Documente Academic

Documente Profesional

Documente Cultură

TC230 Expert IEC60870-5-103

Încărcat de

Manish RandhawaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

TC230 Expert IEC60870-5-103

Încărcat de

Manish RandhawaDrepturi de autor:

Formate disponibile

Voltage Regulator

TAPCON 230 expert

Supplement

2195770/03 EN . Protocol Specification IEC 60870-5-103

All rights reserved by Maschinenfabrik Reinhausen

Dissemination and reproduction of this document and use and disclosure of its content are strictly prohibited

unless expressly permitted.

Infringements will result in liability for compensation. All rights reserved in the event of the granting of patents,

utility models or designs.

The product may have been altered since this document was published.

We reserve the right to change the technical data, design and scope of supply.

Generally the information provided and agreements made when processing the individual quotations and orders

are binding.

The original operating instructions were written in German.

Table of contents

Maschinenfabrik Reinhausen 2014 3 2195770/03 EN TAPCON 230 expert

Table of contents

1 Introduction......................................................................................................................... 4

1.1 Subject to change without notice......................................................................................................... 4

1.2 Completeness...................................................................................................................................... 4

1.3 Supporting documents......................................................................................................................... 4

1.4 Safekeeping......................................................................................................................................... 4

2 Physical interfaces.............................................................................................................. 5

3 Setting device parameters ................................................................................................. 7

4 Protocol specification......................................................................................................... 9

4.1 Message structure............................................................................................................................... 9

4.2 Sequences........................................................................................................................................... 9

4.2.1 Time synchronization ............................................................................................................................................ 9

4.2.2 General query...................................................................................................................................................... 10

4.2.3 General command............................................................................................................................................... 11

4.2.4 Generic data general query................................................................................................................................. 11

4.2.5 Generic command (write entry with execution) ................................................................................................... 12

4.3 Monitoring message for the tap position............................................................................................ 13

5 Data points......................................................................................................................... 15

5.1 Control direction (commands) ........................................................................................................... 15

5.2 Monitoring direction (messages) ....................................................................................................... 16

Glossary............................................................................................................................. 20

1 Introduction

Maschinenfabrik Reinhausen 2014 4 2195770/03 EN TAPCON 230 expert

Introduction

The technical file contains detailed descriptions for implementing the IEC

60870-5-103 interface protocol.

This technical file is intended solely for specially trained and authorized per-

sonnel.

Subject to change without notice

The information contained in this technical file comprises the technical speci-

fications approved at the time of printing. Significant modifications will be in-

cluded in a new edition of the technical file.

The document number and version number of this technical file are shown in

the footer.

Completeness

This technical file is incomplete without the supporting documentation.

Supporting documents

The following documents apply to this technical file:

Operating instructions for TAPCON 230 expert

Quick reference guide to TAPCON 230 expert

Safekeeping

This technical file and all supporting documents must be kept ready at hand

and accessible for future use at all times.

1

1.1

1.2

1.3

1.4

2 Physical interfaces

Maschinenfabrik Reinhausen 2014 5 2195770/03 EN TAPCON 230 expert

Physical interfaces

The device has been developed in accordance with applicable EMC stan-

dards. In regards to complying with EMC standards, please refer to the cor-

responding chapter on the topic of "Electromagnetic Compatibility" in the de-

vice's operating instructions.

You can find additional information on wiring and routing instructions for the

fiber-optic cable in the operating instructions for this device.

The following physical interfaces are available on the device for data trans-

mission using the control system protocol:

RS232 9-pin SUB-D connector

Pin 2: TxD

Pin 3: RxD

Pin 5: GND

RS485 3-pin bush from Phoenix MSTB 2.5/3-GF-5

Pin 1: GND (100 ground resistance)

Pin 2: B (inverted)

Pin 3: A (non-inverted)

Polarity:

A > B by 200 mV corresponds to 1

B < A around 200 mV corresponds to 0

An inactive communication cable corresponds to 1.

The start bit has the designation 0.

Recommended terminating resistor 120 .

Fiber-optic

cable (FO)

F-ST (850 nm or 660 nm)

F-SMA (850 nm or 660 nm)

Table 1: Interfaces available

Transmission on physical level:

Asynchronous with 8 data bits, even parity, 1 stop bit (8E1)

2

2 Physical interfaces

Maschinenfabrik Reinhausen 2014 6 2195770/03 EN TAPCON 230 expert

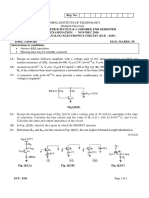

Figure 1: Voltage regulator connections

1 RS485 4 RJ45 (Ethernet)

2 RS232 5 CAN bus

3 Fiber-optic cable

3 Setting device parameters

Maschinenfabrik Reinhausen 2014 7 2195770/03 EN TAPCON 230 expert

Setting device parameters

In order to use the control system protocol, you need to set the device pa-

rameters.

Please refer to the device's operating instructions for more information re-

garding setting the device parameters.

