Documente Academic

Documente Profesional

Documente Cultură

Lindane and Carbaryl in Combined Formulations - 391-399

Încărcat de

megacobTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lindane and Carbaryl in Combined Formulations - 391-399

Încărcat de

megacobDrepturi de autor:

Formate disponibile

ISSN: 0973-4945; CODEN ECJHAO

E-Journal of Chemistry

http://www.e-journals.net 2011, 8(1), 391-399

Simultaneous Determination by

Gas Chromatography of Lindane and

Carbaryl in Combined Formulations

INDRAJIT SEN, AJAY SHANDIL, MANJEET AGGARWAL

and

RAKESH KUMAR KHANDAL

*

Shriram Institute for Industrial Research

19 University Road, Delhi-110007, India

rkhandal@shriraminstitute.org

Received 18 January 2010; Revised 2 April 2010; Accepted 21 May 2010

Abstract: A gas chromatographic method developed and validated for

simultaneous determination of lindane and carbaryl for quality evaluation of

lindane-carbaryl granule, using a glass capillary HP5 column (30 m x 0.32 mm;

0.25 m), temperature programming with flame ionization detector and

dibutylphthalate as an internal standard. The calibration graphs were found

linear in the concentration range of 1 g/mL to 1000 g/mL for both lindane

and carbaryl with correlation coefficient of 0.999 and 0.999 respectively and

co-efficient of variation for intra-day and inter-day repeatability studies at

different concentration levels was found to be less than 2%. The accuracy of

method ranges between 98.5% to 100.8%. Specificity and robustness were also

within the acceptable range. The method is highly sensitive with LOD and

LOQ as 0.5 and 2 g/mL for lindane and carbaryl respectively. The method

has been tried on several formulations of lindane-carbaryl granules for quality

control and has been found to be applicable.

Keywords: Gas chromatography, Carbaryl, Lindane, Combined formulation.

Introduction

Ever since the combination formulations consisting of more than one technical grade

pesticide were allowed around a decade ago in India, there has been a large number of

combination formulations being introduced in the market. The experience with the

combination formulations has been encouraging, as their efficacy has been found to be better

than the formulations containing single ingredient

1

.

Granules of lindane and carbaryl is one of the most widely used agrochemical formulation

consisting of combination of two very important pesticide ingredients namely lindane and carbaryl

present at concentration levels of 4% each. Lindane, also known as gamma-hexachlorocyclohexane

392 R. K. KHANDAL et al.

(-HCH)

2

is an organochlorine chemical that has been used both as an agricultural insecticide and

as a pharmaceutical treatment for infestations of lice and scabies

3,4

. Under the IUPAC system,

lindane is named as gamma-1, 2, 3, 4, 5 and 6-hexachlorocyclohexane, which is a white,

odorless, crystalline solid with molecular weight of 290.82 g/mole and molecular formula of

C

6

H

6

Cl

6

and chemical structure

1, 5

as shown in Figure 1a.

Carbaryl, named as per IUPAC as 1-naphthyl methyl carbamate is a white crystalline

solid having molecular weight of 201.22 g/mole and molecular formula of C

12

H

11

NO

2

with

the chemical structure

1,6-8

as shown in Figure 1b.

Figure 1a. Chemical structure of lindane

(gamma-1, 2, 3, 4, 5 and 6-

hexachlorocyclohexane)

Figure 1b. Chemical structure of carbaryl

(1-napthyl methyl carbamate)

Carbaryl is widely used as an insecticide for home gardens, commercial agriculture and

forestry

9,10

. Lindane-carbaryl granules (a colored formulation) is one of the most widely

used agrochemical formulations. It has a broad range of insecticidal activity, contact

stomach action, nervous and respiratory action

11-16

.

The formulation is used for various crop

pests in soil and agricultural fields

17-21

.

