Documente Academic

Documente Profesional

Documente Cultură

CCPP Operation Manual

Încărcat de

Egit BobyartaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

CCPP Operation Manual

Încărcat de

Egit BobyartaDrepturi de autor:

Formate disponibile

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 1 of 21

Combined Cycle Power Plant Operation

General considerations

Power plant operation includes mainly the following tasks:

start-up and shutdown of the power plant and of all of its ancillary systems,

monitoring of continuous operation,

adjustment of operation to the requirements of the load dispatch center or to the

requisites of the customer,

control of disturbances,

maintenance of the readiness for service of the plant during downtimes (shutdown

heating operation or preservation).

In performing these tasks, both the codes of practice and the specific operating

instructions and regulations of the plant are to be observed.

The configuration of combined cycle plants may be different, but in principle there are

some basic procedures which are determined by the start operation of the gas turbine

itself and, as far as the water/steam part is concerned, they are similar to the start up

procedures of the water/steam-circuit of a conventional plant.

Guidelines for start-up operations

Readiness:

Observing the responsibilities and complying with the technical rules, the operating staff

brings about the mechanical and electrical readiness for operation of the individual plant

parts.

This includes checks and controls, which have to establish

whether all assembly and repair works have been completed properly,

whether the construction and field assembly personnel has left all plant parts,

whether all construction material and assembly equipment (ladders, scaffolds etc.)

have been removed from the plant parts,

whether all components have been cleaned properly, and

whether all mechanical, electrical and I&C connections have been made.

Upon successful completion of all these checks,

manholes, access openings etc. are to be closed,

blanking disks (piping blinds) are to be removed,

pipes and tanks are to be flushed or purged, if necessary, and then to be filled with

the operating medium (water, air, gas, oil etc.),

within the scope of the trial runs, the direction of rotation of drives and the end

position and limit switches are to be checked.

During this mechanical preparation work, also the readiness for operation in the field of

electrical and I&C equipment is prepared.

If the mechanical as well as the electrical and I&C clearance is issued, the plant parts

can be started up in the technically proper order.

Start-up conditions

The type of procedure to be followed for starting up a plant after a layup period depends

on the material temperatures of the plant components particularly of thick-walled

components reached during the time elapsed since the plant had been shut down.

Depending on the level of these material temperatures, a distinction is made between

cold start,

warm start, and

hot start.

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 2 of 21

These temperatures apply to both turbine components and boiler components. A cold

start is to be carried out usually after a longer layup period, e.g. after an

inspection/overhaul of the plant. If the layup time is considerably shorter, e.g. one

weekend, the plant can be started up again following the warm start-up procedure. If

the plant had been shutdown only a few hours ago, a hot start can be carried out.

At Vemagiri Plant the star-up preconditions are:

Hot start defined by shutdown period of less than 8 hours.

Warm Start - defined by shutdown period of 8 to 48 hours.

Cold start - defined by shutdown period of more than 48 hours.

Start-up of the power plant includes also the systematic putting into service of all

auxiliary and ancillary systems.

In modern power plants, the individual start-up steps have been combined into

functional groups which are processed automatically. The functional groups contain also

the stipulated start-up times to be observed in order to avoid high temperature

gradients.

On the other hand, it is to be considered also that any start-up process entails start-up

heat loss and therefore the start-up procedure should be carried out as rapidly as

possible.

The start-up process is thus a compromise between the endeavours to keep start-up

losses as small as possible and the observance of prescribed maximum temperature

gradients in the plant components.

Steps of start-up

The start-up process includes the steps enumerated hereinafter (start-up sequence in

principle). For the specific power plant, the manufacturer's operating instructions are

applicable and the persons in charge of plant operation have to familiarize themselves

with these instructions.

Here are two basic, safety-related mnemonic phrases for start-up of a power plant:

The following applies to all energies and material flows:

Ensure discharge first, and then put supply installations into service

To avoid damage to tubes by overheating in the boiler:

Fire may be available but water must be available

To be referred:

Start-up curves of GTG & STG

Start-up curves for Combined Cycle supplied.

Water balance Diagram.

Heat & Mass balance diagram.

All latest revision of P&IDs.

Combined cycle startup general steps:

Ensure that startup power is available from the grid via 220 Kv/400 Kv switchyard

& via power transformers.

Ensure that all electrical distribution transformers are energized and necessary

voltage levels viz. 6.6 KV, 415 V supplies are available.

Ensure that UPS supply is available.

Check that battery back-up for UPS is in healthy condition. No alarm is existing.

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 3 of 21

Ensure that all emergency D.C drives are available.

Ensure that emergency D.G sets are in Ready condition and on Automatic

mode. It is advisable to take a trial of DG sets one by one.

Ensure that enough raw water is available in the storage area.

Ensure that enough DM water is available in the DM storage tank. Also ensure that

DM water is having proper quality in the storage tank i.e. pH

& conductivity.

Start the Pre-treatment plant. This comprises of the following steps:

Fill the clarifier upto normal working level. Filling of clarifier can be done by

necessary dosing of chlorine, coagulant and polymer, whichever are applicable

or by lime & alum dosing.

Start filling the clarifier water storage tank and fill upto normal working level.

Fill-up the service water tank upto normal working level.

If adequate DM water is available in the DM storage tank, then DM plant can be

started later on.

Normalize the Fire Hydrant & Spray system for fire protection. Ensure that jockey

pumps, motor driven hydrant & spray pumps and Diesel Engine hydrant & spray

pumps are on Automatic selection. It is advisable to check the auto startup of

these pumps by draining the pressure switches / by opening the valves at site.

Start plant compressed air system Instrument air and service air. Normalize the

instrument and service air lines. Check the operation of some valves as a test.

Ensure that dew point monitor of instrument air is in line & dew point is having

sufficient margin above condensation temperature.

Start HVAC system for plant air conditioning.

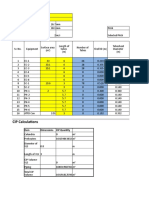

Plant Start Up Curve (proposed)

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 4 of 21

Following general check list to be followed before startup of a HRSG (With

general mistakes that often happen):

Considering COLD START UP More than 48 hours of shutdown. For a longer shutdown

(> 6 days it is preferable to wet preserve the boiler up to superheater outlet valve with

minimum 100 ppm hydrazine hydrate N

2

H

4

).

Cold startup curve (Typical) which resembles the HRSG at Vemagiri.

HP Circuit:

IP Circuit:

All PTWs returned by maintenance department & closed by Shift Charge Engineer

(SCE).

All isolation tools and tackles have been removed by maintenance department.

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 5 of 21

If the HRSG is under wet preservation, drain down the boiler both superheater &

boiler drum(s), completely.

Line up the boiler with respect to the drain & vent valves (As` per operating

procedure securing of drain & vent valves).

Line up the boiler with respect to the feed water circuit to HP, IP and LP.

Normalize dosing system & ensure normal operating level in dosing tanks. For too

long shutdown it is preferable to replace the chemicals as contamination

can occur during several maintenance activities.

Normalize all the instrument impulse lines, flush if required.

Normalize drum water level gauge glass.

Normalize all the transmitters & check the signals at OS.

Rinse entire superheater & water-steam circuit with DM water & refill the boiler

drum upto Start up level.

There are a few ways for filling up the drum effectively without loosing time.

One way to increase the pH of the DM water up to required pH level. This can be done

by taking makeup water in the condenser directly and dosing of hydrazine and/or

ammonia (in case of non- steel tubes in the heat exchangers, ammonia is not

advisable). Keep the CEP in recirculation & check the pH on line. After achieving required

pH, water can be fed to the boiler.