You must set the following parameters:

Parameter RS232 RS485 OF

Communication protocol IEC 60870-5-103

MODBUS format Not required

Communication port RS232 RS485 OF

Baud rate communication 9.6; 19.2; 38.4 or 57.6 kilobaud

Network address Not required

TCP port Not required

OF light on/off Not required Not required ON: Light ON at 1

OFF: Light OFF at 1

Local SCADA address 0 to 254 (255 = broadcast message)

SCADA master address Not required

Unsolicited messages Not required

Repeatedly unsolicited

messages

Not required

Appl. confirm. time exceed-

ed

Not required

RS485 transmit delay time Not required 0254 ms* Not required

Table 2: Device parameters

*) e.g. 2 ms, to compensate for the response time of an external RS485/

RS232 transformer when changing between transmitting and receiving oper-

ation.

Parameter RS232 RS485 OF RJ45

CI protocol DNP3

CI port RS232 RS485 OF RJ45

CI baudrate 9.6; 19.2; 38.4 or 57.6 kilobaud Not required

IP address Not required 0.0.0.0

TCP port Not required 1234

OF inversion Not required ON: Light ON at 1

OFF: Light OFF at

1

Not required

CI address (SCADA) 1...9,999

Master address (SCADA) 0...9,999

3

3 Setting device parameters

Maschinenfabrik Reinhausen 2014 8 2195770/03 EN TAPCON 230 expert

Parameter RS232 RS485 OF RJ45

Unsolicited messages On/Off

Repeatedly unsolicited

messages

1...100 (0 = infinite)

Appl. confirm. time exceed-

ed

1...60 s

RS485 transmit delay time Not required 0254 ms* Not required Not required

Table 3: Device parameters

*) e.g. 2 ms, to compensate for the reaction time of an external RS485/

RS232 transformer when changing between transmitting and receiving oper-

ation.

4 Protocol specification

Maschinenfabrik Reinhausen 2014 9 2195770/03 EN TAPCON 230 expert

Protocol specification

The IEC60870-5-103 interface protocol was originally developed for commu-

nicating between protective devices. The pre-defined function types and the

associated information numbers are not suitable for the information that the

voltage regulator has to transmit.

A function type from the "private sphere" of the protocol is therefore used for

all "non-generic data points".

The information numbers for all general commands and messages with the

function type from the "private sphere" are specific.

Analog values are transferred in the control direction (command) and moni-

toring direction (message) using a generic message type. All measured val-

ues are assigned to class 2 and all parameters to class 1.

In addition to the 9.6 and 19.2 kilobaud rates required by the standard, 38.4

and 57.6 kilobaud can also be selected on the voltage regulator.

Message structure

The function types, type codes and data types listed in the data tables are

explained in the following section.

The following function types are used:

110 = function type from the private sphere (can be defined specifically)

254 = generic function type

255 = global function type

The following type codes are used:

1 = message with time stamp

6 = time synchronization

7 = general query

10 = generic data

20 = general command

21 = generic command

The following data types are used:

7 = short real

Sequences

Sample sequences of the protocol are described in the following section.

Time synchronization

Sample command for time synchronization:

68 f f 68 28 1 6 81 8 1 ff 0 77 9 2f 88 90 9 9 91 16

4

4.1

Function type

Type code

Data type

4.2

4.2.1

4 Protocol specification

Maschinenfabrik Reinhausen 2014 10 2195770/03 EN TAPCON 230 expert

Code (hexadeci-

mal)

Meaning

68 f f 68 28 1 Start of message

6 Type code = 6 (decimal) = time synchronization

81 -

8 Reason for transmission = 8 (decimal) = time syn-

chronization

1 -

ff Function type (or address of 1st octet's information

object) = 255 (decimal) = global function type

0 Info number (or address of 2nd octet's information

object) = 0 = time synchronization

77 -

9 2f 88 90 9 9 Time structure CP56Time2a

91 16 End of message

Table 4: Sample command for time synchronization

After time synchronization, the voltage regulator returns the time synchroni-

zation feedback as positive confirmation. The reason for transmission is set

to 8.

This time specification is used, among other things, for the display in

TAPCONtrol visualization software.

The time stamp in the regulator's telegrams is produced by the communica-

tion card and is only set when the message is sent.

General query

Sample general query (GQ):

68 9 9 68 43 1 7 81 9 1 ff 0 0 d5 16

Code (hexadeci-

mal)

Meaning

68 9 9 68 43 1 Start of message

7 Type code = 7 (decimal) general query

81 -

9 Reason for transmission 0 = not used

1 -

ff Function type (or address of 1st octet's information

object) = 255 (decimal) = global function type

0 Info number (or address of 2nd octet's information

object) = general query initiation

0 -

d5 16 End of message

Table 5: Sample general query

4.2.2

4 Protocol specification

Maschinenfabrik Reinhausen 2014 11 2195770/03 EN TAPCON 230 expert

After the last data message from the general query cycle, the "GQ complete"

message is issued with type code 8 and reason for transmission 10.

