există evaluări

- Report ChenDocument105 paginiReport ChenMarcelo GuerraÎncă nu există evaluări

- 1 s2.0 037604219190008R Main PDFDocument71 pagini1 s2.0 037604219190008R Main PDFMarcelo GuerraÎncă nu există evaluări

- ZEECO Boiler Burner Data SheetDocument11 paginiZEECO Boiler Burner Data SheetMarcelo GuerraÎncă nu există evaluări

- EES Lecture 3 and 4 AssignmentDocument2 paginiEES Lecture 3 and 4 AssignmentMarcelo GuerraÎncă nu există evaluări

- 1 s2.0 001793109190126Y Main PDFDocument14 pagini1 s2.0 001793109190126Y Main PDFMarcelo GuerraÎncă nu există evaluări

- 1 s2.0 001793109190127Z Main PDFDocument10 pagini1 s2.0 001793109190127Z Main PDFMarcelo GuerraÎncă nu există evaluări

- Introduction To Brazing V3 PDFDocument24 paginiIntroduction To Brazing V3 PDFMarcelo GuerraÎncă nu există evaluări

- Heghes PDFDocument119 paginiHeghes PDFMarcelo GuerraÎncă nu există evaluări

- Intl Equip en 2013 PDFDocument108 paginiIntl Equip en 2013 PDFMarcelo Guerra0% (1)

- Lift Arm & BOB-TACH - S530 PDFDocument4 paginiLift Arm & BOB-TACH - S530 PDFeduardo chavezÎncă nu există evaluări

- MM PT6T-3B 72-3Document24 paginiMM PT6T-3B 72-3Panca Xp100% (1)

- Miscellaneous - 4DJNF76KE TSK C00Document3 paginiMiscellaneous - 4DJNF76KE TSK C00Anthony Castro100% (1)

- CH 5 Kerja Dan EnergiDocument21 paginiCH 5 Kerja Dan EnergiDey TandirerungÎncă nu există evaluări

- Calculation Report On Bearing-Aashto-2012Document12 paginiCalculation Report On Bearing-Aashto-2012Tawfiqul IslamÎncă nu există evaluări

- Válvula de Seguridad Anderson Greenwood Crosby - La Rosita - Jos-EDocument66 paginiVálvula de Seguridad Anderson Greenwood Crosby - La Rosita - Jos-EJose Flores100% (2)

- Centrifugal Pumps PresentationDocument28 paginiCentrifugal Pumps Presentationprasoon_eilÎncă nu există evaluări

- Above Ground Pool Plumbing Installation GuideDocument6 paginiAbove Ground Pool Plumbing Installation GuideGodwin IwekaÎncă nu există evaluări

- Xxxx-Spe-Xxx - Mto FormatDocument10 paginiXxxx-Spe-Xxx - Mto FormatVijay GaikwadÎncă nu există evaluări

- Wafflemat Design WhitepaperDocument13 paginiWafflemat Design WhitepaperantiacidoÎncă nu există evaluări

- 490 SSAB Automotive Final PDFDocument33 pagini490 SSAB Automotive Final PDFyujian331Încă nu există evaluări

- Staad Input FileDocument18 paginiStaad Input FileKP SahuÎncă nu există evaluări

- Repair of A Hull 15 M Below The WaterlineDocument8 paginiRepair of A Hull 15 M Below The WaterlineRonny De La CruzÎncă nu există evaluări

- Design Example 4 Reinforced Concrete Parking Garage: 2012 IBC SEAOC Structural/Seismic Design Manual, Vol. 3Document21 paginiDesign Example 4 Reinforced Concrete Parking Garage: 2012 IBC SEAOC Structural/Seismic Design Manual, Vol. 3Mofasa EÎncă nu există evaluări

- Numerical Study of A Self Priming Regenerative Pump For Improved Performance Using Geometric ModificationsDocument6 paginiNumerical Study of A Self Priming Regenerative Pump For Improved Performance Using Geometric ModificationssachinparamaneÎncă nu există evaluări

- Himalaya GasesDocument4 paginiHimalaya Gasesmitr_mmÎncă nu există evaluări

- Correlation of Bendability of Materials With Their Tensile Properties Datsko Bab4480.0001.001Document21 paginiCorrelation of Bendability of Materials With Their Tensile Properties Datsko Bab4480.0001.001lram70Încă nu există evaluări

- Chapter 06 - Understanding Process ConditionsDocument20 paginiChapter 06 - Understanding Process ConditionsMohammed DaghurÎncă nu există evaluări

- Hipps: High Integrity Pressure Protection SystemsDocument9 paginiHipps: High Integrity Pressure Protection SystemsAndrew XuguomingÎncă nu există evaluări

- Replacement Parts BUSHDocument33 paginiReplacement Parts BUSHIsaac Rodríguez BetancourtÎncă nu există evaluări

- Catalogo de Controles CO2Document16 paginiCatalogo de Controles CO2miguel callataÎncă nu există evaluări

- WINMAN Solenoid Valf (5/2 Yollu, 5/3 Yollu) / Solenoid Valve (5/2 Way, 5/3 Way)Document2 paginiWINMAN Solenoid Valf (5/2 Yollu, 5/3 Yollu) / Solenoid Valve (5/2 Way, 5/3 Way)Durulsan MakinaÎncă nu există evaluări

- Comparision of Fabrication TolerancesDocument4 paginiComparision of Fabrication TolerancesSatish Keskar100% (1)

- SCHEME - G Third Semester 2223434Document39 paginiSCHEME - G Third Semester 2223434AnjithÎncă nu există evaluări

- 3 Engine Lubrication System: 3.1 GeneralDocument2 pagini3 Engine Lubrication System: 3.1 GeneralABDAN MUGHNI SYAFA'ATÎncă nu există evaluări

- Cpmpression Member Design: 4.1 Introductory ConceptsDocument40 paginiCpmpression Member Design: 4.1 Introductory ConceptssaadkhalisÎncă nu există evaluări

- Axle Boot MarutiDocument2 paginiAxle Boot MarutinrjmanitÎncă nu există evaluări