Another way is to fill the drum for a stipulated time, say, 15 minutes and then start

dosing hydrazine in the drum with higher concentration than required during operation.

Certain calculated quantity of hydrazine will be dosed. This will help to mix the hydrazine

uniformly giving good pH.

The other way is to dose Morpholine or equivalent chemical in DM makeup line to

deaerator thereby increasing the pH.

In some cases HRSG filling pump is envisaged during design stage for quick filling of

HRSG.

During start-up and low load operation single element control loop based on drum level

measurement which controls 30% level control valve (1LCVFW203VC).

During normal operation HP Drum level is controlled by using single element control or 3

element control. The selection between the 1 element control and the 3 element control

is based upon the steam flow.

The control loop switches from 1 element to 3 element control when the measured HP

steam flow reaches approximately 25% of MCR (82 TPH). 30% feedwater control valve

will be forced closed when steam flow is greater than 30%. Of 82 TPH = 24.6 TPH

If operating level is maintained then during start up some water has to be

drained down to take care of swelling. This is unnecessary wastage of costly

DM water.

Following points in general can be considered for startup of HRSG Condenser preheater

system:

Close preheater inlet control valve , 1CD200V

Close Preheater recirculation valves, 1TCVCD207VA & 1TCVCD207VB.

Close DA level control valve and bypass MOV to level control valve.

Start condensate extraction pumps and keeping another pump standby.

Open preheater inlet control valve slowly.

Start condenser preheater recirculation pumps, 1CD201PA OR 1CD201PB

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 6 of 21

Deaerator circuit

Line up deaerator with respect to the feed, steam and drain & vent system. Ensure that

safety relief valve on the DA is not Gagged.

Then open deaerator drum filling valve and fill deaerator upto startup level.

Continue CEP to run for maintaining the DA level during boiler filling.

If DA feed storage tank (FST) level 1 LT FW 200 A/B/C reaches is greater than high

level, adjust DA drum level by opening Blow down manual valve.

Open Condensate control valve 1 LCV 215 V.

Set deaerator drum level control in automatic operation and maintain minimum required

water level.

The following checks are required:

Check & ensure that no Gag is remaining on safety valves.

Check that no Blind is remaining in the safety valve flange.

If safety valve servicing has been carried out, then it is necessary to float the

safety valves and secure the same (After startup).

IBR requirement also states that after final setting of the safety valves, requisite

height of collar to be provided so that intentional increment of set pressure is

averted.

Normalize all the electrical drives and confirm that Healthy signal is existing on

the Operating Station (OS).

Normalize all the pneumatic valves, check the stroke whenever required. This

ensures freeness of control valves.

Check for proper closure of all the manholes. Sometimes due to use of inferior

quality of ropes/gaskets, overheating of manhole material occurs and material

degraded.

Remove all the isolation tags after normalization. Otherwise misunderstanding can

happen.

Normalize sample lines to SWAS panel.

Ensure that there is no blind remaining at the inlet connections of CBD or IBD

tanks. This can happen if during Annual Inspection of passing of the HRSG drain

valve cannot be controlled, a blind is sometimes provided at the blowdown tank

inlet flange, temporarily. PTW must be issued for this work.

Ensure cooling water supply line is available for CBD or IBD tank. This is required

to cool the tank during blowdown, which is frequent during startup.

Ensure that HRSG Expansion indicators are free to move.

When there is a bypass stack in the system (which is absent in Vemagiri), Check the

operation of diverter damper (DD) whenever GT is not in operation & confirm the

feedback at central control room (CCR).

Considering Steam Turbine Generator (STG) is in IDLE mode and STG

auxiliaries are stand still:

Line up cooling tower for operation.

Ensure that CW basin level is sufficient.

Start one/two circulating water (CW) pump(s) and establish the CW flow.

arryout necessary venting in the CW lines.

Ensure that makeup water for CW basin is available.

Lineup and fill close cooling water CCW system with DM water.

Ensure that necessary chemical parameters are maintained by proper chemical

dosing.

Normalize auxiliary cooling water (ACW) system.

Start STG lube oil system (If not in service) and put the STG on barring gear as

per recommendation from OEM & continue on barring as per OEM recommendation

or as per operating experience.

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 7 of 21

Ensure all the electrical & pneumatic drives are normalized further.

Start and load required numbers of Instrument air compressors.

Ensure that HP LP bypass station has been normalized in all respect.

Ensure that condenser evacuation system has been normalized in all respect.

Ensure that power supply to the steam turbine vacuum breaker valve is in

energized condition. Preferably power supply for this valve from emergency

supply.

Ensure that condensate system has been normalized in all respect.

Ensure that STG drain system has been normalized.

Line up regenerative system as applicable. (e.g. Gland steam condenser, etc.)

HRSG READY TO START PERMISSIVE ON OS. (Typical)

No HRSG trip

HRSG not under conservation , Command from DCS

Flue gas HRSG HTG release

DA circuit HRSG HTG release

LP circuit HRSG HTG release,

HP circuit HRSG HTG release

IP circuit HRSG HTG release,

BD Tank circuit HRSG HTG release,

CPH circuit HRSG HTG release

Utiliites Heating release

Duct burner system HTG release

Now HRSG is ready to take the heat of exhaust gas from GT.

The HRSG heating release signal to be obtained to start the HRSG and following

conditions in general are to be fulfilled.

HP system conditions for HRSG heat release are the following:

HP drum at start-up level

HP feed water main isolation valve opened

HP FW control valve isolation valve1 or 2 or isolation valve of startup control valve

opened

HP FW pumps in operation

Any of boiler recirculation pump running,

HP Boiler recirculation flow greater than minimum.

Both HP attemperation isolation valves closed.

IP system conditions for HRSG heat release are the following:

IP drum level at start-up level

IP feed water main isolation valve opened

IP FW control valve isolation valve 1 or 2 or isolation valve of startup control valve

opened

HP-IP FW pumps in operation

Both IP attemperation isolation valves closed.

LP system conditions for HRSG heat release are the following:

LP drum level at start-up level

LP feed water control valve isolation valves opened

Any of Boiler feed pump is running,

Any of boiler recirculation pump running,

LP Boiler re-circulation flow greater than minimum.

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 8 of 21

During combined cycle startup sequence, the steps are executed automatically in a

logical manner by the DCS.

HRSG startup is executed as per recommended Startup curve from OEM. This can vary

from OEM to OEM but the basic concept remains same:

Main function is performed by the Diverter Damper (DD) wherever applicable. At

Vemagiri DD is not provided. Once GT start command given and if all the start up

permissive is satisfied then GT rolling will be started without Flame ON (called purging)

and after purging sequence is over, before admitting hot gases in the HRSG, it must be

checked there are no flammable gases (resulting from improper combustion in GT) in

HRSG enclosure. To ensure this, the GT must blow cold air into the HRSG. This is done

during the GT startup with the GT FLAME OFF. This is applicable for cold, warm and hot

start of HRSG and is done as per the recommendations of the GT manufacturer.

For starting of GT Static Starting Device (SSD) is used. SSD can have different mode

of operation like:

Turn mode

Purge mode

Fast cooling mode

Wash mode

Above modes are having different speeds as per OEM recommendation.

After purging firing takes place and GT accelerates to FSNL (Full Speed No Load)

condition.

At approximately 80% speed, turbine Blow-off/Anti-surge valves close.

At approximately 90% speed generator exciter breaker closes and builds up necessary

voltage.