General command

Sample general command:

68 a a 68 43 1 14 81 14 1 6e 10 1 0 6d 16

Code (hexadeci-

mal)

Meaning

68 a a 68 43 1 Start of message

14 Type code = 20 (decimal) = general command

81 -

14 Reason for transmission = 20 (decimal) = general

command

1 -

6e Function type (or address of 1st octet's information

object) = 110 (decimal) = private sphere

10 Info number (or address of 2nd octet's information

object) = 16 (decimal) = Auto/Manual

1 Value = OFF

0 -

6d 16 End of message

Table 6: Sample general command

After receiving a valid command, the voltage regulator sends the command

message back as positive confirmation. The reason for transmission is set to

20.

If the command cannot be executed, the reason for transmission is 21.

Generic data general query

Sample generic data general query:

68 a a 68 43 1 15 81 9 1 fe f5 0 0 d7 16

Code (hexadeci-

mal)

Meaning

68 a a 68 43 1 Start of message

15 Type code = 21 (decimal) = general query

81 -

9 Reason for transmission = 9 (decimal) = not used

1 -

fe Function type (or address of 1st octet's information

object) = 254 (decimal) = generic function type

4.2.3

4.2.4

4 Protocol specification

Maschinenfabrik Reinhausen 2014 12 2195770/03 EN TAPCON 230 expert

Code (hexadeci-

mal)

Meaning

f5 Info number (or address of 2nd octet's information

object) = 245 (decimal) = general query generic da-

ta

0 -

0 -

d7 16 End of message

Table 7: Sample generic data general query

After the last data transfer for the "General query", a message entitled "GQ

complete" is transferred with type code 10, info number 245 and reason for

transmission 10.

Generic command (write entry with execution)

Sample generic data general query:

68 14 14 68 43 1 a 81 28 1 fe fa 0 1 37 1 1 7 4 1 0 0 ca

42 42 16

Code(hexadeci-

mal)

Meaning

68 14 14 68 43

1

Start of message

a Type code = 10 (decimal) = generic data

81 -

28 Reason for transmission = 40 (decimal) = generic

write command

1 -

fe Function type (or address of 1st octet's information

object) = 254 (decimal) = generic function type

fa Info number (or address of information object 2nd

octet) = 250 (decimal) = write entry

0 -

1 -

37 1 GIN LSB = 55 (decimal), GIN MSB = 1; 55 = de-

sired voltage value 1

1 -

7 Data type = 7 = short real

4 -

0 0 ca 42 4 bytes of data

42 16 End of message

Table 8: Sample generic command (write entry with execution)

After receiving a valid command, the voltage regulator sends the command

message back as positive confirmation. The reason for transmission is set to

40.

4.2.5

4 Protocol specification

Maschinenfabrik Reinhausen 2014 13 2195770/03 EN TAPCON 230 expert

If the command cannot be executed, the reason for transmission is 41.

The generic command "Write entry with confirmation" (info number 249) is

not implemented.

Monitoring message for the tap position

The tap position is reported in 3 messages simultaneously:

Type code 10

Type code 4

Type code 204

The messages are structured as follows:

Message type 10

Variable structure code 0x81

Reason for transmission 1 or 9

Shared address of ASDU Address set

Function type 254

Information number 244

RII 1

NGD 1

GIN LSB 54

GIN MSB 2

KOD 1

Data type 7 (short real)

Number of data bytes 4

Quantity 1

Data (4 bytes, short real)

Table 9: Structure of a message with type code 10

Message type 4

Variable structure code 0x81

Reason for transmission 1 or 9

Shared address of ASDU Address set

Function type 110

Information number 118

Data (4 bytes, short real) Tap position

Relative time ms (2 bytes) Not used, always 0

Error number (2 bytes) Not used, always 0

Time (2 bytes) Time

Table 10: Structure of telegram with type code 4

Message type 204

Variable structure code 0x81

4.3

4 Protocol specification

Maschinenfabrik Reinhausen 2014 14 2195770/03 EN TAPCON 230 expert

Reason for transmission 1 or 9

Shared address of ASDU Address set

Function type 110

Information number 54

Data (4 bytes, short real) Tap position

Time (4 bytes)

SIN (1 byte)

Table 11: Structure of telegram with type code 204

The examples were taken from various log files where the message traffic

between a computer and the voltage regulator was recorded. The address of

the voltage regulator was set to 1.

Some of the tap positions in the sample telegrams selected are different in

order to show examples with different values. The same tap position is nor-

mally reported in all three telegrams.

Telegram Comments

68 9 9 68 43 1 7 81 9 1 ff 0 0 d5 16 General query command from the computer

68 a a 68 43 1 15 81 1 fe f5 0 0 d7 16 General query command for generic data from