As there are no validated methods available in the literature for the simultaneous determination

of both lindane and carbaryl, we have made an attempt to evaluate the quality of the combined

granular formulation containing lindane and carbaryl with respect to the concentration of the active

ingredients. Though there are methods available for the analysis of lindane in lindane containing

formulation or carbaryl in carbaryl formulations as per CIPAC or WHO specification they do not

mention about the analysis of combined lindane-carbaryl formulations

22-28

. On the other hand

although Indian standard (IS) specification does have a protocol for analysis of lindane-carbaryl

granules (IS: 11784:1986), two different methods are specified for the analysis of lindane and

carbaryl respectively. For the analysis of lindane, the specification (IS: 882-1984) mentioned the gas

chromatographic method using -naphthol as an internal standard, whereas for the analysis of

carbaryl, spectrophotometric method is mentioned (IS: 7539-1975)

29-35

. The analysis of two

components individually using two different methods is not only time consuming but it has also

been observed that, during the gas chromatographic determination of lindane using -naphthol as

an internal standard, produces inaccurate results. This is due to fact that -naphthol generally

formed as an intermediate during the synthesis of carbaryl, is present as an impurity in the lindane-

carbaryl formulation and thereby causes an interference with the accurate determination of lindane

and carbaryl when internal standard used is also -naphthol.

The aim of the present work was to develop and validate an analytical method using a

gas chromatographic technique for simultaneous determination of both lindane and carbaryl

which is comparatively faster with significant precision, accuracy and resolution.

Experimental

The reference standards lindane (purity: 99%) and carbaryl (purity: 99%) were obtained from

Sigma-Aldrich (USA). Dibutyl phthalate having purity 99% was procured from Fluka chemicals

Simultaneous Determination by Gas Chromatography 393

(USA) and acetone (HPLC grade) was purchased from SD fine chemicals, Mumbai, India.

Formulations (within their shelf life) of lindane-carbaryl granules of commercial grade were

procured from the local market. All chemicals were used as received.

Gas chromatography analysis was carried out using VARIAN-CP-3800 Gas Chromatograph

equipped with split/splitless injector, a flame ionization detector was used for the

measurements and glass capillary HP-5, ID: 0.32 mm, length: 30 m, film thickness: 0.25 m;

packed with non-polar polymer [(5%-phenyl)-methylpolysiloxane]. Mettler weighing balances

with a least count of 0.0001 g and 0.001 mg for weighing of samples and standards

respectively. Calibrated A grade glassware of borosil procured from local market.

Preparation of internal standard stock solution (A): Dibutyl phthalate (DBP)

Approximately 0.5 g of dibutyl phthalate was accurately weighed and transferred into 100 mL

volumetric flask, dissolved and diluted to volume using HPLC grade acetone.

Preparation of reference standard solutions (B)

Approximately 2.5 mg each of reference standard of lindane and carbaryl were weighed accurately

and transferred into 25 mL volumetric flask. To this 2.5 mL of internal standard stock solution (A)

was added using a pipette and total volume was made up to the mark by HPLC grade acetone.

Preparation of sample solutions (C)

Approximately 60 mg each of the seven formulations coded as 1 to 7 (lindane 4% and

carbaryl 4% formulations) were accurately weighed individually and transferred into seven

different 25 mL volumetric flask. To this, 2.5 mL of internal standard stock solution (A) was

added and the total volume was made up to the mark using HPLC grade acetone.

Gas chromatographic conditions

Column: Glass capillary HP-5, ID: 0.32 mm, length: 30 m; film thickness: 0.25 m; Carrier

gas: Nitrogen at a flow rate of 1.2 mL/min.; Injector mode: Split of 1:10; Injection volume: 1 L;

Injector temperature: 250

C; Oven temperature: Initial 180

C (12 min) @ 30

C/ min, to

300

C (12 min); Detector: Flame ionization detector at 300

C.

Method development and validation

The method was validated for the determination of lindane and carbaryl for the following

parameters; specificity, linearity, precision, accuracy, limit of detection, limit of quantitation,

robustness and ruggedness as per the ICH (International Conference on Harmonization) guidelines.

Linearity

Linearity of the method was determined by plotting a calibration curve for both lindane and

carbaryl for concentration vs. detector response (area counts in mV). For this purpose, a combined

standard stock solution containing both lindane and carbaryl at concentration level 2500 g/mL

of each was prepared by dissolving about 62.5 mg (accurately weighed) each of the reference

standards in 25 mL of volumetric flask and made up to volume with HPLC grade acetone.