Operator will select synchronization on Automatic mode and Synchronoscope will

match the generator voltage, frequency & phase angle with that of prevailing grid

condition.

Once these conditions are satisfied, generator breaker will be closed and machine will be

loaded up to minimum loading as per OEM recommendation.

At Vemagiri Plant GT the static start system uses a Load Commutating Inverter (LCI)

adjustable frequency drive as the starting means for the gas turbine. By providing

variable frequency power directly to the generator terminals, the generator is used as a

synchronous motor to start the gas turbine.

As heat input increases in the HRSG with increased in GT load, evaporation start taking

place.

At this stage check the following.

All drum vents are in open condition.

All super heater vents and drains are in open condition.

All steam lines drain are in open condition.

HP/IP/LP bypass station is in Ready condition.

HP economizer over protection valve initially in open condition and when HP feed

water flow reaches preset value, it closes automatically. During HP evaporator in

operation, it opens when HP eco inlet pressure greater than preset value.

As soon as Drum pressure reaches 2 bar, drum vents will be closed.

The drum vent valve will remain close during normal boiler operation. Only during start

up from cold condition the vent valve will be kept opened till about 2 bar (g) pressure

and above which the same will be closed. The automatic closing order is pressure above

2 barg OR HRSG under conservation.

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 9 of 21

Then, the gas turbine will carry out its automatic start-up sequence, including air-

purging sequence.

As soon as HRSG is ON, permissive to reheat live steam vent inching MOV open. Then IP

startup inching MOV will be opened and % of opening will be limited by HRH live steam

pressure. The LP startup vent inching type valve opens to exhaust. The startup vents

will operate until the respective steam bypass station is available.

The HRSG drain valves closes automatically according to process conditions.

The reheat live steam startup vent valve and LP startup vent valve, closes as soon as

hot reheat bypass station and LP bypass station is available.

Chemical Dosing System

Line up and start chemical dosing system:

Normally Hydrazine (Oxygen scavenger) dosing to be done at the suction of HP/IP/LP

boiler feed pumps, Tri sodium Phosphate dosing to be done directly in to the drum (For

removing the salts which are not soluble at high pressure, silica and to some extent

maintain PH) and ammonia dosing carried out at CEP discharge (CO

2

scavenger and pH

controller).

Check the samples are free flowing to the SWAS panel.

Check that all cationic resins are fresh or at least not at the end of life.

Sampling points are:

IP drum water

LP drum water

HP drum water

LP superheater

Hot reheat.

HP live steam

IP saturated steam

LP saturated steam

HP saturated steam

HP/IP/ LP feedwater

Deaerator

LP BFP Suction

Evacuation System:

Precondition is that STG must be on turning gear operation.

Line up the gland steam system for evacuation purpose.

After achieving adequate HP steam pressure, vacuum pump / Ejector can be taken in to

service for vacuum pulling from the system.

After starting vacuum pulling seal the glands and put the gland steam pressure and

temperature controllers on auto mode.

Normally after achieving approximately 0.3 bara vacuum in the condenser, bypass

operation can be started. However OEM curves to be followed.

Bypass System:

The next step is to start the bypass system for the following reasons:

This station is equipped with 100 % capacity HP/IP/LP bypass system with following

objectives.

When STG trips i.e. 100 % load throw-off bypass system will divert entire steam in

to the condenser. Your system is designed to bypass 100% steam to condenser.

When load is temporarily lost on the steam turbine.

Quick building of steam parameters during startup of the turbine.

It prevents rapid building of pressure in the HRSG.

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 10 of 21

It facilitates continuous operation of the steam turbine at part loads with HRSG

operating at 100%MCR condition.

A different aspect of using this feature is that, the boiler is started quite before the

rolling of the turbine.

The rolling operation of the turbine may possibly delay due to:

Insufficient vacuum in the condenser.

The time lag in achieving permissible differential temperatures of the turbine

components.

The fault in turbine governing and protection system etc.

For this short non-generation period it is nor advisable to shutdown neither the boiler

nor the steam generated during this time to be vented to atmosphere.

During this period HP/ IP/ LP Bypass System plays vital role by establishing the flow in

superheater/ reheater without wastage of costly dematerialized water and fuel.

Moreover, startup of any boiler / HRSG requires some predefined time as per the nature

of the shutdown period.

When HRSG steam attains a desired preset pressure level bypass valve will be opening

and start steam dumping.

Whenever preset steam flow is achieved the start up vent valve start modulating to

close.

Now continuously monitor the steam parameters and match the parameters with

recommended parameters from STG manufacturer.

Once the desired parameters are achieved steam can be admitted in to the steam

turbine and rolling of the turbine can be started.

Depending on the manufacturer, HP/IP and LP steam can be admitted in phases as per

recommended start up curve.

Make sure that all turbine casing drains, control valve drains are in open condition and

not obstructed.

Check the bearing metal temperatures and the vibrations of the machine, which must be

well with in the limit.

Modern state of the art machines are equipped with Turbine Stress Evaluator (TSE) /

Turbine Stress Calculator (TSC) for safe run-up & loading from different start-up

conditions. This is integral to the DCS system.

Even differential expansion can be taken care of automatically by DCS. However a close

watch by the operator is required and if necessary, manual interfere can be achieved by

the operator.

After necessary soaking period machine to be accelerated to full speed no load (FSNL).

At approx. 90% speed of the machine, exciter breaker will be closed and necessary

voltage will be built up.

Operator can choose to synchronize the machine on automatic mode or on manual

mode.

In automatic mode, which is the safest mode, the Synchronoscope is automatically

switched ON by the Function Group control and generator voltage, frequency and

phase angle are matched with the prevailing grid condition. When this condition is

satisfied, synchronoscope will issue command to close the generator circuit breaker.

Immediately after closing of circuit breaker, generator will be loaded to spinning reserve

load by the programme itself. Operator has to adjust the reactive power as per the

loading or Reactive power control can be put on Auto mode. Operator should check

the reactive power according to the generator characteristic curve supplied by the OEM.

Turbine will follow pre-defined ramp rate as per manufacturers recommendation and will

be loaded up to base load.

Checks to be made for steam purity continuously and necessary steps to be taken for

correcting the deviations. It is of utmost importance that steam parameters to be

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 11 of 21

maintained or else in the long run turbine will be endangered due to various depositions

and undue stress will built up.

All HP & IP super heater drains is having isolation MOV and inching type MOVs. The

isolation MOV is governed by permissive and interlock which is mentioned in detail in

respective logic diagram. There two main parameters for opening and closing drain

MOVs such as Drain pot level and live steam temperature. The inching MOV position is

controlled by HP, IP live steam pressure.

In case LP super heater drains is having one drain MOV which is inching type. The

inching MOV is governed by permissive and interlock which is mentioned in detail in logic

diagram. There two main parameters for opening and closing drain MOVs such as Drain

pot level and live steam temperature. The inching MOV position is controlled by LP live

steam pressure.

For warm and hot start-up, the procedures are similar except that during these

start-ups, all off site systems are in service already.

Start-up in above conditions will be taking less time as machines will be warm or hot, as

the case may be.

Start-up sequence will follow the OEM start-up curves, which are subjected to

modification during the commissioning time.

The VEMAGIRI POWER PLANT startup will be co-ordinated with start-up of the various

equipment and auxiliaries of the plant. Startup power will be supplied from the

APTRANSCO Grid.

Following is the sequence of start-up of the VEMAGIRI POWER PLANT equipment:

Power required for the startup of plant will be from APTRANSCO grid and both the

UTs (Unit Transformers) are considered in service to meet the plant auxiliary and

starting power requirements.