the computer

68 14 14 68 28 1 4 81 9 1 6e 76 0 0 20 41

0 0 0 0 f3 9b 82 0 d 16

Telegram with type 4, sent during the general

query

68 14 14 68 28 1 a 81 9 1 fe f4 0 81 36 2

1 7 4 1 0 0 20 41 d7 16

Telegram with type 10, sent during the general

query

Tap position 10 is reported in bytes 0 0 20 41

68 11 11 68 28 1 cc 81 9 1 6e 36 0 0 0 0

c7 65 80 0 0 d0 16

Telegram with type 204, sent during the gener-

al query

Tap position 0 is reported in bytes 0 0 0 0

68 14 14 68 28 1 4 81 1 1 6e 76 0 0 80 3f

0 0 0 0 fd a4 27 8b a6 16

Telegram with type 4, sent due to a change in

tap position

Tap position 1 is reported in bytes 0 0 80 3f

68 14 14 68 28 1 a 81 1 1 fe f4 0 1 36 2

1 7 4 1 0 0 80 3f ad 16

Telegram with type 10, sent due to a change in

tap position

Tap position 1 is reported in bytes 0 0 80 3f

68 11 11 68 8 1 cc 81 1 1 6e 36 0 0 0 40

18 d5 27 8b 0 db 16

Telegram with type 204, sent due to a change

in tap position

Tap position 2 is reported in bytes 0 0 0 40

Table 12: Examples of messages for monitoring telegrams of the tap position

Examples of messages for

tap position telegrams

5 Data points

Maschinenfabrik Reinhausen 2014 15 2195770/03 EN TAPCON 230 expert

Data points

The data points of the protocol are described in the following section.

Control direction (commands)

Remote mode needs to be set so that commands from the control system

are carried out at the TAPCON 230.

The following data points have the properties stated below:

Type code = 10

Function type = 254

Data type = 7

GIN

LSB

GIN

MSB

Class Description

55 1 1 Desired voltage value 1***

56 1 1 Desired voltage value 2***

57 1 1 Desired voltage value 3***

Table 13: Data points in control direction

***) Deviations may arise between the set value and the value transmitted

via the interface if the value set cannot be depicted accurately as a "short re-

al" value. (e.g. 100.555 via interface => 100.5 in the display)

The following data points have the properties stated below:

Type code = 20

Byte 2 information number = 110

Class = 1

Info

number

byte 1

Description

16 Auto/manual (On = auto mode; Off = manual mode)

17 Raise (On = raise; Off = lower; only in manual mode)

18 Lower (On = lower, Off = no function; only during manual

mode)

19 Desired voltage value 1 (On = active)

20 Desired voltage value 2 (On = active; it must not be possible

for desired value 2 to be activated by a GPI)

21 Desired voltage value 3 (On = active; it must not be possible

for desired value 3 to be activated by a GPI)

5

5.1

5 Data points

Maschinenfabrik Reinhausen 2014 16 2195770/03 EN TAPCON 230 expert

Info

number

byte 1

Description

35 Parallel operation (On = active)

Please note that in order to activate parallel operation, ALL

conditions for parallel operation must be satisfied, e.g. the

voltage regulator group assignment must also be set and the

CAN address must not be 0!

36 Master parallel operation method (On = master, Off = no func-

tion)

Info: "On" has no function if the parallel operation method can

be selected using a General Purpose Input (GPI)!

37 Follower parallel operation method (On = follower, Off = no

function)

Info: "On" has no function if the parallel operation method can

be selected using a General Purpose Input (GPI)!

38 Circulating reactive current parallel operation method (On =

circulating reactive current, Off = no function)

Info: "On" has no function if the parallel operation method can

be selected using a General Purpose Input (GPI)!

48 Auto synchronization parallel operation method (On = auto

synchronization, Off = no function)

Info: "On" has no function if the parallel operation method can

be selected using a General Purpose Input (GPI)!

57 Group 1 parallel operation (On = voltage regulator is assigned

group 1)

Assignment to groups 1 and 2 can be undertaken at the same

time.

Info: Assignment via control system not possible if group 1

can be activated via a General Purpose Input (GPI)!

58 Group 2 parallel operation (On = voltage regulator is assigned

group 2)

Assignment to groups 1 and 2 can be undertaken at the same

time.

Info: Assignment via control system not possible if group 2

can be activated via a General Purpose Input (GPI)!

Table 14: Data points in control direction

Monitoring direction (messages)

The following data points have the properties stated below:

Type code = 10

Function type = 254

Data type = 7

5.2

5 Data points

Maschinenfabrik Reinhausen 2014 17 2195770/03 EN TAPCON 230 expert

GIN

LSB

GIN

MSB

Class Description

54 1 1 Tap position

55 1 1 Desired voltage value 1

56 1 1 Desired voltage value 2

57 1 1 Desired voltage value 3

58 1 1 Operations counter

144 2 2 Actual voltage (in V)

145 2 2 Control deviation (in %)

146 2 2 Active current (in %)

147 2 2 Reactive current (in %)

148 2 2 Apparent current (in %)

149 2 2 Frequency

Table 15: Data points in monitoring direction

The following data points have the properties stated below:

Type code = 1

Byte 2 information number = 110

Class = 1

Info

number

byte 1

Description

16 Auto/manual (On = auto mode; Off = manual mode)

19 Desired voltage value 1 On

20 Desired voltage value 2 On

21 Desired voltage value 3 On

33 General Purpose Output 1 *

34 General Purpose Output 2*

35 Parallel operation On

Please note that only the parameter set here is fed back and

not the current status.

Parallel operation is only active when all conditions for paral-

lel operation are met. Simply setting the "Parallel operation

activation" parameter to On is not enough.