From the combined standard stock solution of lindane and carbaryl, aliquots of 10, 5, 2.5,

1.0, 0.5, 0.1, 0.05 and 0.01 mL were taken into eight individual 25 mL volumetric flask. To all the

flasks, 2.5 mL of the internal standard solution (solution B) was added and the total volume was

made up to the mark with acetone. This gave a series of combined calibration standard solutions of

lindane and carbaryl having concentrations of 1000, 500, 250, 100, 50, 10, 5 and 1 g/mL of

both the compounds. From each of these calibration standards 1 L was injected into the GC.

The calibration curve obtained was subjected to regression analysis by the least square

method to calculate the calibration equation and the correlation coefficient (r).

394 R. K. KHANDAL et al.

Specificity

The specificity of the method was determined by analyzing the sample solution (solution C)

containing all the components i.e. lindane, carbaryl, -naphthol and the internal standard

that is DBP. For this purpose 1 L of one of the sample solutions was injected into the gas

chromatograph and the specificity of the method was measured in terms of the resolution

between the two peaks.

Precision

The precision of the method was determined in terms of repeatability or reproducibility and

intermediate precision studies. Repeatability was determined by evaluating five replicates of

the three different concentrations i.e. 10, 50 and 100 g/mL of the combined calibration

standard solution of lindane and carbaryl on the same day (intra-day) under the mentioned

chromatographic conditions. The intermediate precision of the method was assured by

performing the analysis on three different days (inter-day) and also by different analysts in

the same laboratory (between analysts). Co-efficient of variation or the percent RSD was

calculated in each case.

Accuracy

The accuracy of the method was evaluated by spiking different known concentrations of

lindane and carbaryl into the pre-analyzed sample. One of the seven sample solutions

containing approx. 100 ppm each of carbaryl and lindane was spiked` with varying standard

concentrations of lindane and carbaryl i.e. 50 ppm of each, 100 ppm of each and 150 ppm of

each so as to give a total concentration of 150 ppm, 200 ppm and 250 ppm of both lindane

and carbaryl. 1 L of each of these solutions was injected onto gas chromatograph and the

closeness of the results to the true value was determined.

Robustness

Robustness of the method was determined by analyzing the same sample under different

conditions of method parameters such as two different makes of gas chromatograph, same

column from two different manufacturers, different analysts, varying injection volume.

Limit of detection and limit of quantitation

For the measurement of limit of detection, standard deviation of the background was

determined. Thereafter, standard solutions of very low concentration levels i.e. 0.5, 1.0, 2.0

and 5.0 g/mL were injected till the signal obtained was thrice the standard deviation of the

background. For the measurement of limit of quantitation again, known concentration of

standard carbaryl and lindane solutions were injected till the signal obtained was

reproducible for five replicate injections.

Results and Discussion

Analysis of formulation for lindane and carbaryl content

The chromatogram (Figure 2) for the combined standard solution containing 50 g/mL of

each lindane and carbaryl shows well resolved peaks for the both lindane (RT.5.9 min) and

carbaryl (RT. 8.2 min.).

DBP used as internal standard elutes at retention time, 10.2 minutes. The chromatogram

(Figure 3) for the seven samples of lindane-carbaryl granules also shows well resolved peaks

for lindane, carbaryl and the internal standard.

Time, min

m

V

o

l

t

m

V

o

l

t

Time, min

Simultaneous Determination by Gas Chromatography 395

Figure 2. Gas chromatogram for standard solution containing lindane, carbaryl and DBP

(Internal standard). Peak at R.T.3.3 min is due to -napthol (impurity from carbaryl)

Figure 3. Gas chromatograms of seven sample solutions of lindane-carbaryl granules

On analysis of all the seven different formulations of lindane-carbaryl granules, the

content for both lindane and carbaryl was determined and the results are presented in Table 1.

The results were found to be in agreement with the claim value of 4 percent each of both the

pesticides. From the chromatogram of the seven samples, it can also be seen that besides the

three peaks due to lindane, carbaryl and DBP, there is another peak at R.T 3.3 min.

On analysis, it was found that this peak could be due to -naphthol, which is normally present

in carbaryl as an impurity (formed as an intermediate product) during the synthesis of carbaryl.

