Documente Academic

Documente Profesional

Documente Cultură

Operation of A Centrifugal Oil Purifers

Încărcat de

Jitendra KumarDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Operation of A Centrifugal Oil Purifers

Încărcat de

Jitendra KumarDrepturi de autor:

Formate disponibile

Operation of a Centrifugal oil purifers

Preamble

The following description relies on the reader having an understanding of the function and internal design

of a modern self cleaning centrifugal purifer.

The method describes the operation of a manually controlled system. It is accepted that the

vast majority of units are automated, it is intended allow better understanding of the automated process

by doing this. The " Automation " section will clarify this.

The unit described is a sliding bowl type, does not have on line sludging capability with light

phase requiring heating. Operating water is required for both opening, and closing the bowl. It is accepted

that in common designs only opening water is supplied, once supplied this water leaks out until it reaches

a level determined by a weir arrangement. The water remaining beyond this weir acts to close the bowl

Operating, displacement, seal and sludging water are delivered in finite quantities governed

by the type and sie of bowl, and the supply water pressure. !lthough not mentioned it should be taken

for granted that water introduced is of a set quantity

Starting and stopping

"efore starting the purifier the correct sied gravity ring must be in place for the light phase specific

gravity at required delivery temperature.

#ost units have a brake arrangement fitted acting on the bowl to slow during stopping. This

should be check to be disengaged.

The use of this brake is determined by manufacturers recommendations. The brake should be seen

as an emergency device to slow the bowl in the event of some problem, typically an out of balance of

the bowl caused by sludge not being evenly removed from the bowl.

Where no preference is given it is the authors recommendation that the brake be used.

The reason for this is to allow the bowl to pass as quickly as possible through any critical vibration

harmonics.

$orrect operating and sludging water supply pressure should be checked

The light phase %oil& supply, discharge valves may be opened, the flow control valve and back

pressure valve may be set at appro'imate initial settings. The three way valve is set to recirc %dump&

Remember that when the oil is introduced to the bowl the bowl is cool and so the oil will be cooled

and will tend to pass over with the heavy phase. This action may be reduced by having the back

pressure discharge valve slightly more open than required closing as the bowl warms.

The bowl may be started. (rive to the bowl is via a centrifugal clutch arrangement reducing

the starting current on the motor. The start up time is determined by the slippage of this clutch which is in

turn determined by the number of pads. The oil is now being circulated though the heater. The heating

medium may be introduced to bring the oil to purifying temperature

It should be noted that for some designs the motor is non-standard being able to carry high starting

currents over a longer period. When requesting replacements this should be noted.

Too few pads causes an overly long start up time. In addition, the drag of the liquid as it

leaves the bowl during a sludge cycle causes a reduction in speed. or automated systems, this

speed must be regained before the oil is reintroduced otherwise carryover can occur. With some

designs correct sludging is determined by an e!pected rise in drive current caused by the motor

trying to bring the bowl back to speed. Too few pads may cause problems in both these cases.

Too many pads leads to e!cessive force on the drive gear leading to premature failure

especially of the wheel and the electric motor.

)hen the bowl has reached it operating speed the bowl may be closed by introducing closing

operating water.

this may be checked by viewing the e!ternal speed indicator or by observation of a reduction in amps

as the bowl reaches its operating speed. The best method is a combination of the two. "bserve the

amp reduction and visually check the speed indicator to confirm that a fault has not occurred in the

clutch.

Once correct oil temperature is observed the purification process may begin. *eal water is

introduced to the bowl. The three way valve is operated to supply oil to the bowl. $orrect flow and back

pressure should be set once full flow is achieved. The amount of heating medium to the heater should be

increased as required

The sludge port should be viewed to ensure no leakage from bowl+ remember to close port

before sludging. $heck heavy phase %water& shute to ensure no oil overflow. $heck operating water shute

to ensure valves have isolated

It is unlikely that the bowl will immediately come # on-line #, this is generally due to the bowl being

cold, cooling the oil, increasing its specific gravity and causing it to pass over the heavy phase

$water% shute.

The amount of carryover may be reduced by opening the back pressure valve. The best

solution is to removed the cool oil that is in the bowl by sludging. This may be repeated couple of

times before the bowl has reached operating temperature.

The correct function of the desludging mechanism should be checked.

Sludging

Change three way valve to recirculation (dump). Reduce heating medium to heater if required

Introduce displacement water. This removes the oil from the bowl preventing wastage

pen bowl open operating water

bserve amps ( increase)! chec" sludge port ( see discharge). Close sludge port. There is

normally an audible indication that the bowl has opened

perate bowl closing water

nce amps has returned to normal running the bowl can be assumed closed! again there is

generally an audible indication of this

#ring unit bac" on line

Once the unit has been proved on line and operating correctly the alarms and shutdowns

should be tested. )here the units overflow to a sludge tank the correct operation of the alarm should be

checked.