36 Master parallel operation method On (feedback on parallel

operation method set)

37 Follower parallel operation method On (feedback on parallel

operation method set)

38 Circulating reactive current parallel operation method On

(feedback on parallel operation method set)

39 General Purpose Output 4 *

40 Parallel operation error

42 Local/Remote (On = Remote; Off = Local)

5 Data points

Maschinenfabrik Reinhausen 2014 18 2195770/03 EN TAPCON 230 expert

Info

number

byte 1

Description

43 General Purpose Output 3 *

44 Overvoltage U>

45 Undervoltage U<

46 Overcurrent I>

47 Undercurrent I<

48 Auto synchronization parallel operation method On (feedback

on parallel operation method set)

50 General Purpose Output 5 *

51 Function monitoring

52 General Purpose Output 6 *

53 General Purpose Output 7 *

54 Tap position

Alternatively, the tap position is reported at the following data

points:det:

Type code: 4, info number byte 1: 118

Type code: 204, info number byte 1: 4

55 Raise output

56 Lower output

57 Group 1 parallel operation (group assigned for parallel opera-

tion)

58 Group 2 parallel operation (group assigned for parallel opera-

tion)

59 Negative (On) or positive (Off) power flow

60 High-speed return active

61 Setting the voltage level remotely active

62 Raise input

64 Lower input

65 Auto input

66 Manual input

67 General Purpose Input 1 **

68 General Purpose Input 2 **

69 General Purpose Input 3 **

70 General Purpose Input 4 **

71 General Purpose Input 5 **

72 General Purpose Input 6 **

73 General Purpose Input 7 **

74 General Purpose Input 8 **

75 BCD1

76 BCD2

77 BCD4

5 Data points

Maschinenfabrik Reinhausen 2014 19 2195770/03 EN TAPCON 230 expert

Info

number

byte 1

Description

78 BCD8

80 BCD10

81 BCD20

82 BCD prefix

Table 16: Data points in monitoring direction

*) The voltage regulator has messages which can be parameterized and put

on a relay. These messages (General Purpose Output GPO) are also trans-

mitted via the communication interface.

**) The voltage regulator has messages which can be parameterized and put

on an input. These messages (General Purpose Input GPI) are also trans-

mitted via the communication interface.

Glossary

Maschinenfabrik Reinhausen 2014 20 2195770/03 EN TAPCON 230 expert

Glossary

EMC

Electromagnetic compatibility

GIN

Generic Identification Number

KOD

Kind of Description

LSB

Least Significant Byte

MSB

Most Significant Byte

NGD

Number of Generic Data Sets

OF

Abbreviation for fiber-optic cable

RII

Return Information Identifier

MR worldwide

Australia

Reinhausen Australia Pty. Ltd.

17/20-22 St Albans Road

Kingsgrove NSW 2208

Phone: +61 2 9502 2202

Fax: +61 2 9502 2224

E-Mail: sales@au.reinhausen.com

Brazil

MR do Brasil Indstria Mecnica Ltda.

Av. Elias Yazbek, 465

CEP: 06803-000

Embu - So Paulo

Phone: +55 11 4785 2150

Fax: +55 11 4785 2185

E-Mail: vendas@reinhausen.com.br

Canada

Reinhausen Canada Inc.

3755, rue Java, Suite 180

Brossard, Qubec J4Y 0E4

Phone: +1 514 370 5377

Fax: +1 450 659 3092

E-Mail: m.foata@ca.reinhausen.com

India

Easun-MR Tap Changers Ltd.

612, CTH Road

Tiruninravur, Chennai 602 024

Phone: +91 44 26300883

Fax: +91 44 26390881

E-Mail: easunmr@vsnl.com

Indonesia

Pt. Reinhausen Indonesia

German Center, Suite 6310,

Jl. Kapt. Subijanto Dj.

BSD City, Tangerang

Phone: +62 21 5315-3183

Fax: +62 21 5315-3184

E-Mail: c.haering@id.reinhausen.com

Iran

Iran Transfo After Sales Services Co.

Zanjan, Industrial Township No. 1 (Aliabad)

Corner of Morad Str.

Postal Code 4533144551

E-Mail: itass@iran-transfo.com

Italy

Reinhausen Italia S.r.l.

Via Alserio, 16

20159 Milano

Phone: +39 02 6943471

Fax: +39 02 69434766

E-Mail: sales@it.reinhausen.com

Japan

MR Japan Corporation

German Industry Park

1-18-2 Hakusan, Midori-ku

Yokohama 226-0006

Phone: +81 45 929 5728

Fax: +81 45 929 5741

Luxembourg

Reinhausen Luxembourg S.A.

72, Rue de Prs

L-7333 Steinsel

Phone: +352 27 3347 1

Fax: +352 27 3347 99

E-Mail: sales@lu.reinhausen.com

Malaysia

Reinhausen Asia-Pacific Sdn. Bhd

Level 11 Chulan Tower

No. 3 Jalan Conlay

50450 Kuala Lumpur

Phone: +60 3 2142 6481

Fax: +60 3 2142 6422

E-Mail: mr_rap@my.reinhausen.com

P.R.C. (China)

MR China Ltd. (MRT)

360

4 E

200120

86 21 61634588

86 21 61634582

mr-sales@cn.reinhausen.com

mr-service@cn.reinhausen.com

Russian Federation

OOO MR

Naberezhnaya Akademika Tupoleva

15, Bld. 2 ("Tupolev Plaza")

105005 Moscow

Phone: +7 495 980 89 67

Fax: +7 495 980 89 67

E-Mail: mrr@reinhausen.ru

South Africa

Reinhausen South Africa (Pty) Ltd.