Start (cold, warm & hot) will be initiated only after the following plant/equipment

conditions are met:

i) GTG Ready to Start

ii) HRSG Ready to Start

iii) STG Ready to Start

iv) BOP/Offsite equipment Ready or in operation

v) All instruments are charged and in service.

Required conditions for the each of the above equipment Ready to start condition is

explained below

Plant equipment ready to Start

Certain conditions, considered to be those required for commencement of the startup

sequencing, must be met prior to initiation of the VEMAGIRI POWER PLANT start. These

conditions are monitored by the GTG, HRSG, STG, and BOP/Offsite equipment sequence

logic. Each condition can be fulfilled by manual operator action or by the actions of pre-

set sequencing logic. When all the conditions are met, a portion of, or the complete

VEMAGIRI POWER PLANT, is defined as being in a Ready to Start state. Following are

some typical READY condition lists for the GTG, HRSG and STG.

GTG Ready to Start

- MCC breakers set in auto mode

- Cooling water system ready

- Fuel gas pressure adequate

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 12 of 21

- Gas turbine/generator permissive to start systems ready

- Evaporative cooler ON as required

- HRSG ready

All starting will be done automatically, with the operator to hold the start up sequence at

either crank (pre-ignition) or fire (post-ignition, pre-accelerate) points of start up. An

auto mode selection will result in a start without any holds.

Before issuing the start command, or during startup, the operator may make the

preselected load or base load. If a selection is made, the unit will automatically load to

the selected point and control there. If no selection is made, the unit will load to a low

load referred to as spinning reserve after synchronization. Turbine governor will

automatically be regulated to maintain the megawatt setting assigned to spinning

reserve.

HRSG Ready to Start

Typically ready conditions have already been discussed earlier. Conditions listed below

will be satisfied to fulfil the HRSG Ready to Start condition:

- The HP, IP and LP drum levels normal

- HRSG recirculation pumps in operation

- The HP, IP and LP drum level controller set points within an allowable deviation of

the start-up levels. These are dependent on drum configuration and pressure at start

(determined by HRSG vendor for each start as a function of pre-start drum

pressure).

- HP/IP and LP feed water pumps are in service in minimum recirculation mode

- There are no HRSG trip conditions

- HRSG super heater steam shutoff and bypass valves are closed

- HP and IP economizer vents are closed

- HP/IP and LP feedwater shutoff valves are normally closed prior to start and opened

at the starting point.

- HP, IP and LP superheater vent valves are closed

- HP, IP and LP superheater drain valves are closed

- HP, IP and LP intermittent blowdown valves are closed

- Drip leg drain valves on HP and LP steam headers and bypass lines are in auto and

the valves are closed

- GTG No Trip

- Instrument air pressure OK

STG Ready to Start

Typically ready conditions below will be satisfied to fulfil the STG Ready to Start

condition:

- HP stop valves, reheat stop valves are closed

- LP admission valves are closed

- Steam turbine motor operated and pneumatic operated drain valves are in auto

mode

- Lube oil pressure normal

- Lube oil tank level normal

- Control oil pressure normal

- Turning gear motor is running and turning gear is engaged

- Steam seal system is in service

- Condenser vacuum OK

- CCW system in service

- CW and ACW system at least one pump running and in service

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 13 of 21

Plant Load Control

The purpose of the co-ordinated control scheme is to provide the operation of the Gas

Turbine Generator (GTG), Heat Recovery Steam Generator (HRSG) and the Steam

turbine Generator (STG) in coordinated manner. The co-ordinated control scheme has

been implemented in DCS. The MW demand from the plant coordinated control system

will be sent to GTG control system and will be executed within the GTG maximum/base

load. The STG will follow the GTG-HRSG and will operate on the sliding pressure mode

(valves wide open). However, if the demand exist even after the GTG reaches the

max/base load the additional MW demand should be met by the supplementary firing in

HRSG. GTG load will be restricted to 50% load in the event of only one (1) CW pump

operation.

Plant Load Control Modes

Plant Load Control Without HRSG Supplementary Firing

The plant load control system will be provided to control the output of the entire

combined cycle modules so as to meet the load demand as set by the operator in DCS

operator station. For meeting the load demand, the plant load coordinated control

system will regulate the power generated by the gas turbine generator unit while

forwarding about 2/3rd (can be adjusted) of the demand to the gas turbine generator

(GTG) considering the 1/3rd (can be adjusted) power demand will be compensated by

the steam turbine generator (STG).

The plant coordinated control loop will compare the total generated power output to the

grid with the load demand signal set by the operator and accordingly generate set point

signals for the load controllers of the gas turbine. The set point signals shall be limited

by maximum (base load) and minimum preset load (house load) limits. The maximum

loading rate permitted will be limited by the loading rate as determined by the gas

temperature ramps which shall be preset in the control system. The set point for the

GTG will be provided from the coordinated control loop as indicated in the co-ordinated

control schematic.

Plant Load Control With HRSG Supplementary firing

The GTG base load can be considered as one of the start permissive for the HRSG

supplementary firing, so that the supplementary firing shall not be in operation during

part load operation of the GTG. The MW demand signal generated from the plant

coordinated control loop after GTG reaches its max/base load shall generate alarm in the

plant DCS to indicate the additional power required to meet the plant MW demand.

Based on the MW demand the operator has to make decision to bring the supplementary

firing in operation considering minimum/maximum number of burners in operation &

minimum/maximum heat input.

Once burners system in service, the operator can set the burner system in Auto mode &

the additional MW (power) demand signal shall be sent to the burner system from plant

coordinated control loop to increase/decrease the heat duty, till the MW demand met.

The burner system will operate within the minimum & maximum heat duty limitations.

The supplementary firing shall be withdrawn/burners shut down once the demand is less

than the minimum heat duty of the HRSG burner system & also GTG load demand

reduced below the base load.

HRSG Normal Shutdown:

During normal shutdown of HRSG following procedure is followed in general:

Case 1: Duct burners are ON (Auxiliary firing ON)

The duct burner load will be reduced gradually by modulating the fuel control valve

till the minimum opening position is reached.

Duct burner is taken out of service upon reaching the minimum load point of the fuel

control valve. (Called Turn Down Ratio)

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 14 of 21

Unloading of GTG will follow; this in turn will also start unloading of HRSG steam

generation and STG load.

At this stage it is advisable to take HP-LP bypass system in service as a precaution

against imbalance in the temperature at turbine end. OR

The GTG unloading is continued till the minimum load / permissible steam

temperature of the STG is reached, as per OEM guide line.

Shutdown STG by opening first the generator breaker either manually from a

minimum load OR automatically by Reverse power protection.

By pass stations comes into operation.

GTG is further unloaded till the minimum sustainable load of HRSG is achieved. This

load is defined by either % of GT load OR % of MCR steam flow OR minimum steam

temperature at superheater outlet.

As HRSG load goes down drum level control will follow the logical sequence and will

be transferred to 1-element control. Also feed control station will be changed over to

30% from 100% depending on the logic.

As HRSG shutdown is initiated, IP & LP pegging steam to the deaerator will be closed

via HRSG function group logic. At this stage operator should ensure that necessary NPSH

is available at the suction of BFPs (A suction pressure variation will be indication).

It is advisable to operate boiler blow down (for a brief period) through bottom

header at approximately 30% of the boiler load, as this will discharge some insoluble

salts at higher pressure.

After reaching minimum sustainable load, GTG is also tripped the GT sequencer.