This was further confirmed from the Gas chromatogram of the standard solution of -naphthol

(Figure 4). This observation further substantiates the apprehension about using -naphthol

as an internal standard (as specified in IS 117484:1986 for lindane-carbaryl granules) and

this is why, the present method has been developed using DBP as an internal standard.

Time, min

m

V

o

l

t

396 R. K. KHANDAL et al.

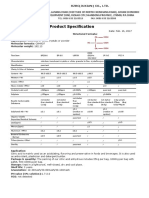

Table 1. Percent purity of lindane and carbaryl in lindane-carbaryl granule formulations

using the developed method

Lindane Carbaryl

S. No. Label claim,

%m/m

Observed,

%m/m

% RSD

(n=3)

Label claim,

%m/m

Observed,

%m/m

%RSD

(n=3)

1 4 3.9 0.11 4 4.0 0.17

2 4 3.8 0.98 4 3.9 0.25

3 4 4.0 0.74 4 3.8 0.29

4 4 4.1 0.85 4 3.8 0.21

5 4 3.9 0.77 4 4.1 0.56

6 4 4.2 0.14 4 4.0 0.98

7 4 3.9 0.65 4 4.2 0.29

Figure 4. Chromatograms showing specificity of the method (a) acetone solvent blank (R.T.1.8 min);

(b) -naphthol reference standard (R.T.3.3 min); (c) lindane reference standard (R.T.5.9 min);

(d) carbaryl reference standard (R.T.8.2 min); (e) DBP Reference Standard (R.T.10.2 min)

Validation of the developed method

Specificity

The specificity of the method is indicated in Figure 4, which shows chromatogram for

each of the individual components, i.e. lindane, carbaryl, DBP and -naphthol. The peak

corresponding to each component elutes at different retention times, thereby causing no

overlapping of the peaks. Although, the formulation consists of -naphthol as an impurity

but the peak for -naphthol does not interfere with the peaks due to lindane, carbaryl or

DBP. The resolution factor (R

S

) values for the various component peaks were always >2,

which clearly indicates that there is a complete separation of different components of the

formulation when analyzed by the developed method. Thus, the specificity of the method

can be considered as established as per the standard guidelines

36

(International Conference

on Harmonization).

a

b

c

d

e

Simultaneous Determination by Gas Chromatography 397

Linearity

Calibration graphs were plotted for the calibration range 1 to 1000 g/mL for lindane and carbaryl.

Both lindane and carbaryl gave linear response over the studied range of concentration and the

least squares linear regression analysis of the data provided excellent correlation coefficient (r) of

more than 0.999 for both the compounds i.e. 0.9999 for lindane and 0.9998 for carbaryl.

Accuracy

Accuracy of the method evaluated on the basis of the comparison of the theoretical

concentration level of the spiked solutions with the observed concentration gave acceptable

and good percent recoveries of more than 98% for each spiked level (Table 2).

Table 2. Recovery studies for the determination of lindane and carbaryl by the developed

method

Compound

Original

concentration,

ppm

Spiked

concentration,

ppm

Total

concentration,

ppm

Observed

concentration,

ppm

Percent

Recovery

RSD, n= 5

99.32 49.42 148.74 146.49 98.49 0.18

99.32 98.84 198.16 196.65 99.24 0.22 Lindane

99.32 148.26 247.58 245.94 99.34 0.17

101.58 49.5 151.08 150.84 99.84 0.32

101.58 99 200.58 197.46 98.44 0.26 Carbaryl

101.58 148.5 250.08 246.99 98.76 0.54

Precision

Results obtained from the chromatographic analysis of the samples on the same day or intra-

day (n=5) and on different days or inter day (n=5) are given in Table 3. The RSD values

obtained were well below 2% for intra-day and inter-day precision for both the compounds,

which is very well within the acceptable limits.

Limit of detection and limit of quantitation

The limit of detection (LOD) was calculated on the basis of S/N (signal to noise) ratio of 1:3

and was found to be 0.5 g/mL for both lindane and carbaryl. The limit of quantitation

(LOQ) was obtained as 2.0 g/mL evaluated on the basis of reproducible signal obtained on

injecting 5 replicates of the same concentration.