No. 15, Third Street, Booysens Reserve

Johannesburg

Phone: +27 11 8352077

Fax: +27 11 8353806

E-Mail: support@za.reinhausen.com

South Korea

Reinhausen Korea Ltd.

21st floor, Standard Chartered Bank Bldg.,

47, Chongro, Chongro-gu,

Seoul 110-702

Phone: +82 2 767 4909

Fax: +82 2 736 0049

E-Mail: you-mi.jang@kr.reinhausen.com

U.S.A.

Reinhausen Manufacturing Inc.

2549 North 9th Avenue

Humboldt, TN 38343

Phone: +1 731 784 7681

Fax: +1 731 784 7682

E-Mail: sales@reinhausen.com

United Arab Emirates

Reinhausen Middle East FZE

Dubai Airport Freezone, Building Phase 6

3rd floor, Office No. 6EB, 341 Dubai

Phone: +971 4 2368 451

Fax: +971 4 2368 225

Email: service@ae.reinhausen.com

Maschinenfabrik Reinhausen GmbH

Falkensteinstrasse 8

93059 Regensburg

+49 (0)941 4090-0

+49(0)941 4090-7001

sales@reinhausen.com

www.reinhausen.com

2195770/03 EN 02/14

S-ar putea să vă placă și

- Build Your Own Low-Power Transmitters: Projects for the Electronics ExperimenterDe la EverandBuild Your Own Low-Power Transmitters: Projects for the Electronics ExperimenterEvaluare: 5 din 5 stele5/5 (4)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Încă nu există evaluări

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDe la EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsEvaluare: 3.5 din 5 stele3.5/5 (6)

- Delta DVP CatalogDocument39 paginiDelta DVP CatalogElectromateÎncă nu există evaluări

- Pae Receiver Type t6r Maintenance HandbookDocument80 paginiPae Receiver Type t6r Maintenance Handbookcmge_200580% (5)

- A600 User Guide - (Homemade) - Manual-ENG PDFDocument27 paginiA600 User Guide - (Homemade) - Manual-ENG PDFMikiPopovicÎncă nu există evaluări

- ABB DCS400 ManualDocument202 paginiABB DCS400 ManualDavid ZammitÎncă nu există evaluări

- MV 3000 Getting Started ManualDocument160 paginiMV 3000 Getting Started ManualterranohrÎncă nu există evaluări

- Ks 40 PDFDocument12 paginiKs 40 PDFHamilton Teodoro100% (2)

- (M. S. Tyagi (Auth.), B. L. Sharma (Eds.) ) Metal-S (B-Ok - CC) PDFDocument379 pagini(M. S. Tyagi (Auth.), B. L. Sharma (Eds.) ) Metal-S (B-Ok - CC) PDFskinhugoÎncă nu există evaluări

- BB2398461 01 en DNP3 TC240Document78 paginiBB2398461 01 en DNP3 TC240Oscar Mercado GarcíaÎncă nu există evaluări

- TAPCON® 230 Expert - Protocol Description For IEC 61850 (Previous Generation)Document20 paginiTAPCON® 230 Expert - Protocol Description For IEC 61850 (Previous Generation)Jorge López100% (1)

- Abbauto 50xm100n ManualDocument165 paginiAbbauto 50xm100n ManualBromax DandanÎncă nu există evaluări

- TD - Datasheet TK400 NDDocument4 paginiTD - Datasheet TK400 NDSocaciu VioricaÎncă nu există evaluări

- HAT520N enDocument17 paginiHAT520N enCris BOlivarÎncă nu există evaluări

- fp0 A D Converter Unit Technical Manual 0811 PDFDocument42 paginifp0 A D Converter Unit Technical Manual 0811 PDFHuuThienÎncă nu există evaluări

- Ws3000 2dte EngDocument83 paginiWs3000 2dte EngpasupuÎncă nu există evaluări

- Vacon NXL Lift ALFIFF28 Application Manual UD00973Document44 paginiVacon NXL Lift ALFIFF28 Application Manual UD00973TanuTiganuÎncă nu există evaluări

- Manual Control CrisolDocument60 paginiManual Control CrisolBaruch Cervantes GonzalezÎncă nu există evaluări

- SEW Communications Interfaces Parameter ListDocument37 paginiSEW Communications Interfaces Parameter ListRoman JambrekÎncă nu există evaluări

- Hat530n en ManualDocument19 paginiHat530n en Manualdario sanchezÎncă nu există evaluări

- Pac8000 Controllers Ds Gfa1831Document2 paginiPac8000 Controllers Ds Gfa1831mealysrÎncă nu există evaluări

- CP500 CK516Document52 paginiCP500 CK516Yago PereiraÎncă nu există evaluări

- Vacon NXL Brake Control ALFIFF30 Application ManuaDocument52 paginiVacon NXL Brake Control ALFIFF30 Application ManuaTanuTiganuÎncă nu există evaluări