HRSG can be kept under hot box up if the shutdown is planned for a shorter

period. This depends on the rate of depletion of the drum pressure. If drum pressure

reaches less than 2 bar, startup and drum vents will open as per HRSG protection

sequence.

If the HRSG is hot boxed up, then special precautions to be taken during startup

activities with respect to the opening of the line drains and vents. As in this case,

sometimes, operators may Force close the drain valves.

Case 2 : Duct burners are OFF (Auxiliary firing OFF)

The procedure will be same as in case 1, except the following:

No shut down sequence will be initiated for duct burner firing logic.

HRSG Quick Shutdown

A quick shutdown (Protective load shedding - PLS) for GTG will be initiated as per

GT / HRSG protection matrix supplied by the OEM. PLS can be initiated from the GT

protection OR can be initiated from HRSG protection.

GT is de-loaded at a much faster rate than the normal de-loading gradient during

PLS. Normally during PLS operation if at any moment of time the cause of the PLS is

reset, then GT sequencer will automatically stop de-loading of GT and will maintain

status quo. Operator will interfere at this phase to load the GT depending on the

prevailing situation. OR operator can also Reset the PLS from the operating station.

This type of unloading creates more stress to the GT & HRSG parts.

After reaching the Reverse power zone, GT generator breaker will be opened and

GT will trip on Flame OFF condition. OR depending upon manufactures design, GT can

be on FSNL for a stipulated time (called cooling time) and then trips on Flame OFF.

HRSG Trip:

HRSG trips one of the following conditions, IN GENERAL :

Hardwired HRSG emergency push button (from control desk) pressed.

STG trip (signal from STG trip logics) with any of HP,IP & LP Steam bypass stations

closed, to prevent over pressure of HRSG.

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 15 of 21

DA circuit HRSG trip.

LP circuit HRSG trip.

IP circuit HRSG trip.

HP circuit HRSG trip.

Flue gas HRSG trip.

If condenser vacuum rises above trip limit & STG trip protection fails to trip the STG,

then GT trip command will be initiated which will in turn automatically trip the HRSG.

(Please remember that the last protection of STG from high vacuum is the Rupture

diaphragm).

Operation of the plant

General considerations

Trouble-free duty operation in the range from full load to partial load should be the most

frequent operating condition of a fossil-fueled steam power plant. In this operating

condition, there is maximum exploitation of the power plant at the lowest cost and thus

the plant performs at the

best efficiency,

lowest specific fuel consumption,

lowest specific steam consumption,

lowest specific heat consumption, and

highest availability.

Thus it is the task of the operating staff to ensure the operationability of all plant parts

by regular inspection and maintenance, immediate notification of the technical

management, and if possible elimination of irregularities and faults.

Aims of operation

The optimum operation includes not only trouble-free operation at the operating point of

maximum efficiency of the overall plant (at approx. 80 to 100% of load) but also

observance of other requirements with regard to

safety,

economic efficiency,

quality of products, and

environmental protection.

Conditions and criteria of operation

The most important criterion of the point of load at which the plant should be operated

is provided via the load dispatch center from the consumers of the main products

(electricity and/or heat). The power plant can only produce as much of its main products

as the consumers demand. Thus it has also to be taken into account that, depending on

the development of demand, power plants of different design types and efficiency are

used by the companies at different times and are operated at different load points in

order to reach an optimum overall economic result.

It is also important to

reduce the quantity of fresh water required (for cooling as well as for water

treatment),

minimize the waste water arising, and

minimize possibly arising waste.

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 16 of 21

The environmental protection ordinances and the limits stipulated therein are to be

complied with. Deviations from these standards are permitted only in very restricted

exceptional cases.

An economical management of the fuel and consumables and a proper and careful

treatment of all plant parts must be as natural for the operating staff as is the

continuing brushing up of its operating knowledge and capabilities.

In the following list some actions are compiled which considerably reduce the specific

heat consumption (and thus the exploitation of the fuel energy) and increase the

availability and economic efficiency of the plant:

short start-up periods by ensuring flawless performance of all plant parts and strict

observance of the operating rules and standards;

short shutdown periods;

adjustment of steam output of the steam generator to the steam demand of the

turbine;

purposeful hooking up and hooking off of plant parts and equipment in order to

reduce auxiliary consumption;

keeping the steam parameters within the limits in order to keep injection into the

reheater low;

regular cleaning of heating surfaces and condenser pipes in order to maintain heat

transfer and reduce head loss;

keeping the water quality of feedwater, boiler water, condensate (condensate

polishing plant, chemical treatment) within the limits in order to avoid scaling and

corrosion and to keep the necessary blowdown volumes as low as possible.

Preventive inspection and repairs

The operating staff has to observe attentively the function of all systems of the plant.

This may be done by permanent observation of the monitoring devices in the control

room but also by cyclical and periodical walk-around inspections of the installation.

Based on the manufacturer's recommendations and on experiences gained with

commissioning of the plant, control check lists should be prepared and used by the crew

which helps to establish a systematic control.

If a high availability of the plant is required, also preventive replacement of parts which

have reached a certain degree of use may be advisable. Long-term availability also

depends on the maintenance strategy which is to be defined by the power plant owner.

Maintenance strategy

Depending on the contractual and economic objectives he has to meet, the plant owner

has to decide on the maintenance strategy of the plant.

This includes programming of shutdowns for inspection, controls and preventive repairs,

purchase and storage of spare parts and contracting out of maintenance work to outside

companies.

Normally, the maintenance strategy is an economic compromise between repair costs

and losses caused by undelivered power.

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 17 of 21

Controllable losses in combined cycle power plants.

Controllable losses in Steam & Power generating systems fall in different categories.

Before going into details let us go through the following facts quickly:

The fundamental difference between electricity and other commodities is that,

electricity cannot be stored in a large scale, in a practical manner.

Storing of electricity is very expensive & hence should be produced whenever

demanded.

Large fluctuations in the demand during the day requires quick reactions from

generating stations in order to maintain the balance between demand and

production, thus reducing the chance of Grid disturbances.

Hence the major pricing is on reliable supply of electricity, efficiently delivered

and quality maintained.

However efficiency of plants also means that losses to be minimum, because in todays

market, the overall production cost is a key factor of success.

Electricity must be offered at lowest cost and hence whole world is focusing on

minimizing the losses.

The major factor contributing to the efficient production of electricity and steam is HEAT

RATE. All roads finally meet at this point and this is the deciding factor for the pricing.

Before we proceed further, let us focus on the key issues, which directly / indirectly

decide the amount of loss being incurred by the process.

What is Performance?

As per Webstars third new International Dictionary, the definition of performance is:

Performance is a measure of achievement as against expectations.

Capacity to achieve desired results Performance is the outcome of effort /

activity.

This implies that Plant performance improvement lies in the efforts given to maximize

the transformation of energy/ minimizing the losses.

The above two definitions suggests the two features that characterize performance

considerations:

A set of expectations derived from the claim and promises (Qualitative) & a set of

results that one would like to realize (Quantitative).

Effectiveness refers to the extent to which the programmed requirements are met

and Efficiency refers how economically the resources are utilized when providing a

given level of satisfaction.

We are concerned about the second part i.e. how economically the scarce resources are

utilized i.e. Efficiency and reciprocal of efficiency is Heat rate.

Type of Power Plants generally available for base load / peak load operations:

1. Diesel Generator Plants.

2. Steam Turbine plants.

3. Gas Turbine Plants.

4. Nuclear Plants.

5. Combined cycle Plants.

6. Co-generation Plants.

Each of the above plants has their own characteristics and to be dealt accordingly.