Table 3. Intra-day and Inter-day precision studies for the determination of lindane and

carbaryl by the developed method

Intra-day

precision, n=5

Inter-day precision, n=5

Compound

Prepared

solution

concentration,

g/mL

Observed

concentration, g/mL

% RSD Observed

concentration, g/mL

% RSD

Lindane 10 9.8 0.1 9.6 0.77

50 49.4 0.34 49.1 0.22

100 99.6 0.29 99.3 0.12

Carbaryl 10 9.9 0.27 9.7 0.57

50 49.7 0.18 49.5 0.33

100 99.5 0.14 99.1 0.17

398 R. K. KHANDAL et al.

Robustness

The method was found to be robust even with small changes in the analytical conditions; such

as a change in gas flow rate (0.01 mL/min), a change in temperature conditions of detector

( 2 C), a change in injector temperature ( 2 C), use of different gas chromatograph (Varian

CP3800 and Agilent 6890) and use of same column from different manufacturers (HP5, DB5,

CP-sil 8 CB). Under all of these conditions, the analytical value of the analytes in the test

solution was not affected and was in accordance with the actual values as per the label claim.

Conclusion

A validated gas chromatographic method has been developed for the simultaneous

determination of lindane and carbaryl in a combined granular formulation containing both

lindane and carbaryl using dibutyl phthalate (DBP) as an internal standard. At present, the

major constraint for the simultaneous determination of these two analytes is the non-

availability of a single validated method. The work described in this paper has shown that

the analytical method developed is precise, accurate, sensitive and robust for the

determination of both analytes. The method is specific to the analysis of lindane and

carbaryl in the granule formulations without any interference from the other ingredients

including the impurities such as -naphthol present in the granules. The developed method

was successfully applied to the simultaneous quantitative analysis of lindane and carbaryl in

the combined formulation of lindane-carbaryl granules and therefore can be used for the

routine quality control, ensuring efficiency and efficacy of the formulation for the desired

purpose. Even though the method has been developed using granular formulation of

combined pesticides, the same can be adopted without any further studies even for other

type of formulations containing the combination of lindane and carbaryl.

Acknowledgment

The authors are thankful to the Management of Shriram Institute for Industrial Research for

the guidance and support provided for undertaking the research study. The authors also

thank Bayers India Ltd. for providing the samples of Sevidol (combined formulation of

lindane-carbaryl granules) for the purpose of evaluation for the analytical method

development and validation.

References

1. Tomlin C D S, Pesticide Manual, British Crop Protection Council Publication, UK,

200, 10

th

Ed., 1995.

2. Chan S, Kong M F, Wong Y C, Wong S K and Sin D W M, J Agric Food Chem.,

2007, 55, 3339-3345.

3. Sun Feel, Lin Feng-Yi, Wong Sue-Sun and Li Gwo-Chen, J Food Drug Anal., 2000,

8(2), 103-111.

4. Kong M K, Chan S, Wong Y C, Wong S K and Sin W M, J AOAC Int., 2007, 90,

1133-1141.

5. Rodrigues M V N, Reyes F G R, Magalhes P M and Rath S, J Braz Chem Soc.,

2007, 18(1), 135

6. Mohammad A Mottaleb and Mohammad Z Abedin, Anal Sci., 1999, 15(3), 283.

7. Frber Harald and Schler Heinz F, J Agric Food Chem., 1993, 41(2), 217-220.

8. Baynes R E and Riviere J E, Am J Vet Res., 1998, 59, 168-175.

9. Chen K.C and Dorough H.W, Drug Chem Toxicol., 1979, 2, 331-354.

10. To-Luty S, Latuszyska J, Halliop J, Tochman A, Przylepa E, Bychawski E and

Obuchowska D, Ann Agric Environ Med., 1994, 1, 57-67.

Simultaneous Determination by Gas Chromatography 399

11. To-Luty S, Tokarska-Rodak M, Latuszyska J and Przebirowska D, Ann Agric

Environ Med., 2001, 8, 47-50.