The testing of the alarms and shut downs is paramount. "nce completed, especially for main engine

lube oil purifiers, a note should be made in the engineroom log book

It is common to find dedicated sludge tanks for the purifiers. The level in which is kept

artificially high and &ust off the high level alarm. In this way the tank acts as a back up alarm for the

purifier.

Automation

The vast majority of units will be fully automated for ,#* enginerooms. *ludging will involve pressing a

single button. ! controller will then cycle through the operating, displacement and seal water valves as

well as operate the three way valve. The heater will have an independent controller although a ero

output signal may be generated by the purifier controller during the sludge period.

(etection of correct desludging may be by drive motor current, as discussed, flap

arrangement which is struck by the discharge from the open bowl or by measuring the discharge pressure

which falls to or below ero pressure during the sludge cycle.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Brochure o Pumps Deepwell Gas CarriersDocument4 paginiBrochure o Pumps Deepwell Gas CarriersJohn MarxisÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Overall Arrangement: Description of The Salient PartsDocument6 paginiOverall Arrangement: Description of The Salient PartsJitendra KumarÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Oxygen AnalysersDocument2 paginiOxygen AnalysersJitendra KumarÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Overview of Microbiological AttackDocument10 paginiOverview of Microbiological AttackJitendra KumarÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Parallel Operation of GeneratorsDocument5 paginiParallel Operation of GeneratorsJitendra KumarÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

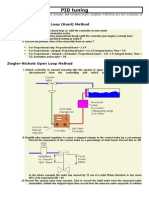

- PID TuningDocument4 paginiPID TuningJitendra Kumar100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Pilgrim NutDocument2 paginiPilgrim NutJitendra KumarÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Oil WhirlDocument2 paginiOil WhirlJitendra KumarÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Motor Ship Steam Plan1Document3 paginiMotor Ship Steam Plan1Jitendra KumarÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Oil Distribution Within A Journal BearingDocument2 paginiOil Distribution Within A Journal BearingAnkit DedhiyaÎncă nu există evaluări

- Microbes of Microbiological Attac1Document3 paginiMicrobes of Microbiological Attac1Jitendra KumarÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Oily Water SeperatorsDocument2 paginiOily Water SeperatorsJitendra KumarÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Molybdenum DiSulphideDocument1 paginăMolybdenum DiSulphideJitendra KumarÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Increasing Propulsive EfficiencyDocument6 paginiIncreasing Propulsive EfficiencyJitendra KumarÎncă nu există evaluări

- Tooth Design: Forces Acting On Spur GearsDocument77 paginiTooth Design: Forces Acting On Spur GearsJitendra KumarÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Materials Used in Ships Sea Water SystemsDocument1 paginăMaterials Used in Ships Sea Water SystemsAnkit DedhiyaÎncă nu există evaluări

- Marpol 73Document12 paginiMarpol 73Jitendra KumarÎncă nu există evaluări

- Navigation LightingDocument1 paginăNavigation LightingJitendra KumarÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Motor Ship Steam Plant ControlDocument1 paginăMotor Ship Steam Plant ControlJitendra KumarÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Metallurgical TestingDocument1 paginăMetallurgical TestingJitendra KumarÎncă nu există evaluări

- LNG Reliquifactio1Document1 paginăLNG Reliquifactio1Jitendra KumarÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Microbes of Microbiological Attac1Document3 paginiMicrobes of Microbiological Attac1Jitendra KumarÎncă nu există evaluări

- Mechanical GovernorsDocument1 paginăMechanical GovernorsJitendra KumarÎncă nu există evaluări

- Lube Oil Requirements For Diesel EnginesDocument3 paginiLube Oil Requirements For Diesel EnginesJitendra KumarÎncă nu există evaluări

- Lifting Using Accessories: Calculation of LoadDocument2 paginiLifting Using Accessories: Calculation of LoadJitendra KumarÎncă nu există evaluări

- LNG Containment DesignsDocument3 paginiLNG Containment DesignsJitendra KumarÎncă nu există evaluări

- Low Sulphur FuelsDocument1 paginăLow Sulphur FuelsJitendra KumarÎncă nu există evaluări

- Liquified Gas CargoesDocument2 paginiLiquified Gas CargoesJitendra KumarÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Jacket Water SystemDocument2 paginiJacket Water SystemJitendra KumarÎncă nu există evaluări

- Module 4 - Instruction Set Architecture (ISA) v2 (Student) PDFDocument49 paginiModule 4 - Instruction Set Architecture (ISA) v2 (Student) PDFnedunilavanÎncă nu există evaluări

- Concepts of Mind: CrystaqueousDocument51 paginiConcepts of Mind: CrystaqueousCasa GrandeÎncă nu există evaluări

- Cap 05Document10 paginiCap 05haulam leeÎncă nu există evaluări

- Jean Piaget ProjectDocument13 paginiJean Piaget ProjectRoland Aparece100% (1)