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 18 of 21

Conventional steam power plants are suitable for use as coal burning plants in base

load, if cheap coal is available. Whereas combined cycle power plants are more

economical than steam power plants due to its higher efficiency & lower specific price

and low gestation period.

However, whatever the type of plant be, the important factors that control the whole

system are:

Heat Rate: This is the ratio of input and output.

Availability: This is the amount of actual hours for which the plant is available to deliver

energy OR the ratio between declared capacity and nameplate / installed capacity,

calculated on annualizes basis.

Hence all type of losses finally contributes to increase in Heat Rate & hence

must be minimized.

Following are the factors (Losses), in general, which have impact on Heat Rate of a

combined cycle power plant and needs attention:

Losses related to Gas Turbine:

Pressure drop across Gas Turbine Air Intake Filters (AIF): AI filters play an

important role in a gas turbine power plant. Efficient cleaning of air is a

prerequisite for efficient operation of gas turbine compressor. Hence pressure loss

in the AIF system must be minimized. An increase in pressure loss in the inlet

system of approx. 1 Kpa results in an increase of 1.5 Deg C in the exhaust system.

Gas Turbine Axial compressor blade fouling: This is a frequent phenomenon in gas

turbines, as, for a gas turbine, major power is consumed by the compressor, hence

any dirt / salt deposition on the compressor blades decreases the compressor

efficiency & thereby turbine output.

To minimize these losses, followings steps are normally taken:

I. Check the air intake filters regularly, clean by air pulsation (cleaning will not

be effective if air pressure is not sufficient), replace defective filters.

II. Check for proper fitment, if small air gap is there at the base, air bypassing

will occur.

III. Monitor gas turbine power drop from a reference point and set an on-line

and off-line compressor wash regime depending upon the practical operating

experience.

A dirty compressor cannot deliver required quantity of air causing low GT power output

and low axial compressor efficiency.

Losses related to HRSGs

The heat transfer in HRSGs involve losses which are associated with following major

factors:

Physical properties of water-steam cycle & exhaust gases do not match causing

exergic and energetic losses.

Heat transfer surfaces cannot be infinitely large.

The inlet feed water temperature should be sufficiently high in order to prevent

back end corrosion.

Following are the practical problems faced in a specific 156 MW Combined

Cycle Power plant (This can vary from plant to plant):

Losses due to defective /faulty insulation should be minimized. In the above

mentioned plant, they have faced problem with defective insulation causing heat

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 19 of 21

loss. It has been observed that insulating medium, if wet during erection in rainy

season, causes a poor insulation & creates Hot Spots.

Loss of heat also can occur in the top and bottom pent house, if not sealed

properly, causing short circuiting of flue gases in the header section.

In that plant, they have substantially reduced the Boiler blow down loss by

innovatively modifying the boiler water chemical regime. They have not operated

boiler blow down since last one and half months approximately, thereby saving a

lot of makeup water. The basic understanding is that, as modern power stations

are equipped with DM plants having highest quality of feed water, hence dosing of

Tri-sodium phosphate in the HP drum has been reduced drastically and residual

phosphate level in the HP drum has been bench marked as 500 ppb (HP drum

pressure is 72 Barg). Also in the water -steam circuit, ammonia dosing has been

stopped, as dosing of Hydrazine in the downstream of condensate pump is

sufficient of taking care of scavenging of carbon-di-oxide, as Hydrazine is breaking

down to ammonia in the HP drum. This has saved a substantial cost in the chemical

and makeup water. This plant is operating with 0.5 to 0.8 % of cycle makeup.

Initially they had experienced problem of high Cationic conductivity problem in the

water-steam circuit and this had occurred due to interference from Ammonia. Safe

Cationic conductivity is critical for modern steam turbine operation.

Losses due to leakages in the valves, flanges etc are being taking care by either

on-line sealing or a strategic shutdown planning, considering the generation target

involved.

It is not always prudent to take shutdown of machines only to attend a minor /

non-critical leakage or passing.

Losses in the Steam Turbine and Condenser section includes but not limited to the

following reasons:

Major loss of power output of a steam turbine is due to poor / bad vacuum in the

condenser.

There are number of reasons of poor vacuum in the condenser.

Condenser tube fouling contributes to poor vacuum.

Another reason of poor vacuum can be attributed to inefficient Steam ejector /

vacuum pump or in-leakage air into the condenser. Thus it is necessary to check

the circuit under vacuum periodically along with steam ejector nozzles etc.

Poor vacuum can also be attributed to improper or off-design functioning of the

cooling towers and cooling water system. Hence it is necessary to check the

performance of cooling towers and take necessary preventive maintenance for

performance improvement.

Proper treatment and maintaining threshold values in the circulating water system

will aid in minimizing losses, as requirement of cooling tower blowdown will come

down.

So in every part of the power generating station there lies a potential to minimize

losses, in any form or by any way.

Losses in the electrical systems also to be looked into details and process optimization to

be done to minimize the losses.

We should strive hard to improve the HEAT RATE by controlling losses or by

optimizing the process.

Part load operation of Combined cycle power plant.

The efficiency of gas turbine mainly depends on clean and cool intake air. Also exhaust

gas temperature and temprature of annular gap and axial gap between casing, nozzles

and rotating wheel bucket are also limiting factors for receiving efficient output from gas

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 20 of 21

turbine. When gas turbine operates with part load the EGT also remains on lower side,

hence input to HRSG becomes less.

0

1000

2000

3000

4000

5000

6000

GT1 GT2 GT3

Power In

MWH

Heat rate

kcal/kwh

From above performance curves it is evident that operating GTG in lower load increases

the heat rate i.e. kcal/kwh, hence must be avoided unless operating condition makes it

inevitable. More over lower EGT and gas flow invariably reduces the steam generation,

and unless the drum pressure is maintained by controlling steam flow or by additional

heat input by supplementary firing (can be done as GT exhaust contains 16 % oxygen

by volume) a reduction in heat transfer would become forthcoming with higher stack

loss.

In combined cycle power plant where plant is in part load the operation, the optimized

part load condition must be selected basis waste gas temperature through stack,

number of expansion stages of STG and condenser vacuum. Reduction in steam

pressure will cause steam chest valve to open more and more causing more steam flow

demand to maintain the load and can cause, wet steam at LP stage causing mechanical

vibration, overloading of condenser and reduction in vacuum if there is limitation in

cooling water flow. All above events worsen the thermal efficiency ration of turbine

hence invariably bring down overall thermal efficiency, Ideally the LP stage exhaust

steam condition should be just as saturated dry steam in corresponding vacuum (-

pressure) in condenser and in condenser only latent heat to be extracted to convert the

saturated steam to saturated condensate at same pressure in condenser.

In boiler side due to pressure drop saturation temprature will be lowered causing rapid

evaporation and enhance possibility of priming if the variation of GTG and STG loads are

frequent and not organized. With enhanced steam flow there would be less degree of

superheat as the volume & temperature of GT exhaust gas flow remains less with part

load. In the situation where part load operation is unavoidable the plant should be

operated in boiler pressure control mode if supplementary firing is not intended. Where

option available to enhance the power out put, the GTG should be selected for primary

control of load variation to maintain the steam pressure with STG on standby load

control mode. When operating part load condition of combined cycle power plant the

Steam pressure and temprature must be maintained as required by design at the inlet of

STG to avoid above-mentioned operational problem. The GTG load to be increased in

case of power demand which in turn produce improve quality steam for STG, improving

thermal efficiency ratio. The excess steam may be used for regenerative feed heaters,

LARSEN & TOUBRO LIMITED EPC POWER

TRAINING MANUAL

PROJECT 388.5 MW Combined Cycle Power Plant DOC No. IBDC/ L&T/ VCCPP/ 15

DOC. TITLE CCPP Operation Page No. Page 21 of 21

process steam, or educators to improve condenser vacuum, to have more work in LP

stage etc.