12. To-Luty S, Przebirowska D, Latuszyska J and Tokarska-Rodak M, Ann Agric

Environ Med., 2001, 8, 137-144.

13. Bhaskara Besagarahally L and Nagaraja Padmarajaiah, E-J Chem., 2006, 3(4), 250-256.

14. Chang S K, Williams P L, Dauterman W C and Riviere J E, Toxicol., 1994, 91, 269-

280

15. Elderkin S, Wiles R and Campbell C, Fruit Forbidden: Illegal pesticides in the U S

food supply, Washington D C, Environmental Working Group, 1995.

16. Howard P H, Handbook of Environmental Fate and Exposure Data for Organic

Chemicals, Vol.III.Pesticides, Chelsea, MI, Lewis Publishers, 1991,132.

17. Caldas E D, Coelho R, Souza L.C.K.R and Silva S C, Bull Environ Contam Toxicol.,

1999, 62, 199.

18. Harris C A, Human-Exp- Toxical., 1997, 18, 602-606.

19. Waldron Lechner D and Abdel-Rahman M.S, J Toxicol Environ Health, 1986, 18, 241-256.

20. Majidi Mir Reza, Asadpour-Zeynali Karim and Mohammad Nazarpur, J AOAC Int.,

2009, 92(2), 548-554.

21. Schaner Angela, Konecny Jaclyn, Luckey Laura and Hickes Heidi, J AOAC Int.,

2007, 90(5), 1402-1410.

22. Manirakiza P, Covaci A and Schepens P, Chromatographia, 2000, 52, 787.

23. Cai L, Xing J, Dong L and Wu C, J Chromatogr A, 2003, 1015, 11.

24. Rodrigues M V N, Reyes F G R, Rehder V L G and Rath S, Chromatographia, 2005,

6, 291-297.

25. Lewri S.de Jager and Andrews Anthony R, J Anal., 2000, 125, 1943-1948.

26. Pedrosa Valber A, Caetano Josiane, Machado Sergio A S and Bertotti Mauro,

Sensors, 2008, 8, 4600-4610.

27. Kendrick Peter N, Andrew J Trim, Atwal Jaswinder K and Brown Peter M, Bull

Environ Contam Toxicol., 1991, 46, 654-661.

28. Sastry C S P, Vijaya D and Mangala D S, Analyst, 1987, 112, 75-78.

29. Bureau of Indian Standard; IS: 7539.

30. Bureau of Indian Standard; IS: 11784:1986 & IS: 882:1984.

31. Carbaryl: Method 5006, NIOSH manual of Analytical Methods (NMAM), Issue.2, 4

th

Ed., 1994.

32. Yuen S H, Analyst, 1965, 90, 569-571.

33. Medina J R, Calumpang S M F and Medina M J B, Philippine Agriculturist, 1991,

74(2), 195.

34. Mathew Lata, Reddy M L P, Rao Talasila Prasada, Lyer Chonatumatom S P and

Damodaran Alathur D, Analyst, 1995, 120, 1799.

35. Best R J and Hersch N R, J Agric Food Chem., 1964, 12(6), 546-549.

36. Guidance for Industry Q2B Validation of Analytical Procedures: Methodology, ICH

November 1996, http://www.fda.gov/cber/guidelines.htm

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Hitachi U-4100 BrochureDocument7 paginiHitachi U-4100 BrochuremegacobÎncă nu există evaluări

- Hitachi U-4100 Brochure Optical PartsDocument11 paginiHitachi U-4100 Brochure Optical PartsmegacobÎncă nu există evaluări

- Thermosel BrochureDocument2 paginiThermosel BrochuremegacobÎncă nu există evaluări

- Matest Catalogue 2014 - 96 DpiDocument528 paginiMatest Catalogue 2014 - 96 DpiRobertHening100% (2)

- Thermos ElDocument2 paginiThermos ElmegacobÎncă nu există evaluări

- Hg ASTM Thermometers CatalogDocument4 paginiHg ASTM Thermometers CatalogmegacobÎncă nu există evaluări

- Thermosel Brochure PDFDocument2 paginiThermosel Brochure PDFmegacobÎncă nu există evaluări