- Dokumen - Tips - Protocol Description Iec 60870 5 101Document18 paginiDokumen - Tips - Protocol Description Iec 60870 5 101alextivanÎncă nu există evaluări

- FX-PCA Advanced Application Programmable Controller Catalog PageDocument5 paginiFX-PCA Advanced Application Programmable Controller Catalog Pageosc824Încă nu există evaluări

- Rexroth Inline Terminal With Two Analog Input Channels: R-Ib Il Ai 2/Sf-PacDocument22 paginiRexroth Inline Terminal With Two Analog Input Channels: R-Ib Il Ai 2/Sf-PacEnrique Albarracín EstupiñanÎncă nu există evaluări

- MadenshaDocument31 paginiMadenshamuhammad arifÎncă nu există evaluări

- E500 FD Rel11 Part1 OverviewDocument35 paginiE500 FD Rel11 Part1 OverviewЖорж КаназирскиÎncă nu există evaluări

- Automation Component AK 1703 ACP: Answers For EnergyDocument6 paginiAutomation Component AK 1703 ACP: Answers For EnergybepperigaÎncă nu există evaluări

- Instructions and Advices To Use The Electronic Controller Logik 19Document31 paginiInstructions and Advices To Use The Electronic Controller Logik 19Muhammad Zeeshan SaeedÎncă nu există evaluări

- 252938358-01 T1Document332 pagini252938358-01 T1interrupt30Încă nu există evaluări

- MFC-151 Manual enDocument11 paginiMFC-151 Manual enathanasiosÎncă nu există evaluări

- 101-0020 USB-RS485 Converter Manual R2Document8 pagini101-0020 USB-RS485 Converter Manual R2Juan Pablo Villazon RichterÎncă nu există evaluări

- AtexNotes For BusTerminal enDocument17 paginiAtexNotes For BusTerminal enValkure OmegaÎncă nu există evaluări

- P 7132 BGM en A5Document32 paginiP 7132 BGM en A5Orlando Jose Romero ReyesÎncă nu există evaluări

- Manual Instalacion RTUDocument25 paginiManual Instalacion RTUlmbkn2013Încă nu există evaluări

- EtherWAN M29060-A00 User ManualDocument177 paginiEtherWAN M29060-A00 User ManualJMAC SupplyÎncă nu există evaluări

- Tek Tr502 - SM Tracking GenDocument69 paginiTek Tr502 - SM Tracking GenayohaiÎncă nu există evaluări

- RH850/F1x 100-Pin RH850/R1x 100-PinDocument35 paginiRH850/F1x 100-Pin RH850/R1x 100-Pinmurtadha 2016Încă nu există evaluări

- Description of Option Option E1: E1: Analogue Controller OutputsDocument4 paginiDescription of Option Option E1: E1: Analogue Controller OutputsHeri MunirÎncă nu există evaluări

- MAP DE Module (ICP MAP0007)Document3 paginiMAP DE Module (ICP MAP0007)MounirÎncă nu există evaluări

- FX2N 4AD TC - UserGuide - JY992D65501 G PDFDocument8 paginiFX2N 4AD TC - UserGuide - JY992D65501 G PDFTam DangÎncă nu există evaluări

- DNP 3Document121 paginiDNP 3pauloheideckeÎncă nu există evaluări

- Lmx31X Precision Voltage-To-Frequency Converters: 1 Features 3 DescriptionDocument23 paginiLmx31X Precision Voltage-To-Frequency Converters: 1 Features 3 DescriptionAlonso Herrera SeguraÎncă nu există evaluări

- Digital PresureDocument11 paginiDigital PresurejlfyÎncă nu există evaluări

- Abb PLC SystemDocument25 paginiAbb PLC SystemskshnaÎncă nu există evaluări

- Description of Hardware: February 00Document8 paginiDescription of Hardware: February 00Alex asherÎncă nu există evaluări

- SCC-TC Series ThermocoupleDocument16 paginiSCC-TC Series ThermocoupleBica RazvanÎncă nu există evaluări

- 900 sg001 - en P PDFDocument30 pagini900 sg001 - en P PDFJesus Gerardo Esparza LopezÎncă nu există evaluări

- S7-200 Technical SpecificationsDocument78 paginiS7-200 Technical SpecificationsThuy Nguyen Xuan0% (1)

- T-288ND/T-288NE User's Manual: Network Series ModemDocument85 paginiT-288ND/T-288NE User's Manual: Network Series ModemWest CharleÎncă nu există evaluări

- Rückenbreite Bis 10 MM (1 Blatt 0,106 MM) : Hardware and EngineeringDocument94 paginiRückenbreite Bis 10 MM (1 Blatt 0,106 MM) : Hardware and EngineeringAdilson DominguesÎncă nu există evaluări

- Duobias M 200 TM Section02 Performance SpecificationDocument12 paginiDuobias M 200 TM Section02 Performance SpecificationtonytomsonÎncă nu există evaluări

- Bridge TEM SpecificationsDocument8 paginiBridge TEM SpecificationsKaiser IqbalÎncă nu există evaluări