Lowering the initial steam temperature by desuperheating would result in reduction in

overall thermal efficiency.

S-ar putea să vă placă și

- Combined Cycle Power Plant Operation GuideDocument21 paginiCombined Cycle Power Plant Operation GuideParmeshwar Nath Tripathi100% (3)

- Power PlantDocument11 paginiPower Plantarvidkumar87060Încă nu există evaluări

- Thermal Power Plant: Pre-Operational ActivitiesDe la EverandThermal Power Plant: Pre-Operational ActivitiesEvaluare: 4 din 5 stele4/5 (4)

- Combined Cycle PrinciplesDocument43 paginiCombined Cycle PrinciplesFazalur Rehman Babar100% (1)

- Commissioning of Combined Cycle Power PlantsDocument30 paginiCommissioning of Combined Cycle Power Plantsa_mohid1780% (5)

- Combine Cycle Power Plant Design InformationDocument47 paginiCombine Cycle Power Plant Design Informationkalasivan0% (1)

- 220021enc Combined Cycle Power Plant OverviewDocument27 pagini220021enc Combined Cycle Power Plant OverviewBalajirao Samatham100% (4)

- CCPP Plant Operating ProceduresDocument123 paginiCCPP Plant Operating Proceduressprotkar100% (5)

- Shuaiba North HRSG ManualDocument91 paginiShuaiba North HRSG Manualmartinp17171100% (7)

- Power Plants and Heat RateDocument3 paginiPower Plants and Heat Ratemasreenu100% (1)

- HRSG StartupDocument20 paginiHRSG StartupKvvPrasad100% (1)

- 02B HRSGDocument50 pagini02B HRSGrseclen100% (2)

- CEP SamalkotDocument96 paginiCEP SamalkotkukugargÎncă nu există evaluări

- Performance Improvement of Combined Cycle Power Plant Based On The Optimization of The Bottom Cycle and Heat RecuperationDocument6 paginiPerformance Improvement of Combined Cycle Power Plant Based On The Optimization of The Bottom Cycle and Heat Recuperationwgxiang100% (4)

- Operating Manual 670 MW Coal Fired Power Plant Training SimulatorDocument134 paginiOperating Manual 670 MW Coal Fired Power Plant Training SimulatorsprotkarÎncă nu există evaluări

- HRSGDocument9 paginiHRSGdeepeshgmat100% (4)

- Combined Cycle PowerplantDocument34 paginiCombined Cycle PowerplantDarrel CamachoÎncă nu există evaluări

- Book 9HA CCPP Operations Training at AEPLDocument174 paginiBook 9HA CCPP Operations Training at AEPLFazalur Rehman Babar100% (2)

- CCPPDocument34 paginiCCPPphanindra100% (1)

- Power Plant Start Up ProcedureDocument4 paginiPower Plant Start Up ProcedureFirman Adi Susetyo50% (2)

- Power PlantDocument42 paginiPower Planthaitham1995Încă nu există evaluări

- CCPP Operations Training at Albario EngineeringDocument2 paginiCCPP Operations Training at Albario EngineeringFazalur Rehman Babar0% (1)

- Heat Rate Test of Commbine Cycle Power Plants (CCPP) On Gas FuelDocument35 paginiHeat Rate Test of Commbine Cycle Power Plants (CCPP) On Gas FuelMunibÎncă nu există evaluări

- Mechanical Engineering Project - Thermal Power Plant Study - WWW - Amie.nbcafe - inDocument24 paginiMechanical Engineering Project - Thermal Power Plant Study - WWW - Amie.nbcafe - inbtdoss72100% (1)

- Combined Cycle FundamentalsDocument76 paginiCombined Cycle FundamentalsVinnu89% (9)

- How To Start Combined Cycle Power PlantDocument37 paginiHow To Start Combined Cycle Power PlantBv Rao100% (1)

- Start-Up in Steps Siemens V94.2 Gas Turbine at KAPCODocument13 paginiStart-Up in Steps Siemens V94.2 Gas Turbine at KAPCOFazalur Rehman Babar89% (19)

- SOP For Turbine ChecklistDocument11 paginiSOP For Turbine Checklistpradeep.selvarajanÎncă nu există evaluări

- Super Critical BoilerDocument78 paginiSuper Critical BoilerSam100% (2)

- Heat Recovery Steam Generator 5Document29 paginiHeat Recovery Steam Generator 5Hitesh SinglaÎncă nu există evaluări

- 500 MW Boiler-1Document14 pagini500 MW Boiler-1Priyal Patil100% (1)

- Plant Performance CalculationsDocument2 paginiPlant Performance CalculationsKalki Communication Technologies Ltd100% (1)

- HP-Bypass and LP BypassDocument3 paginiHP-Bypass and LP Bypassdinesh7136100% (1)

- 500 MW Turbine Design DataDocument19 pagini500 MW Turbine Design Datasanjay kumar100% (1)

- Heat Recovery Steam GeneratorsDocument94 paginiHeat Recovery Steam GeneratorshoangpalestineÎncă nu există evaluări

- Contoh CCPP Plant Operating Manual ProceduresDocument163 paginiContoh CCPP Plant Operating Manual ProceduresDwi Mulyanti Dwimulyantishop100% (1)

- Combined Cycle Systems for UtilitiesDocument22 paginiCombined Cycle Systems for UtilitiesAli Bari100% (1)

- Alstom GT24>26Document20 paginiAlstom GT24>26Shin Hye Yean100% (3)

- From Turbine Manual: Gas Turbine Inlet Bleed HeatingDocument3 paginiFrom Turbine Manual: Gas Turbine Inlet Bleed HeatingSnehal PatelÎncă nu există evaluări

- HRSGDocument5 paginiHRSGbhp_4677Încă nu există evaluări

- BHEL turbine operation manual 500 MWDocument2 paginiBHEL turbine operation manual 500 MWAlam50% (2)

- BR GT GasturbineDocument9 paginiBR GT GasturbineVioleta Patriche100% (1)

- Gas-Steam Turbine Technical Data 2012Document8 paginiGas-Steam Turbine Technical Data 2012Ninh Quoc Trung100% (1)

- Heat Balance & Thermal Power Plant Performance (MDT)Document44 paginiHeat Balance & Thermal Power Plant Performance (MDT)Anita BaitadeÎncă nu există evaluări

- HRSG Start Up & Shut Down Description (Yazd Combined Cycle Power Plant)Document16 paginiHRSG Start Up & Shut Down Description (Yazd Combined Cycle Power Plant)En CsakÎncă nu există evaluări

- Extending the Range of Single-Shaft Combined Cycle Power PlantsDocument12 paginiExtending the Range of Single-Shaft Combined Cycle Power PlantsSrinivasa Rao PallelaÎncă nu există evaluări

- Power Plant Question Bank Answer KeyDocument112 paginiPower Plant Question Bank Answer KeysistersoundÎncă nu există evaluări

- Thermax HRSGDocument12 paginiThermax HRSGrevenk100% (1)

- HRSG Operator Training ManualDocument184 paginiHRSG Operator Training ManualXcdxtv100% (10)