- Dacell DN-10W, DN-20W, DN-25W, DN-30W, DN-50W Digital Indicator ManualDocument39 paginiDacell DN-10W, DN-20W, DN-25W, DN-30W, DN-50W Digital Indicator ManualmegacobÎncă nu există evaluări

- Dacell Dn-10w, Dn-15w, Dn-20w SpecDocument1 paginăDacell Dn-10w, Dn-15w, Dn-20w SpecmegacobÎncă nu există evaluări

- Brookfield Ametek Thermosel Accessory: Manual No. M94-204-L0416Document25 paginiBrookfield Ametek Thermosel Accessory: Manual No. M94-204-L0416megacobÎncă nu există evaluări

- Matest Catalogue 4 Bitumen AsphaltDocument82 paginiMatest Catalogue 4 Bitumen AsphaltmegacobÎncă nu există evaluări

- Thermos ElDocument2 paginiThermos ElmegacobÎncă nu există evaluări

- gpm.521.r 4.enDocument5 paginigpm.521.r 4.enmegacobÎncă nu există evaluări

- Matest Catalogues PDFDocument528 paginiMatest Catalogues PDFmegacobÎncă nu există evaluări

- Digital PenetrometerDocument1 paginăDigital PenetrometermegacobÎncă nu există evaluări

- Instruction & Operation Manual: Digital Vacuum RegulatorDocument38 paginiInstruction & Operation Manual: Digital Vacuum RegulatormegacobÎncă nu există evaluări

- Cannon DVR 1000 FlyerDocument2 paginiCannon DVR 1000 FlyermegacobÎncă nu există evaluări

- Gardco ASTM ThermometersDocument15 paginiGardco ASTM ThermometersmegacobÎncă nu există evaluări

- Cannon CT-1000 Installation and Operation ManualDocument30 paginiCannon CT-1000 Installation and Operation ManualmegacobÎncă nu există evaluări

- Brookfield Ametek Thermosel Accessory: Manual No. M94-204-L0416Document25 paginiBrookfield Ametek Thermosel Accessory: Manual No. M94-204-L0416megacobÎncă nu există evaluări

- 3m Detector de Limpieza en SuperficiesDocument12 pagini3m Detector de Limpieza en SuperficiesRonaldSacachipanaÎncă nu există evaluări

- Chemical Fact File: Dust: Respirable, Particulates Not Otherwise Regulated - NIOSH 0600Document1 paginăChemical Fact File: Dust: Respirable, Particulates Not Otherwise Regulated - NIOSH 0600megacobÎncă nu există evaluări

- Sci Guide To ATP Monitoring 2Document35 paginiSci Guide To ATP Monitoring 2megacobÎncă nu există evaluări

- Dust Analyzer Meters: Product code: HHPC - 2 (0.5 μm)Document1 paginăDust Analyzer Meters: Product code: HHPC - 2 (0.5 μm)megacobÎncă nu există evaluări

- ATP Monitoring Limits ExplainedDocument3 paginiATP Monitoring Limits ExplainedAjit Singh RathoreÎncă nu există evaluări

- Selection Guide of Clamp Meters: 2200 2200R 2002PA 2002R 2204R 2210R AC Clamp Meters ModelDocument3 paginiSelection Guide of Clamp Meters: 2200 2200R 2002PA 2002R 2204R 2210R AC Clamp Meters ModelmegacobÎncă nu există evaluări

- Direct Reading Particulate Monitor and Air Station: Contact UsDocument2 paginiDirect Reading Particulate Monitor and Air Station: Contact UsmegacobÎncă nu există evaluări

- TCGRX ATP Brochure 0Document12 paginiTCGRX ATP Brochure 0megacobÎncă nu există evaluări

- TCGRX ATP2 SellSheetDocument2 paginiTCGRX ATP2 SellSheetmegacobÎncă nu există evaluări

- Guide To ATP For Road Hauliers and Manufacturers: March 2017Document17 paginiGuide To ATP For Road Hauliers and Manufacturers: March 2017megacobÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Kinematics 02.06.17Document77 paginiKinematics 02.06.17Murughesh Murughesan100% (1)