- Introduction To Forensic Science Questioned DocumentsDocument50 paginiIntroduction To Forensic Science Questioned DocumentsLyka C. De Guzman100% (2)

- Sampling With Automatic Gain Control 4Document31 paginiSampling With Automatic Gain Control 4anandbabugopathotiÎncă nu există evaluări

- RCA 1 and 2 Wafer CleanDocument3 paginiRCA 1 and 2 Wafer CleanJoonhyuk HwangÎncă nu există evaluări

- Subaltern Voice in The Novel of Anita Nair's Lessons in Forgetting: A Female PerspectiveDocument2 paginiSubaltern Voice in The Novel of Anita Nair's Lessons in Forgetting: A Female PerspectiveIJELS Research JournalÎncă nu există evaluări

- Jackson - Chimu Sculptures of Huacas Takaynamo and El DragonDocument26 paginiJackson - Chimu Sculptures of Huacas Takaynamo and El DragonguillermoÎncă nu există evaluări

- Manual SIMOTION Rotary Knife V2.0Document140 paginiManual SIMOTION Rotary Knife V2.0Luis Adrian PerezÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Grade 8 Science Unit 1 Force, Motion and EnergyDocument68 paginiGrade 8 Science Unit 1 Force, Motion and EnergyKeil Morada73% (26)

- CVE 202 Lecture - 28062021Document11 paginiCVE 202 Lecture - 28062021odubade opeyemiÎncă nu există evaluări

- What Is Engineering SurveyingDocument5 paginiWhat Is Engineering SurveyingHui EdroxÎncă nu există evaluări

- Disha Computer KnowledgeDocument247 paginiDisha Computer KnowledgeBalachandarMahadevanÎncă nu există evaluări

- 01 Reading Diagnostic Test StudentDocument4 pagini01 Reading Diagnostic Test StudentCicely Guevara LeónÎncă nu există evaluări

- Formalization of UML Use Case Diagram-A Z Notation Based ApproachDocument6 paginiFormalization of UML Use Case Diagram-A Z Notation Based ApproachAnonymous PQ4M0ZzG7yÎncă nu există evaluări

- AQUINAS de Motu Cordis LAT - ENGDocument9 paginiAQUINAS de Motu Cordis LAT - ENGOta FlegrÎncă nu există evaluări

- Tesla Case PDFDocument108 paginiTesla Case PDFJeremiah Peter100% (1)

- Filipino ScientistsDocument2 paginiFilipino ScientistsJohn Carlo GileÎncă nu există evaluări

- Direct 3 DDocument406 paginiDirect 3 Dxlam99Încă nu există evaluări

- The Collection of Mining and Metallurgical Art of The Institute of Engineering of Porto (Isep)Document1 paginăThe Collection of Mining and Metallurgical Art of The Institute of Engineering of Porto (Isep)Costa, PatríciaÎncă nu există evaluări

- Brainstorming WhahahDocument20 paginiBrainstorming WhahahJohnrey V. CuencaÎncă nu există evaluări

- Demo On Tableau DesktopDocument46 paginiDemo On Tableau DesktopDeepak GuptaÎncă nu există evaluări

- Land Reclamation in SingaporeDocument27 paginiLand Reclamation in SingaporeAbdul JabbarÎncă nu există evaluări

- RSP OSS SchulungDocument248 paginiRSP OSS Schulungsalloum18Încă nu există evaluări

- Simple Stress & StrainDocument34 paginiSimple Stress & StrainfaisalasgharÎncă nu există evaluări

- SMT Syllabus 2018 19Document90 paginiSMT Syllabus 2018 19sanjanaÎncă nu există evaluări

- Safe City in Malaysia's ContextDocument8 paginiSafe City in Malaysia's Contextuyunaman100% (1)

- Developing Training Program For Effective and Quality Volleyball PlayersDocument13 paginiDeveloping Training Program For Effective and Quality Volleyball PlayersDeogracia BorresÎncă nu există evaluări

- Educational Planning (Felipe)Document102 paginiEducational Planning (Felipe)Felipe Beranio Sullera Jr.100% (4)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDe la EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterÎncă nu există evaluări

- A Practical Handbook for Drilling Fluids ProcessingDe la EverandA Practical Handbook for Drilling Fluids ProcessingÎncă nu există evaluări

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDe la EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesEvaluare: 4.5 din 5 stele4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDe la EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentEvaluare: 4.5 din 5 stele4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDe la EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialÎncă nu există evaluări

- Shorting the Grid: The Hidden Fragility of Our Electric GridDe la EverandShorting the Grid: The Hidden Fragility of Our Electric GridEvaluare: 4.5 din 5 stele4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressDe la EverandNuclear Energy in the 21st Century: World Nuclear University PressEvaluare: 4.5 din 5 stele4.5/5 (3)