- Turbine Heat Rate CalculationDocument2 paginiTurbine Heat Rate Calculationkaruna34650% (2)

- Aux Steam SystemDocument14 paginiAux Steam SystemDipti BhanjaÎncă nu există evaluări

- Power Plant Familirization - NTPCDocument489 paginiPower Plant Familirization - NTPCminksy051100% (8)

- Sp9907-A - Chiller Statup ProceduresDocument4 paginiSp9907-A - Chiller Statup ProceduresEmerson Penaforte100% (1)

- Preparing Process Unit for Initial StartupDocument7 paginiPreparing Process Unit for Initial StartupTan JieShengÎncă nu există evaluări

- CcOLD STARTUPDocument15 paginiCcOLD STARTUPAnonymous ICKtnYvC100% (1)

- Turbine Operation GuideDocument27 paginiTurbine Operation GuidebhaskarÎncă nu există evaluări

- Commissioning of HydroDocument59 paginiCommissioning of Hydropawannhpc100% (3)

- Stage - 3 Steam Generator Operating ProcedureDocument22 paginiStage - 3 Steam Generator Operating Procedurerishikesh chandanÎncă nu există evaluări

- How to safely warm up and cool down a cement kilnDocument15 paginiHow to safely warm up and cool down a cement kilnrupesh soniÎncă nu există evaluări

- Commissioning Checklist PDFDocument74 paginiCommissioning Checklist PDFaanouar77Încă nu există evaluări

- Design Guide For Short Circuit Calculation Generation SystemDocument22 paginiDesign Guide For Short Circuit Calculation Generation SystemEgit Bobyarta50% (2)

- KKS Guideline For Equipments-Rev1Document74 paginiKKS Guideline For Equipments-Rev1Dragos Ungureanu100% (1)

- Basic Instrumentation Measuring Devices and Basic Pid ControlDocument125 paginiBasic Instrumentation Measuring Devices and Basic Pid ControlCuong Nguyen ChiÎncă nu există evaluări

- Basic Instrumentation Measuring Devices and Basic Pid ControlDocument125 paginiBasic Instrumentation Measuring Devices and Basic Pid ControlCuong Nguyen ChiÎncă nu există evaluări

- GET6600G Section 2 Rev 1 BookmarksDocument10 paginiGET6600G Section 2 Rev 1 BookmarksBaptÎncă nu există evaluări

- 210014-P7002-E02-0042-00 - Relay Coordination For 400V & 6kVDocument52 pagini210014-P7002-E02-0042-00 - Relay Coordination For 400V & 6kVEgit Bobyarta80% (5)

- Hazardous Zone, Class, DivisionDocument26 paginiHazardous Zone, Class, DivisionHạo Nam-Born To WinÎncă nu există evaluări

- IEEE STD 1050-89Document81 paginiIEEE STD 1050-89Flo Mirca100% (1)

- 3 Phase - 307048 Unit 65 Three Phase SystemsDocument9 pagini3 Phase - 307048 Unit 65 Three Phase SystemsEgit BobyartaÎncă nu există evaluări

- 21 Surface CondensersDocument12 pagini21 Surface CondensersMohsin EhsanÎncă nu există evaluări

- Burgmann iTDGS Product PresentationDocument16 paginiBurgmann iTDGS Product PresentationAbdulrahman AlkhowaiterÎncă nu există evaluări

- Commercial Refrigeration Product Catalog 2011-2012: Edition 3Document72 paginiCommercial Refrigeration Product Catalog 2011-2012: Edition 3erreagaaÎncă nu există evaluări

- Marine Steam Turbine Generator GuideDocument55 paginiMarine Steam Turbine Generator GuideDharmendra KumarÎncă nu există evaluări

- High-Powered Air-Cooled Condensers: STULZ The Natural ChoiceDocument4 paginiHigh-Powered Air-Cooled Condensers: STULZ The Natural ChoicerobinssonÎncă nu există evaluări

- E401 1000 Air Cooled CondensersDocument4 paginiE401 1000 Air Cooled CondensersNguyen Anh TuanÎncă nu există evaluări

- Calculations For Heat Exchanger, CIP & ATFD (Master Copy)Document21 paginiCalculations For Heat Exchanger, CIP & ATFD (Master Copy)saurabhzalte100% (1)

- Boiler ProblemsDocument59 paginiBoiler ProblemsDharmendra BurraÎncă nu există evaluări

- Technical DiaryDocument127 paginiTechnical Diarytushar67100% (1)

- HP LP BypassDocument34 paginiHP LP BypassharisankarÎncă nu există evaluări

- Heat Rate EpriDocument48 paginiHeat Rate EpritbfakhrimÎncă nu există evaluări

- Katpp Project Report 17 AugustDocument41 paginiKatpp Project Report 17 AugustRamniwas DhakarÎncă nu există evaluări

- Coal-Fired Power Plant: Presented byDocument21 paginiCoal-Fired Power Plant: Presented byMuhamad Adam JemaliÎncă nu există evaluări

- 11 CPRIJournalVol-7Paper10Document13 pagini11 CPRIJournalVol-7Paper10rezaÎncă nu există evaluări

- Steam CondenserDocument26 paginiSteam CondenserPushkar Pandit100% (1)

- A. Summary of The Heat Balance For Turbine Hall, Temperature and EnthalpiesDocument9 paginiA. Summary of The Heat Balance For Turbine Hall, Temperature and EnthalpiesXype LanderÎncă nu există evaluări

- Air Ejector Selection PDFDocument9 paginiAir Ejector Selection PDFmyungkwan haÎncă nu există evaluări

- Manual WPC 4000 5000 7000 9000 15000 12 - 2015Document32 paginiManual WPC 4000 5000 7000 9000 15000 12 - 2015Sabiho GinoÎncă nu există evaluări

- VEIT Ironing Technology For TextileCare 06 1219Document24 paginiVEIT Ironing Technology For TextileCare 06 1219Ƥαѵαи Καlψαƞ ΚÎncă nu există evaluări

- 03 APC ReductionDocument55 pagini03 APC ReductionDevanshu SinghÎncă nu există evaluări

- General Layout of Modern Steam Power PlantDocument15 paginiGeneral Layout of Modern Steam Power PlanttabishkhanaligÎncă nu există evaluări

- TR 109546Document301 paginiTR 109546Piyush AgarwalÎncă nu există evaluări

- Operation Principles of Steam Turbine. 1. Explain Why Main Condenser Is Kept On VacuumDocument2 paginiOperation Principles of Steam Turbine. 1. Explain Why Main Condenser Is Kept On VacuumFernandez John Ralph L.Încă nu există evaluări

- Vacuum SystemDocument28 paginiVacuum SystemSam100% (1)

- Pump Installation Safety and Best PracticesDocument62 paginiPump Installation Safety and Best Practicesdieguineo100% (1)

- Framed Foundation Design for Turbo GeneratorDocument31 paginiFramed Foundation Design for Turbo GeneratorVisa Meena2351Încă nu există evaluări

- Indian BOE Coaching Services Provides Expert Guidance on Combustion SystemsDocument10 paginiIndian BOE Coaching Services Provides Expert Guidance on Combustion SystemsAlok DoshiÎncă nu există evaluări

- Cement Kiln Waste Heat RecoveryDocument25 paginiCement Kiln Waste Heat RecoveryhoangpalestineÎncă nu există evaluări

- Kiwicool User ManualDocument10 paginiKiwicool User ManualJaÎncă nu există evaluări

- Technical Specification 800 MWDocument581 paginiTechnical Specification 800 MWRINJU100% (1)