- CH1502LDocument87 paginiCH1502LDivyakumar PatelÎncă nu există evaluări

- DuctilityDocument3 paginiDuctilityCarlo CastorÎncă nu există evaluări

- DPC DR Moin by Suhan KhalidDocument9 paginiDPC DR Moin by Suhan KhalidRasheed doustamÎncă nu există evaluări

- The Astronet Infraestructure RoadmapDocument178 paginiThe Astronet Infraestructure RoadmapALÎncă nu există evaluări

- High-Solids Polyester Resins For Appliance and General Metal CoatingsDocument6 paginiHigh-Solids Polyester Resins For Appliance and General Metal CoatingsSyed Ubaid AliÎncă nu există evaluări

- Adblue Diesel Exhaust Fluid-PI SheetDocument2 paginiAdblue Diesel Exhaust Fluid-PI SheetAntonio AriasÎncă nu există evaluări

- Heat Loss PDFDocument2 paginiHeat Loss PDFJessica ZagitaÎncă nu există evaluări

- 41471909199Document2 pagini41471909199shivraj SonkarÎncă nu există evaluări

- Analytical Instruments in Water-Steam-Cycles: An Introduction For The Non-ChemistDocument27 paginiAnalytical Instruments in Water-Steam-Cycles: An Introduction For The Non-ChemistMaxi MaxiÎncă nu există evaluări

- Aim Is To Investigate Foaming Capacity of Different Washing Soap and Effect of Addition of Sodium Carbonate On ThemDocument3 paginiAim Is To Investigate Foaming Capacity of Different Washing Soap and Effect of Addition of Sodium Carbonate On ThemSachin SoniÎncă nu există evaluări

- Absolute Dating Methods ExplainedDocument20 paginiAbsolute Dating Methods ExplainedJorilyn LlandaÎncă nu există evaluări

- CEX 5231 Ass 3 2015 - 2016Document2 paginiCEX 5231 Ass 3 2015 - 2016MufeesÎncă nu există evaluări

- 2017 - Product Specification - RZBC (JUXIAN) - CAADocument1 pagină2017 - Product Specification - RZBC (JUXIAN) - CAAediasianagri100% (1)

- How Enzymes Work - The Role of Proteins in Chemical ReactionsDocument12 paginiHow Enzymes Work - The Role of Proteins in Chemical ReactionsRahil BhavanÎncă nu există evaluări

- Schedule of Rate For Standard Stock Materials Common SR 2021-22 (11 KV System)Document161 paginiSchedule of Rate For Standard Stock Materials Common SR 2021-22 (11 KV System)sagar mukulÎncă nu există evaluări

- HEC Past PaperDocument21 paginiHEC Past PaperTalha Aslam100% (1)

- HTL Ispat PVT LTD: 428 5.100 TotalDocument1 paginăHTL Ispat PVT LTD: 428 5.100 Totalmadhav jadhavÎncă nu există evaluări

- Coordination Complexes of Cobalt PDFDocument3 paginiCoordination Complexes of Cobalt PDFSergio A Rueda VÎncă nu există evaluări

- Heat 1Document36 paginiHeat 1ZainabÎncă nu există evaluări

- FINISHINGDocument32 paginiFINISHINGdyuti singhÎncă nu există evaluări

- Saudi Aramco welding inspection planDocument12 paginiSaudi Aramco welding inspection planspravin231Încă nu există evaluări

- Corrosion On BoilersDocument105 paginiCorrosion On BoilersPlínio Silveira100% (1)

- HEAT TRANSFER LAB REPORTDocument45 paginiHEAT TRANSFER LAB REPORTnighatÎncă nu există evaluări

- Science 9 exam questions on atomic structure and bondingDocument3 paginiScience 9 exam questions on atomic structure and bondingLimar Anasco Escaso67% (3)

- Cables: Compensating and ExtensionDocument32 paginiCables: Compensating and ExtensionAyadi_AymanÎncă nu există evaluări

- Opto Semi Koth0001eDocument17 paginiOpto Semi Koth0001eAnurag ChadhaÎncă nu există evaluări

- Titration CurveDocument12 paginiTitration Curveoguztop10Încă nu există evaluări

- Acematt Ok 412Document1 paginăAcematt Ok 412optimus_1404Încă nu există evaluări