- Sat TM 1703 Acp PDF 745kbDocument6 paginiSat TM 1703 Acp PDF 745kbIbrar H MalikÎncă nu există evaluări

- FN8000 Control Panel F-74-800Document14 paginiFN8000 Control Panel F-74-800Dani Setia RamdaniÎncă nu există evaluări

- Catalyst 4948 Switch OverviewDocument12 paginiCatalyst 4948 Switch OverviewstarimedoÎncă nu există evaluări

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142De la EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142Încă nu există evaluări

- Windom by k3mtDocument5 paginiWindom by k3mtvictorplugaruÎncă nu există evaluări

- Low Noise J-FET Dual Op Amps TL072Document9 paginiLow Noise J-FET Dual Op Amps TL072Jose M PeresÎncă nu există evaluări

- GP1A50HR/GP1A51HR GP1A52HR/GP1A53HR: Opic PhotointerrupterDocument6 paginiGP1A50HR/GP1A51HR GP1A52HR/GP1A53HR: Opic PhotointerrupterPhong Nguyễn WindyÎncă nu există evaluări

- Input Output InterfacingDocument48 paginiInput Output InterfacingLokesh Kumar ChoudharyÎncă nu există evaluări

- AVR 33 Series 10 150 KVA 2Document2 paginiAVR 33 Series 10 150 KVA 2phyomauk htunÎncă nu există evaluări

- 30V Panel Volt Meter Using PIC MCUDocument4 pagini30V Panel Volt Meter Using PIC MCUreynielÎncă nu există evaluări

- @3 FET FundamentalsDocument210 pagini@3 FET Fundamentalschâu nguyễn ngọcÎncă nu există evaluări

- lm358 LM 358 258 158 PDFDocument42 paginilm358 LM 358 258 158 PDFWinexÎncă nu există evaluări

- N - Channel 500V - 0.22 - 20A - To-247 Powermesh Mosfet: Stw20Nb50Document8 paginiN - Channel 500V - 0.22 - 20A - To-247 Powermesh Mosfet: Stw20Nb50La Tienda del PatínÎncă nu există evaluări

- A Survey On Interlaken Protocol For Network ApplicationsDocument5 paginiA Survey On Interlaken Protocol For Network ApplicationsEditor IJRITCCÎncă nu există evaluări

- 300+ Top Microprocessors Questions and Answers PDF: Prisma™ Cloud SecurityDocument14 pagini300+ Top Microprocessors Questions and Answers PDF: Prisma™ Cloud SecurityAawez AkhterÎncă nu există evaluări

- Pinout at Haval M4 PDFDocument4 paginiPinout at Haval M4 PDFErasmo Israel Garcia OchoaÎncă nu există evaluări

- Title: Model Ut601: Operating ManualDocument26 paginiTitle: Model Ut601: Operating ManualScott TylerÎncă nu există evaluări

- Spice BJTDocument13 paginiSpice BJTpoint_1990Încă nu există evaluări

- Amd Duron 850 - D850aut1bDocument5 paginiAmd Duron 850 - D850aut1bcoyotesmith2Încă nu există evaluări

- DS 1147 SS CMCDT2100LTC ADocument3 paginiDS 1147 SS CMCDT2100LTC ANightcrawlerÎncă nu există evaluări

- Tic 266Document5 paginiTic 266Eric AndrésÎncă nu există evaluări

- Analog Electronics Circuit (ECE - 2101) (Make Up) RCSDocument2 paginiAnalog Electronics Circuit (ECE - 2101) (Make Up) RCSdeevÎncă nu există evaluări

- Manualde Servicio Transmisor Elenos Elc40 (ET)Document94 paginiManualde Servicio Transmisor Elenos Elc40 (ET)carlos enrique0% (1)

- DTZZIII User's GuideDocument4 paginiDTZZIII User's GuideDiego BaezÎncă nu există evaluări

- DC aDCghskjskksks FjsDocument4 paginiDC aDCghskjskksks FjsSaiteja GundapuÎncă nu există evaluări

- U3761mb TelefonoDocument23 paginiU3761mb Telefonogabriel6276Încă nu există evaluări

- Vestel 17ips19-5pDocument4 paginiVestel 17ips19-5pMihai MikeÎncă nu există evaluări

- Electric Circuits &electronics Device Question PaperDocument5 paginiElectric Circuits &electronics Device Question PaperSalai Kishwar JahanÎncă nu există evaluări

- Fan Speed Controller and Fan Fault Detector Family: FeaturesDocument2 paginiFan Speed Controller and Fan Fault Detector Family: FeaturesShrikant A. Desai100% (1)

- Manual de Rejuvenecedor de Pantalla 100-CRTDocument64 paginiManual de Rejuvenecedor de Pantalla 100-CRTJavier Ortiz GuilenÎncă nu există evaluări

- CST Application Note - Dual Band GSM Antenna PDFDocument6 paginiCST Application Note - Dual Band GSM Antenna PDFTDMA2009Încă nu există evaluări

- 16 Marks AnswerDocument27 pagini16 Marks AnswergomsÎncă nu există evaluări